Waste gas treatment and transport device for environment protection equipment

A technology of waste gas treatment and conveying device, which can be used in combination devices, electrical components, static electricity, etc., and can solve problems such as waste gas explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

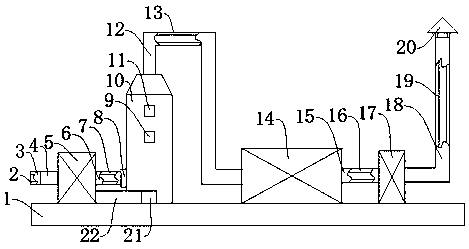

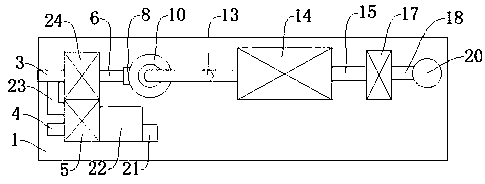

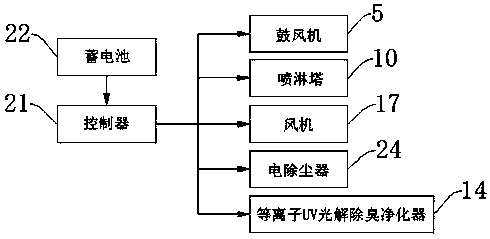

[0019] The present invention will be further described below in conjunction with accompanying drawing:

[0020] Such as Figure 1-Figure 3 As shown, a waste gas treatment and conveying device for environmental protection equipment includes a bottom plate 1, a spray tower 10, a plasma light deodorizing purifier 14, and a waste gas pipe 3 is arranged on the upper side of the bottom plate 1, and the waste gas pipe 3 acts as an air intake , the inner wall of the waste gas pipe 3 is provided with a first antistatic layer 2, and the side above the base plate 1 away from the waste gas pipe 3 is provided with an electrostatic precipitator 24, which plays a role in dust removal. 5 acts as a blower, the blower 5 is provided with a fourth connecting pipe 23 on the side close to the waste gas pipe 3, and the front of the fourth connecting pipe 23 is provided with an air pipe 4, and the air pipe 4 plays the role of air intake, and the blower 5 is far away from the side of the waste gas pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com