High-strength terylene microfiber needling fabric

A high-strength, acupuncture technology, applied in the field of non-woven fabrics, can solve the problems affecting the quality of microfiber leather, not easy to dye evenly and deeply, and the amount of dyes used is large, and achieves high added value of products, obvious ecological benefits, and raw material costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Raw materials:

[0031] Island-fixed sea-island staple fiber was purchased from Yangzhou Tianlun Fiber Co., Ltd.

[0032] Polyester filament: the total fineness is 68D-75D, purchased from Zhejiang Xingfa Chemical Fiber Group Co., Ltd.;

[0033] PVA is a widely used water-soluble high molecular polymer, its performance is between plastic and rubber. purchased from Suzhou COSCO Chemicals.

[0034] PU resin is a common raw material for the manufacture of microfiber leather.

[0035] The DMF aqueous solution is a dimethylformamide (DMF) solvent, which is a common raw material for the DMF impregnation process in textiles.

[0036] Disperse dyes can be purchased from Zhejiang Longsheng Group, or you can configure disperse dyes yourself:

[0037] For every L of disperse dye, the dosage of high-temperature leveling agent is 1.0g, the dosage of diffusing agent is 0.5g, and the dosage of acetic acid with a concentration of 98% by weight is 1g. The high-temperature leveling a...

Embodiment 2

[0058] The difference with embodiment 1 is:

[0059] In step (4), every 100 kilograms of PVA aqueous solution is mixed with 15 kilograms of polyvinyl alcohol PVA and 85 kilograms of water in the PVA aqueous solution.

[0060] Every 100 kilograms of PU resin and DMF mixture is composed of 20 kilograms of polyester polyol PU resin and 80 kilograms of dimethylformamide DMF.

[0061] Every 100 kg of DMF aqueous solution is composed of 20 kg of dimethylformamide DMF and 80 kg of water.

[0062] Every 100 kg of cleaning agent for pre-dyeing treatment is composed of 3 kg of TF-108 scouring agent, 3 kg of JFC penetrating agent, 12 kg of liquid alkali (30% NaOH aqueous solution), 3 kg of TF-101C deoiling spirit and 79 kg of water. All the other are with embodiment 1.

[0063]

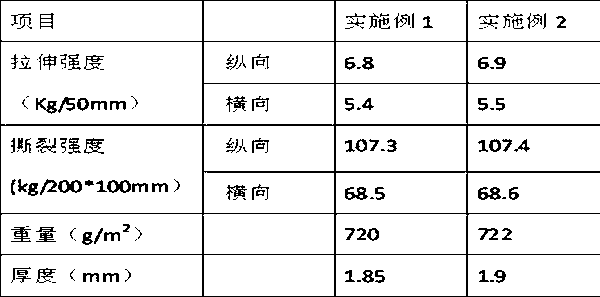

experiment example 1

[0065] Air permeability measurement of Examples 1-2 The air permeability was measured by the Fraser method of ISO 9237, and the measured air pressure was 125Pa. The results are shown in Table 1 below:

[0066] Table 1:

[0067] Example 1 Example 2 Air permeability (cm3 / cm2 / sec) 96 98

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com