Gas dispensing device and semiconductor process plant employing the same

A gas distribution and gas technology, applied in the field of microelectronics, can solve the problems of uneven distribution of plasma, uneven distribution of process gas, and influence on the uniformity of processing/treatment such as etching, etc., to achieve uniform plasma distribution, uniform distribution, Effect of Uniform Semiconductor Device Processing/Handling Results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

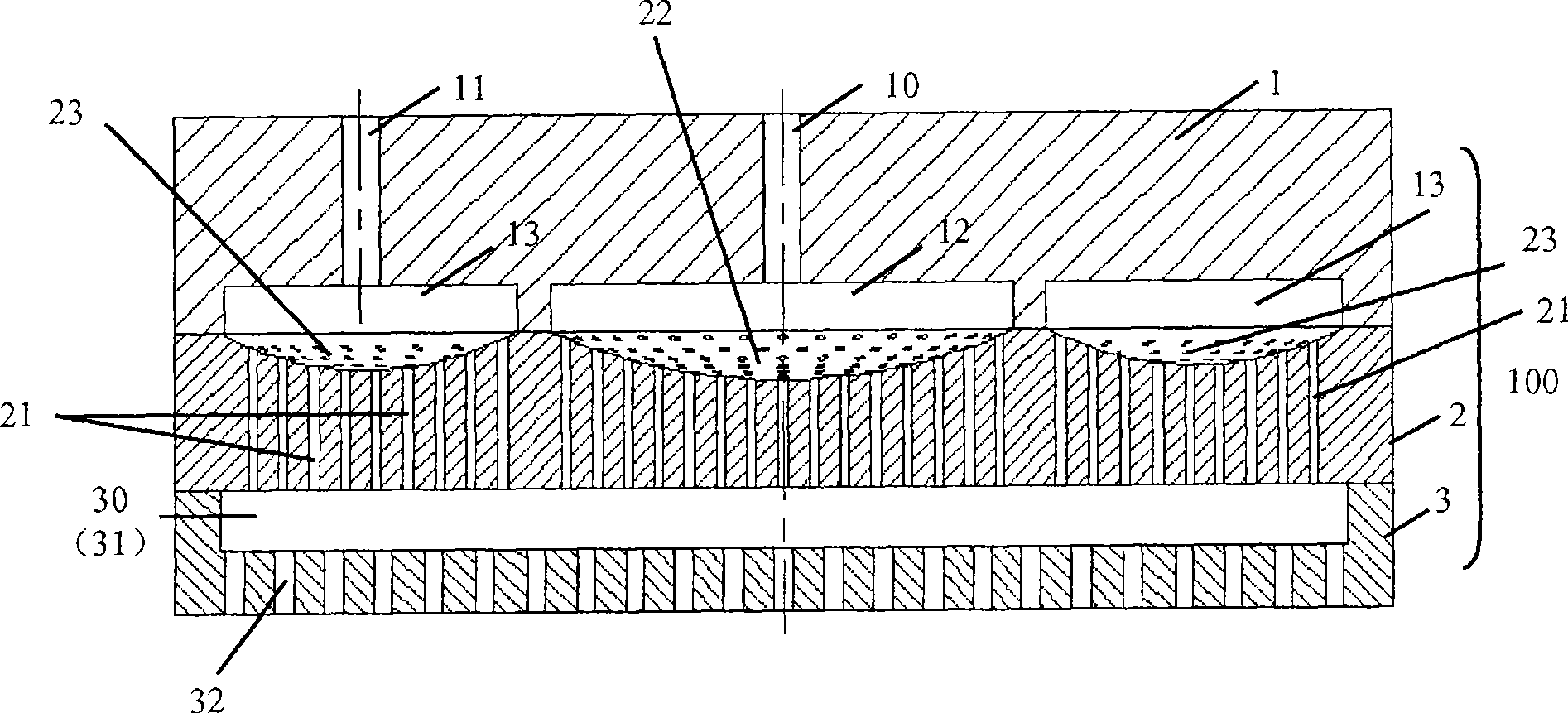

[0055]Similar to the first embodiment, the baffle 2 in this embodiment is also provided with a central concave area 22 of the baffle and an edge concave area 23 of the baffle on its upper surface. The difference from the first embodiment is that a recessed area is also provided on the lower surface of the baffle 2 corresponding to the concave area 22 in the center of the baffle and the concave area 23 on the edge of the baffle, that is, the flow baffle Plate central concave area 52 and baffle edge concave area 53, and a number of through holes 21 are set on the baffle 2, making it pass through the central concave area 22 and central concave area 52 on the baffle 2 , and through the edge concave region 23 and the edge concave region 53 on the spoiler 2, so that the process gas in the concave region (22, 23) is introduced into the concave region (52, 53), and here Diffusion further for a more even process gas distribution. In addition, similar to the spoiler central concave reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com