Alloy melt purifier and its method

A melt purification and alloy technology, applied in the field of alloy melt processing, can solve the problems of unfavorable overall uniform degassing of molten pools, high usage of inert gas, low degassing efficiency, etc., so as to improve degassing purification efficiency and reduce coil The effect of increasing the entry and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

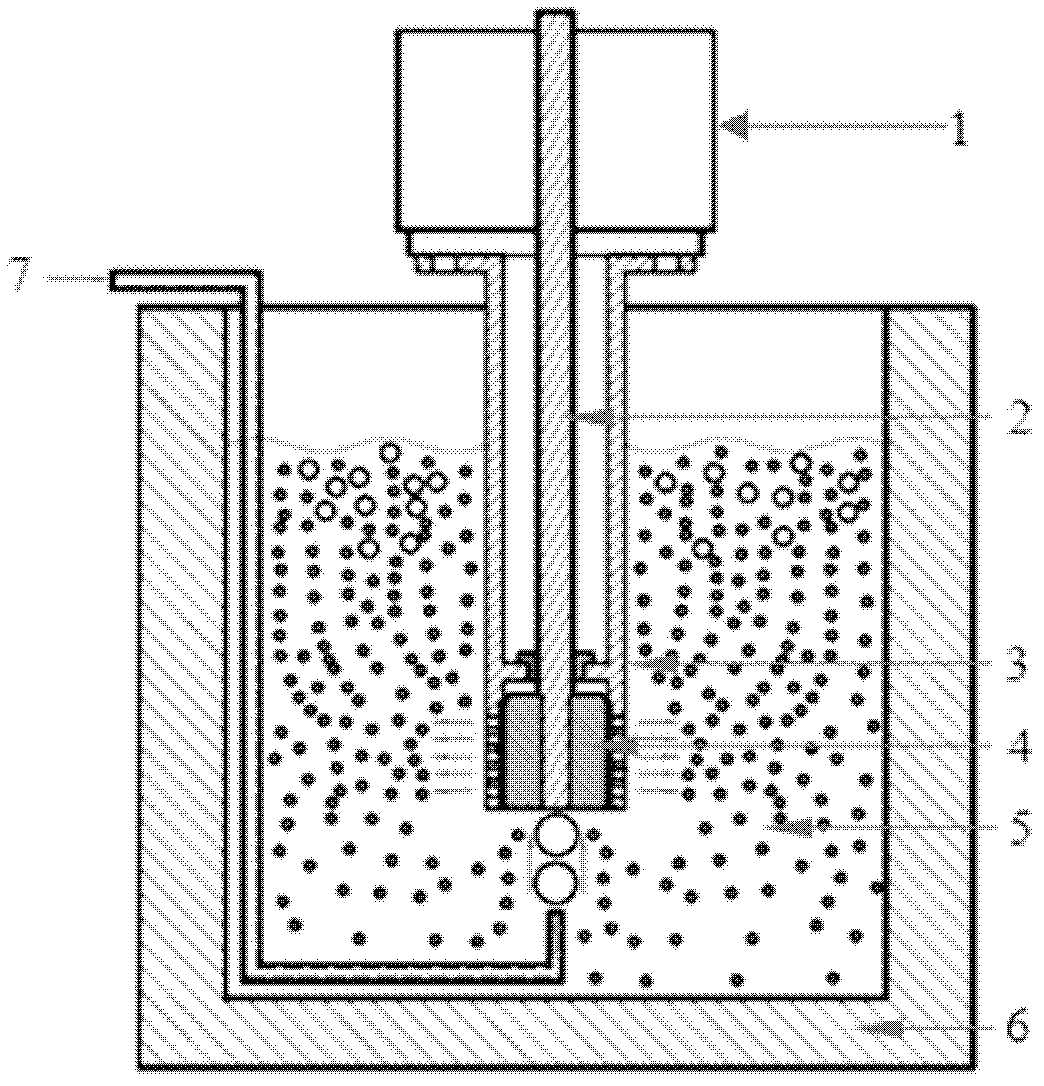

[0031] Use the device of the present invention to carry out degassing and purification treatment on 7075 aluminum alloy. The material connecting shaft 2, stator 3 and rotor 4 in the device is Sialon ceramics. The gap between 3 and rotor 4 is set to 200 μm, and the cross-sectional area of the hole opened on the lower end wall of stator 3 is 4 mm 2 , the melting temperature of the aluminum alloy melt 5 is 750°C, first, preheat the device to 650°C-710°C; extend the stator 3 of the alloy melt purification device into the heat preservation container 6 below the liquid level of the alloy melt 5 to be treated 50 mm position; feed argon gas into the alloy melt 5 below the rotor 4, the pressure of the argon gas is controlled at 0.15MPa, and the flow rate is 1L / min; the motor is started to drive the rotor 4 to rotate, and the speed of the rotor 4 gradually increases from the initial high speed. Switch to medium-speed and low-speed operation; purify for 60s, stop feeding argon, turn of...

Embodiment 2

[0041] Utilize the device of the present invention to carry out degassing and purification treatment on A356 aluminum alloy. The device structure setting, degassing and purification process and the measurement process of the cleanliness of the alloy melt 5 in this embodiment are basically the same as those in Embodiment 1, and the difference is connected in the device. Shaft 2, stator 3 and rotor 4 are made of molybdenum with MoSi2 coating, and the cleaning time is 90s;

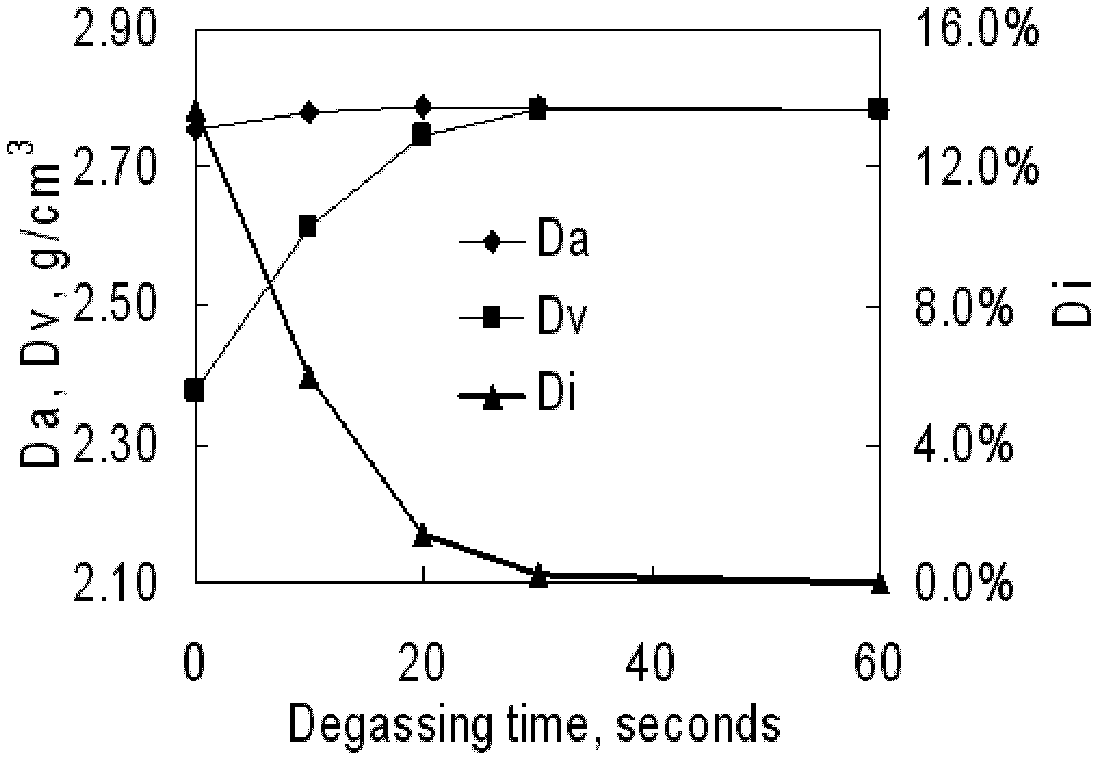

[0042] The density and density index of the A356 aluminum alloy melt 5 during the degassing purification process vary with the purification time as shown in Image 6 As shown, it can be seen from the figure that after 60 seconds of purification, the density index of A356 aluminum alloy can be reduced to less than 1%;

[0043] The comparison of the degassing effect of the device and method of the present invention with the conventional alloy melt degassing purification method for processing the A356 aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com