Dyeing process capable of forming PTT/PET composite fiber fabric with crepe feeling

A composite fiber fabric and process technology, applied in the field of dyeing technology, can solve the problems of fabrics prone to color difference, scratches and polish, uneven dyeing, etc., and achieves the effects of soft hand feeling, good dyeing effect, and uniform dyeing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

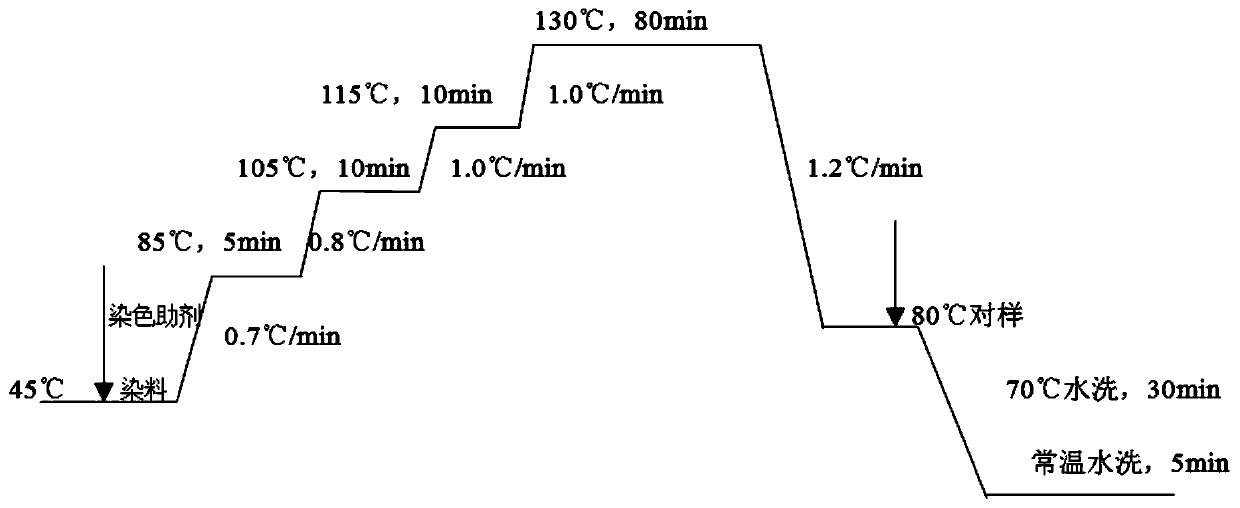

Method used

Image

Examples

Embodiment

[0026] Fabric fabric: warp direction is 75D PET, weft direction is 75D PTT / PET composite yarn, warp and weft density: 75*42, fabric width is 192cm, fabric surface density is 110g / m 2 , The gram weight of the fabric is 211g / m, and the structure of the fabric adopts twill weave.

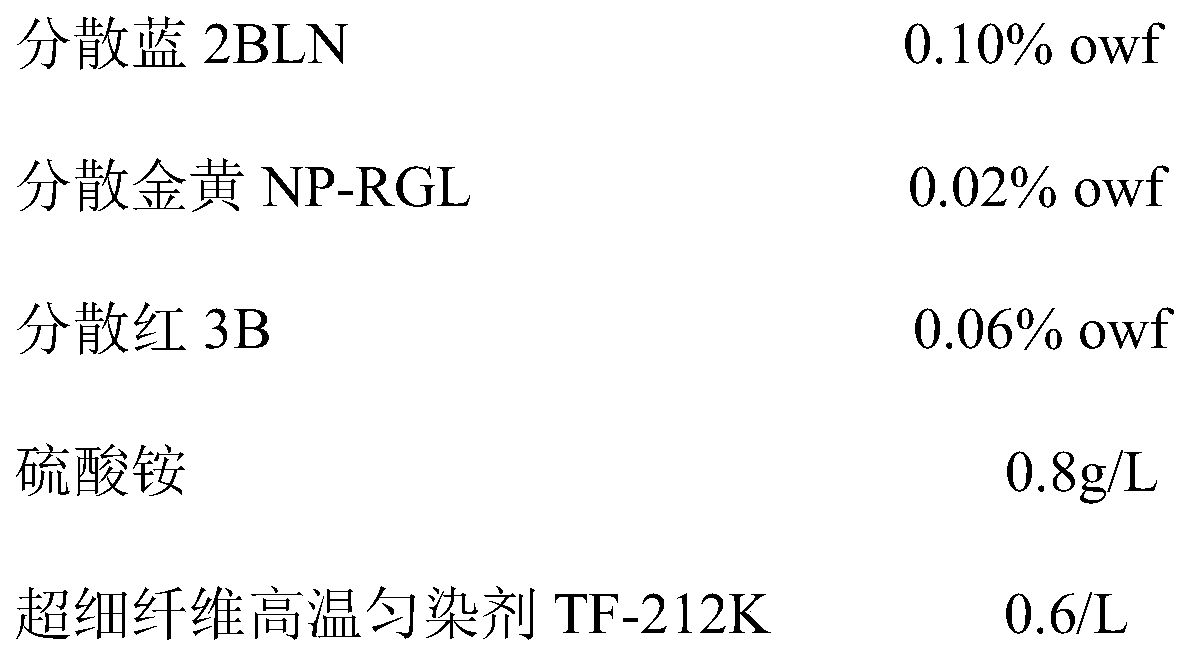

[0027] The dyestuff that this embodiment adopts, various auxiliary agents and the manufacturer and the model of the equipment used are as follows:

[0028] Dyes: Disperse Blue 2BLN (Zhejiang Boao Dyestuff Industry Co., Ltd.), Disperse Golden NP-RGL (Zhejiang Longsheng Group Co., Ltd.), Disperse Red 3B (Zhejiang Deou Chemical Manufacturing Co., Ltd.);

[0029] Microfiber high-temperature leveling agent TF-212K (Zhejiang Chuanhua Co., Ltd.), ammonium sulfate (Shanghai Petrochemical Xinyuan Chemical Industry Co., Ltd.), color repair agent S-8231 (Yixing Hualian Chemical Co., Ltd.).

[0030] Equipment: SAF3-2HT high temperature and high pressure airflow overflow dual-purpose dyeing machine (Deyijia Machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com