Method for splitting polyester/polyamide compound fibre and ultrafine fabric fabric made from same

A technology of ultra-fine fiber fabrics and composite fibers, which is applied in the fields of conjugated synthetic polymer artificial filaments, fiber treatment, textiles and papermaking, and can solve the problems of high weight loss rate and low degree of disintegration of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The commercially available polyester / polyamide composite fiber gray cloth (the weft yarn is a star-shaped polyester / polyamide composite fiber, the fineness is 150d / 46f×16p, the warp is ordinary polyester, the fineness is 64d / 24f, FDY) in 40% Treat in acetic acid solution, the bath temperature is 75°C, the bath ratio is 1:60, and the time is 45 minutes.

[0049] The shrinkage difference between nylon and polyester in the treated fabric is 4.4%, the weight loss rate of the fabric is 0, and the splitting degree is 90%.

[0050] Dyeing test is carried out on the treated fabric, the color difference eye method GB25D-1995, the color difference level of the fabric is ≥ 4, indicating that the dyeing is very uniform.

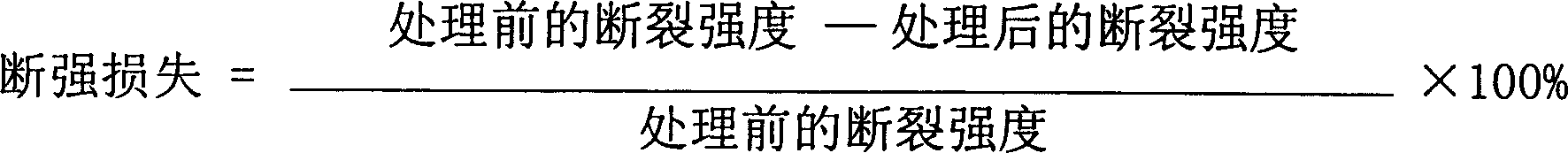

[0051] The breaking strength of the weft yarn of the fabric before and after treatment was measured respectively, and then the loss of breaking strength was calculated as 4.6%.

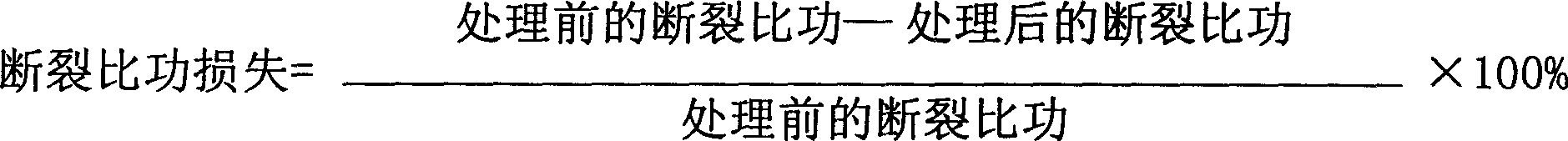

[0052] The specific work at break of the weft yarn of the fabric before and after tr...

Embodiment 2

[0059] Same as Example 1, only the concentration of the changed acetic acid solution is 20%.

[0060] The shrinkage difference between nylon and polyester in the treated fabric is 1.4%, the weight loss rate of the fabric is 0, and the splitting degree is 83%.

[0061] Carry out the dyeing test on the treated fabric, the color difference eye method GB25D-1995, the color difference level of the fabric is ≥4.

Embodiment 3

[0063] The commercially available polyester / polyamide fiber composite fiber clothing fabric (the weft yarn is orange petal-shaped polyester / polyamide fiber composite fiber, and the fineness is 167d / 46f×16p, and the warp yarn is ordinary polyester, and the fineness is 83d / 96f, PET) Treat in 40% acetic acid solution, the bath temperature is 75° C., the bath ratio is 1:60, and the time is 45 minutes.

[0064] The shrinkage difference between nylon and polyester in the treated fabric is 2.3%, the weight loss rate of the fabric is 0, and the splitting degree is 88%.

[0065] Dyeing test is carried out on the treated fabric, the color difference eye method GB25D-1995, the color difference level of the fabric is ≥ 4, indicating that the dyeing is very uniform.

[0066] The breaking strength of the weft yarn of the fabric before and after treatment was measured respectively, and then the loss of breaking strength was calculated as 0%.

[0067] The specific work of breaking of the wef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com