Manual tufting carpet with moisture absorption and moisture guide functions and weaving method of manual tufting carpet

A technology for tufting carpets and carpets, which is applied in the direction of carpets, textiles, papermaking, embroidery machines, etc., can solve the problems of poor moisture absorption performance and slow application, and achieve the effect of improving the function of moisture absorption and moisture conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 : Preparation method of 50 denier Coolmax fiber carpet:

[0030] A method for weaving a hand-tufted carpet with moisture absorption and moisture conduction function, comprising the following steps:

[0031] a. Alkali reduction steps:

[0032] (1) The Coolmax fiber with a denier of 50 denier was conventionally deweighted at a temperature of 95°C for 40 minutes without adding a deweighting accelerator, and the twist of the decremented fiber was 1000 twists per 100 cm;

[0033] (2) Wash the fibers reduced in step (1) for 20 minutes at a water temperature of 40°C, and add a dispersant with a concentration of 2g / L at the same time;

[0034] b. Preparation steps:

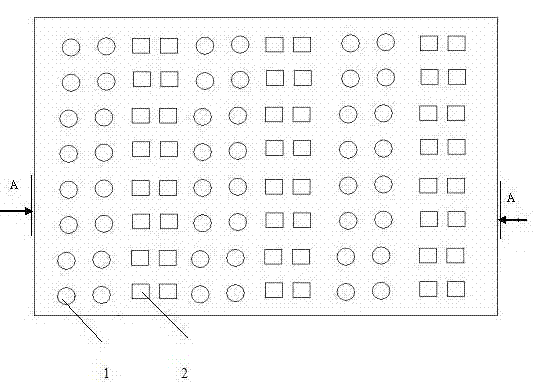

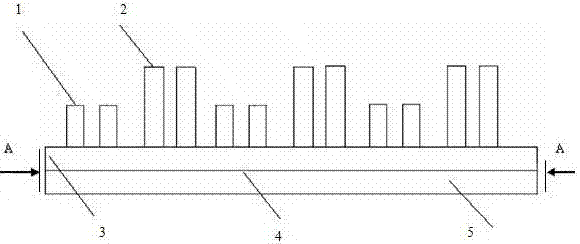

[0035] The yarn composed of 28 strands of fiber (4×50 denier) / strand that has undergone alkali reduction treatment is formed into a broken end, and the yarn composed of 11 strands of fiber (4×50 denier) / strand is formed into a loop end, according to the grid layer base The size of the squares on th...

Embodiment 2

[0046] Embodiment 2: the preparation method of the Coolmax fiber carpet of 75 deniers:

[0047] A method for weaving a hand-tufted carpet with moisture absorption and moisture conduction function, comprising the following steps:

[0048] a. Alkali reduction steps:

[0049] (1) The Coolmax fiber with a denier of 75 denier was conventionally deweighted at 98°C for 50 minutes without adding a deweighting accelerator, and the twist of the decremented fiber was 900 twists per 100 cm;

[0050] (2) Wash the fibers reduced in step (1) with water at 35°C for 15 minutes, and add a dispersant with a concentration of 1.5g / L at the same time;

[0051] b. Preparation steps:

[0052] 18 fibers of 75 denier / 4 strands that have been processed by alkali reduction are formed into broken heads, and 6 strands of 75 denier / 4 strands of fibers are formed into loop heads, which are repeatedly and alternately woven according to the size of the grid on the grid layer base cloth. The number of pass...

Embodiment 3

[0063] Embodiment 3: the preparation method of the Coolmax fiber carpet of 100 deniers:

[0064] A method for weaving a hand-tufted carpet with moisture absorption and moisture conduction function, comprising the following steps:

[0065] a. Alkali reduction steps:

[0066] (1) The Coolmax fiber with a denier of 100 denier was conventionally deweighted at 97°C for 60 minutes without adding a deweighting accelerator, and the twist of the decremented fiber was 800 twists per 100 cm;

[0067] (2) Wash the fibers reduced in the step (1) at a water temperature of 37°C for 18 minutes, and at the same time add a dispersant with a concentration of 1g / L;

[0068] b. Preparation steps:

[0069] After alkali reduction processing, each strand is composed of 4 100-denier Coolmax fibers, a total of 12 strands of yarn to form a broken end, and 4 strands of yarn to form a loop end, which are repeatedly and alternately woven according to the size of the grid on the grid layer base fabric. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com