Gas distributor for slurry bed reactor

A gas distributor and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as inability to break bubbles well, frequent beating of check balls, etc., achieve wide gas diffusion area and reduce pressure The effects of reducing and increasing gas holdup and heat and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

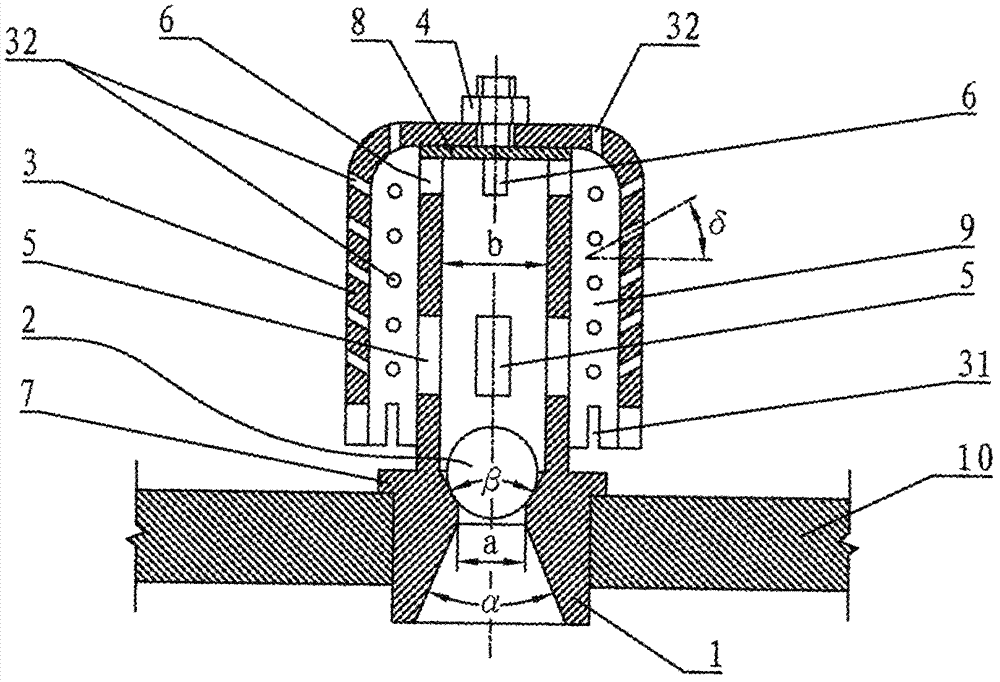

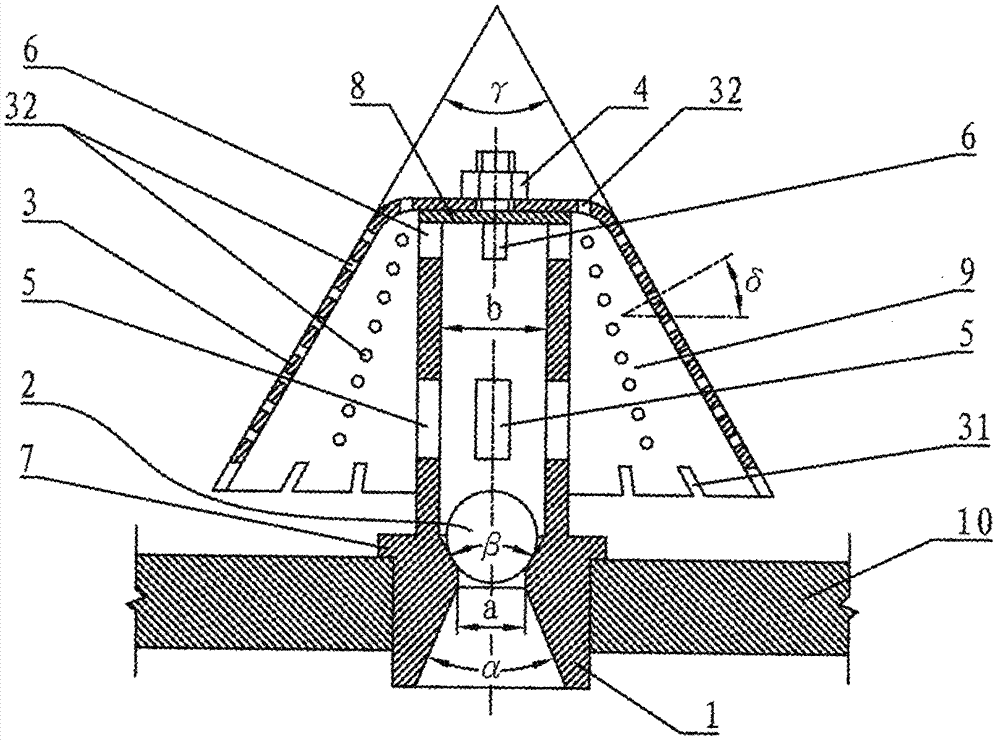

[0012] see figure 1 , figure 2 , the present invention is used for the gas distributor of slurry bed reactor (referred to as gas distributor for short), is provided with bubble cap 3, inlet pipe 1, non-return ball 2. The cylinder body of the bubble cap 3 is provided with an air distribution hole 32 obliquely upward, and the bottom of the cylinder body of the bubble cap 3 is provided with a slit 31 . The intake pipe 1 is composed of an upper section of the intake pipe and a lower section of the intake pipe, and an annular channel 9 is formed between the barrel of the bubble cap 3 and the upper section of the intake pipe. The top of the intake pipe 1 (that is, the top of the upper section of the intake pipe) is provided with a connecting plate 8; the connecting plate 8 is generally circular, and is fixedly connected (for example, welded together) with the top of the intake pipe 1 . The top plate of the bubble cap 3 and the connection plate 8 can be fixed together by means of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com