Light and thin heat preservation core-spun hollow knitted fabric

A knitted fabric, hollow technology, applied in the field of knitted fabrics, can solve the problems of bloated, insufficient warmth, inconvenient movement, etc., and achieve the effect of comfortable wearing and more warmth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] see Figure 1-4 , in the embodiment of the present invention, a kind of frivolous warm-keeping core-spun hollow knitted fabric, the raw material according to weight percentage comprises: 91% 24s cotton polyester sheath-core blended hollow yarn, 9% 30D DuPont spandex, 91% 24s cotton polyester leather The core blended hollow yarn is composed of 54% cotton fiber, 16% water-soluble vinylon fiber, and 21% 50D / 48FDTY cross-section low elastic yarn.

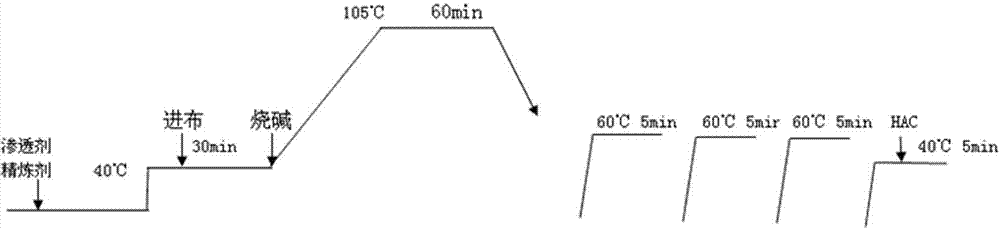

[0025] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0026] (1) Taking materials: Weigh each raw material according to weight percentage;

[0027] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0028] (3) Weaving gray yarn: use rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D ...

Embodiment 2

[0035] see Figure 1-4 , in the embodiment of the present invention, a light and thin warm core-spun hollow knitted fabric, the raw materials according to the percentage by weight include: 10% 24s cotton-polyester sheath-core blended hollow yarn, 60% 32s cotton fiber, 20% 32s water-soluble vinylon Fiber, 10% 30D DuPont spandex.

[0036] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0037] (1) Taking materials: Weigh each raw material according to weight percentage;

[0038] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0039] (3) Weaving gray yarn: use a rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D Dupont spandex to obtain gray cloth, the weight of the gray cloth is 290g / SQM, and the door width is 155cm;

[0040] (4) ...

Embodiment 3

[0046] see Figure 1-4 , in the embodiment of the present invention, a light and thin warm core-spun hollow knitted fabric, the raw materials according to the percentage by weight include: 11% 24s cotton-polyester sheath-core blended hollow yarn, 56% 32s cotton fiber, 22% 32s water-soluble vinylon Fiber, 11% 30D DuPont spandex.

[0047] The production process of the light and thin warm core-spun hollow knitted fabric, the specific steps are as follows:

[0048] (1) Taking materials: Weigh each raw material according to weight percentage;

[0049] (2) Wrapped yarn: Mix cotton fiber and water-soluble vinylon fiber evenly according to the weight ratio of 75:25, and then core-wrap 50D / 48FDTY cross-section low-elastic yarn to obtain gray yarn;

[0050] (3) Weaving gray yarn: use a rib machine to weave 24s cotton polyester skin-core blended hollow yarn and 30D DuPont spandex to obtain gray cloth, the weight of the gray cloth is 295g / SQM, and the door width is 160cm;

[0051] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com