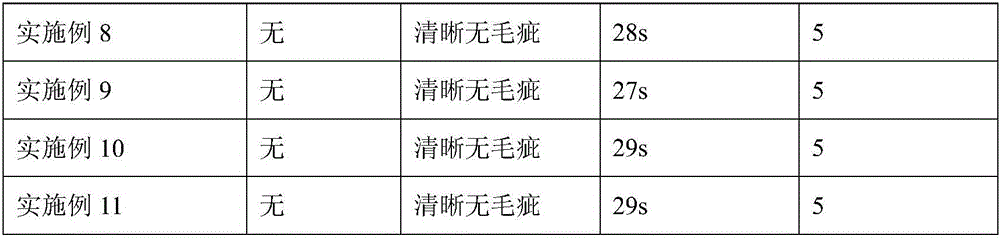

Patents

Literature

54results about How to "Shorten foaming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

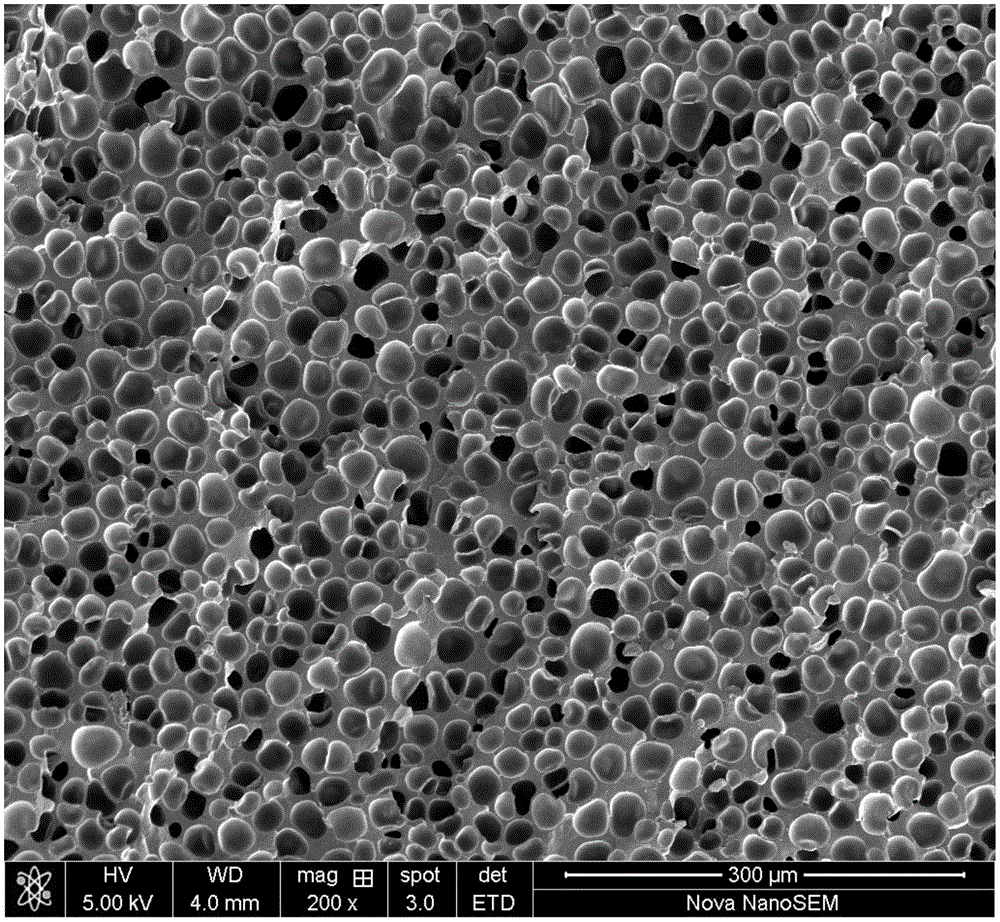

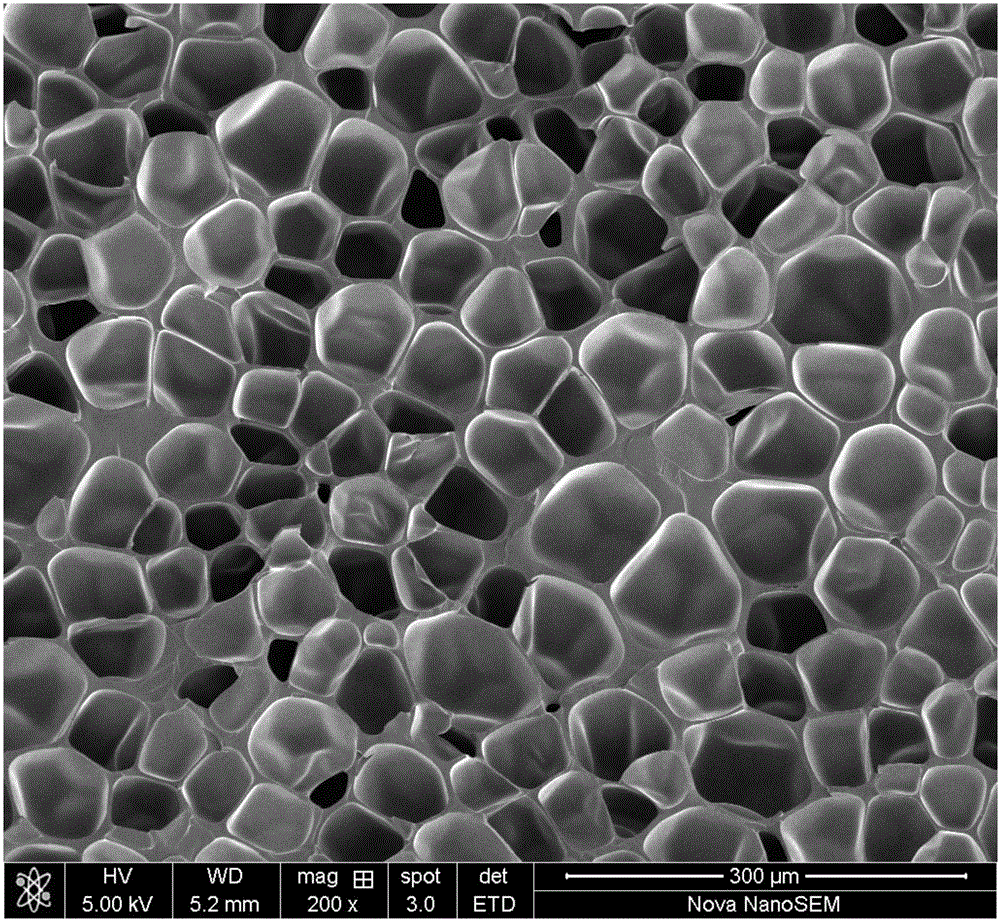

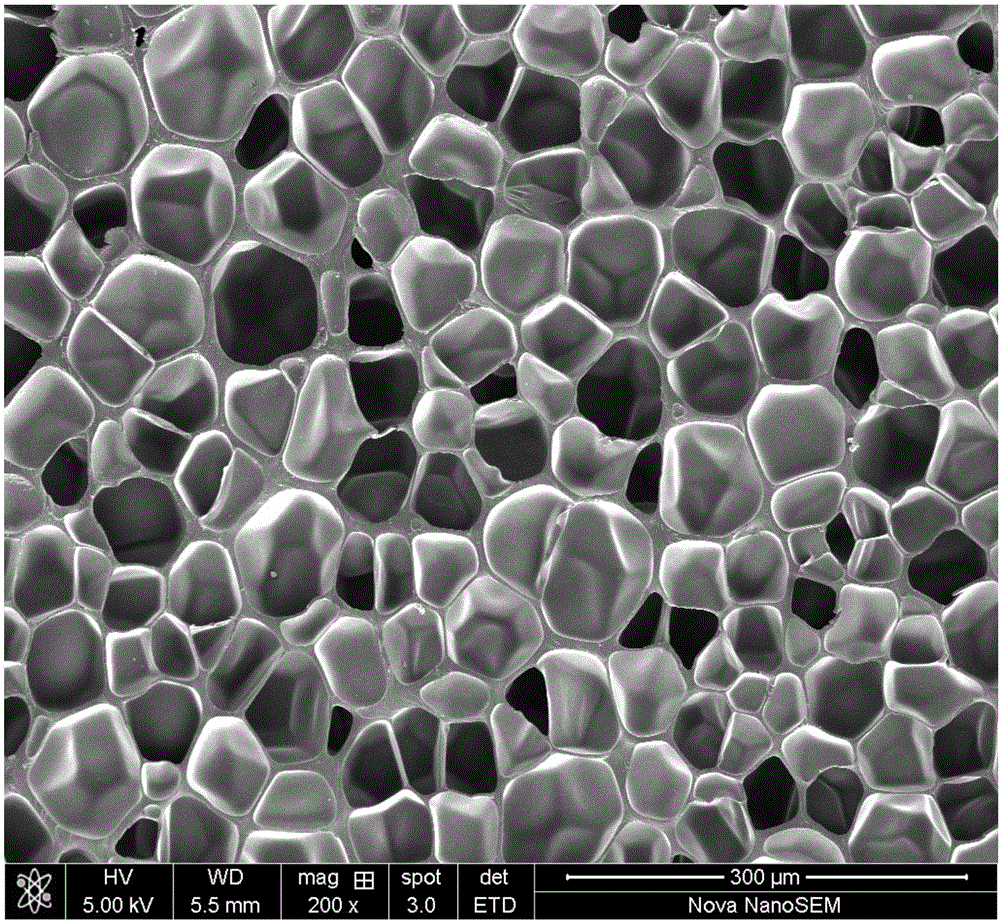

Method for preparing thermoplastic polymer foamed beads

The invention discloses a method for preparing thermoplastic polymer foamed beads. The method comprises the following steps: 1) putting polymer particles into a sealed container heated to a foaming temperature, and putting the sealed container in a vacuum environment; 2) introducing supercritical fluid into the sealed container, and performing swelling diffusion; 3) after swelling diffusion of the supercritical fluid lasts for 5-60 minutes, releasing the pressure of the sealed container to discharge out the supercritical fluid, and controlling the pressure release velocity to induce nucleation and growth of foam pores so as to enable the polymer particles to swell and grow; 4) leading the polymer particles inside the sealed container into the vacuum environment to further swell and grow, thereby obtaining the polymer foamed beads with a high foaming ratio, wherein the foaming temperature in the step 1) is a temperature that the polymer particles can generate plastic deformation but cannot flow yet, the forming temperature is within Tg-Tg+40 DEG C for an amorphous polymer, and Tg is a glass-transition temperature of the amorphous polymer; for a crystallized polymer, the foaming temperature is within Tm-20 DEG C and Tm, and Tm is a melting point of the crystallized polymer.

Owner:HANGZHOU BOSTE NEW MATERIALS TECH CO LTD

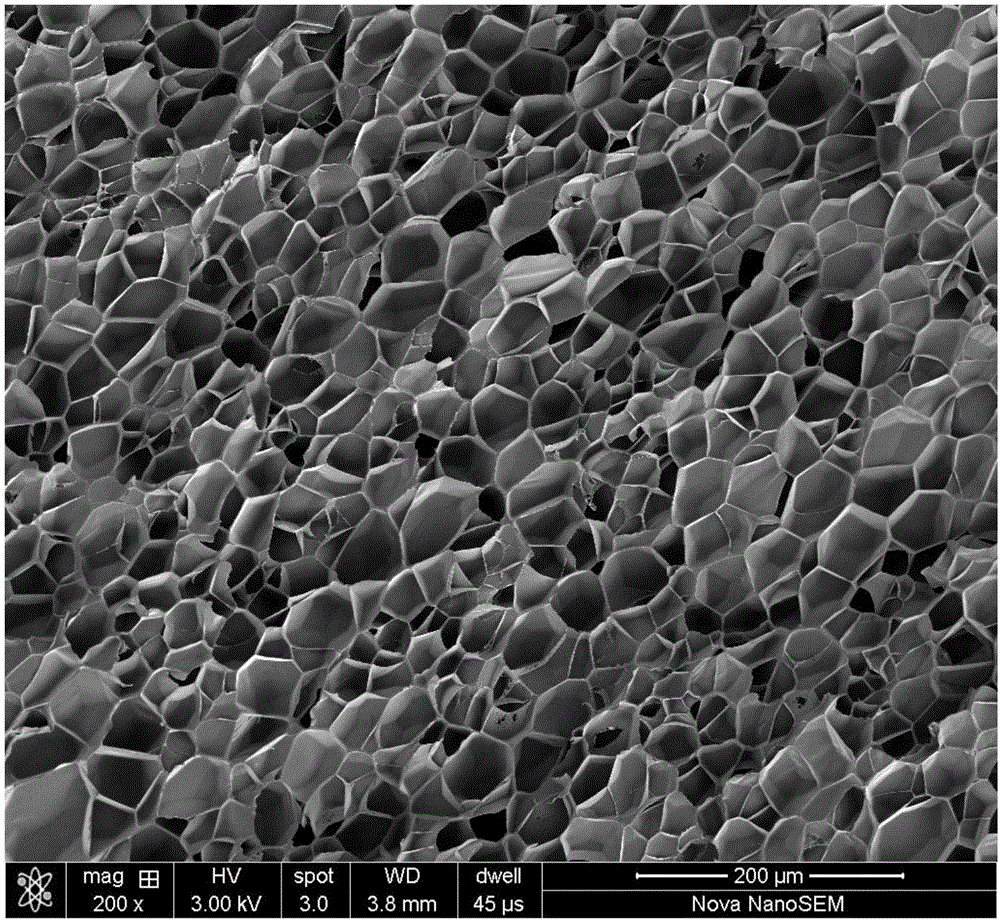

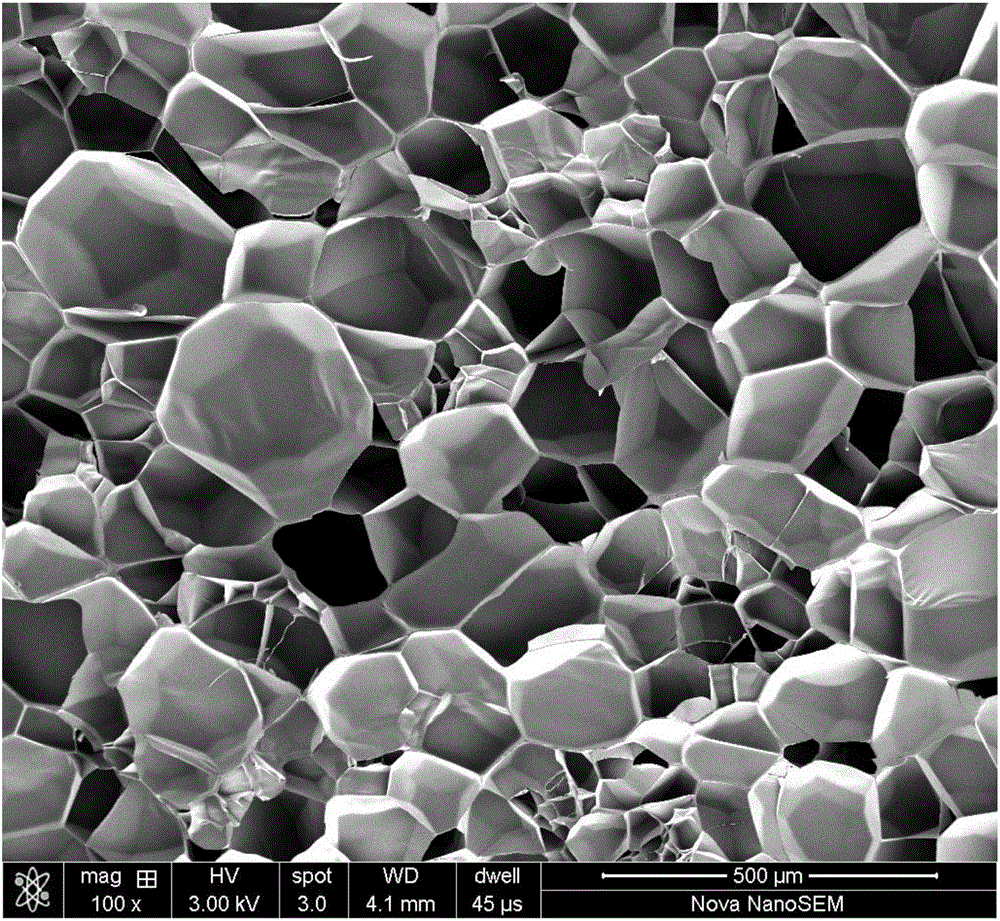

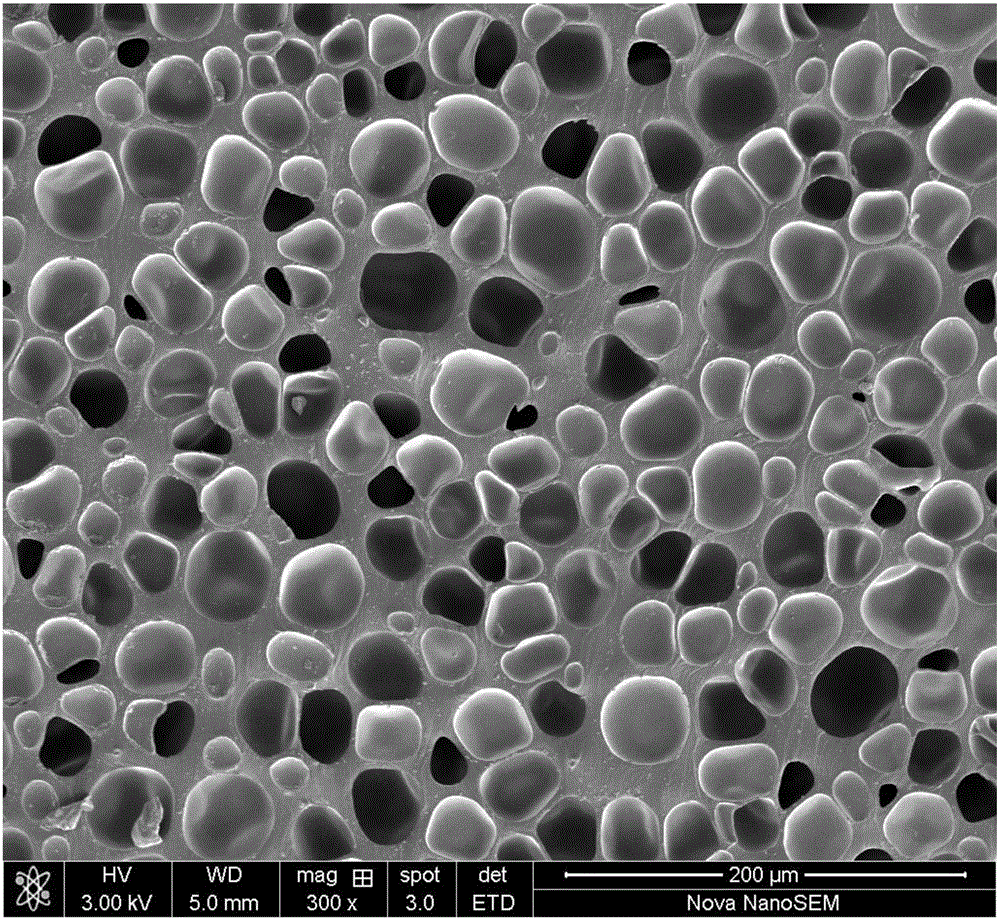

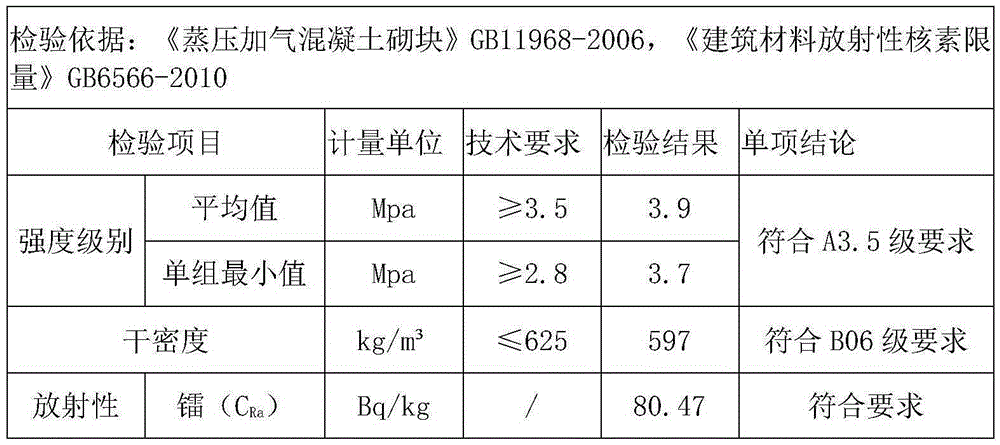

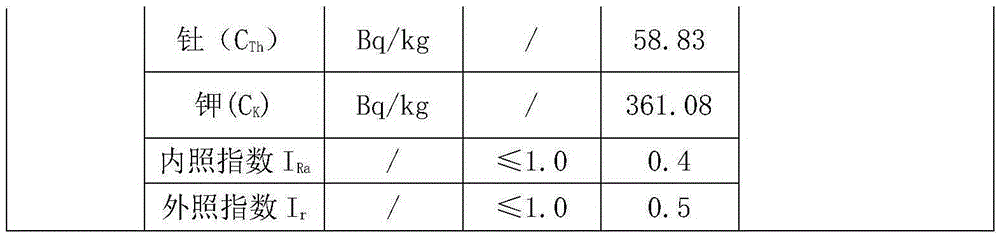

Red mud autoclaved aerated concrete building block and preparation method of red mud autoclaved aerated concrete building block

The invention discloses a red mud autoclaved aerated concrete building block and a preparation method of the red mud autoclaved aerated concrete building block. The building block is prepared from the following ingredients in parts by weight: 5 to 15 parts of red mud, 15 to 60 parts of pulverized fuel ash, 2 to 8 parts of plaster, 10 to 35 parts of quicklime, 5 to 10 parts of concrete, 0.01 to 0.03 parts of aluminum powder and water. The red mud is used for replacing phosphorus slag and undergoes a series of reactions with raw materials such as the pulverized fuel ash, the plaster, the quicklime, the concrete and the aluminum powder to prepare the aerated concrete building block; the product weight is light; the strength is high; the stability is good; the heat conductivity coefficient is low; the performance is excellent; the problem that the red mud cannot be easily and synthetically utilized is solved; the stored red mud can be fast digested; the goal of saving national resources is achieved, a lot of soil is also restored; in addition, the production process is environment-friendly and has no pollution; a new path is opened up for the comprehensive utilization of the red mud.

Owner:贵州源隆新型环保墙体建材有限公司

High-magnification thermoplastic polyurethane microporous foamed plate and production method thereof

InactiveCN106146875AImprove solubilityIncrease the speed of diffusionSolubilityThermoplastic polyurethane

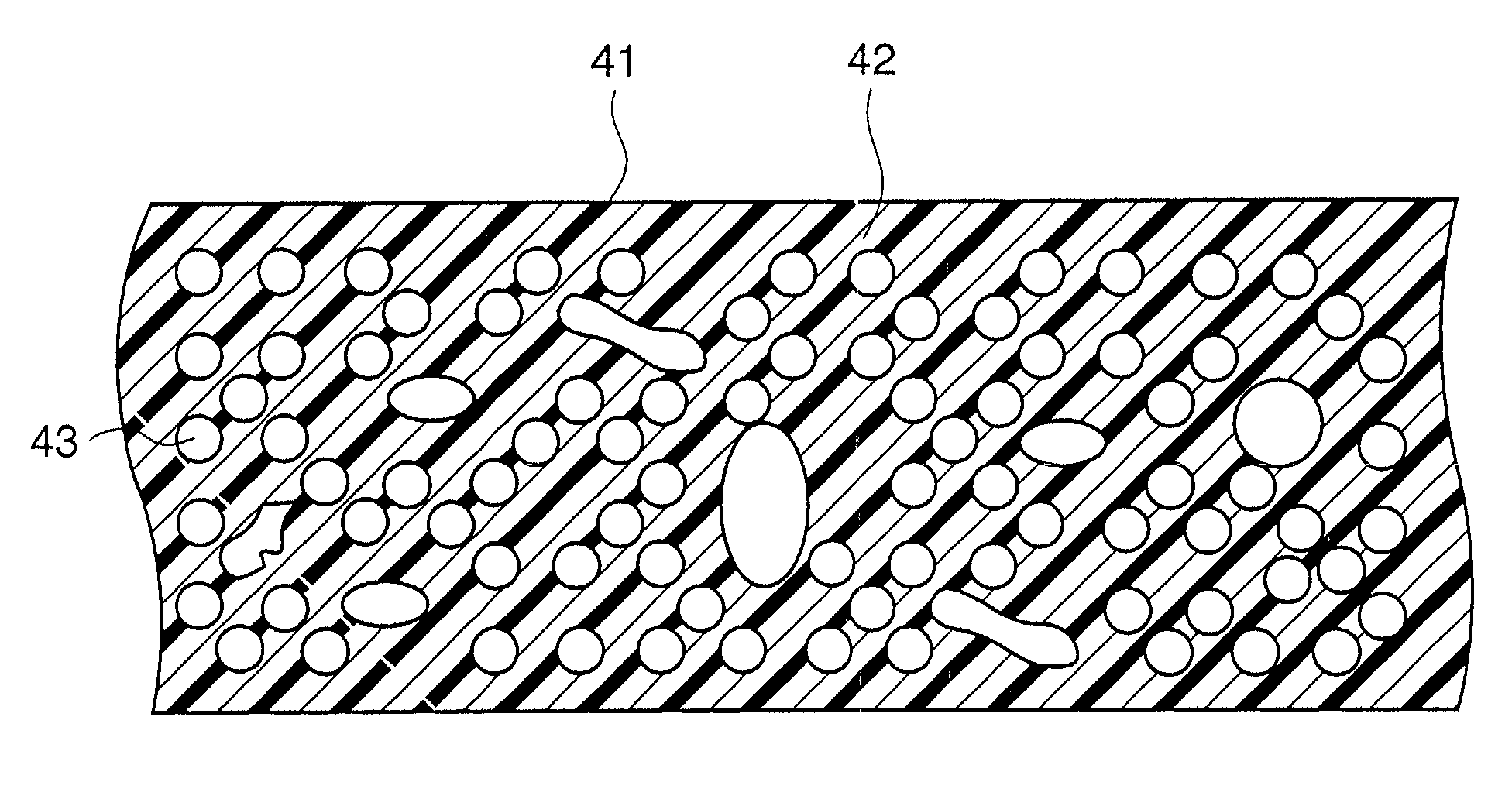

The invention relates to a high-magnification thermoplastic polyurethane microporous foamed plate which is prepared from the following components in parts by weight: 70-100 parts of TPU (thermoplastic polyurethane) and 0-30 parts of polydimethylsiloxane. The high-magnification thermoplastic polyurethane microporous foamed plate has the advantages that, as a supercutical fluid has relative high solubility in the polydimethylsiloxane and the polydimethylsiloxane has relatively low interfacial tension, a little polydimethylsiloxane mixed in the TPU greatly accelerates the diffusion velocity of the supercutical fluid in the TPU; a diffusion equilibrium time of the supercutical fluid in the TPU is shortened; the volume of a die cavity is slightly more than that of a TPU plate; moreover, a die made of a breathable metal material is laid on a surface of a die, so that the supercutical fluid can synchronously diffuse to enter the TPU plate through the upper surface and the lower surface of the TPU plate; in comparison with that the supercutical fluid can diffuse to enter the TPU plate through the upper surface only, a diffusion distance is shortened; the diffusion equilibrium time is shortened; the production efficiency is improved; in addition, the invention also provides a production method of the high-magnification thermoplastic polyurethane microporous foamed plate.

Owner:ZHEJIANG XINHENGTAI ADVANCED MATERIAL

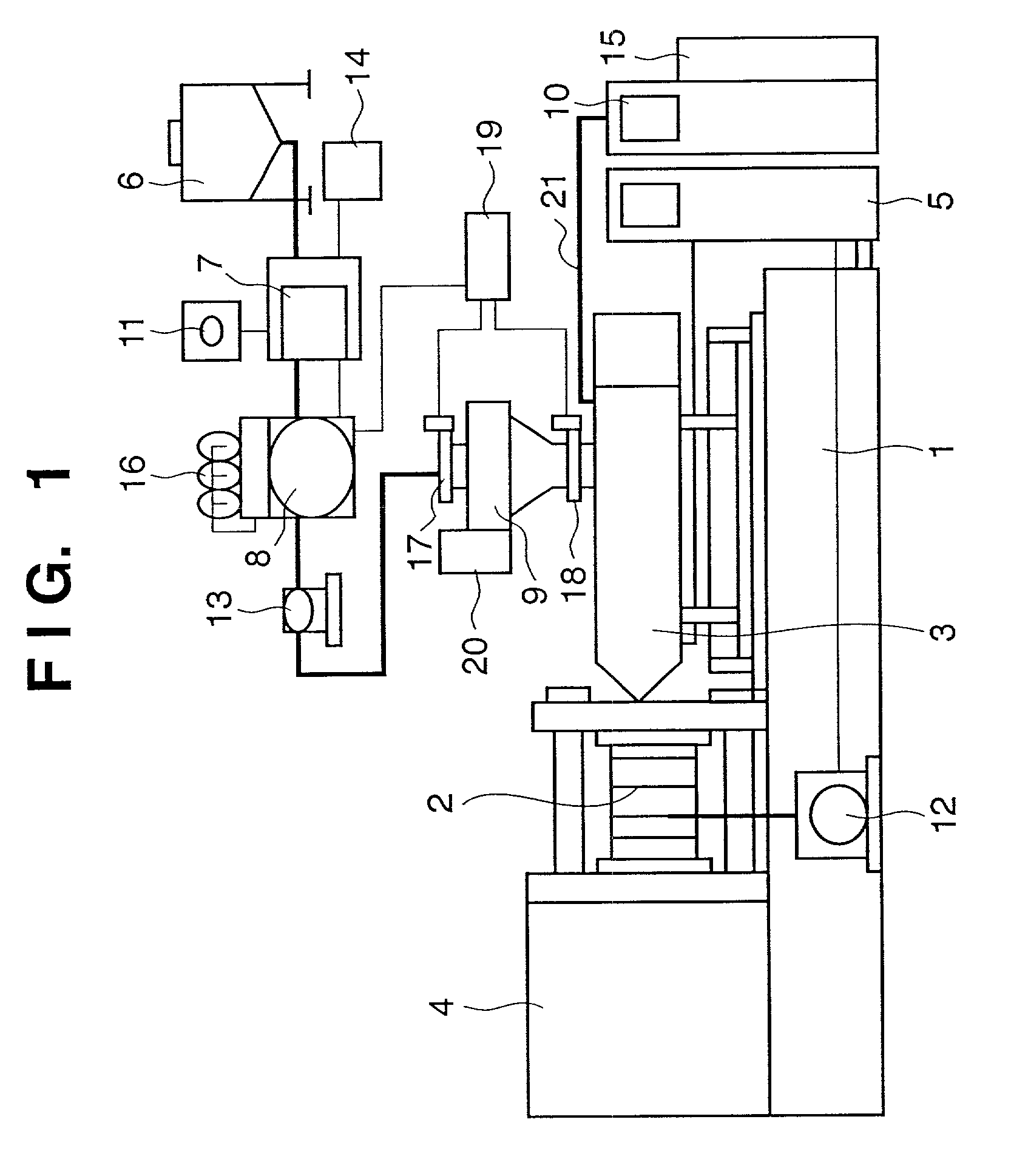

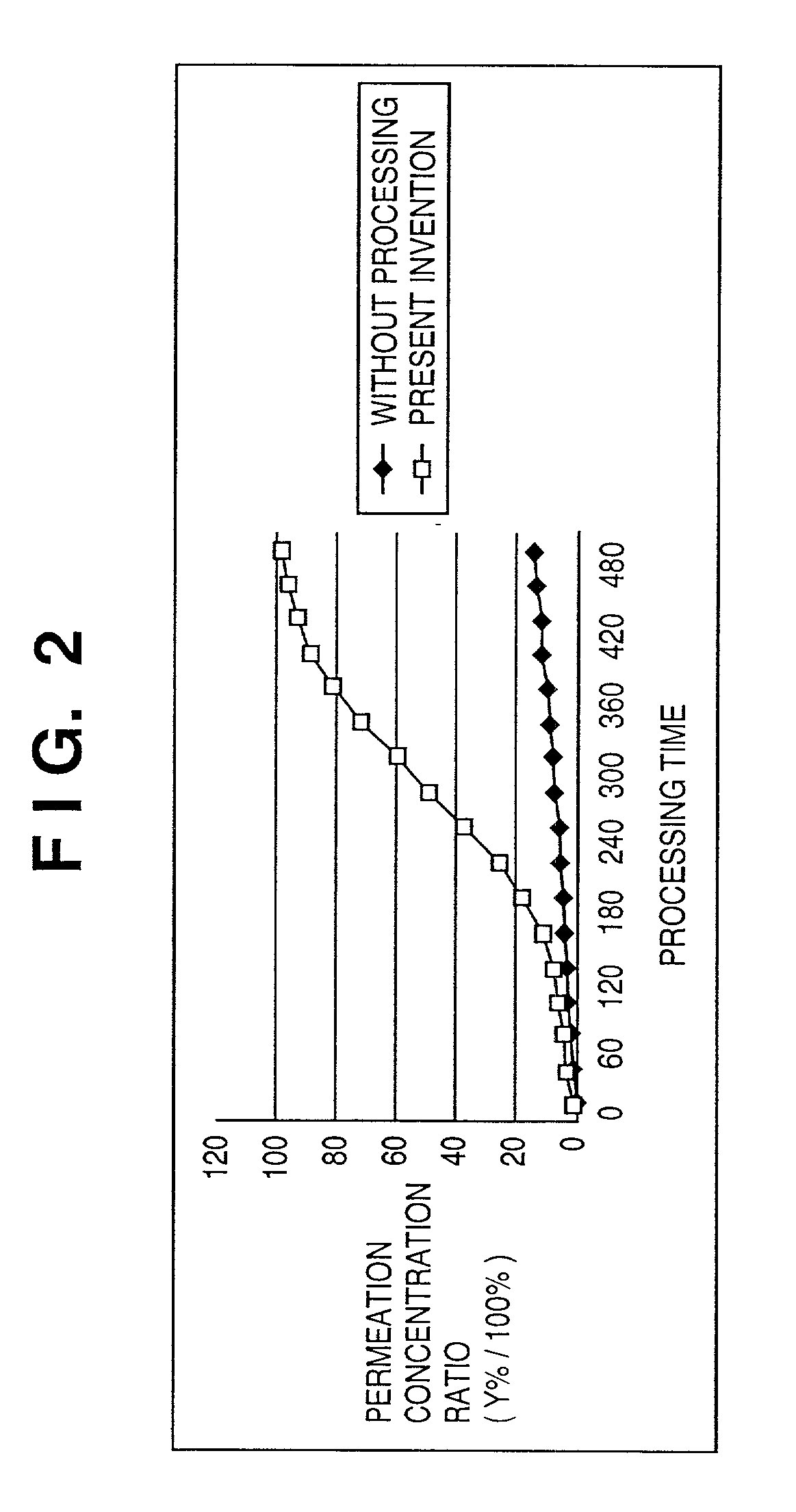

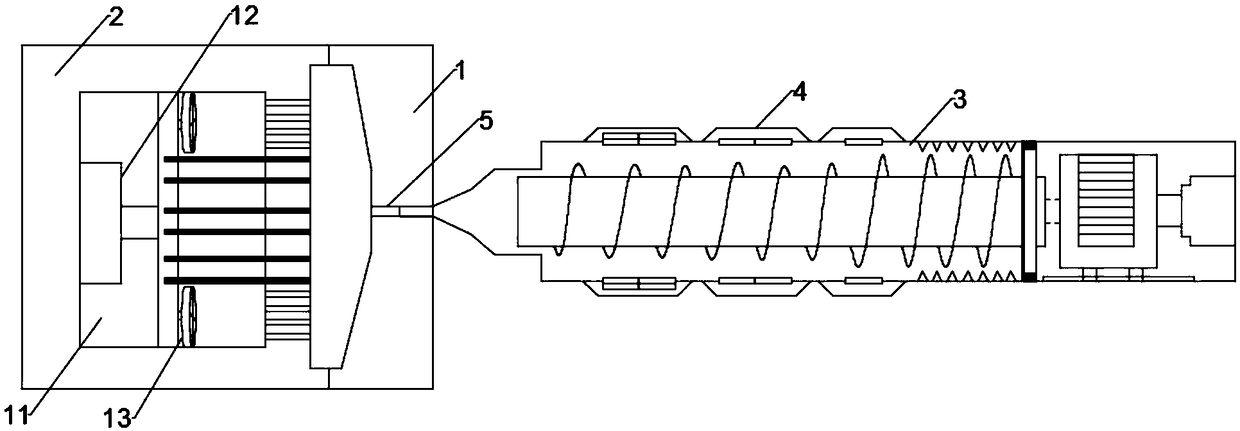

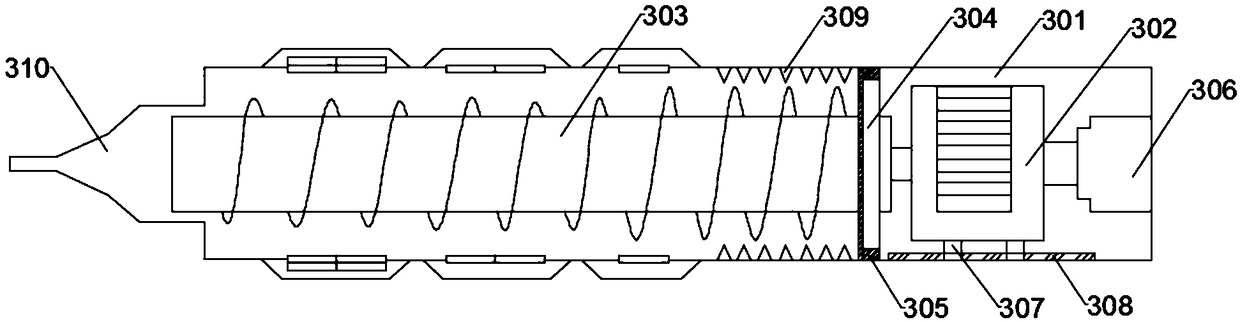

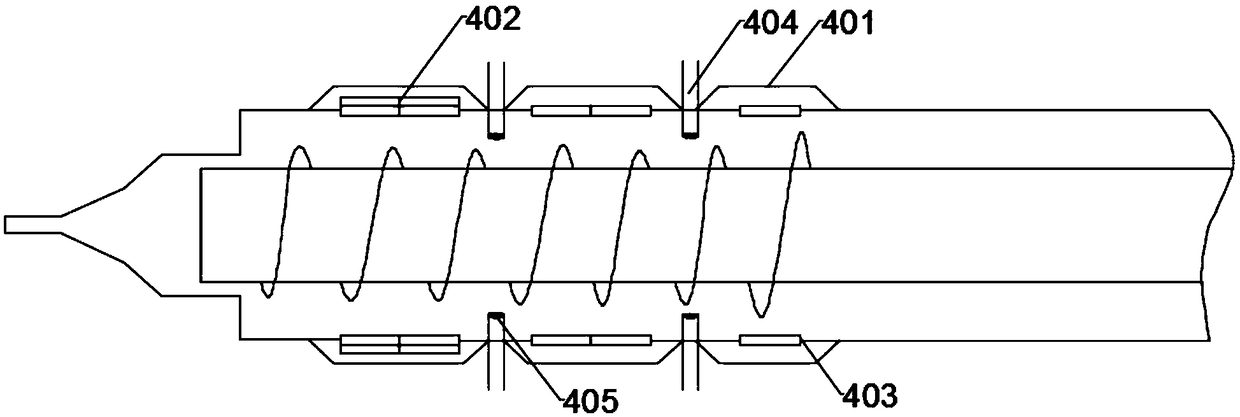

Foam molding method and apparatus

InactiveUS7107601B2Shorten foaming timeReduce the overall diameterUndesired vibrations/sounds insulation/absorptionRecord information storageShell moldingProduct gas

According to this invention, there is provided a molding method and apparatus which increase the gas permeation speed in obtaining a foamed resin molded product by letting a gas permeate a molten resin material. To achieve this object, a chip- or pellet-like resin material is evacuated and subjected to dehumidifying / drying processing, and replacement processing in an inert gas in a pre-processing unit, the resin material is then held in an inert gas of a predetermined temperature and pressure in an inert gas permeation unit for a predetermined period of time, the temperature and pressure are decreased, the material is fed to a material hopper whose temperature and pressure are controlled, the material is fed to a plasticizing unit to which a gas of a predetermined temperature and pressure is fed, the resin material is melted in the plasticizing unit, the resin material is injected / charged into a mold which is evacuated in advance to a pressure not more than atmospheric pressure, the pressure is restored to atmospheric pressure after the resin material is cooled for a predetermined period of time, and a foamed product is extracted by opening the mold.

Owner:CANON KK

Method for preparing light porous particle controlled release fertilizer

ActiveCN104262005AImprove water absorptionGood fertilizer effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateDipotassium phosphate

The invention discloses a method for preparing a light porous particle controlled release fertilizer. The method comprises the following steps: uniformly mixing CRT screen glass powder, 5-20 percent of monopotassium phosphate, dipotassium phosphate, potassium sulfate, tripotassium phosphate, potassium chloride, zinc dihydrogen phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, cobalt oxide and manganese oxide, pressing, molding, feeding the mixture into a roller kiln at the temperature of 650-660 DEG C, and preserving the temperature to be 780-790 DEG C for 15-30 minutes; and reducing the temperature to be 50-80 DEG C or below at a rate of 100-200 DEG C per minute, thereby obtaining the light porous particle controlled release fertilizer. The light porous particle controlled release fertilizer prepared by the invention can be widely applied to the fields of indoor horticulture, urban gardening, street planting and farmlands. The preparation process is simple in operating process and low in cost, the production cost of the controlled release fertilizer can be effectively reduced, the environment is protected, wastes are changed into valuable materials, and the light porous particle controlled release fertilizer is suitable for large-scale industrial production and has obvious economic benefits and environmental protection benefits.

Owner:广西丰岭肥业有限公司

Method for preparing foamed ceramic by microwave sintering of cobalt smelting waste slag

InactiveCN109553393AMass consumptionSolve environmental problemsCeramic materials productionCeramicwareHigh energySlag

The invention belongs to the technical field of resource utilization of solid wastes, and particularly relates to a method for resource utilization of cobalt smelting waste slag. The invention provides the method for preparing foamed ceramic by microwave sintering of the cobalt smelting waste slag. The method comprises the following steps: carrying out proportioning by using the cobalt smelting waste slag, filler, a liquid phase agent, a plasticizer and a foaming agent, carrying out grinding, mixing, granulating, and mold pressing or mold powder accumulation to prepare a green body; and carrying out microwave sintering to prepare the foamed ceramic. The microwave heating method is adopted, and compared with a conventional electric heating or fuel heating mode, the microwave heating methodhas the advantages that the foaming temperature is greatly reduced, the foaming time is shortened, and therefore energy consumption is greatly reduced. According to the method, the problems of high energy consumption in existing formed ceramic industry and high additional value comprehensive utilization of the cobalt smelting waste slag are solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

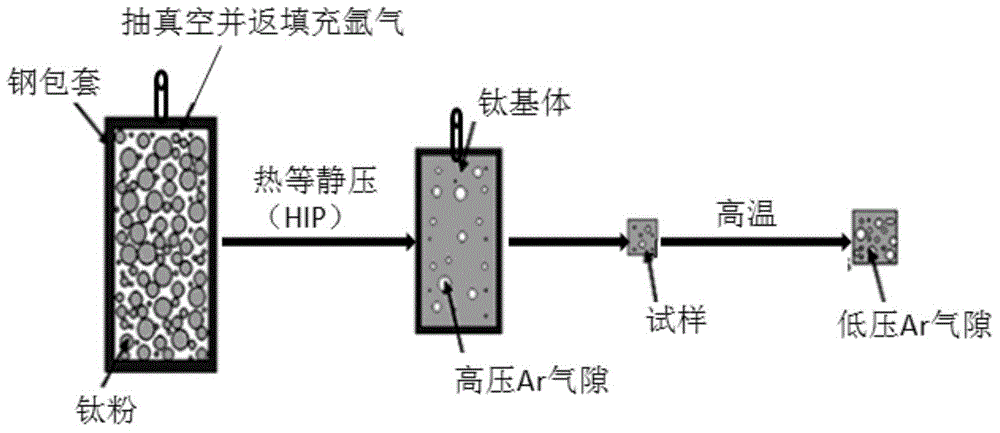

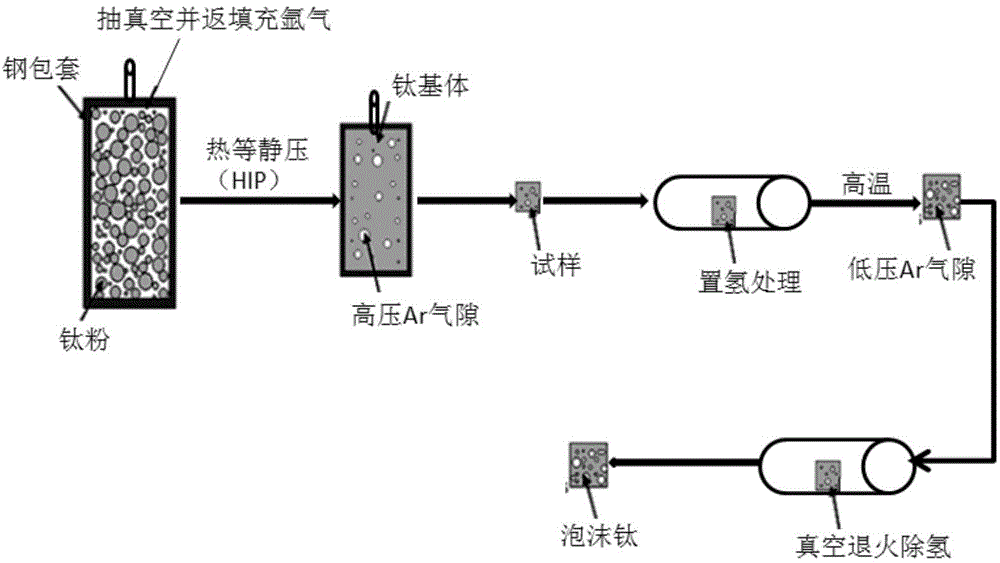

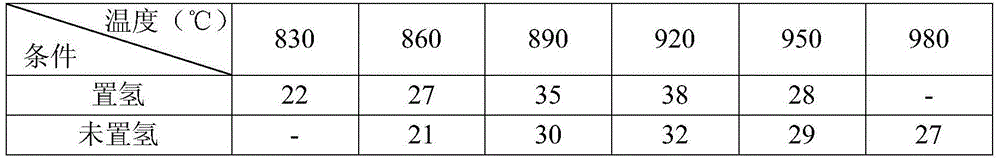

Preparation method of foam titanium under hydrogen-assisted action

The invention provides a preparation method of foam titanium under the hydrogen-assisted action. The preparation method comprises the following four steps: preparing a preformed blank test sample, hydrogenating, foaming at high temperature and removing hydrogen, and specifically comprises the following steps: filling titanium powder into a steel capsule, performing vacuum-pumping, re-filling a certain pressure of argon, carrying out hot isostatic pressure and processing a preformed blank formed by the hot isostatic pressure into a cuboid shape; then putting into a hydrogen treatment furnace and filling a certain content of hydrogen; carrying out high-temperature foaming in the vacuum environment; finally putting into the hydrogen treatment furnace to carry out vacuum annealing to obtain the foam titanium. The preparation method of the foam titanium under the hydrogen-assisted action has the benefits that the hydrogen is introduced in the process of preparing the foam titanium by adopting a gas capture method, hydrogen-induced high-temperature plasticity is utilized to improve the foaming performance of the foam titanium and improve the foaming efficiency and the porosity of the foam titanium, and finally, the hydrogen is removed to optimize the mechanical property of the foam titanium. The preparation method has the characteristics of high product porosity and low preparation cost, and the industrial production can be realized. The preparation method can be applied to the fields of aerospace and the like.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

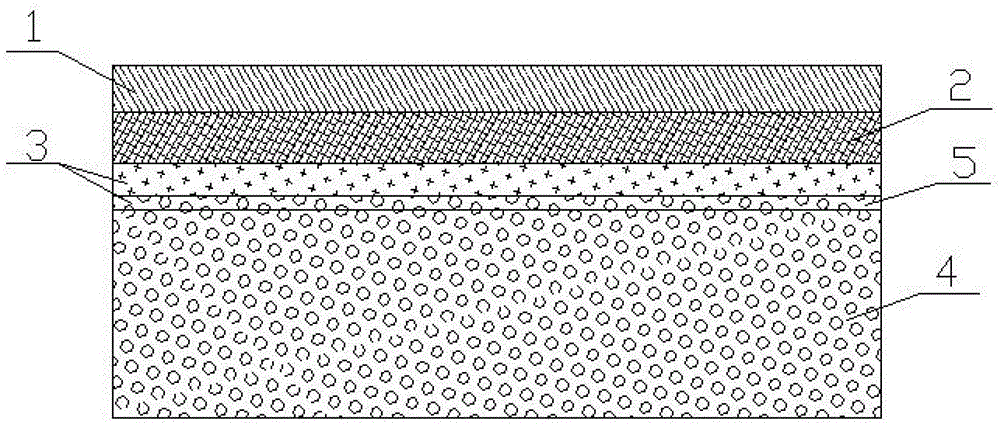

Thermal-insulation decorative plate and preparation method thereof

InactiveCN102720320AImprove bindingTightly boundCovering/liningsSynthetic resin layered productsThermal insulation

The invention relates to a thermal-insulation decorative plate, which comprises a foaming material layer and a cloth cover material layer arranged on the foaming material layer and capable of enabling the foaming material layer to permeate in. The cloth cover material layer is coated with a sand solidification material layer, and decorative sand for forming decorative patterns is solidified in the sand solidification material layer. The invention further relates to a preparation method of the thermal-insulation plate, during foaming, foaming materials in the foaming material layer enter the cloth cover material layer and bond with the cloth cover material layer to form the thermal-insulation decorative plate. By mean of the preparation method, bonding between a thermal-insulation layer and the sand solidification material layer of the thermal-insulation decorative plate is firm and not prone to layering.

Owner:辽宁兴胜防水材料科技发展有限公司

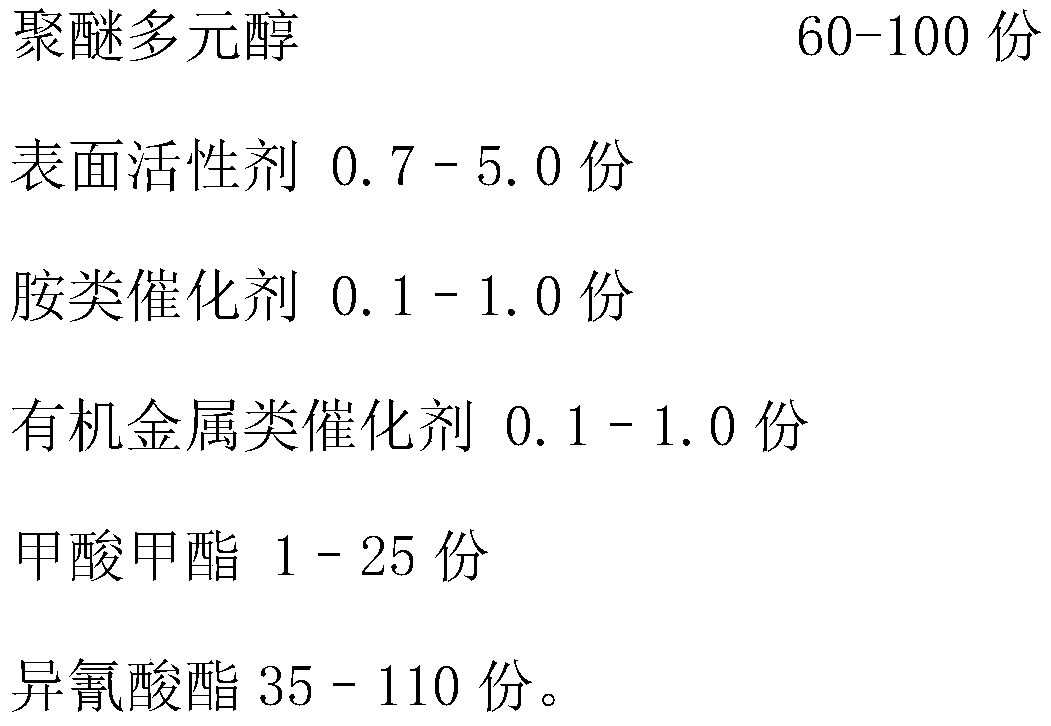

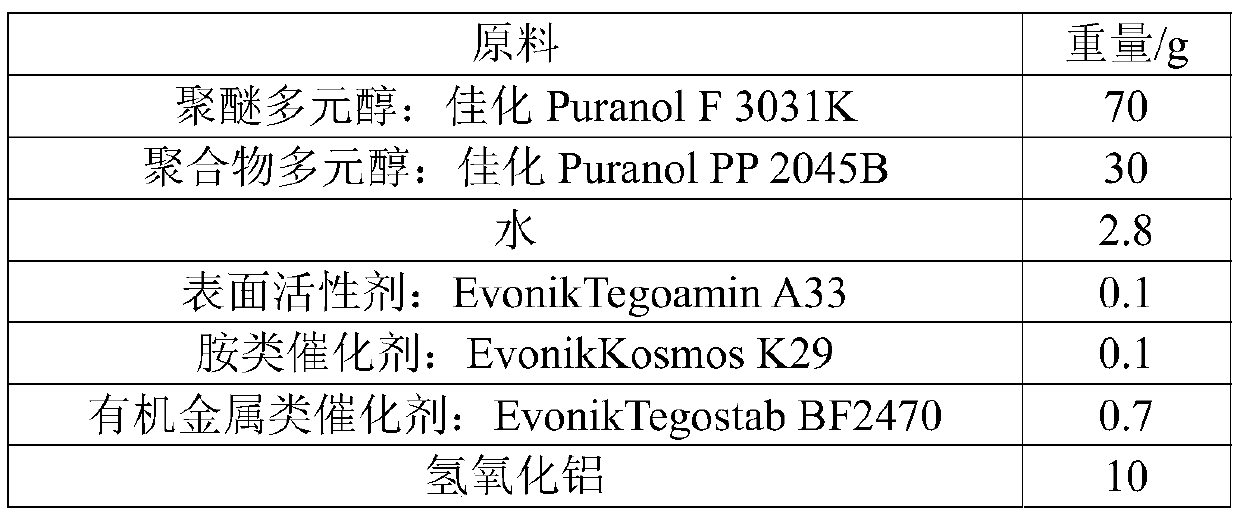

Polyurethane flexible foam sponge and preparation method thereof

The invention discloses a polyurethane flexible foam sponge and a preparation method thereof. The polyurethane flexible foam sponge is composed of the following ingredients according to a certain weight ratio: polyether polyol+polymer polyol, a surfactant, an amine catalyst, an organometallic catalyst, a crosslinking agent, a filler, an auxiliary material, water, methyl formate and isocyanate. The preparation method comprises the following steps: mixing the above material except isocyanate, and adding the mixture into a low-pressure foaming machine; adding isocyanate into the low-pressure foaming machine, rapidly stirring and mixing, carrying out a foaming reaction, and standing to obtain the polyurethane flexible foam sponge. By using methyl formate as the foaming agent instead of dichloromethane, the foaming agent is environmentally-friendly; and the foaming is easier, thus improving conversion rate of the sponge product and saving use amount of a physical foaming agent.

Owner:JIAHUA CHEM TECH DEV SHANGHAI CO LTD

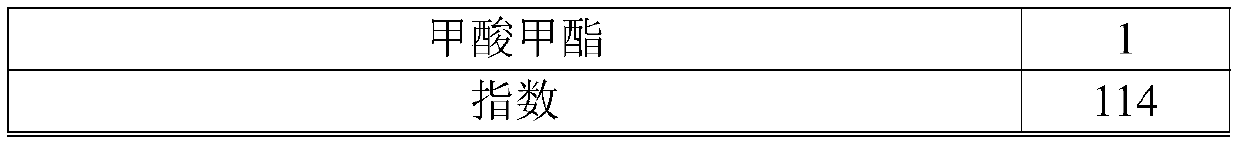

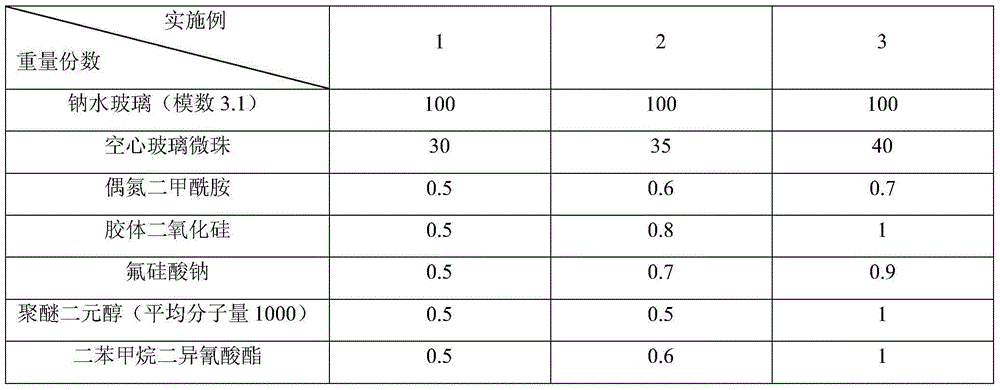

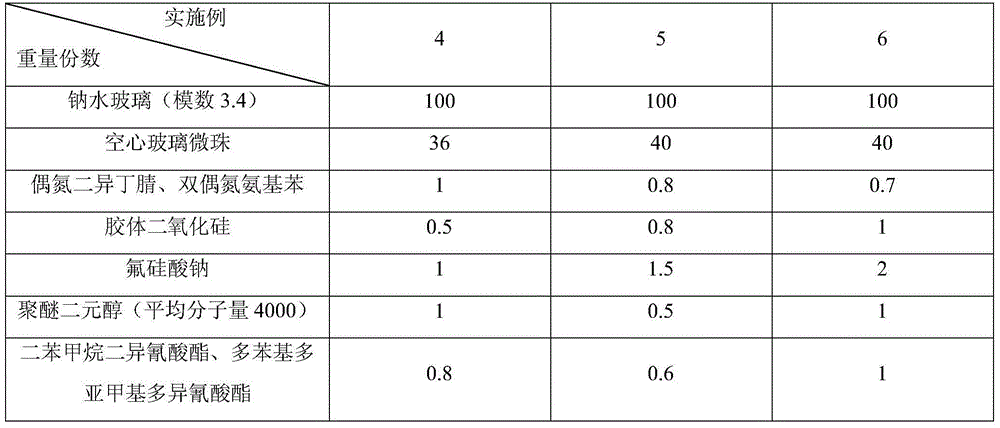

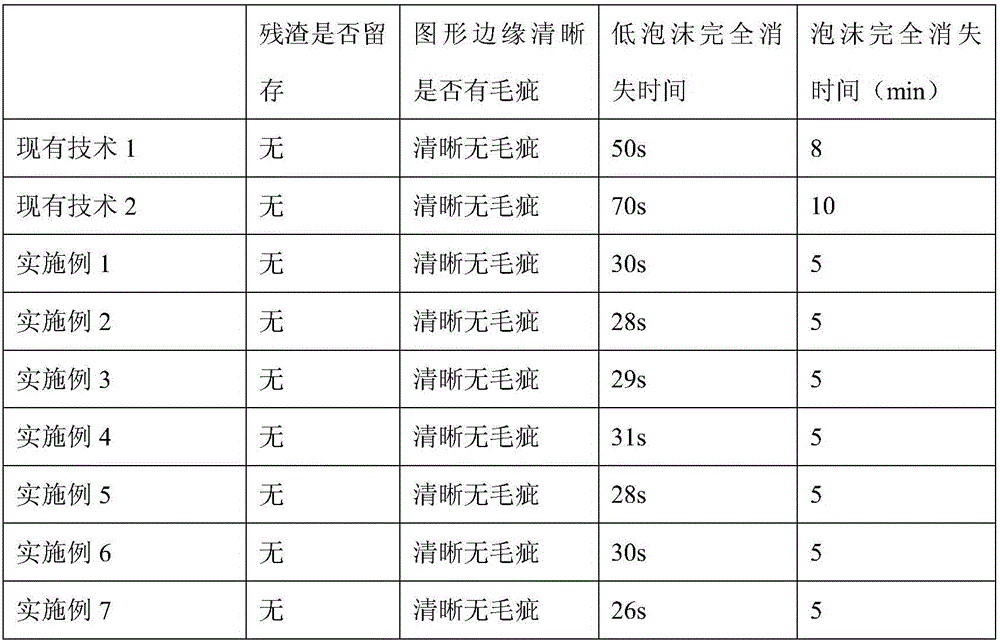

Silicate fireproof thermal insulation material and preparation method thereof

ActiveCN104876629ALight weightLow thermal conductivityCeramicwareThermal insulationEnergy consumption

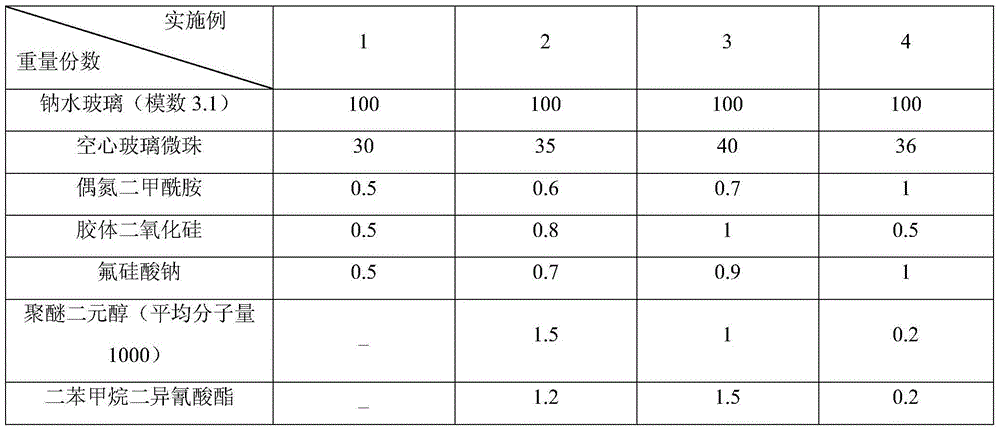

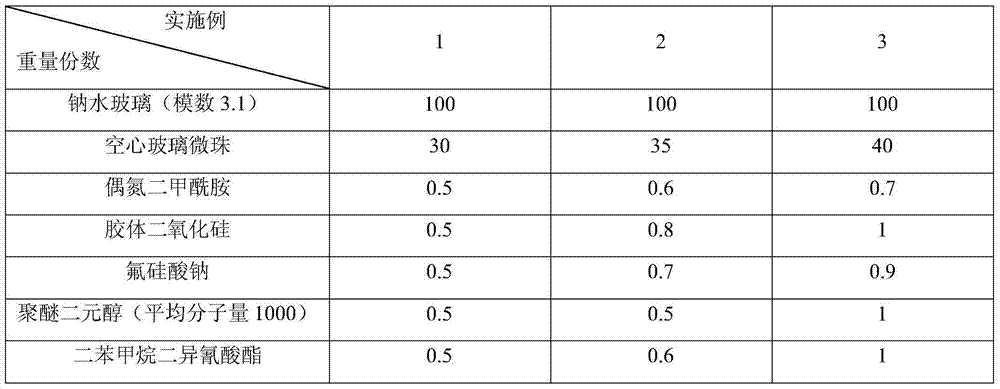

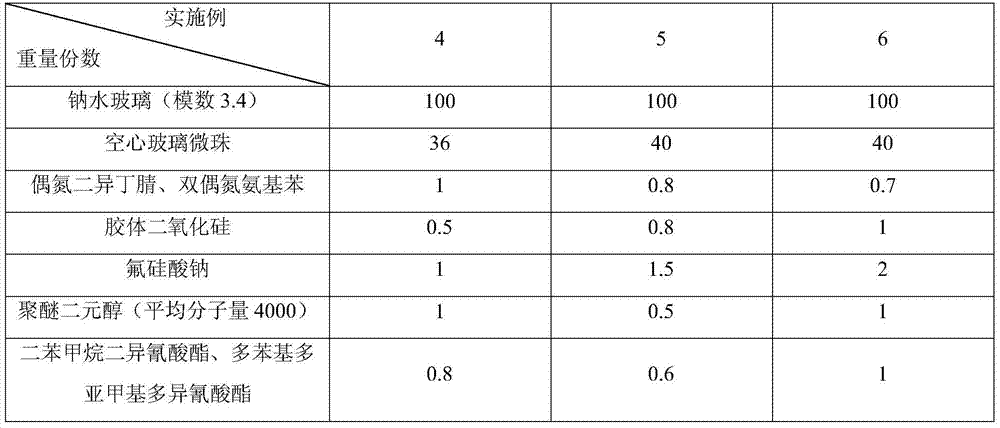

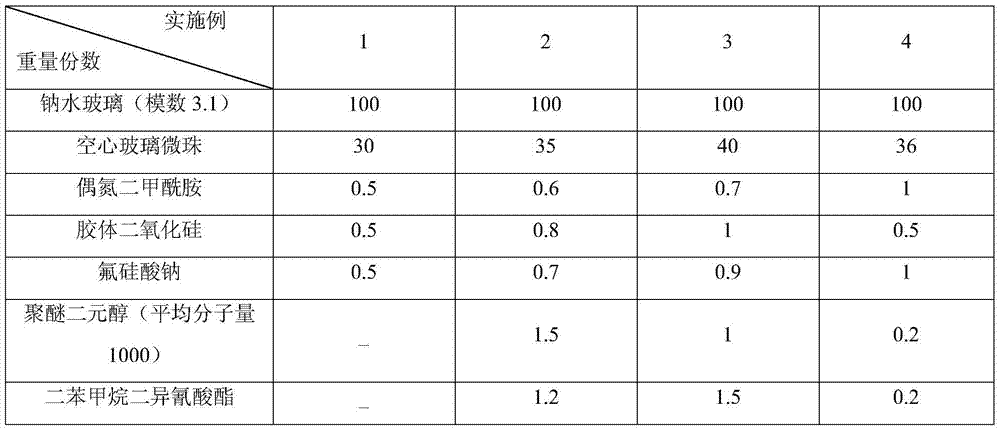

The invention provides a silicate fireproof thermal insulation material composition. The silicate fireproof thermal insulation material composition is prepared from 100 parts by weight of water glass, 30-40 parts by weight of hollow glass microbeads, 0.5-1 part by weight of chemical foaming agent, 0.5-2 parts by weight of binder, 0.5-2 parts by weight of curing agent, 0.5-1 part by weight of polyether polyol and 0.5-1 part by weight of polyisocyanate; the fireproof thermal insulation material has the advantages of small volume weight, low heat conductivity coefficient and high compressive strength. The invention also provides a preparation method of the silicate fireproof thermal insulation material; the preparation method is simple in process, low in energy consumption and short in time.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

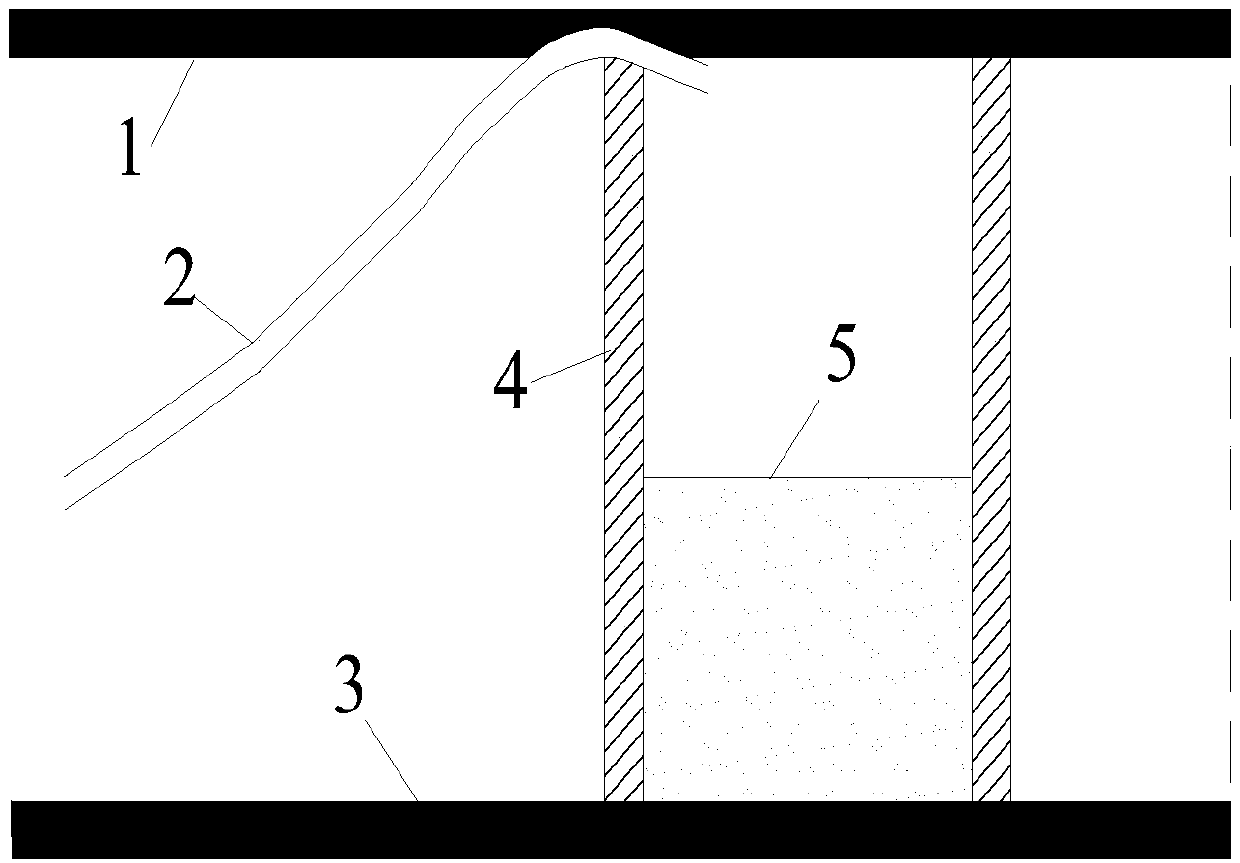

Elastic cured foam material for underground goaf and application thereof

The invention provides an elastic cured foam material for an underground goaf and belongs to the technical field of fire prevention and fire extinguishment of the underground goaf. The elastic cured foam material for the underground goaf, provided by the invention, is prepared from the following raw materials in parts by weight: 30 to 50 parts of polyisocyanate, 2 to 10 parts of a polyol compound,1 to 5 parts of a foaming agent, 2 to 6 parts of a chain extender, 1 to 6 parts of a crosslinking agent, 0 to 10 parts of a flame retardant, 1 to 4 parts of a foam stabilizer, 0 to 3 parts of an anti-ageing agent, 0 to 6 parts of filler, 0.1 to 2 parts of a catalyst and 0 to 5 parts of a softening agent. The elastic cured foam material for the underground goaf, provided by the invention, has theadvantages of great stretching rate, strong compression resisting capability and good sealing performance, and also has the advantages of rapid foaming speed, short curing time and long ageing time.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

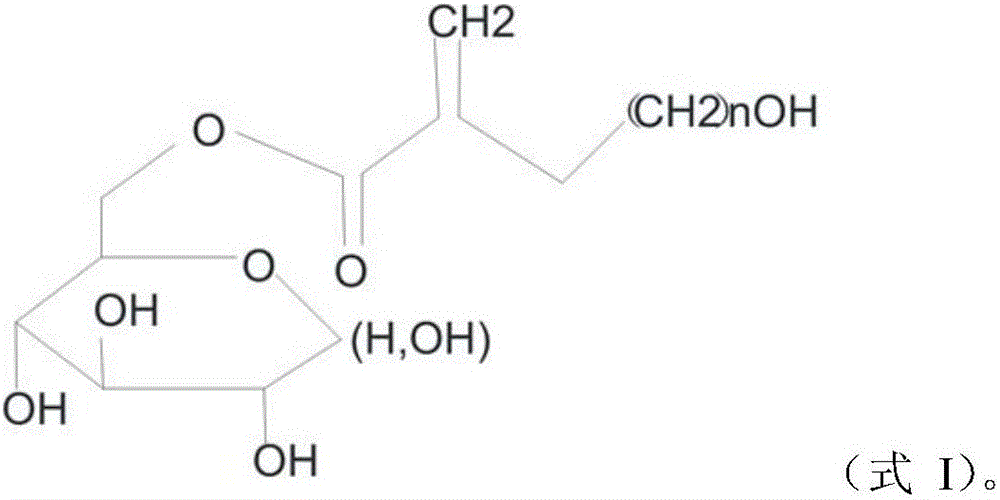

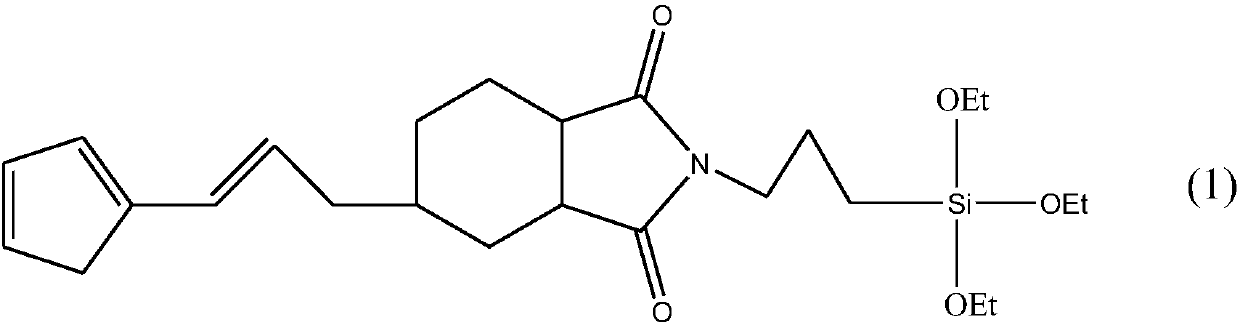

Photoresist developing solution

ActiveCN106527065AExcellent process marginLong developing timePhotosensitive material processingPhotoresistChemical compound

The invention discloses a photoresist developing solution, which comprises water, a nonionic surfactant and inorganic base, wherein the nonionic surfactant comprises castor oil polyoxyethylene ether and a chemical compound shown in a structural formula I in the description. The developing solution provided by the invention has an excellent process redundancy, can be used for process of various photoresist only by regulating exposure quantity and film thickness, and has a long developing aging and a wide application range of developing.

Owner:绵阳艾萨斯电子材料有限公司

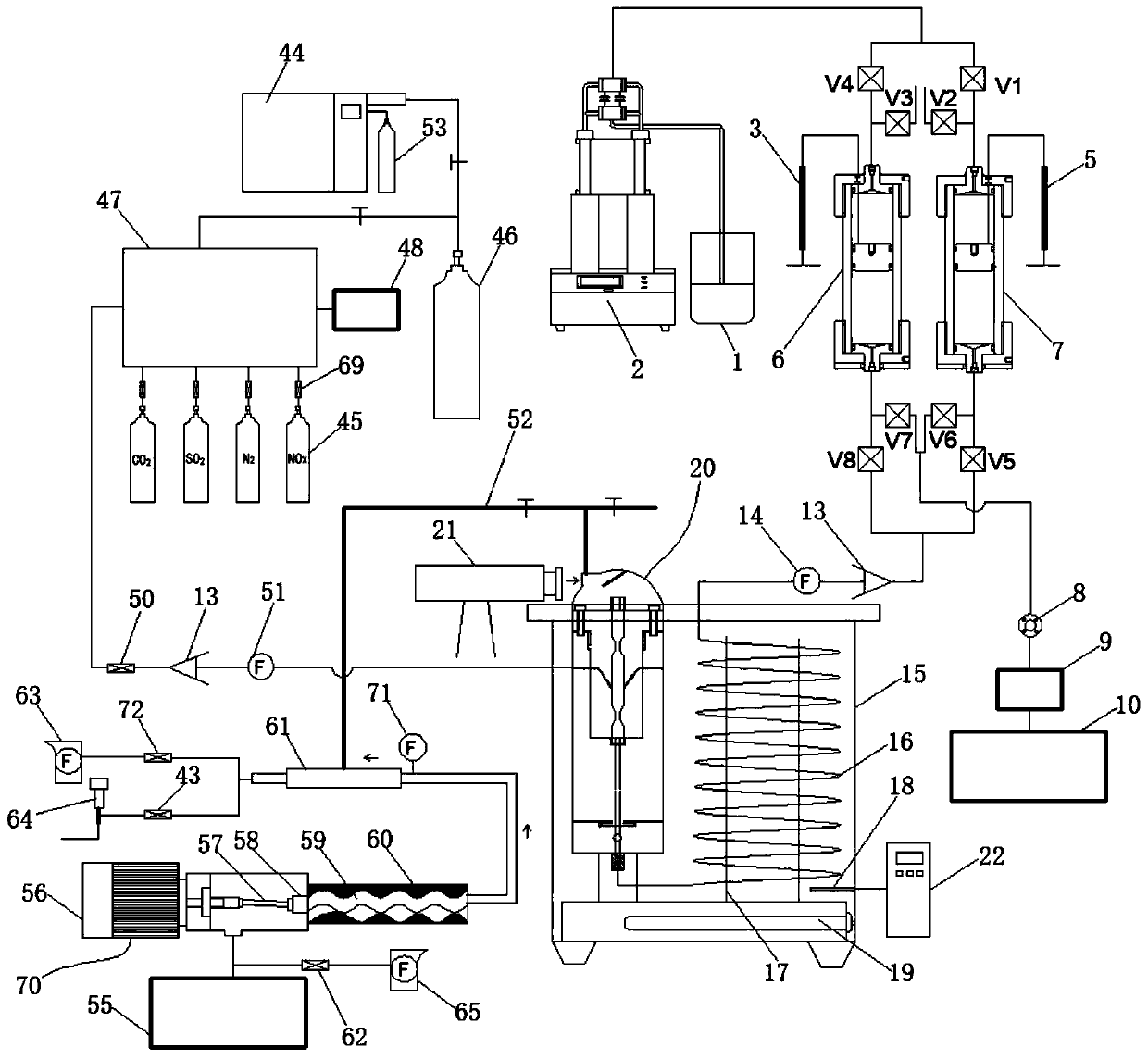

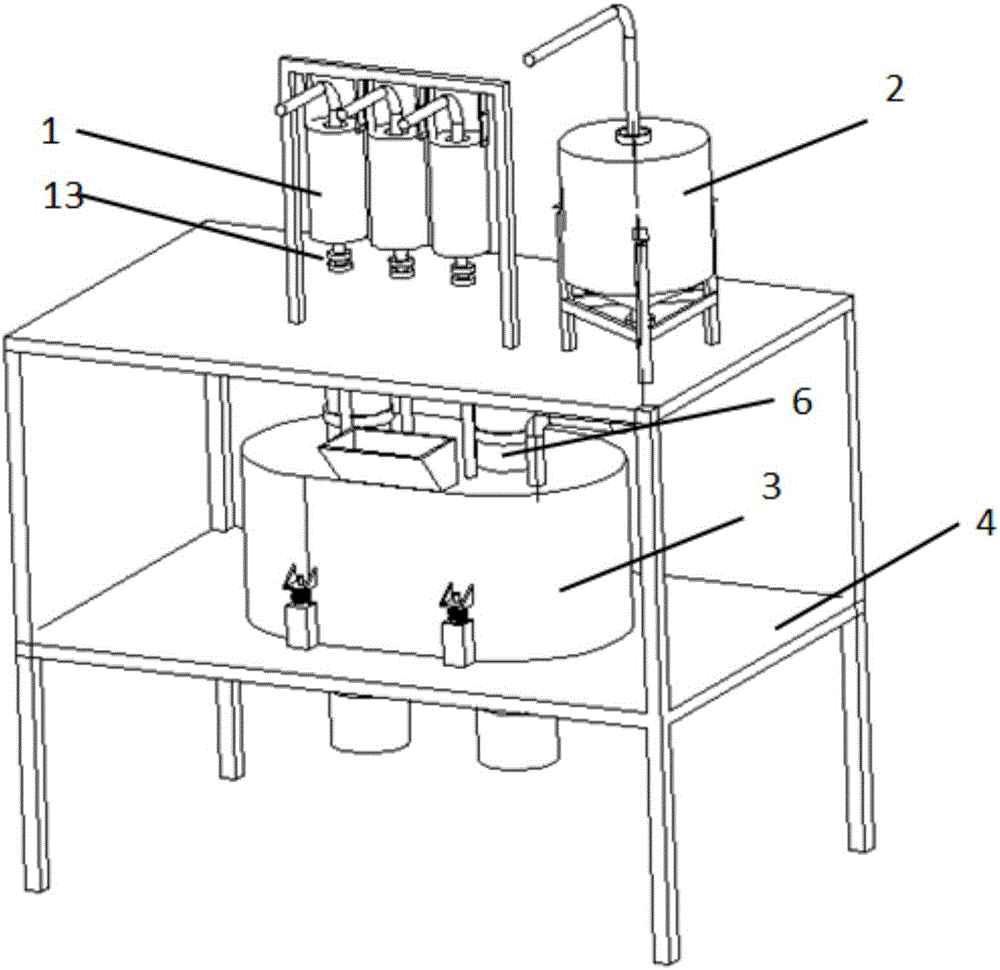

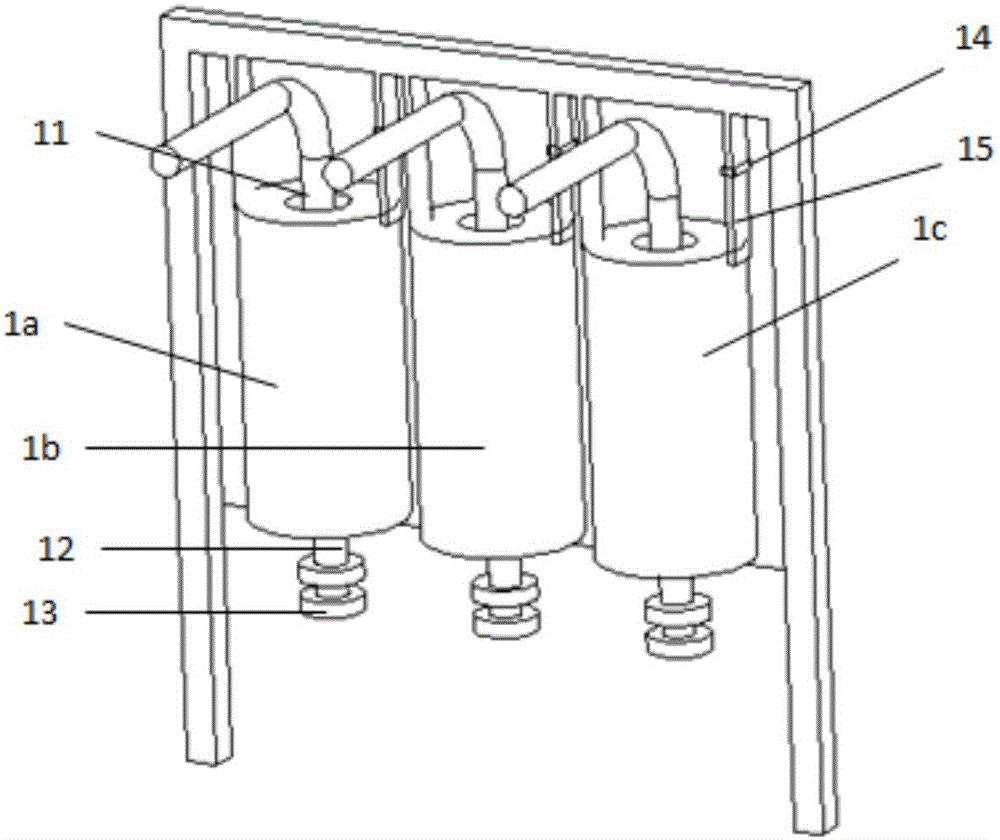

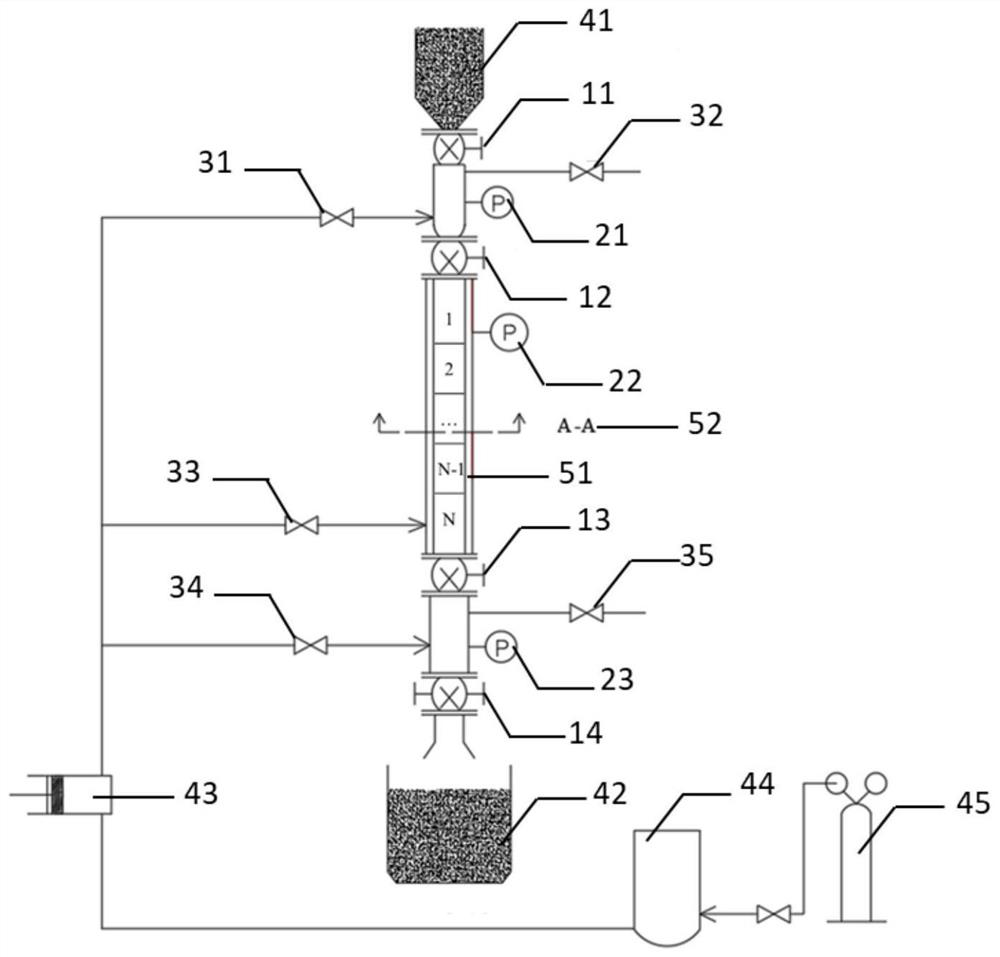

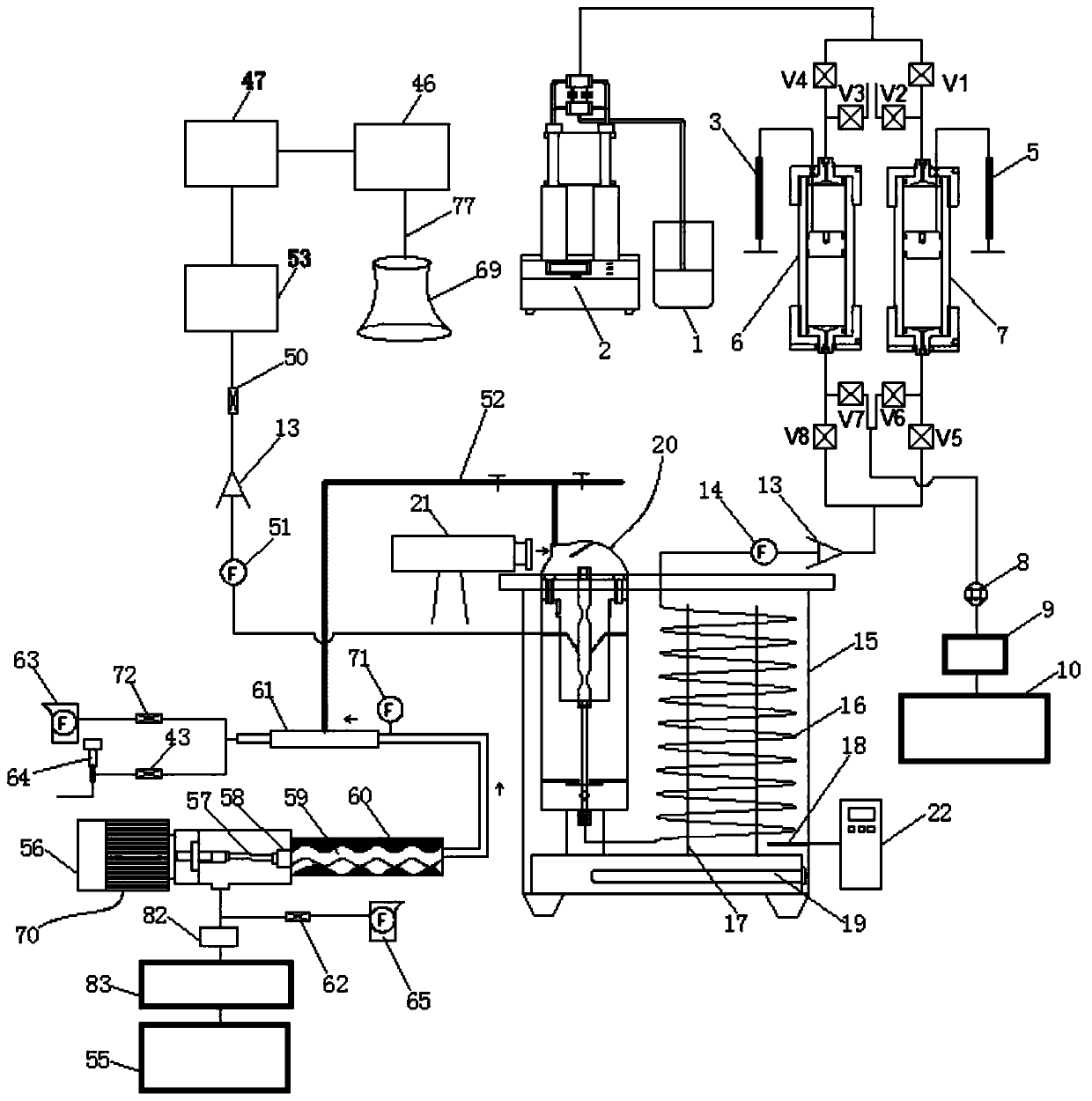

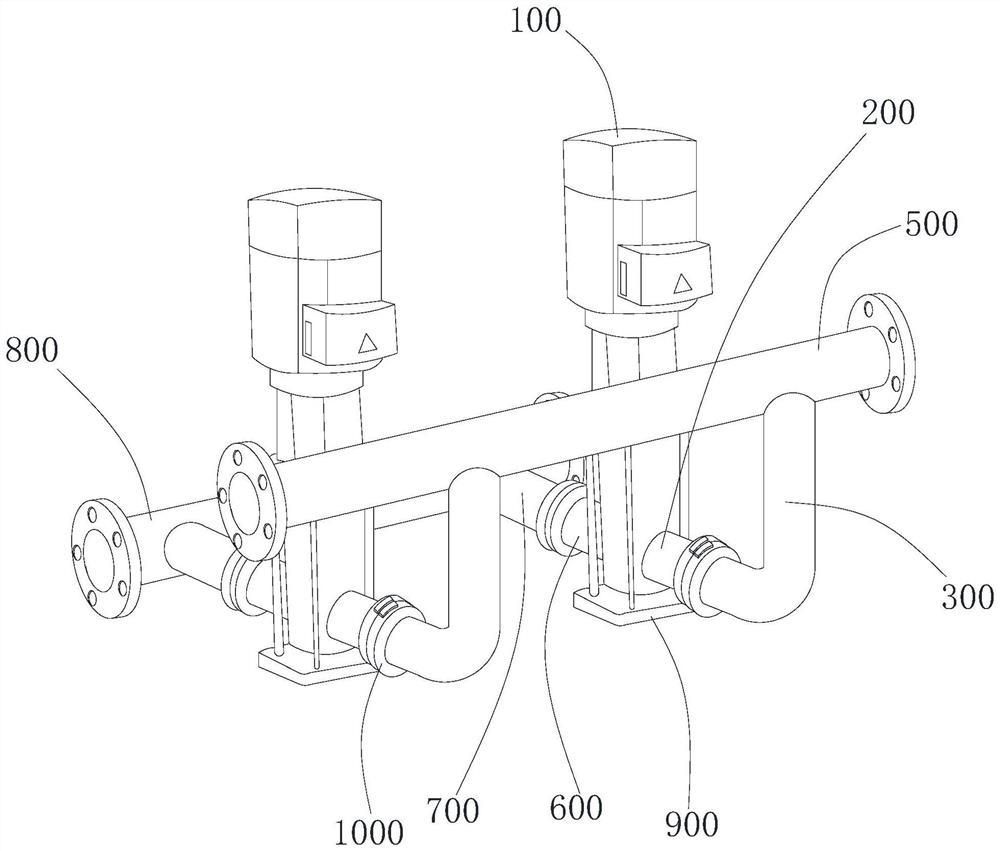

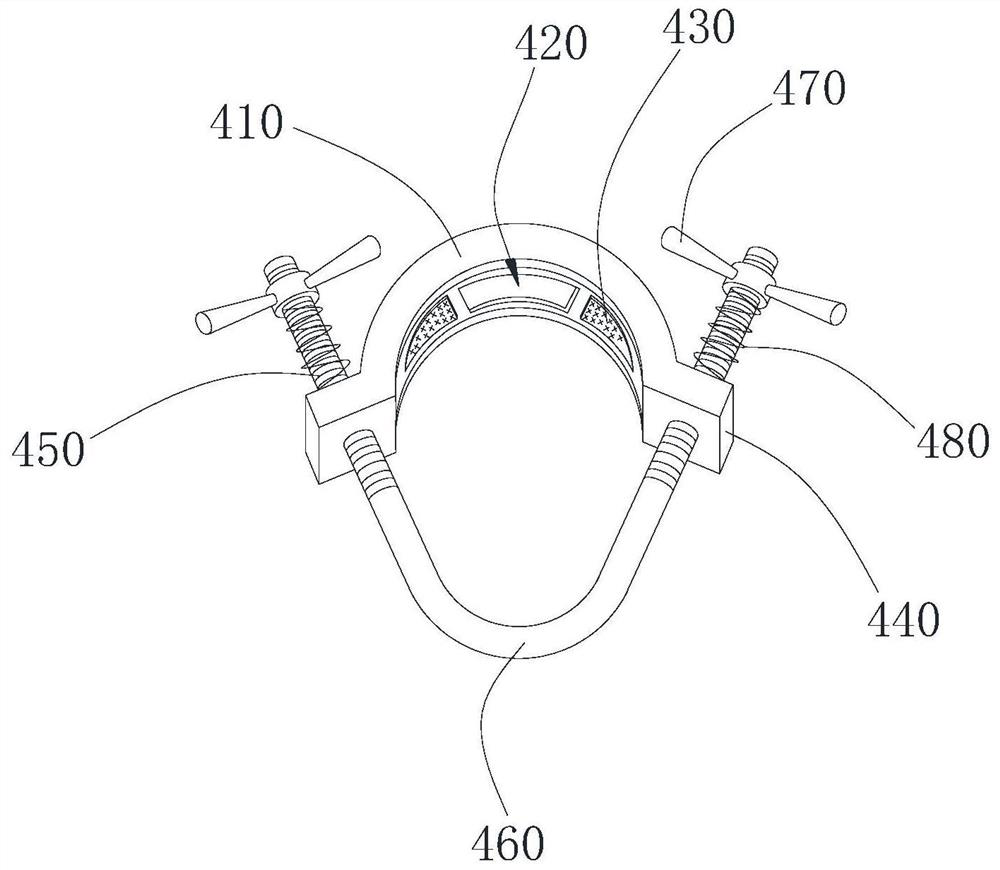

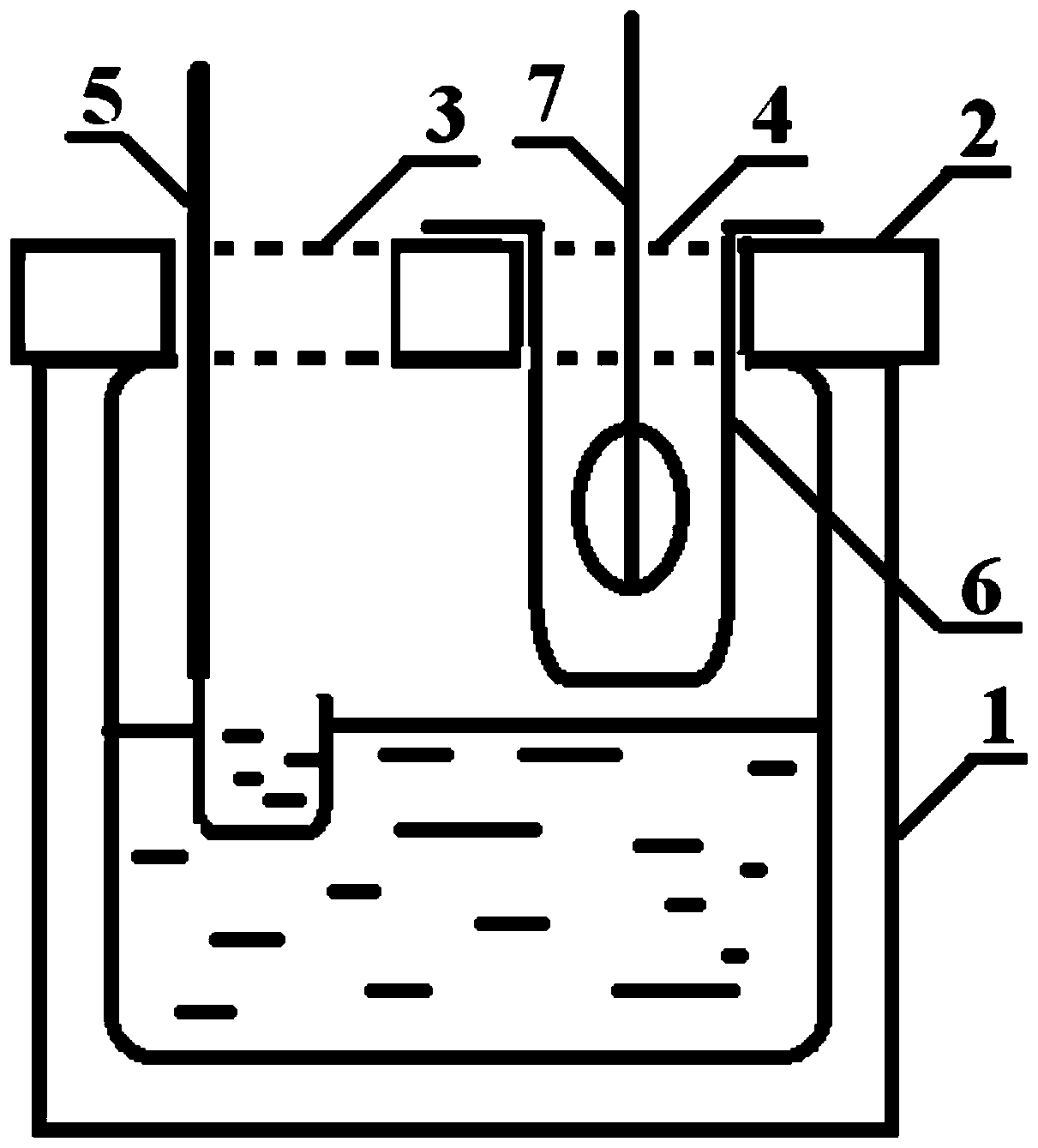

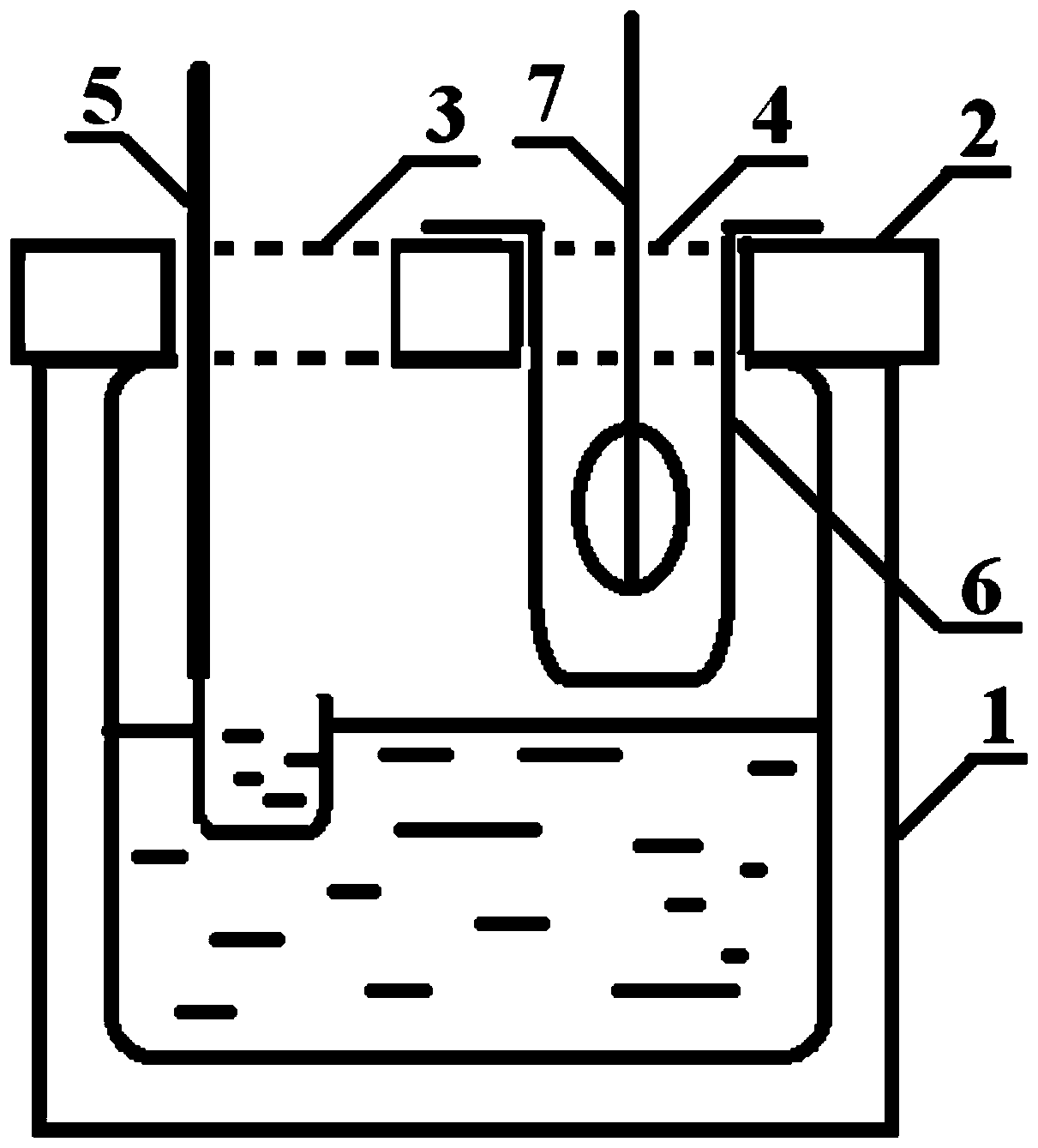

Laboratory research device for coal and electricity integrated three-waste-based foaming material

ActiveCN110743446AGuaranteed constant currentGuaranteed constant voltage supplyFlow mixersTransportation and packagingGas liquid chromatographicGas cylinder

The invention discloses a laboratory research device for a coal and electricity integrated three-waste-based foaming material. Two input ends of a water liquid mutual drive unit are correspondingly connected with an output end of a constant current constant pressure pump and an output end of a liquid filling pump, and an output end of the water liquid mutual drive unit is connected with a liquid channel of a novel foaming device through a coil pipe; the coil pipe and the novel foaming device are arranged in a circulating water bath, and a high-speed camera is used for collecting foam images ofthe novel foaming device; a high-pressure storage tank is correspondingly connected with a gas chromatograph and a gas mixing tank; a vacuum pump is connected with the gas mixing tank; a calibrationgas cylinder is connected with the gas mixing tank; the gas mixing tank is connected with a pneumatic connector of the novel foaming device through an electromagnetic pressure reducing valve, a checkvalve and a vortex-type gas flowmeter sequentially; two output branches of a mixed slurry agitator is correspondingly connected with a feeding port of a screw rod pump and a weighing device A; and adischarging port of the screw rod pump and a discharging port of the novel foaming device are connected with two feeding ports of a three-waste-based foaming material mixer. According to the laboratory research device, a basis can be provided for the qualitative and quantitative research of the three-waste-based foaming material.

Owner:CHINA UNIV OF MINING & TECH

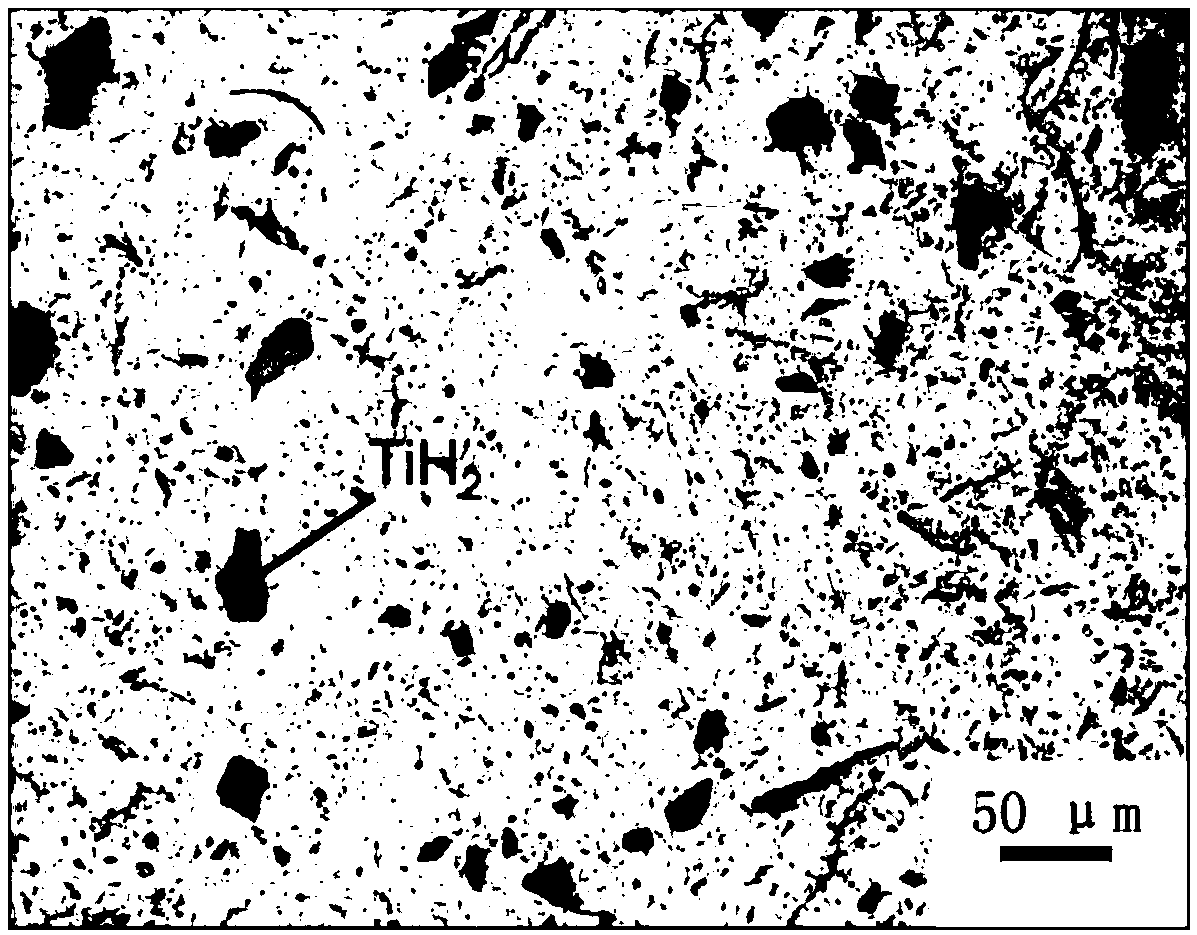

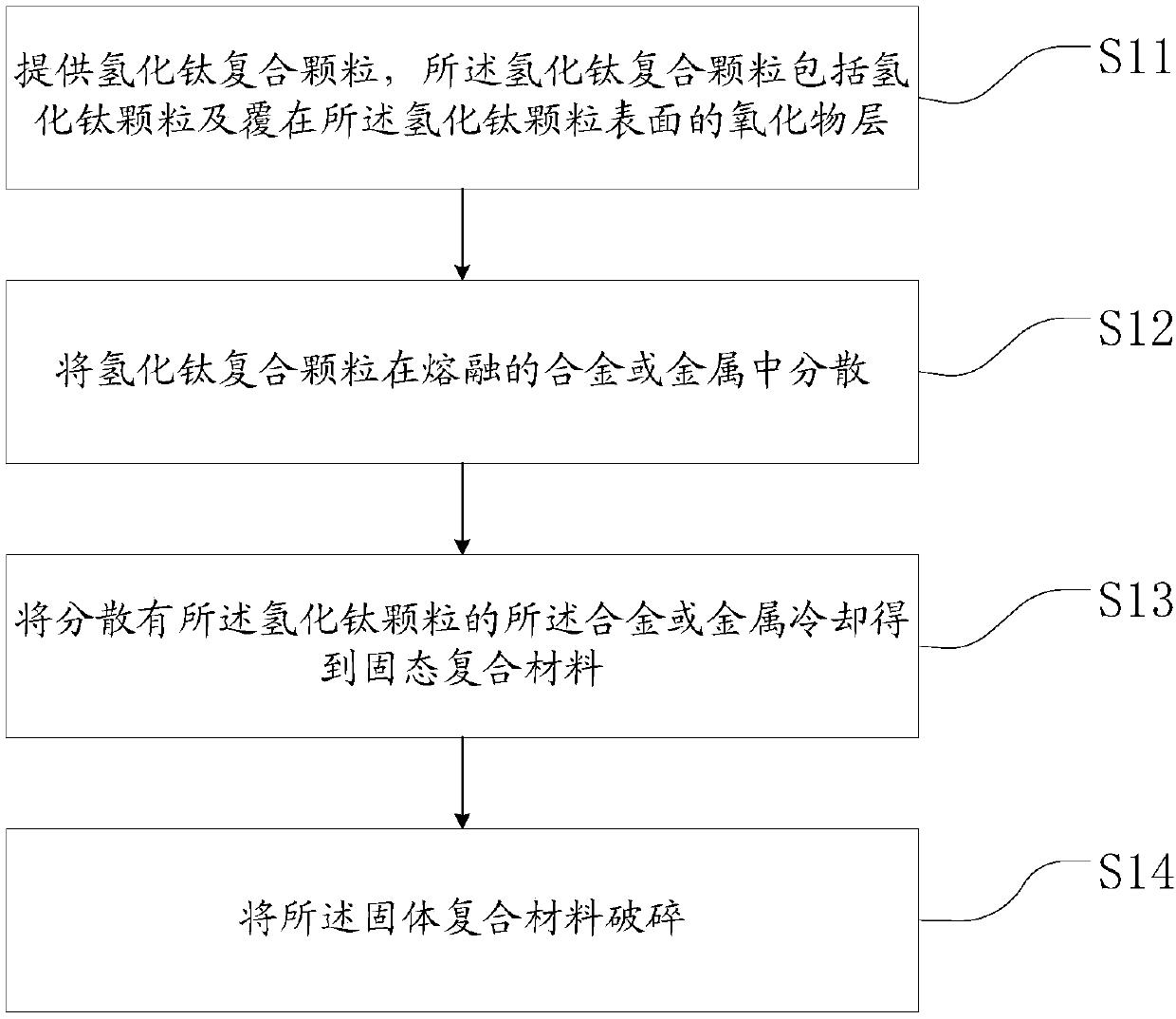

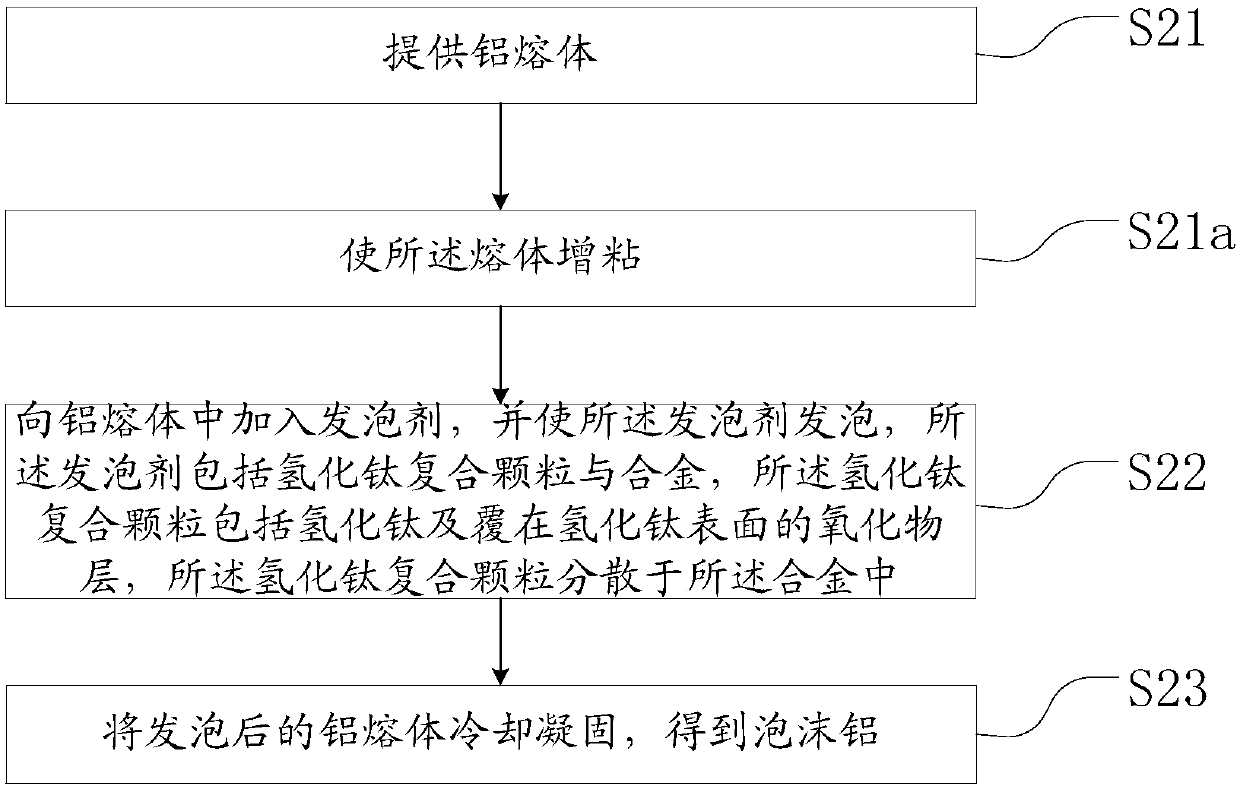

Coated foaming agent and preparation method thereof and preparation method of foamed aluminum

The invention relates to a coated foaming agent. The coated foaming agent comprises titanium hydride composite particles and an alloy; each titanium hydride composite particle comprises a titanium hydride particle and an oxide layer coating the titanium hydride particle; the titanium hydride composite particles are dispersed in the alloy. A preparation method of the coated foaming agent comprisesthe following steps of providing the titanium hydride composite particles, wherein each titanium hydride composite particle comprises the titanium hydride particle and the oxide layer coating the titanium hydride particle; dispersing the titanium hydride composite particles in the molten alloy; cooling the alloy in which the titanium hydride composite particles are dispersed to obtain a solid composite material; and crushing the solid composite material. A preparation method of foamed aluminum comprises the following steps of providing aluminum melt; adding the foaming agent into the aluminummelt, and making the foaming agent foamed; and performing cooling solidification on the foamed aluminum melt to obtain the foamed aluminum.

Owner:TSINGHUA UNIV

High-permeability PVC artificial leather and application thereof

PendingCN112796115AIncrease active chlorine contentImprove solubilityTextiles and paperNatural resinPolymer science

The invention discloses high-permeability PVC artificial leather and application thereof. The high-permeability PVC artificial leather is prepared from polyvinyl chloride, tetraethylenepentamine, modified polyvinyl chloride, a self-made adhesive, soybean protein, natural resin, vegetable oil, vinyl acetate-ethylene copolymer emulsion, a plasticizer, a stabilizer and a foaming agent. Polyvinyl chloride molecules subjected to chlorination treatment improve the thermal deformation temperature and the dissolving property of the material, and meanwhile, the processed material has good cohesiveness; the chlorinated polyvinyl chloride is modified by tetraethylenepentamine, so that the tensile strength of the material is enhanced to the maximum extent; the self-made adhesive utilizes vinyl acetate-ethylene copolymer emulsion, modified natural resin, modified vegetable oil and modified soybean protein, so that the peel strength of the PVC artificial leather is improved; and when the artificial leather is prepared, calendaring film forming and foaming treatment on the two sides are carried out at the same time, the foaming treatment provides more pressure for calendaring film forming, so that the material and the cloth base are combined more tightly, and the foaming time is shortened.

Owner:南通中奥车用新材料有限公司

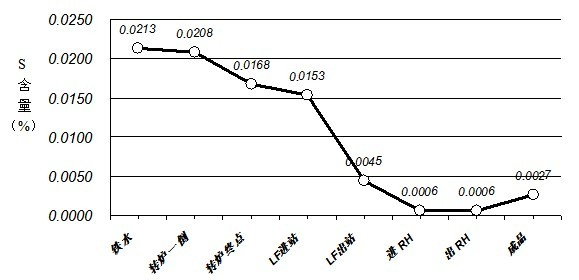

Molten steel refining purification assisting agent and preparation method thereof

The invention belongs to the technical field of steel making and relates to a molten steel refining purification assisting agent and a preparation method thereof. The molten steel refining purification assisting agent comprises the following components in part by mass: 20 to 30 parts of metal aluminum, 35 to 55 parts of Al2O3, 0.5 to 8 parts of CaO and 1 to 12 parts of SiO2. After the molten steel refining purification assisting agent is used, a harmful element, namely sulfur in molten steel can be removed on the basis of completion of deoxidization of molten steel and steel slag, a refining slag system with high inclusion absorption performance is achieved successfully, refining action is brought into full play, the original molten steel refining process can be greatly simplified, the aim of purifying molten steel is fulfilled and production cost is lowered.

Owner:陈兰君

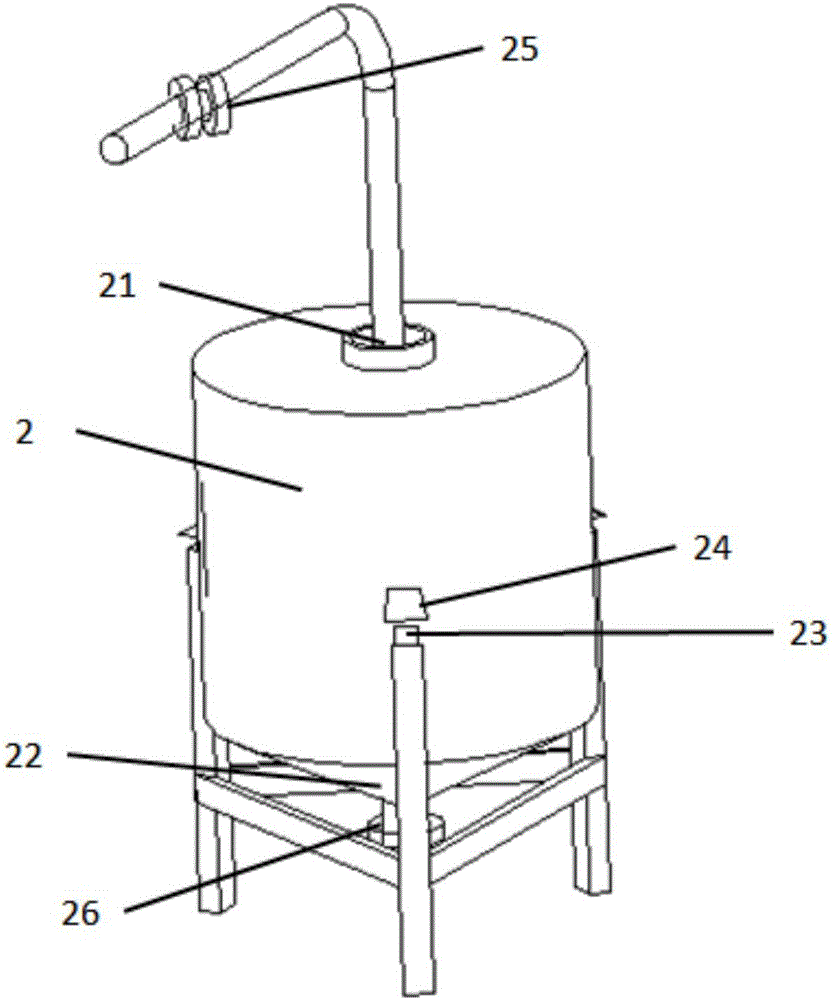

Pouring device for preparing foaming concrete

InactiveCN106738342AMonitor weight changes at any timeControl the amount added at any timeMixing operation control apparatusIngredients proportioning apparatusFoam concretePolymer science

The invention discloses a pouring device for preparing foaming concrete and belongs to the technical field of building block equipment. The pouring device comprises a plurality of additive tanks, a water tank, a mixing and pouring tank and a worktable. The tops of the additive tanks are provided with additive feed inlets, and the bottoms of the additive tanks are provided with additive discharge outlets which communicate with the mixing and pouring tank. The top of the water tank is provided with a water inlet, and the bottom of the water tank is provided with a water outlet which communicates with the mixing and pouring tank. The top of the mixing and pouring tank is provided with a dry material feed inlet, and the bottom of the mixing and pouring tank is provided with a pouring outlet. The mixing and pouring tank is internally provided with a stirring paddle which is connected with a power device to supply power. According to the pouring device, materials can be sequentially added according to the process order, meanwhile, a weighing device is arranged and can accurately control the addition amount of the materials, the whole pouring process is controlled through a computer, and manpower, material resources and time are saved.

Owner:HARBIN TIANSHUN CHEM TECH DEV CO LTD

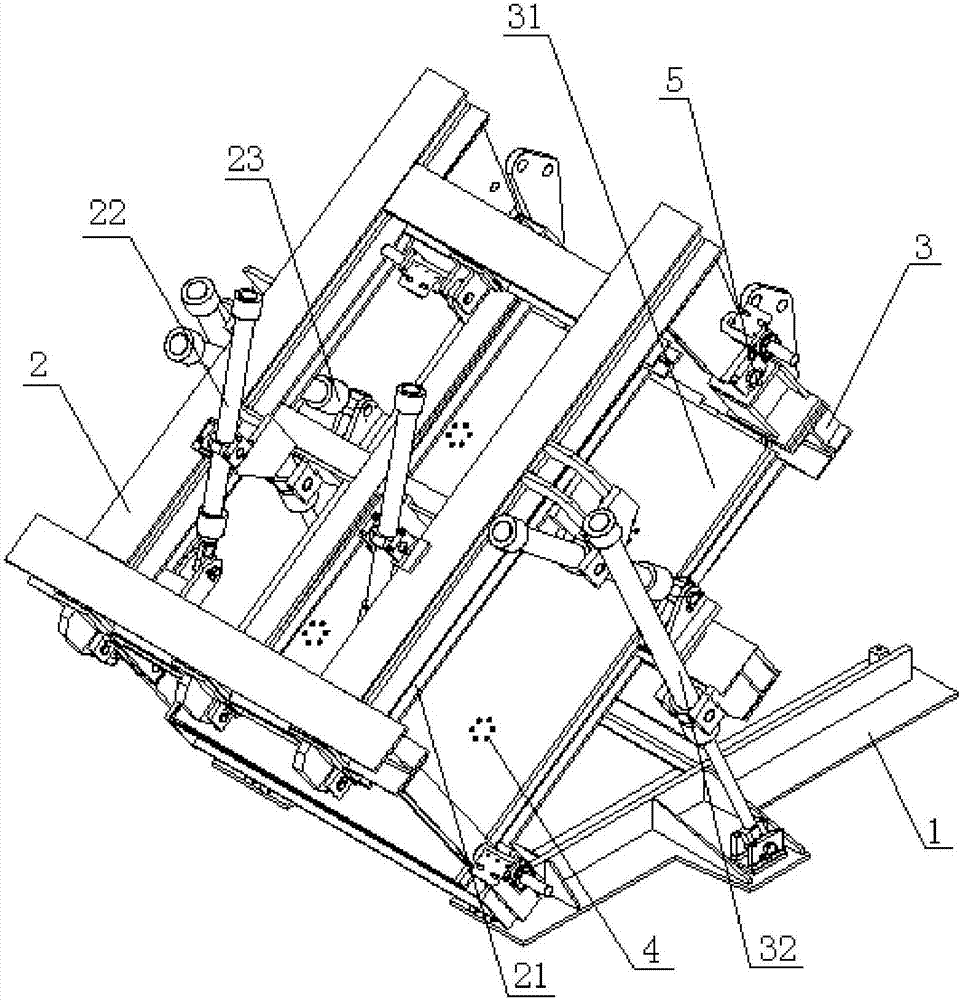

Multi-angle mold-closing foaming fixture for automotive carpet and use method of multi-angle mold-closing foaming fixture

The invention discloses a multi-angle mold-closing foaming fixture for an automotive carpet and a use method of the multi-angle mold-closing foaming fixture. The multi-angle mold-closing foaming fixture for the automotive carpet comprises a base, wherein an upper mold base and a lower mold base are arranged on the base; an upper mold plate is arranged in the upper mold base; a lower mold plate is arranged in the lower mold base; an air bag is arranged at the bottom of the lower mold base; upper overturning mechanisms for allowing overturning of the upper mold base and lower overturning mechanisms for allowing overturning of the lower mold base are arranged on the base; lateral overturning mechanisms for allowing overturning of the upper mold plate are arranged on two sides of the upper mold base; lock pins and lock holes in mutual matching are arranged between the end parts of the upper mold base and the lower mold base and are mutually matched when the upper mold plate is in the zero-degree position. The multi-angle mold-closing foaming fixture for the automotive carpet is concise wholly, convenient to maintain, simple to operate, good in overall strength, stable in operation and flexile to rotate, the production efficiency is improved, manual operation is reduced, the overturning angle is large, and with the adoption of a mold-closing raw material filling method, foaming time is shortened, and the production demand of a manufacturer is met.

Owner:ANHUI XINMENG EQUIP CO LTD

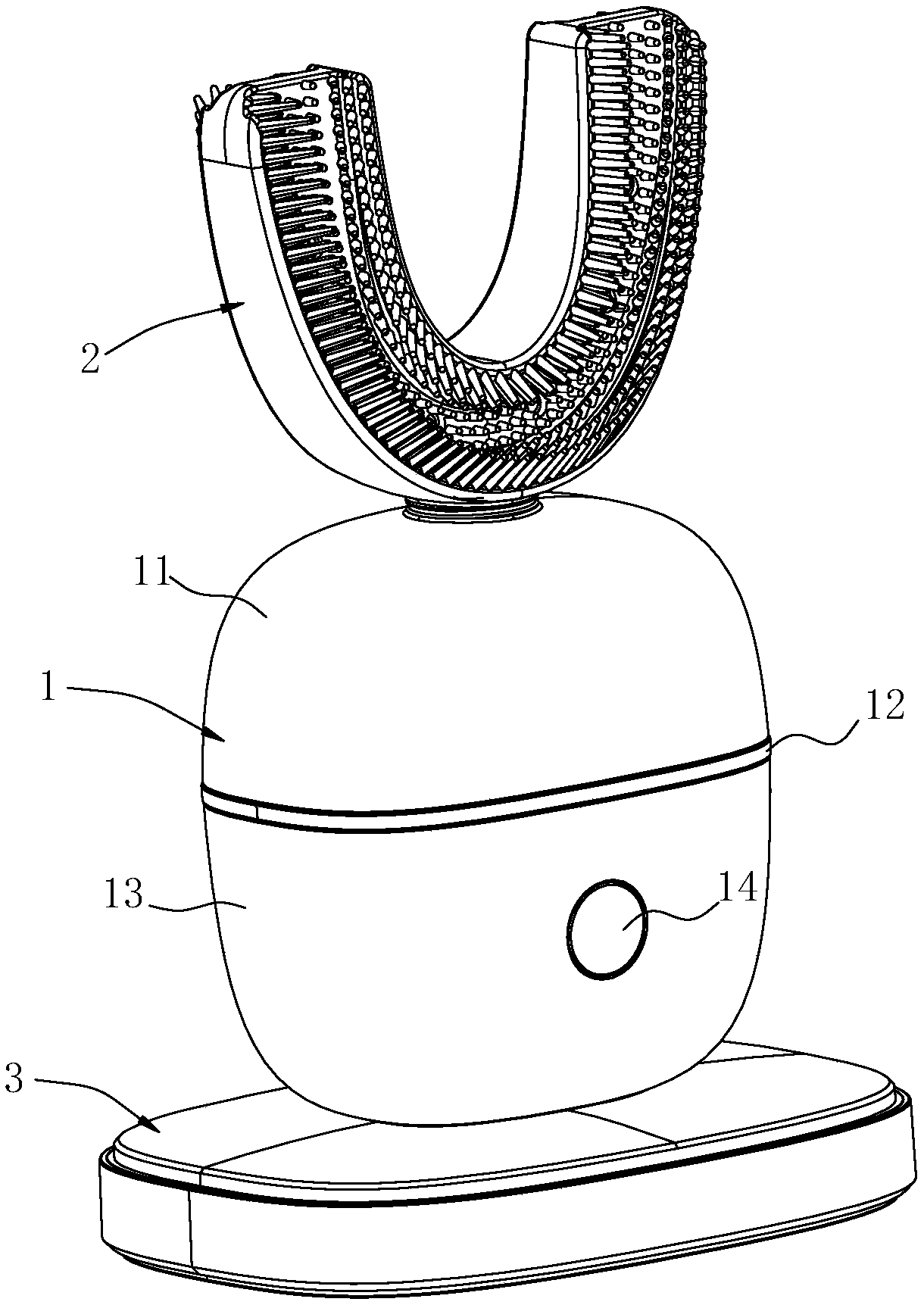

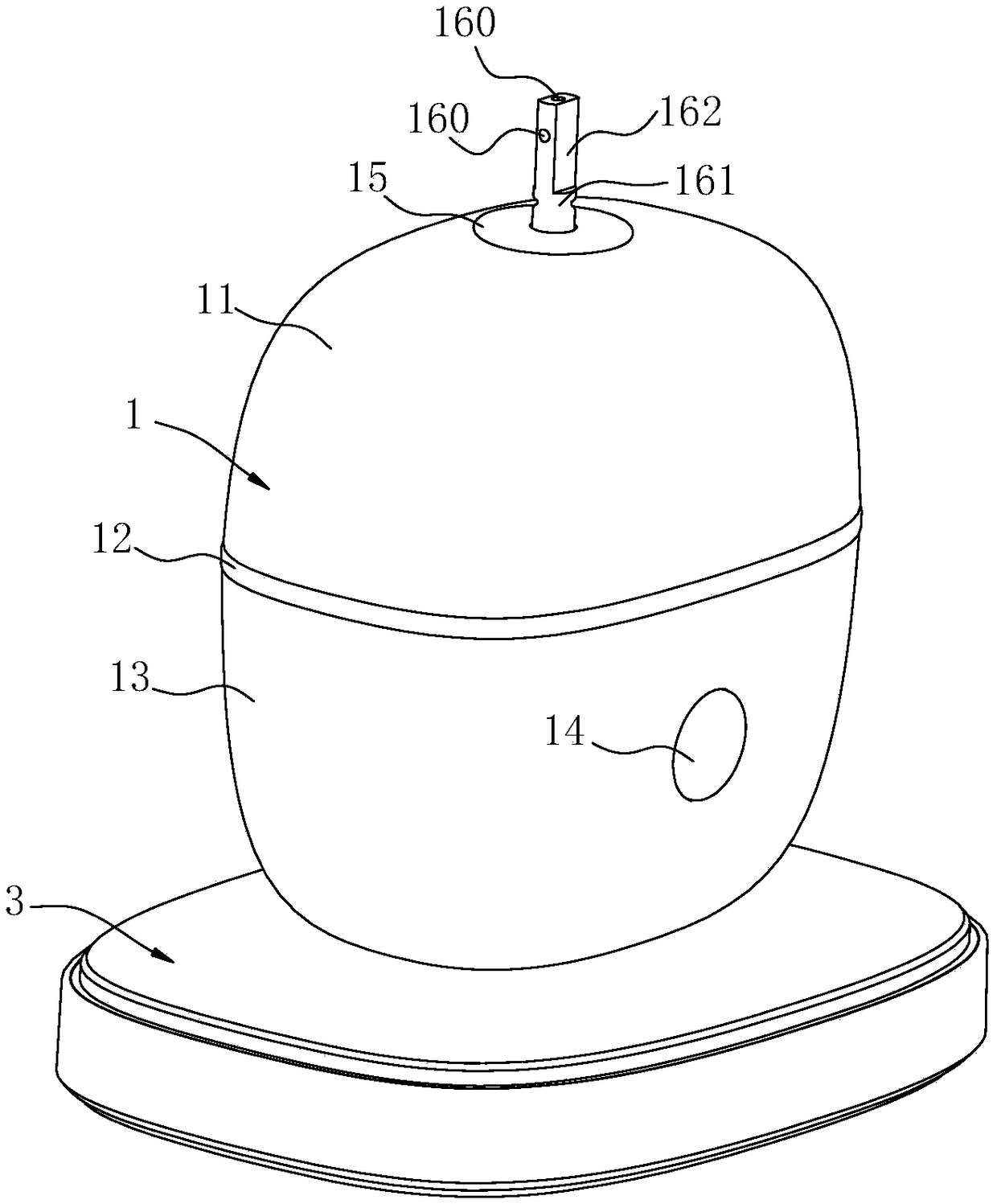

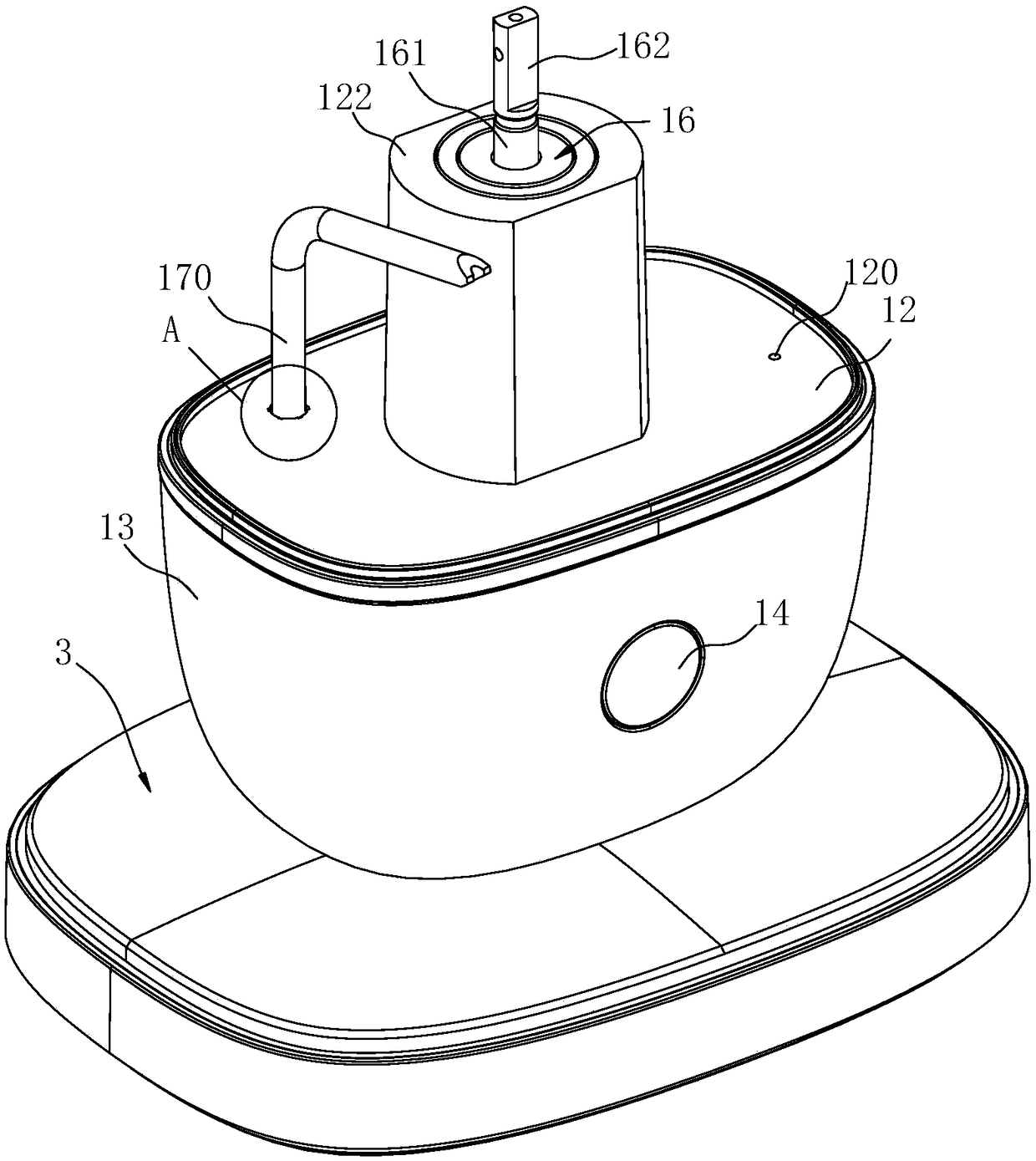

Electric toothbrush and control method thereof

The invention discloses an electric toothbrush. The electric toothbrush comprises a main electric toothbrush body and a toothbrush head, the main electric toothbrush body comprises a main body plate,a vibrating motor, an air pump and a cover body covering the upper surface of the main body plate, a toothpaste chamber used for accommodating toothpaste liquid is formed between the cover body and the main body plate, and a toothpaste passage communicated with the toothpaste chamber is formed in a rotary shaft of the vibrating motor; a connecting part connected with the toothbrush head is arranged at the end, extending to the outer portion of the cover body, of the rotary shaft, a toothpaste extruding port communicated with the toothpaste passage is formed in the connecting part, and the airpump is communicated with the toothpaste chamber. The toothpaste liquid can be automatically extruded out by the toothbrush, and the environment-friendly and quick purpose is achieved. The invention further provides a control method of the electric toothbrush. The method is used for controlling the electric toothbrush, the toothpaste liquid can be subjected to bubblization and be extruded out to the toothbrush head, and the toothbrush is beneficial for shortening time of tooth brushing.

Owner:SHENZHEN USPARKLE CO LTD

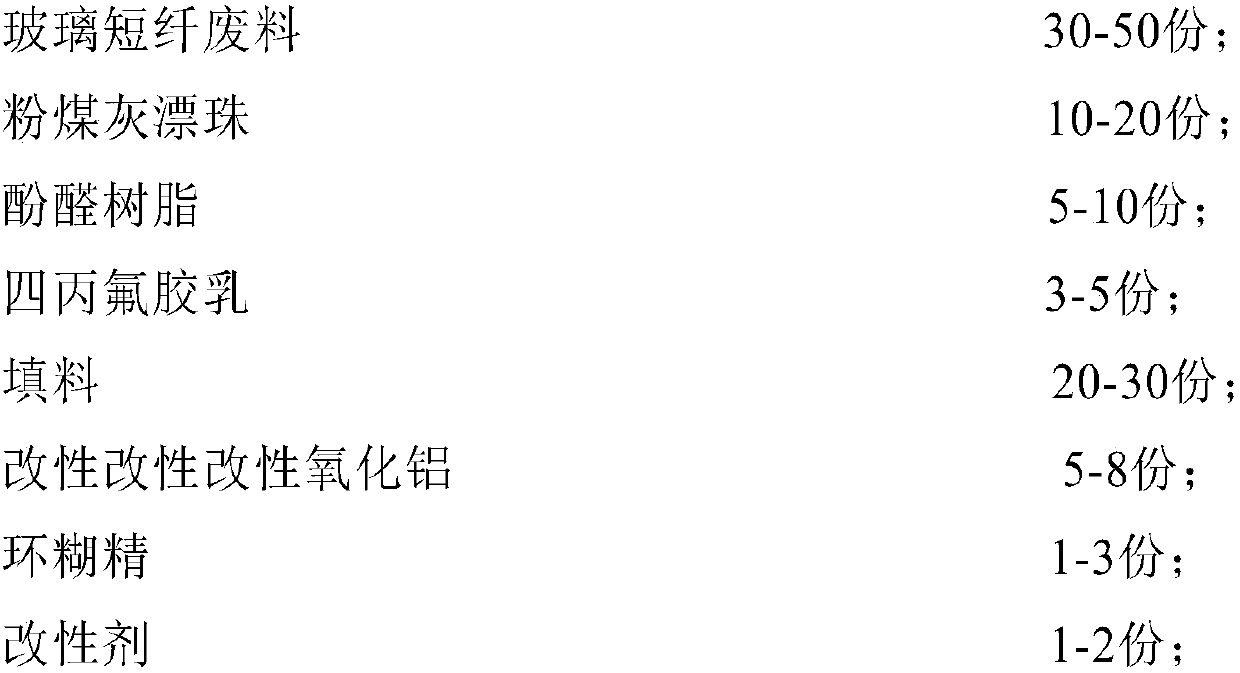

Fireproof and heat-insulating decorative composite board

InactiveCN107654038AImprove insulation effectIncreased durabilityFireproof paintsCovering/liningsComposite plateFire prevention

The invention relates to a fireproof and heat-insulating decorative composite board. The fireproof and heat-insulating decorative composite board comprises an aluminum alloy base layer, a foaming material heat-insulating layer, a reinforcing layer, an interface fireproof layer and a surface impact-resistant layer from bottom to top in sequence. The interface fireproof layer comprises, by weight, 30-50 parts of glass staple waste, 10-20 parts of flyash floating beads, 5-10 parts of phenolic resin, 3-5 parts of tetrapropyl ammonium fluoride latex, 20-30 parts of a filler, 5-8 parts of modified aluminium oxide, 1-3 parts of cyclodextrin and 1-2 parts of a modifier. The surface impact-resistant layer comprises a stainless steel panel layer and an impact-resistant paint layer. According to thefireproof and heat-insulating decorative composite board, the organic heat-insulating layer is in organic combination with the interface fireproof layer, the overall heat-insulating performance is improved, the fireproof performance of the composite plate is further improved, heat insulation, fire prevention and impact resistance are integrated, and the fireproof heat-insulating decorative composite board is a novel building material.

Owner:苏州巴洛特新材料有限公司

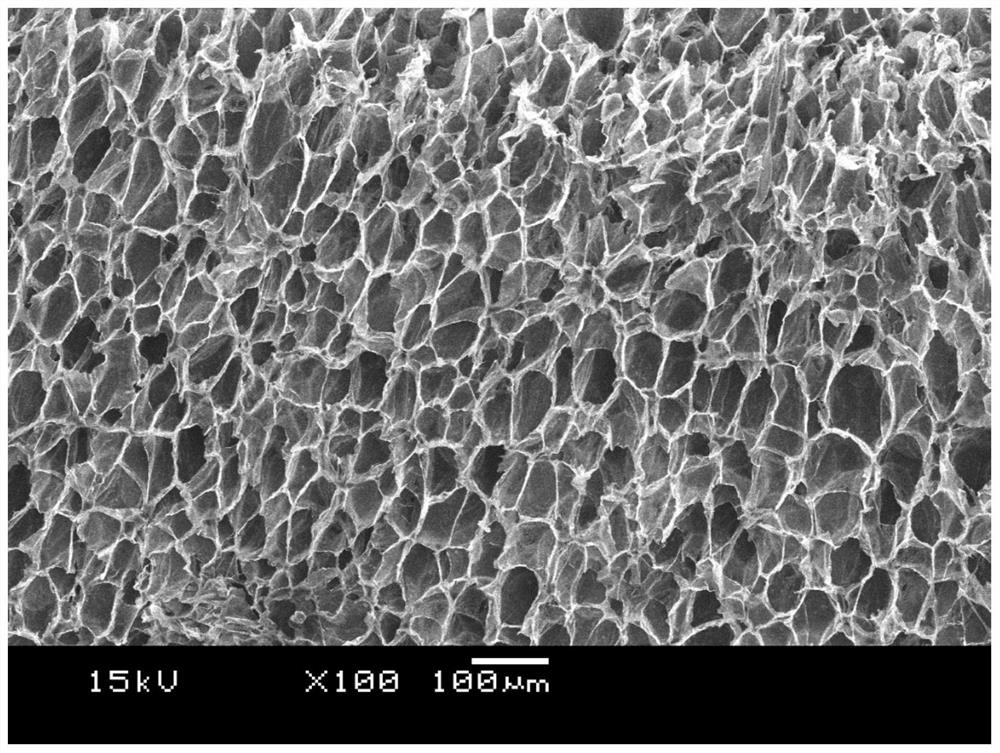

Method for preparing aperture-controllable low-temperature foam glass

InactiveCN104118980AReduce pollutionShorten foaming timeGlass shaping apparatusFoaming agentPolymer science

The invention discloses a method for preparing aperture-controllable low-temperature foam glass. The foam glass mainly comprises the following raw materials: a fluxing agent, a foam stabilizer, a foaming agent and glass powder. The preparation method comprises the following steps of carrying out wet mixing on the fluxing agent, the foam stabilizer and the foaming agent, drying and then grinding to form a mixture, carrying out wet mixing on the mixture and glass powder, molding, carrying out heat treatment under a high temperature condition and annealing to obtain the high-performance foam glass. In the preparation process, by changing the mixing ratio and particle sizes of the foam stabilizer, the foaming agent and the glass powder, the aperture and pore structure of the foam glass are adjusted. The preparation method disclosed by the invention has the advantages that the process is simple, the preparation energy consumption is less and the production cost can be effectively reduced; the prepared foam glass has sound absorption, heat preservation and thermal insulation effects, belongs to the national Class A fireproof material and can be widely used in indoor as thermal insulation, sound absorption and fireproof materials; since the foam glass material prepared by the method disclosed by the invention is mainly prepared from waste glass, the environmental pollution is reduced and the resource reutilization is achieved.

Owner:ZHEJIANG GAOMING GLASS

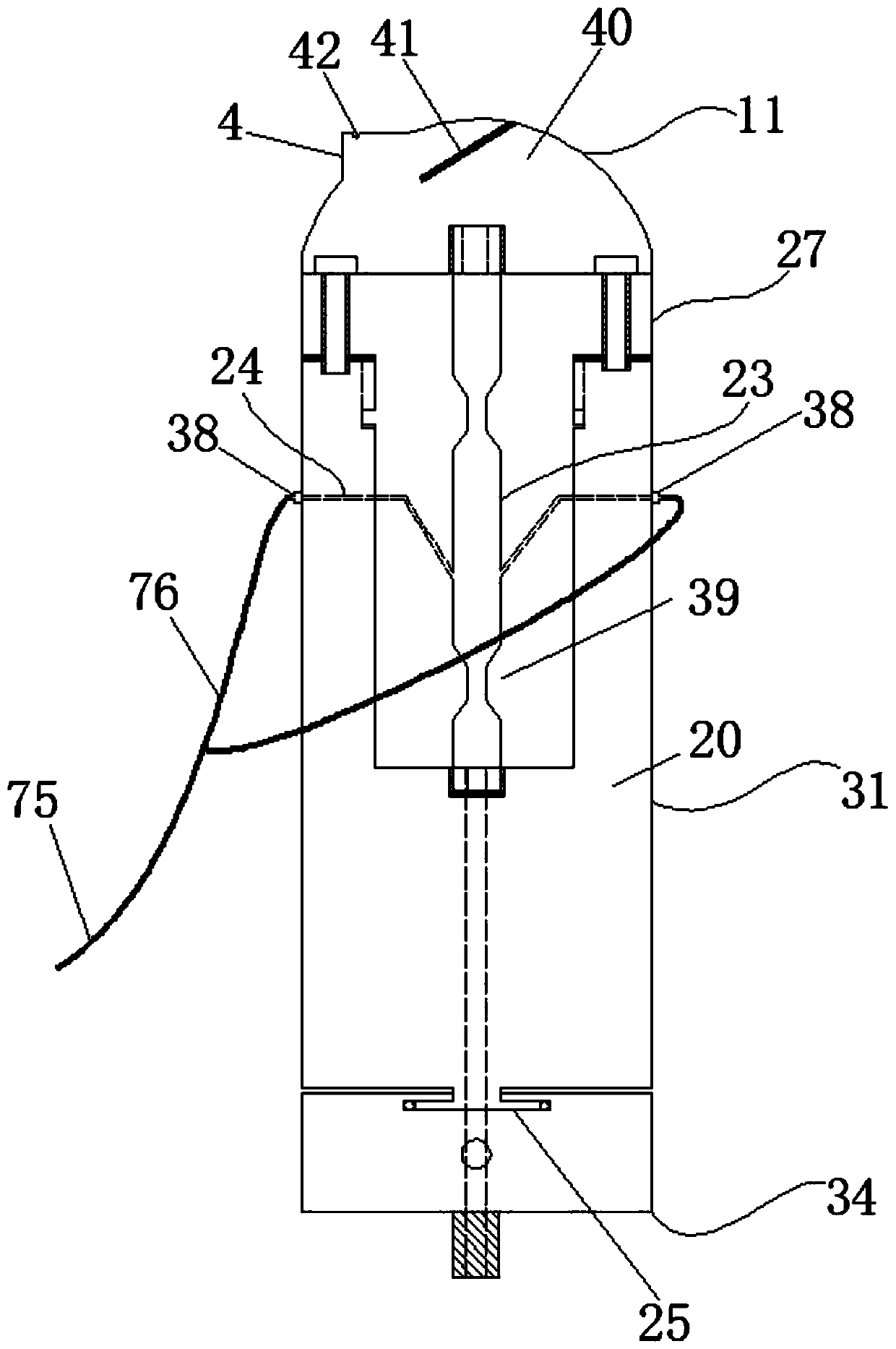

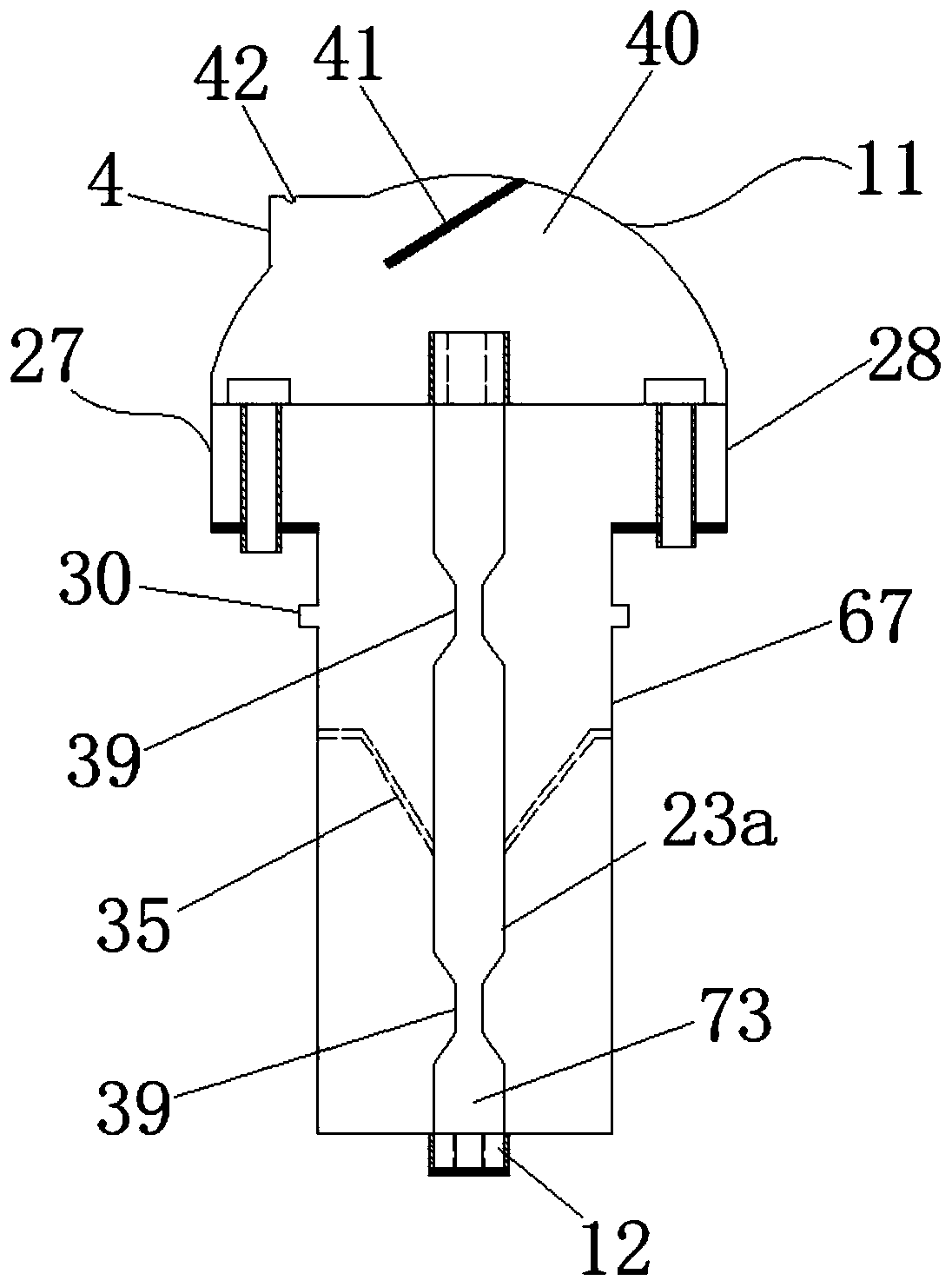

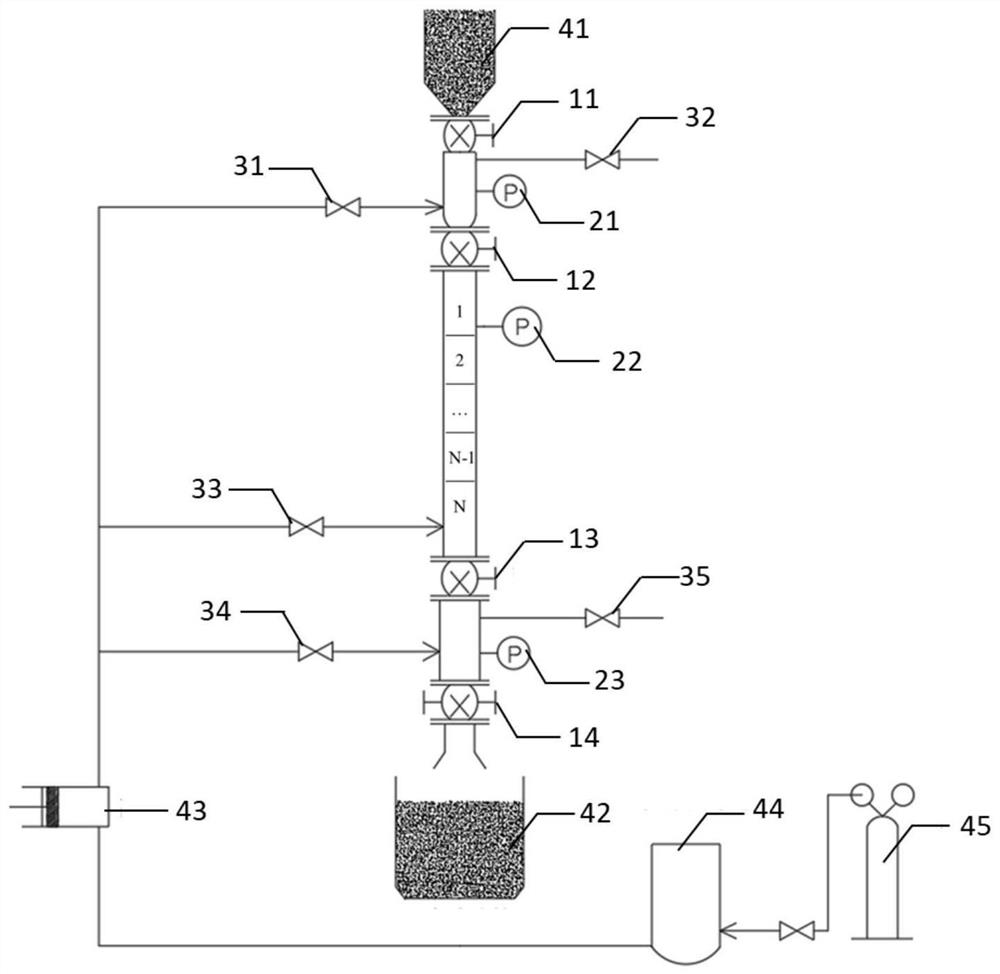

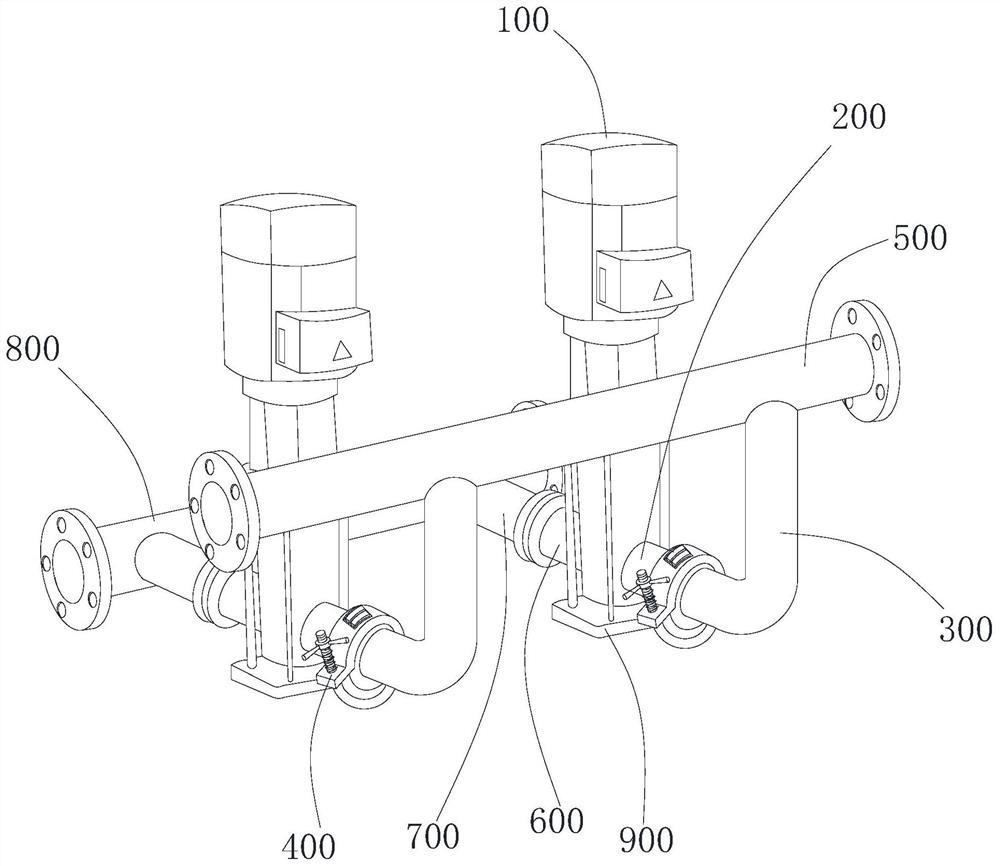

Method and device for preparing polymeric foam material

The invention discloses a method and a device for preparing a polymer foaming material. The device comprises a saturation unit, a foaming unit and a feeding unit; the saturation unit is used for saturating polymer particles in a physical foaming agent; the foaming unit is used for foaming the saturated polymer particles in the saturation unit; the feeding unit is used for transferring the polymerparticles into the saturation unit; the feeding unit, the saturation unit and the foaming unit are coaxially connected in sequence; the feeding unit is connected with the saturation unit through a first valve; and the saturation unit is connected with the foaming unit through a third valve. According to the method and the device for preparing the polymer foaming material, the energy consumption isreduced, the foaming process procedure is simplified, the production cost is reduced, the foaming time is shortened, and the foam pore size uniformity of the obtained foaming beads is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

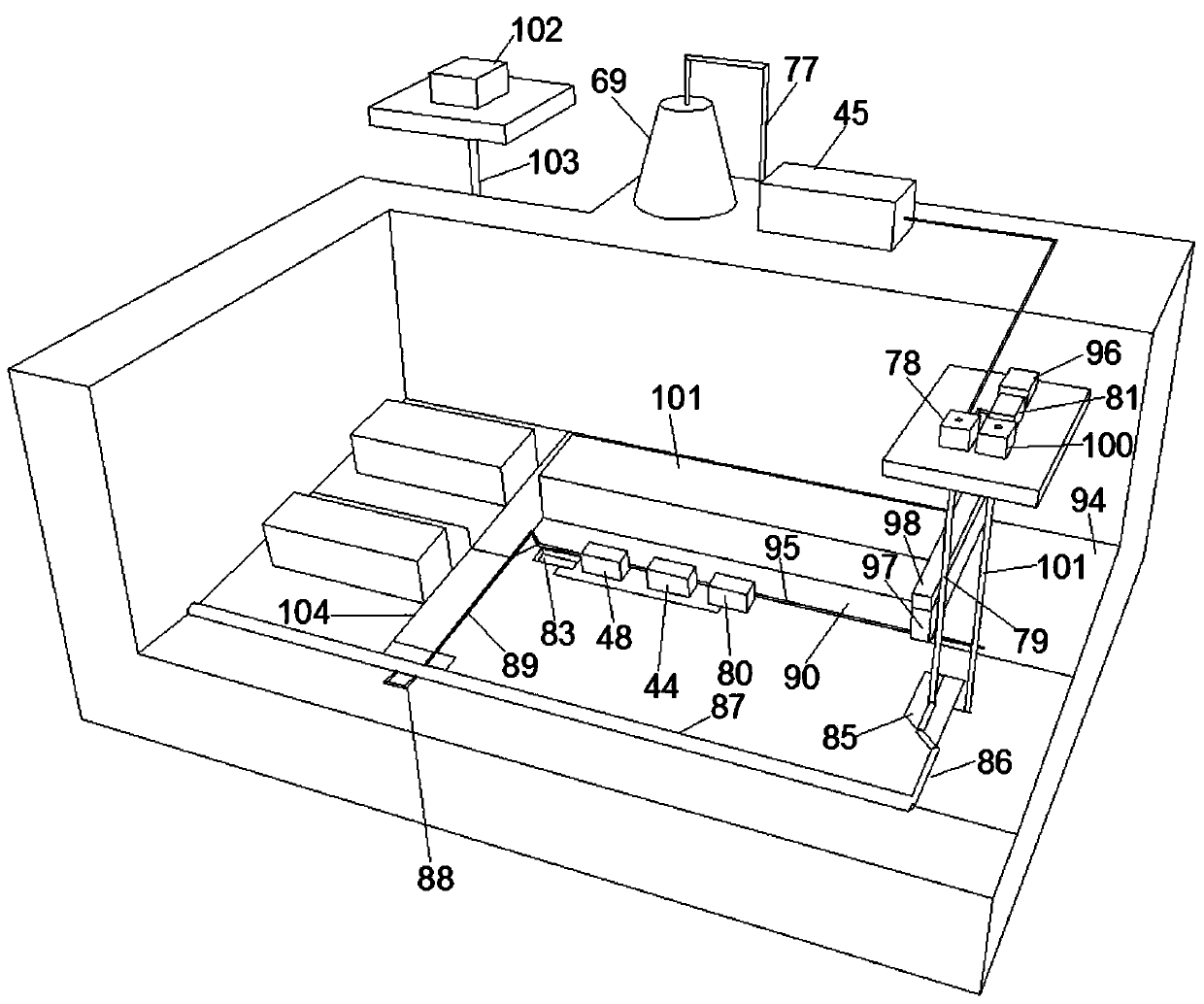

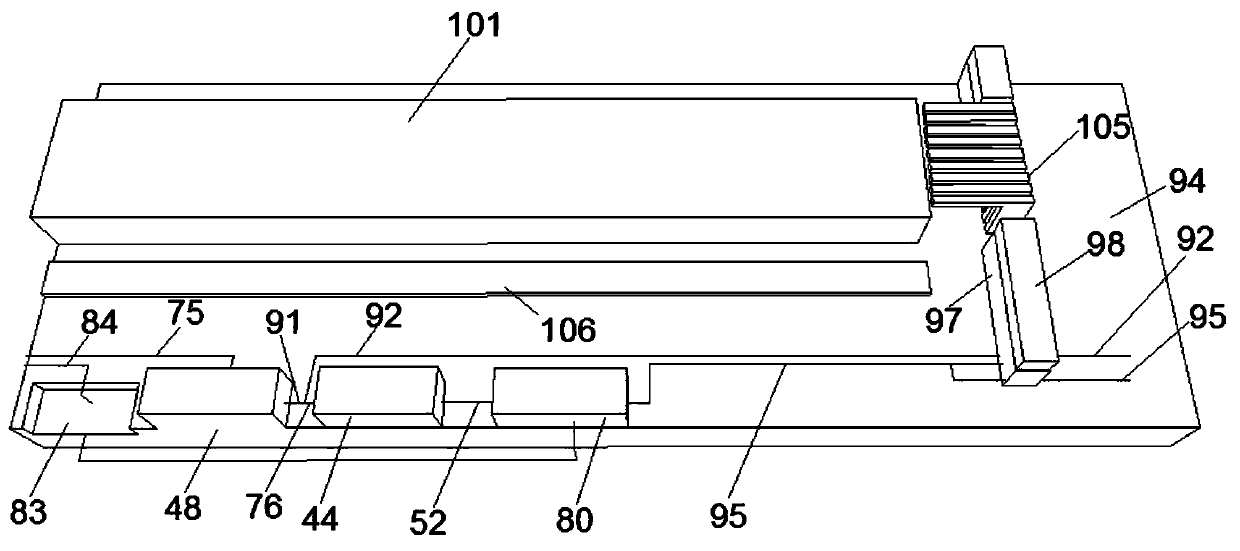

Preparation system of coal-electricity integrated three-waste-based foamed material and using method thereof

ActiveCN110732283AExtended service lifeReduced service lifeFlow mixersTransportation and packagingFoaming agentFlue gas

The invention discloses a preparation system of a coal-electricity integrated three-waste-based foamedmaterial and a using method thereof. The preparation system is characterized in that: a water-liquid mutual driving unit is used for supplying a foaming agent mixed solution to a novel foam maker through a coil pipe under the driving of a constant-flow constant-pressure pump; desulfurization equipment and compression equipment are sequentially used for treating flue gas to form flue gas liquid, and gasification equipment is used for treating the flue gas liquid to form flue gas to be suppliedto the novel foam maker; a three-waste-based foamed material mixer is used for fully and uniformly mixing a generated foam material and a mixed slurry to generate the three-waste-based foamed material. The comprises the following steps: carrying out desulfurization and compression treatment on flue gas, treating high-salt mine well water, and mixing and stirring fly ash, cement and high-salt minewell water to form the mixed slurry; supplying flue gas and a foaming agent mixed solution to the novel foam maker to generate a foamed material; uniformly mixing the foamed material and the mixed slurry to generate a three-waste-based foamed material; injecting into a self-top-contact region; and injecting flue gas into a worked out section. According to the system and the method, three wastes are scientifically treated and recycled, and the preparation process can be monitored.

Owner:CHINA UNIV OF MINING & TECH

Method for preparing enhanced micropore polycarbonate composite sheet through chemical foaming

The invention relates to a method for preparing an enhanced micropore polycarbonate composite sheet through chemical foaming, and belongs to the technical field of plastic foamed composite materials.The method comprises the following steps that a, polyolefin sheet preparing is conducted; b, polycarbonate sheet preparing / preparation is conducted; c, stacking and matching are conducted, a polyolefin sheet and a polycarbonate sheet are assembled, and a to-be-pressed blank board is obtained; and d, hot pressing is conducted, and a press vulcanizer is adopted for conducting hot pressing on the to-be-pressed blank board. According to the high-molecular material foaming processing principle, the micropore foamed PC sheet is prepared through the formed PC sheet via a novel micropore foaming technology. By means of the method, the PC material usage amount and production cost can be effectively reduced, and the weight of a PC box is reduced; meanwhile, the original cold and heat resistance, abrasion resistance, impact resistance and other characters of the PC material are reserved, the method can be widely applied to bag manufacturing, automobiles, electrons, electric appliances and other industries, a new micropore foamed plastic preparing path is developed, and obvious economic and social benefits are achieved.

Owner:XIANGXING FUJIAN BAG ANDLUGGAGE GRP CO LTD

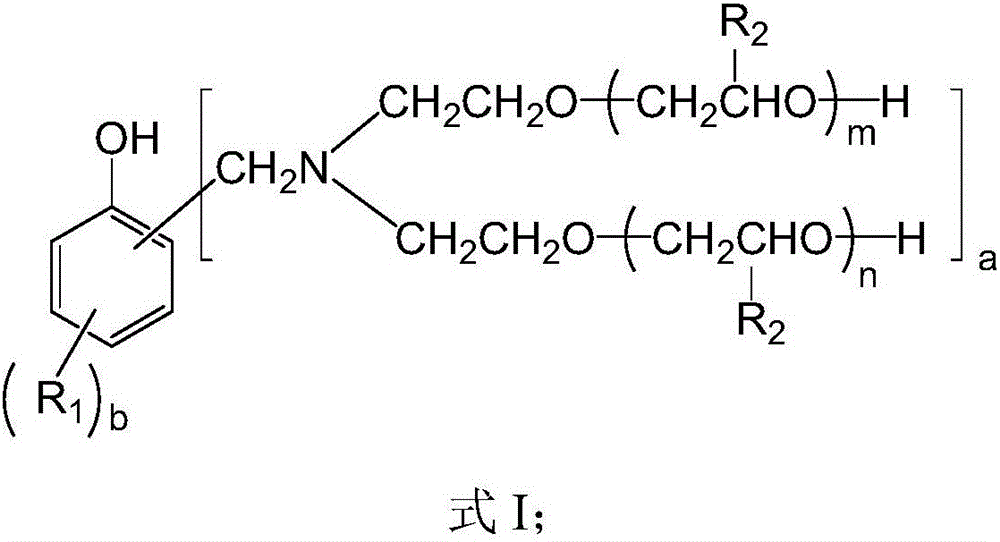

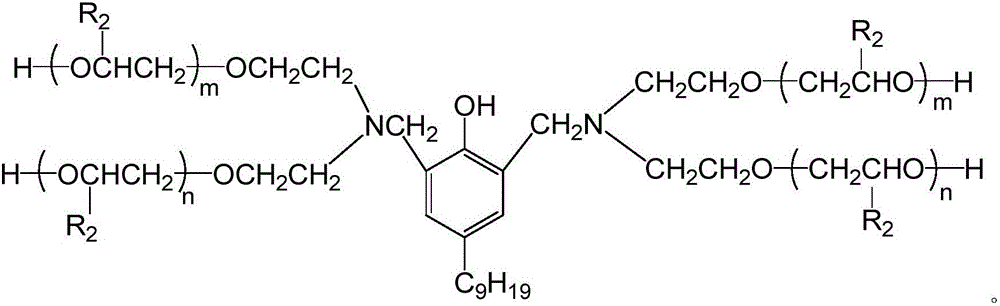

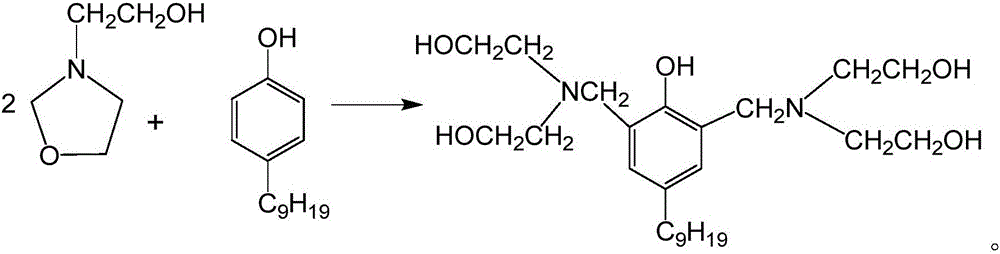

Polyether glycol, preparation method thereof, and foam material

The invention discloses polyether glycol, a preparation method thereof, and a foam material. The polyether glycol is a polymer prepared through ring-opening addition of mannich base and non-substituted or alkyl-substituted ethylene oxide, wherein the mannich base is a product obtained through mannich reaction of non-substituted or alkyl-substituted phenol and N-hydroxyethyl oxazolidine. According to the polyether glycol provided by the invention, a benzene ring is contained in a molecular structure, so that the polyether glycol has better fire resistance. In addition, the polyether glycol provided by the invention has higher reaction activity, and can be beneficial for shortening the foaming time when being used as the foam material. In addition, the preparation method provided by the invention adopts a reaction still as a reaction device, so that the reaction efficiency is greatly improved, and the preparation time is shortened.

Owner:于天荣

Plastic slipper injection molding injection mold and method

ActiveCN108790232AAvoid Burnt SituationsIncrease the amount of foamDomestic footwearSurface mountingDrive motor

The invention discloses a PVC blowing slipper injection mold which comprises a fixed mold base, a movable mold base and a plastic mixing crushing mechanism, wherein the plastic mixing crushing mechanism comprises an accommodating reaction cylinder and a drive motor; the drive motor is connected with a squeezing screw; a thermal insulating panel is arranged at one end of the squeezing screw and isconnected with a displacement air cylinder; a movable sliding block is mounted on the lower surface of the drive motor; a sliding rail is further arranged on the inner wall of the accommodating reaction cylinder; the squeezing screw is sequentially divided into a crushing section, a melting stirring section and a squeezing section from right to left; the accommodating reaction cylinder is providedwith a friction bulge; the accommodating reaction cylinder is provided with subsection heating mechanisms at the melting stirring section and the squeezing section separately; and an air blowing pipeis further arranged on the accommodating reaction cylinder. The subsection heating manner is adopted to avoid the situation that plastic is burnt; an air blowing mechanism is added to increase the foaming quantity; and water-cooling and air-cooling manners are adopted to carry out air blowing foaming treatment and efficient cooling function, so that the injection molding period is shortened and the operating convenience is also improved.

Owner:定州市鼎足鞋业有限公司

Modified ADC (azodicarbonamide) foaming agent with heat conduction and preparation method of modified ADC foaming agent

The invention discloses an ADC (azodicarbonamide) foaming agent with heat conduction and a preparation method of the ADC foaming agent. The ADC foaming agent comprises the ADC foaming agent and a ZnO / MgO composite material, wherein the using amount of the ZnO / MgO composite material is 5%-40% of the mass of the ADC foaming agent, and the mass content of ZnO in the ZnO / MgO composite material is 1-50%. The method comprises the following steps: uniformly mixing the ADC foaming agent and the ZnO / MgO composite material in a mixing machine for 10-30min at normal temperature, wherein the using amount of the ZnO / MgO composite material is 5%-40% of the mass of the ADC foaming agent, and the mass content of ZnO in the ZnO / MgO composite material is 1-50%. The ADC foaming agent disclosed by the invention has the beneficial effects that the modified ADC foaming agent provided by the invention has good heat conduction performance in the foaming process, so that the foaming time is shortened, on the one hand, the energy consumption of a manufacturer is reduced, and the on the other hand, the utilization rate of equipment is improved.

Owner:HANGZHOU HI TECH FINE CHEM

Formula and preparation method for environment-friendly EVA foamed sole

The invention provides a formula and a preparation method for an environment-friendly EVA foamed sole, and relates to the technical field of shoemaking. The formula for the environment-friendly EVA foamed sole comprises the following raw materials in parts by mass: 70-85 parts of an EVA raw material, 15-25 parts of a POE raw material, 5-15 parts of thermoplastic ethylene propylene rubber, 5-8 parts of polyvinyl acetate, 2-10 parts of octylene, 8-19 parts of ethylene, 15-26 parts of a high polymer of an amide group, 2-5 parts of dicumyl peroxide, 0.2-0.8 part of bis(tert-butylperoxyisopropyl)benzene, 0.4-2 parts of palmitic acid, 20-30 parts of silica gel and 5-13 parts of talcum powder. The sole can be well demolded during shoemaking to ensure that the sole has good quality; the sole is well foamed to save raw material cost; and a shoe has good friction performance through silica gel particles.

Owner:中山精美鞋业有限公司

Foaming device and method for a porous magnesium alloy

The present invention provides a porous magnesium alloy foaming device, comprising: a melting furnace; a furnace cover arranged on the top of the melting furnace, the furnace cover is provided with a first through hole and a second through hole; A pipetting spoon with a through hole; a foaming mold fixed in the second through hole, the foaming mold is suspended inside the melting furnace; a stirrer arranged in the foaming mold. The foaming device provided by the invention can realize foaming in a short process, saves the addition of tackifier and heat preservation and foaming, and does not stir for a long time in a semi-solid state. On the one hand, it will not change the existing alloy composition, and has little impact on product performance. On the other hand, the foaming process is suitable for most magnesium alloys and has good formability. On the other hand, the foaming time is shortened and the foaming efficiency is improved; and the structure design of the melting furnace and the foaming mold can make the foaming agent decompose. The speed matches the cooling and viscosity increasing speed of the magnesium alloy liquid, so as to prevent the precipitated bubbles from aggregating and overflowing, and the obtained porous magnesium alloy has a small and uniform pore size.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

A kind of silicate fire-proof and thermal insulation material and preparation method thereof

The invention provides a silicate fireproof and thermal insulation material composition, comprising 100 parts by weight of water glass, 30-40 parts by weight of hollow glass microspheres, 0.5-1 part by weight of a chemical foaming agent, and 0.5-2 parts by weight of an adhesive , 0.5-2 parts by weight of curing agent, 0.5-1 part by weight of polyether polyol, and 0.5-1 part by weight of polyisocyanate. The fireproof and thermal insulation material has the advantages of small bulk density, low thermal conductivity and high compressive strength. The invention also provides a preparation method of the silicate fireproof and thermal insulation material. The preparation method has the advantages of simple process, low energy consumption and short time.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com