Preparation method of double-sided different-velvet fiber fabric

A technology of velvet fiber and fabric, which is applied in the field of preparation of double-sided velvet fiber fabric, to achieve the effect of full hand feeling and better comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation method of double-sided foreign cashmere fiber fabric, its process is as follows:

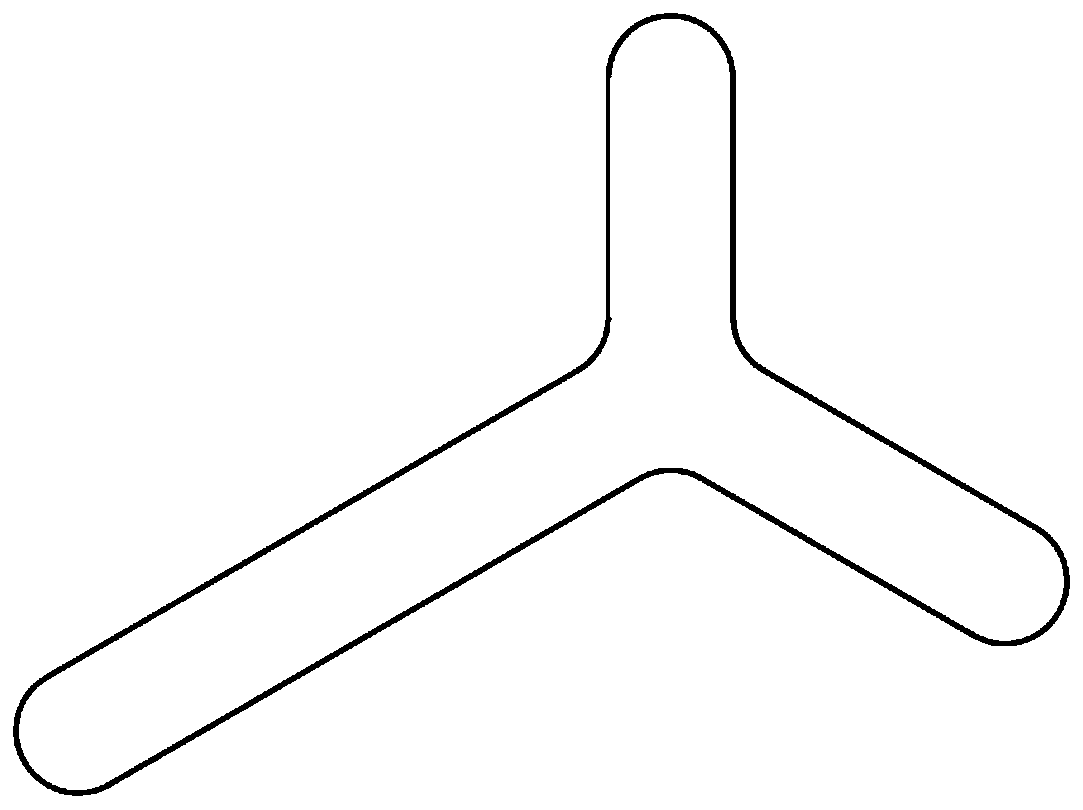

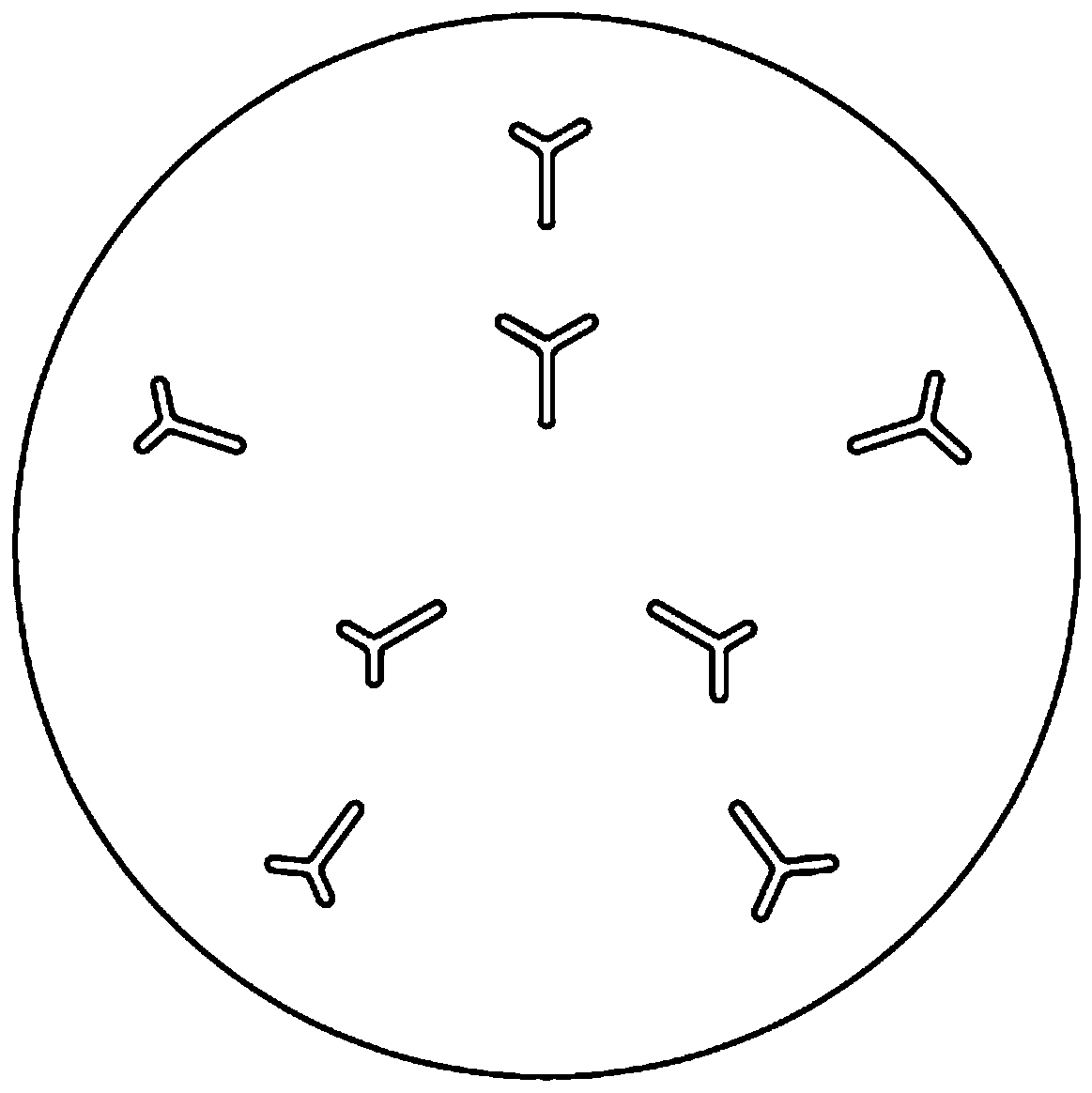

[0035] (1) The preparation of the cationic polyester full-drawn yarn: the CDP melt (intrinsic viscosity is 0.66dL / g) is extruded from the trilobal spinneret hole on the spinneret and cooled by ring blowing; wherein, three The ratio of the length of the shortest leaf and the longest leaf of the leaf-shaped spinneret hole is 1.0:1.5, and the longest leaf length is 0.18mm, and the ratio of the length of the two short leaves is randomly distributed (the number of spinneret holes is 24, with one of three Starting from the leaf-shaped spinneret hole, along the clockwise direction, the ratio of the lengths of the two short leaves of all spinneret holes is: 1.3, 1.2, 1.2, 1.3, 1.3, 1.1, 1, 1.4, 1.1, 1.3, 1, 1, 1.4 . The included angle of the center line is 120°; all the trilobal spinneret holes are concentrically distributed, and the center line of the longest lobe of each ...

Embodiment 2

[0044] A kind of preparation method of double-sided foreign cashmere fiber fabric, its process is as follows:

[0045] (1) Preparation of the cationic polyester full-drawn yarn: the CDP melt (intrinsic viscosity is 0.64dL / g) is extruded from the trilobal spinneret hole on the spinneret and cooled by ring blowing; wherein, three The ratio of the lengths of the three leaves of the leaf-shaped spinneret hole is 1.0:1.0:1.7, the longest leaf length is 0.20mm, and the ratio of the lengths of the two short leaves is randomly distributed (the number of spinneret holes is 18, and one of the three leaf-shaped Starting from the spinneret hole, along the clockwise direction, the length ratios of the two short leaves of all spinneret holes are: 1.3, 1.2, 1.2, 1.3, 1.3, 1.1, 1, 1.1, 1.3, 1.1, 1.2, 1.2, 1, 1.4 . The spinneret holes are distributed in concentric circles, and the center line of the longest lobe of each trilobal spinneret hole passes through the center of the circle and point...

Embodiment 3

[0054] A kind of preparation method of double-sided foreign cashmere fiber fabric, its process is as follows:

[0055] (1) The preparation of the cationic polyester full-drawn yarn: the CDP melt (intrinsic viscosity is 0.65dL / g) is extruded from the trilobal spinneret hole on the spinneret and cooled by ring blowing; wherein, three The ratio of the length of the three leaves of the leaf-shaped spinneret hole is 1.0:1.3:1.9, the longest leaf length is 0.18mm, and the ratio of the lengths of the two short leaves is randomly distributed (the number of spinneret holes is 30, and one of the three leaf-shaped Starting from the spinneret hole, along the clockwise direction, the length ratios of the two short leaves of all spinneret holes are: 1.3, 1.2, 1.2, 1, 1.1, 1.4, 1, 1, 1.2, 1.3, 1.3, 1.1, 1, 1.4 , 1.1, 1.3, 1, 1, 1.4, 1.1, 1.3, 1.1, 1.2, 1.2, 1, 1.4, 1.1, 1, 1.1, 1.2), all three leaves have the same width, and the ratio of the shortest length to width of the shortest leaf is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com