Raw material formula of PU wheel, raw material production process and processing method thereof

A technology of raw materials and formulations, applied in other household appliances, household components, applications, etc., can solve the problems of high heat production of rubber carcass, black marks on the road surface, environmental pollution, etc., and achieve good grip, not easy to slip, and wear resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

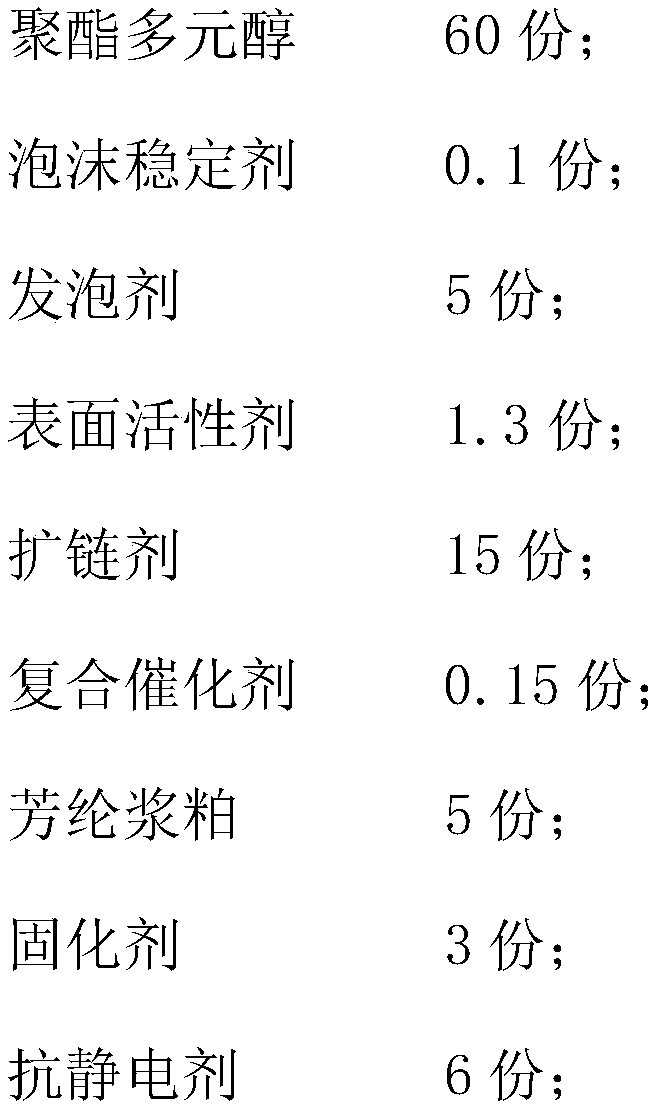

Embodiment 1

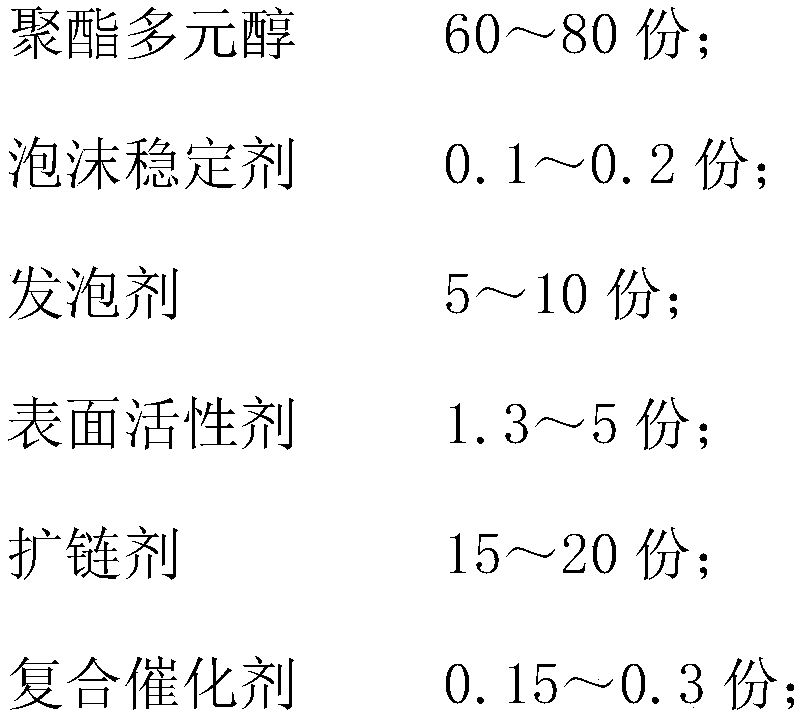

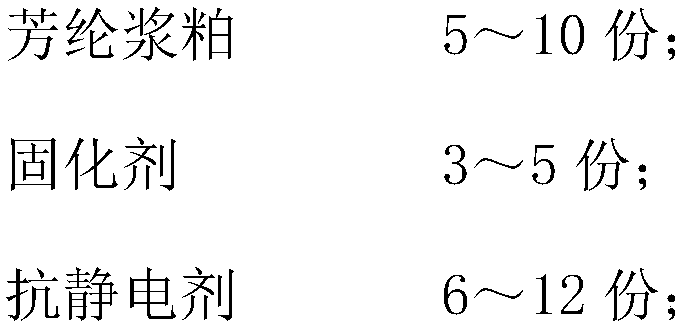

[0048] A raw material formulation of a PU wheel, comprising A component and B component, wherein, A component consists of the following raw materials in parts by weight:

[0049]

[0050] The B component consists of the following raw materials in parts by weight:

[0051] 20-parts of polyester polyol;

[0052] 5 parts of polyether polyol;

[0053] 80 parts of isocyanate.

[0054] Specifically, the function of the foam stabilizer is to make the pores of the foam more uniform and dense. The foam stabilizer Y~10366 can be selected, and the aramid pulp is selected from aramid 1414 pulp, with an average length of 2mm and a surface area of 8㎡ / g , has a better reinforcing effect.

[0055] Described tensio-active agent is foam stabilizer and silicone surfactant, and wherein the weight parts of both are respectively:

[0056] Foam stabilizer 0.1 part;

[0057] Among them, the foam stabilizer can emulsify the foam material, stabilize the foam and adjust the cells.

[0058] Sp...

Embodiment 2

[0105] A raw material formulation of a PU wheel, comprising A component and B component, wherein, A component consists of the following raw materials in parts by weight:

[0106]

[0107] The B component consists of the following raw materials in parts by weight:

[0108] Polyester polyol ~50 parts;

[0109] 30 parts of polyether polyols;

[0110] 90 parts of isocyanate.

[0111] Specifically, the function of the foam stabilizer is to make the pores of the foam more uniform and dense. The foam stabilizer Y~10366 can be selected, and the aramid pulp is selected from aramid 1414 pulp, with an average length of 2mm and a surface area of 8㎡ / g , has a better reinforcing effect.

[0112] Described tensio-active agent is foam stabilizer and silicone surfactant, and wherein the weight parts of both are respectively:

[0113] 3 parts of foam stabilizer;

[0114] The foam stabilizer can emulsify the foam material, stabilize the foam and regulate the cells.

[0115] Specifical...

Embodiment 3

[0162] A raw material formulation of a PU wheel, comprising A component and B component, wherein, A component consists of the following raw materials in parts by weight:

[0163]

[0164]

[0165] The B component consists of the following raw materials in parts by weight:

[0166] 40 parts of polyester polyols;

[0167] 17.5 parts of polyether polyols;

[0168] 85 parts of isocyanate.

[0169] Specifically, the function of the foam stabilizer is to make the pores of the foam more uniform and dense. The foam stabilizer Y~10366 can be selected, and the aramid pulp is selected from aramid 1414 pulp, with an average length of 2mm and a surface area of 8㎡ / g , has a better reinforcing effect.

[0170] Described tensio-active agent is foam stabilizer and silicone surfactant, and wherein the weight parts of both are respectively:

[0171] 1.55 parts of foam stabilizer;

[0172] The foam stabilizer can emulsify the foam material, stabilize the foam and regulate the cells. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com