Release agent for aluminum alloy casting and preparation method thereof

A release agent, aluminum alloy technology, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of poor protection of the inner wall of the mold, affecting the quality of the casting, shortening the life of the mold, etc., to increase lubricity and anti-corrosion Electrostatic function, improvement of uniform smoothness, and smooth demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

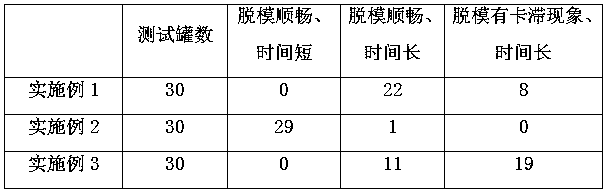

Embodiment 1

[0024] The invention provides a mold release agent for aluminum alloy casting, wherein the main materials used include the following raw materials in parts by weight: 8 parts of graphite lubricating oil, 6 parts of slippery agent, 4 parts of lotus leaf hydrophobic agent, formazan 3 parts of modified silicone oil, 2 parts of silicone defoamer, 18 parts of butyl-3-methylimidazolium hexafluorophosphate, 60 parts of deionized water, 2 parts of heat stabilizer and 0.8 parts of flow aid.

[0025] The slip agent is specifically ER erucamide.

[0026] The present invention also provides a method for preparing a release agent for aluminum alloy casting, the specific preparation steps are as follows:

[0027] Step 1: Prepare raw materials, first prepare graphite lubricating oil, slip agent, lotus leaf hydrophobic agent, methyl modified silicone oil, silicone defoamer, butyl-3-methylimidazole hexafluorophosphate, deionized Water, heat stabilizer and flow aid, spare;

[0028] Step 2: Ad...

Embodiment 2

[0034] The invention provides a release agent for aluminum alloy casting, wherein the main material used includes the following raw materials in parts by weight: 9 parts of graphite lubricating oil, 7 parts of slip agent, 5 parts of lotus leaf hydrophobic agent, formazan 4 parts of modified silicone oil, 2.5 parts of silicone defoamer, 21 parts of butyl-3-methylimidazolium hexafluorophosphate, 55 parts of deionized water, 1.5 parts of heat stabilizer and 0.7 parts of flow aid.

[0035] The slip agent is specifically ER erucamide.

[0036] The present invention also provides a method for preparing a release agent for aluminum alloy casting, the specific preparation steps are as follows:

[0037] Step 1: Prepare raw materials, first prepare graphite lubricating oil, slip agent, lotus leaf hydrophobic agent, methyl modified silicone oil, silicone defoamer, butyl-3-methylimidazole hexafluorophosphate, deionized Water, heat stabilizer and flow aid, spare;

[0038] Step 2: Add gra...

Embodiment 3

[0044] The invention provides a mold release agent for aluminum alloy casting, wherein the main materials used include the following raw materials in parts by weight: 10 parts of graphite lubricating oil, 8 parts of slippery agent, 6 parts of lotus leaf hydrophobic agent, 5 parts of modified silicone oil, 3 parts of silicone defoamer, 24 parts of butyl-3-methylimidazolium hexafluorophosphate, 50 parts of deionized water, 1 part of heat stabilizer and 0.6 parts of flow aid.

[0045] The slip agent is specifically ER erucamide.

[0046] The present invention also provides a method for preparing a release agent for aluminum alloy casting, the specific preparation steps are as follows:

[0047]Step 1: Prepare raw materials, first prepare graphite lubricating oil, slip agent, lotus leaf hydrophobic agent, methyl modified silicone oil, silicone defoamer, butyl-3-methylimidazole hexafluorophosphate, deionized Water, heat stabilizer and flow aid, spare;

[0048] Step 2: Add graphite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com