Method for preparing thermoplastic polymer foamed beads

A technology of thermoplastic polymers and foamed beads, which is applied in the field of preparing thermoplastic polymer foamed materials, can solve the problems of easy shrinkage and deformation of foamed beads, unsafe and environmentally friendly blowing agent gas, and high energy consumption in the process. Achieve the effect of shortening the foaming time, cleaning and environmental protection process, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

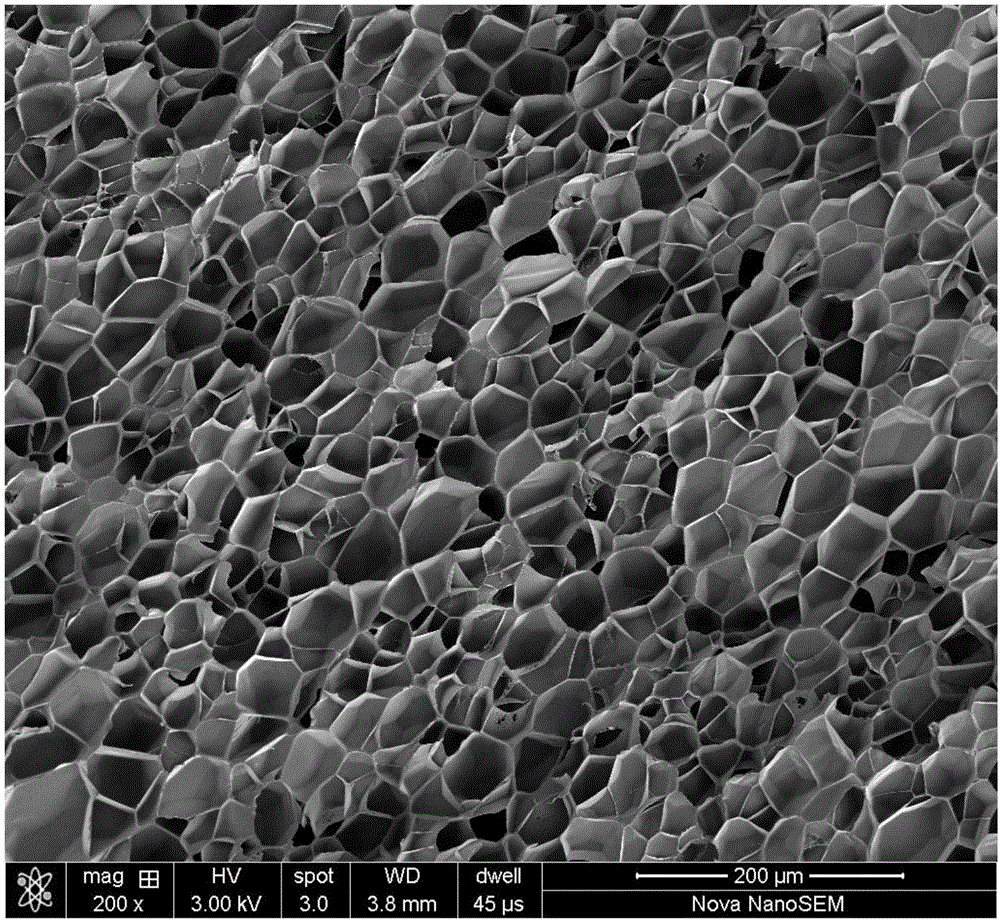

[0032] The autoclave installed on the hot press 1 is heated to 105°C, and PE particles with an average diameter of 2.3mm, a number average molecular weight of 150,000, and a melting point of 110°C are put into the autoclave, and the kettle body 2 is raised and closed by the oil cylinder 4. Die and apply pressure to seal, pass 20MPa supercritical CO into the autoclave through the inlet valve 5 2 . Simultaneously start the vacuum pump 7 to form a vacuum outside the autoclave in the heat press 1. CO 2 After diffusing into the PP particles for 20 minutes, quickly open the exhaust valve 6 to release the CO in the autoclave. 2 Air pressure, the cells nucleate and grow inside the PE particles, trigger the expansion of the PE particles, and open the autoclave through the rapid drop of the oil cylinder 4, so that the PE particles pop out from the autoclave into the vacuum environment, and the cells inside the PE particles grow further. Larger, the particles expand further. The foam...

Embodiment 2

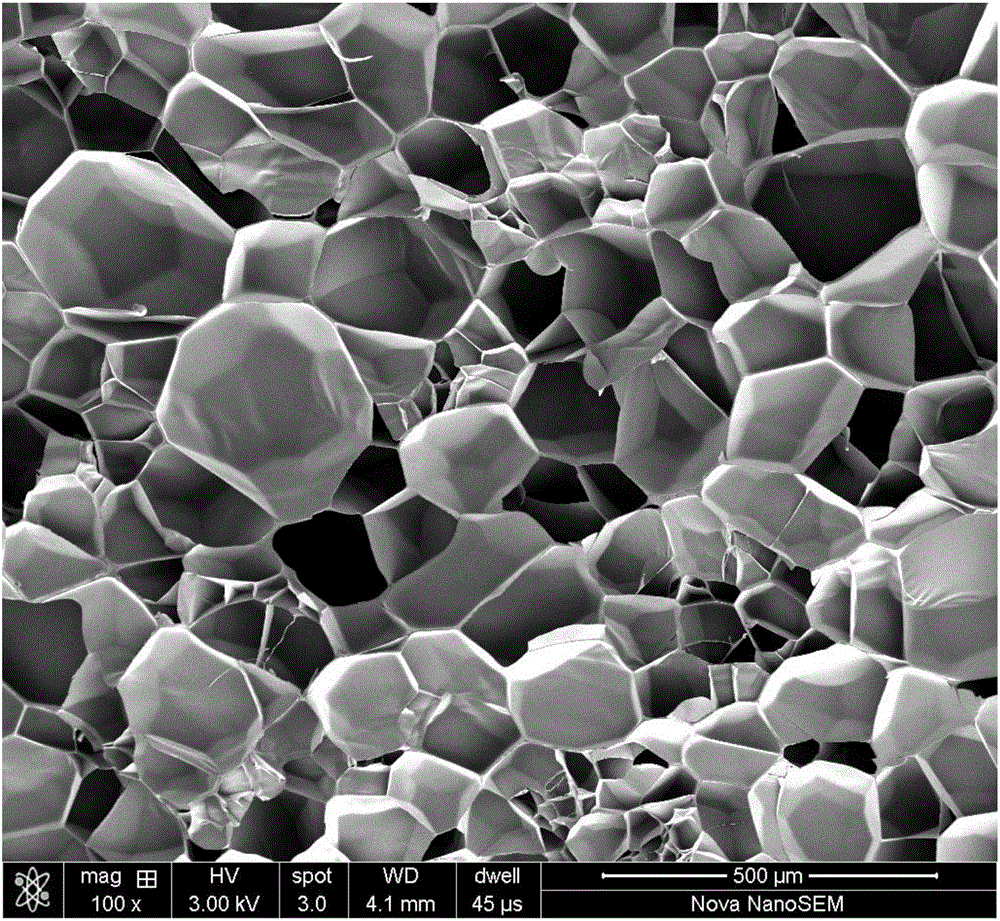

[0034] Heat the autoclave installed on the hot press 1 to 124°C, put PP particles with an average diameter of 3.4mm, a number average molecular weight of 210,000, and a melting point of 132°C into the autoclave, and the kettle body 2 is raised and closed by the oil cylinder 4. Die and apply pressure to seal, pass 15MPa supercritical CO into the autoclave through the inlet valve 5 2 . Simultaneously start the vacuum pump 7 to form a vacuum outside the autoclave in the heat press 1. CO 2 After diffusing into the PP particles for 30 minutes, quickly open the exhaust valve 6 to release the CO in the autoclave. 2Air pressure, the bubbles nucleate and grow inside the PP particles, triggering the expansion of the PP particles, and open the autoclave through the rapid drop of the oil cylinder 4, so that the PP particles pop out from the autoclave into the vacuum environment, and the internal bubbles grow further, and the particles further expand . The foaming performance of the fo...

Embodiment 3

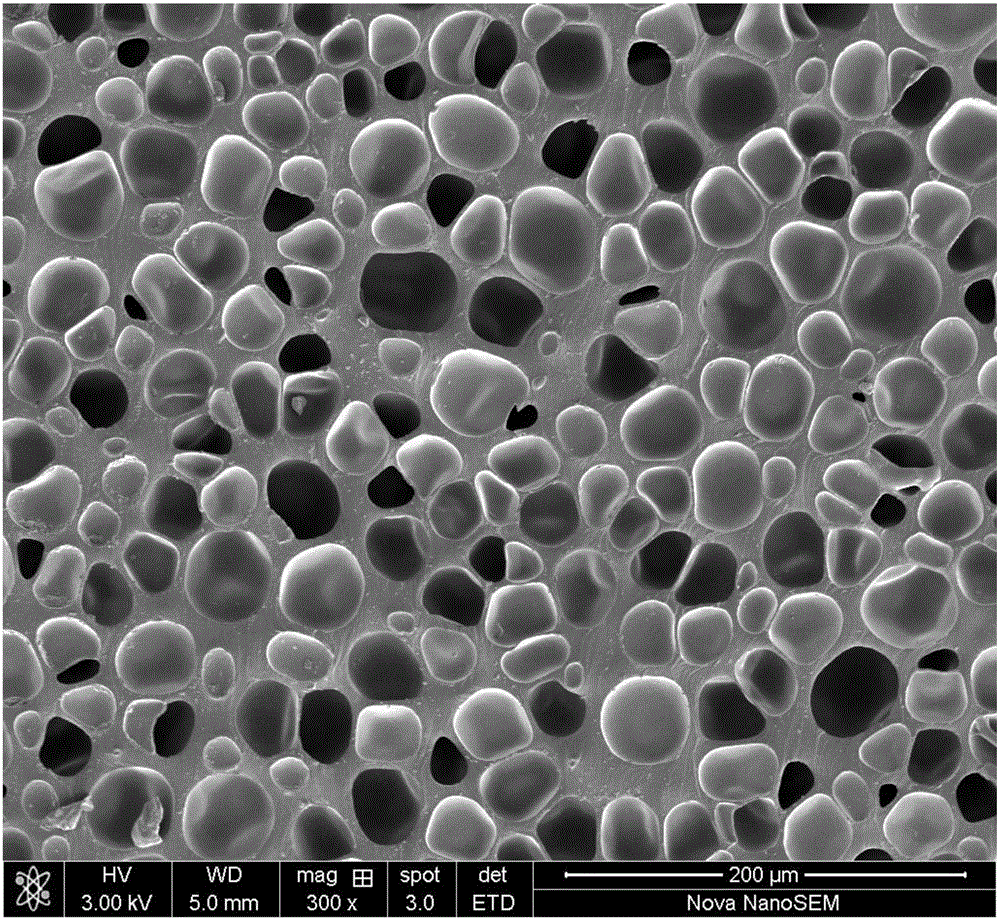

[0036] The autoclave installed on the hot press 1 is heated to 132°C, and TPU particles with an average diameter of 4.1 mm, a number average molecular weight of 80,000, and a melting point of 142°C are put into the autoclave, and the still body 2 is raised and closed by the oil cylinder 4 Die and apply pressure to seal, pass 25MPa supercritical CO into the autoclave through the inlet valve 5 2 . Simultaneously start the vacuum pump 7 to form a vacuum outside the autoclave in the heat press 1. CO 2 After diffusing into the PE particles for 10 minutes, quickly open the exhaust valve 6 to release the CO in the autoclave. 2 air pressure, the bubbles nucleate and grow inside the TPU particles, triggering the expansion of the TPU particles, and the autoclave is quickly lowered through the oil cylinder 4, so that the TPU particles are ejected from the autoclave into the vacuum environment, and the bubbles inside the TPU particles grow further. The particles expand further. The fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com