Dyeing and finishing technology for PFY (polyester filament yarn) Huayao fabric

A processing technology, polyester filament technology, applied in the field of textile printing and dyeing, can solve the problems of poor bulkiness and limitations, achieve the effect of small color difference, good color brightness, and improve dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

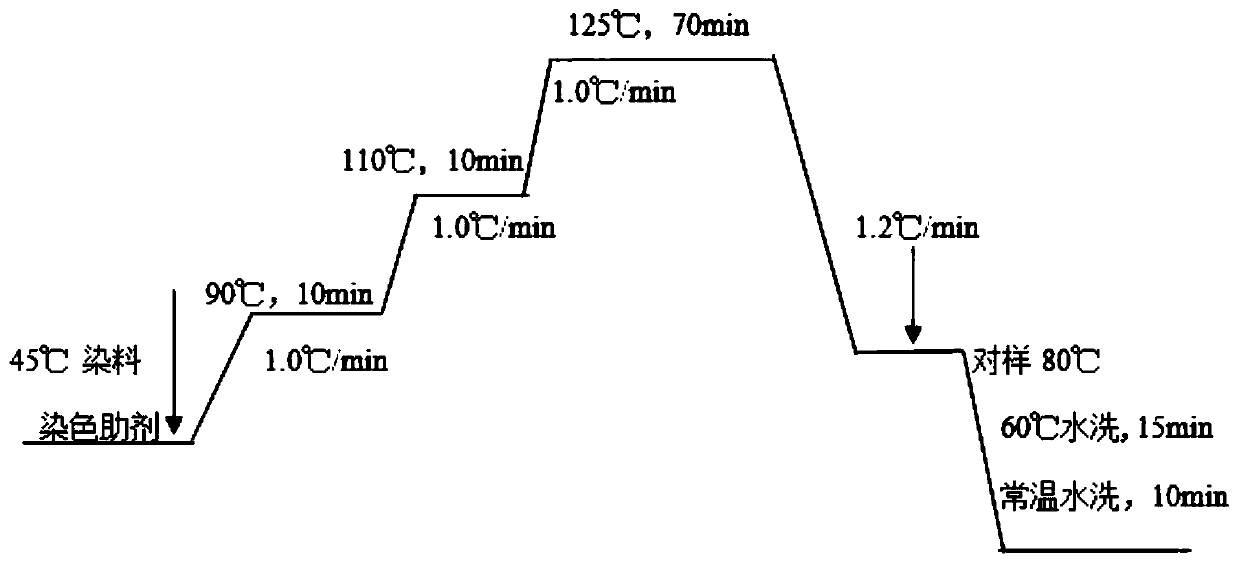

Method used

Image

Examples

Embodiment

[0036] Fabric gray cloth: door width 162cm, fabric surface density 100g / m 2 , Meek weight 162g / m, the fabric structure adopts twill weave, warp and weft density: 75D*75D, weft twisting. The color to be processed in this embodiment is bright red.

[0037] The dyestuff that this embodiment adopts, various auxiliary agents and the manufacturer and the model of the equipment used are as follows:

[0038] The dyes Disperse Scarlet GS, Disperse Red FB, and Disperse Red Jade SE-2GF were all from Zhejiang Longsheng Group Co., Ltd.

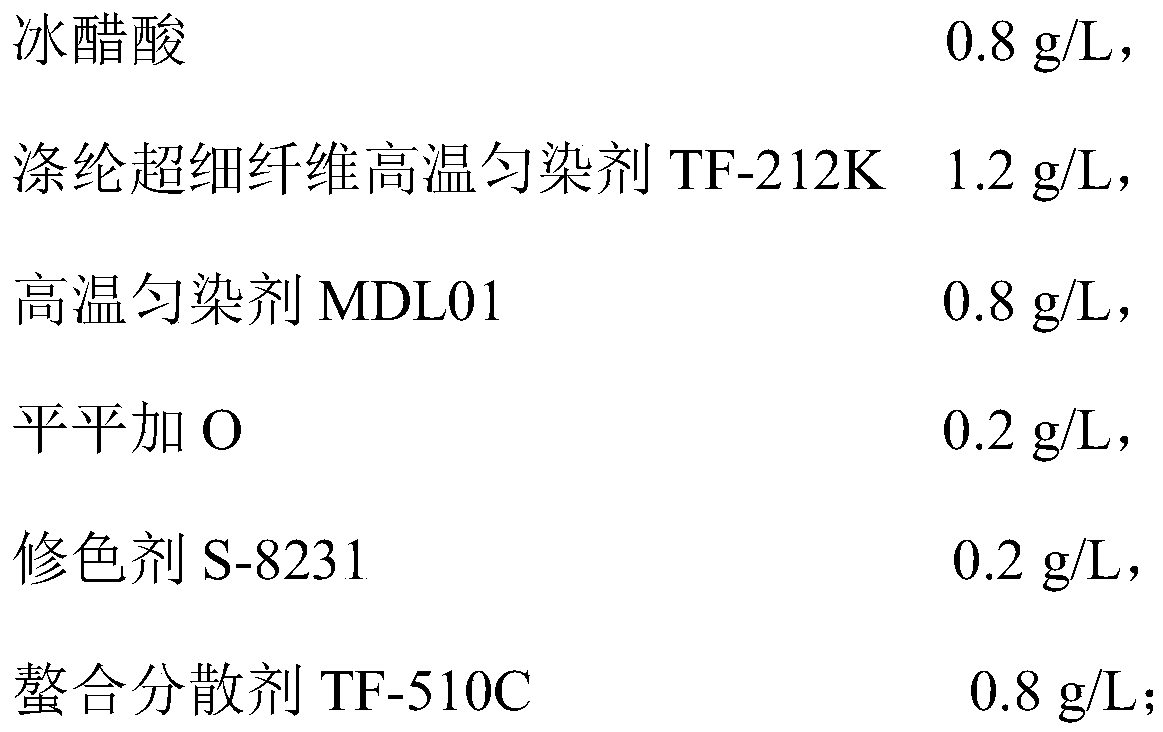

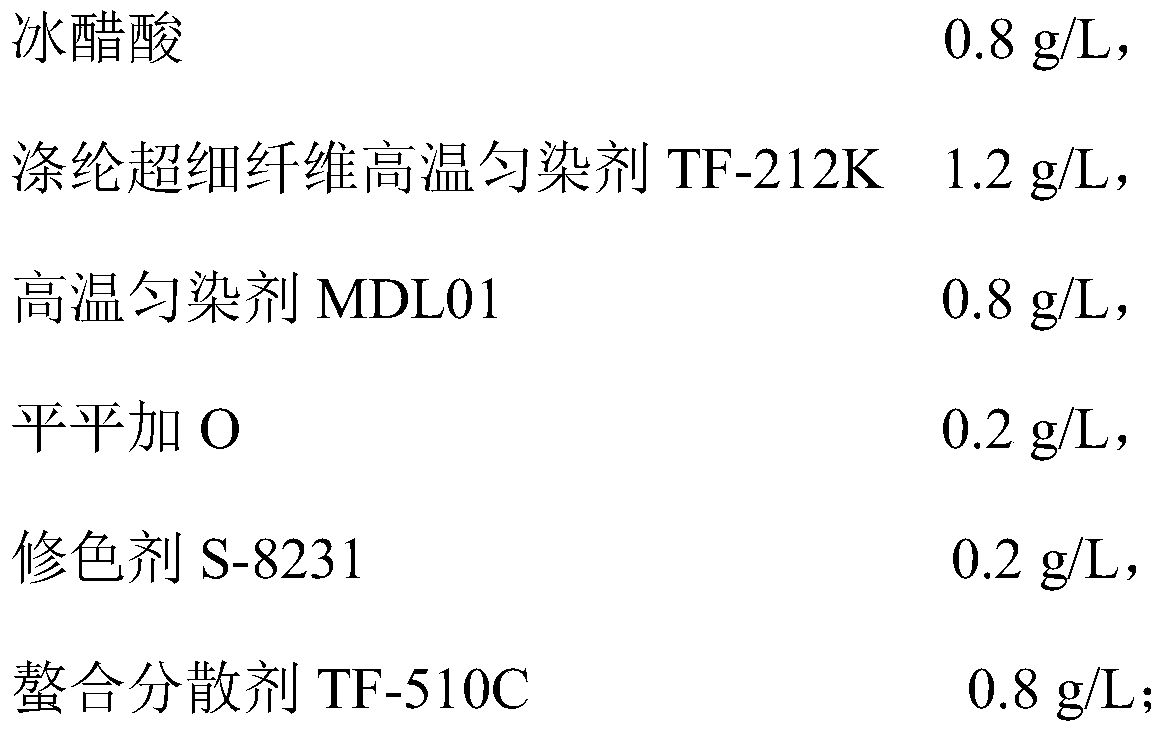

[0039] Various additives 32-ion membrane alkali (Jiangsu Suhua Group Co., Ltd.), long car fast desizing agent TF-127HA, Pingpingjia O, polyester superfine fiber high temperature leveling agent TF-212K, chelating dispersant TF- 510C, fluorine-based waterproof and oil-repellent finishing agent TF-4109, all from Zhejiang Transchem Co., Ltd.; color repair agent S-8231 (Yixing Hualian Chemical Co., Ltd.), high-temperature leveling agent MDL01 (Tona Trading (S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com