A dry powder type ecological interior wall coating based on shell powder

A technology of interior wall paint and shell powder, applied in conductive paint, antifouling/underwater paint, coating, etc., can solve the problem of low utilization efficiency of visible light, difficulty in large-scale production and use, and low utilization rate of sunlight catalysis, etc. problem, to achieve the effect of excellent physical and mechanical properties, high cost of solution, and high UV-visible light photocatalytic function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Produce dry powder type ecological interior wall paint according to the following steps:

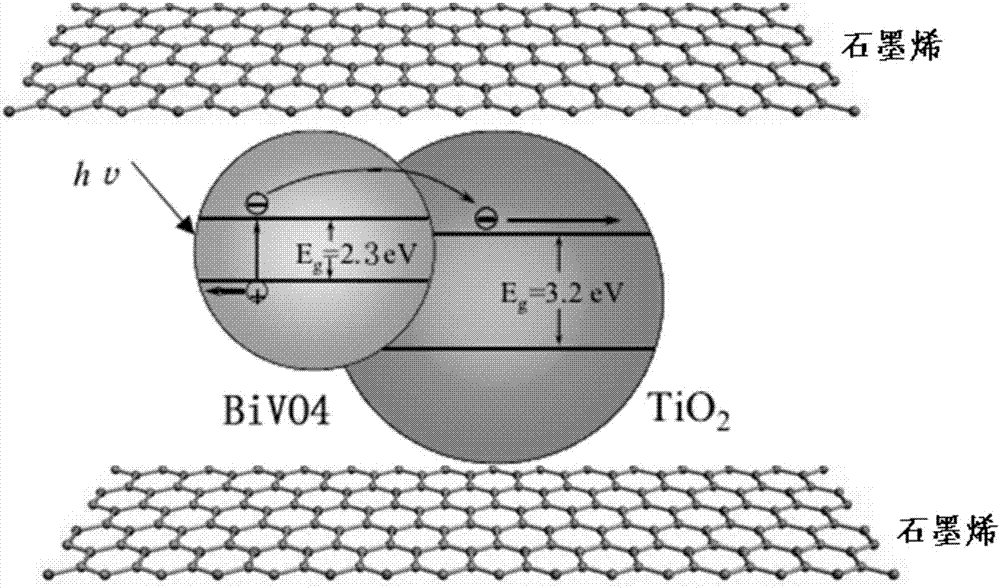

[0015] (1) First prepare the TiO2-bismuth vanate-graphene ternary composite nanomaterial with ultraviolet-visible light photocatalytic function, the method is as follows:

[0016] At first prepare bismuth vanadate nano microsphere, its method is that 2mmol bismuth nitrate and 2mmol ammonium vanadate are dissolved in 30mL respectively, the nitric acid of 2mol / L and 30ml, in the sodium hydroxide aqueous solution of 2mol / L, then under room temperature, two The two solutions were mixed together to form a uniform suspension, and then 2.0 g of surfactant sodium dodecyl sulfonate was added to the mixed solution, and the stirring was continued at room temperature for 1 h, then transferred to a 100 ml reaction kettle, and kept at 180° C. The reaction was heated for 10 hours. After the reaction, the product was centrifuged and washed three times with distilled water and absolute ethanol; t...

Embodiment 2

[0022] Step (1), (2) are identical with embodiment 1, and step (3) changes as follows:

[0023] (3) Preparation of dry powder type ecological interior wall paint based on shell powder: Mix the following raw materials in mass percentages to obtain dry powder type ecological interior wall paint: after calcination at 600 degrees Celsius, it is pulverized and prepared, and the particle diameter is 45% of shell powder of 600 mesh , 15% of kaolin, 15% of light calcium carbonate, 10% of nano-silicon dioxide, 5% of TiO2-bismuth vanate-graphene ternary nanocomposite material, and 10% of adhesive powder.

Embodiment 3

[0025] Step (1), (2) are identical with embodiment 1, and step (3) changes as follows:

[0026] (3) Preparation of dry powder type ecological interior wall paint based on shell powder: Mix the following raw materials in mass percentages to obtain dry powder type ecological interior wall paint: after calcination at 600 degrees Celsius, it is pulverized and prepared, and the particle diameter is 45% of shell powder of 1000 mesh , 15% of kaolin, 10% of light calcium carbonate, 12% of nano silicon dioxide, 8% of TiO2-bismuth vanate-graphene ternary nanocomposite material, and 10% of adhesive powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com