Polyurethane flexible foam sponge and preparation method thereof

A polyurethane soft foam and sponge technology, which is applied in the field of polyurethane foam, can solve the problems of performance improvement and long foaming time of polyurethane soft foam, and achieve the effects of shortening foaming time, making foaming easier and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

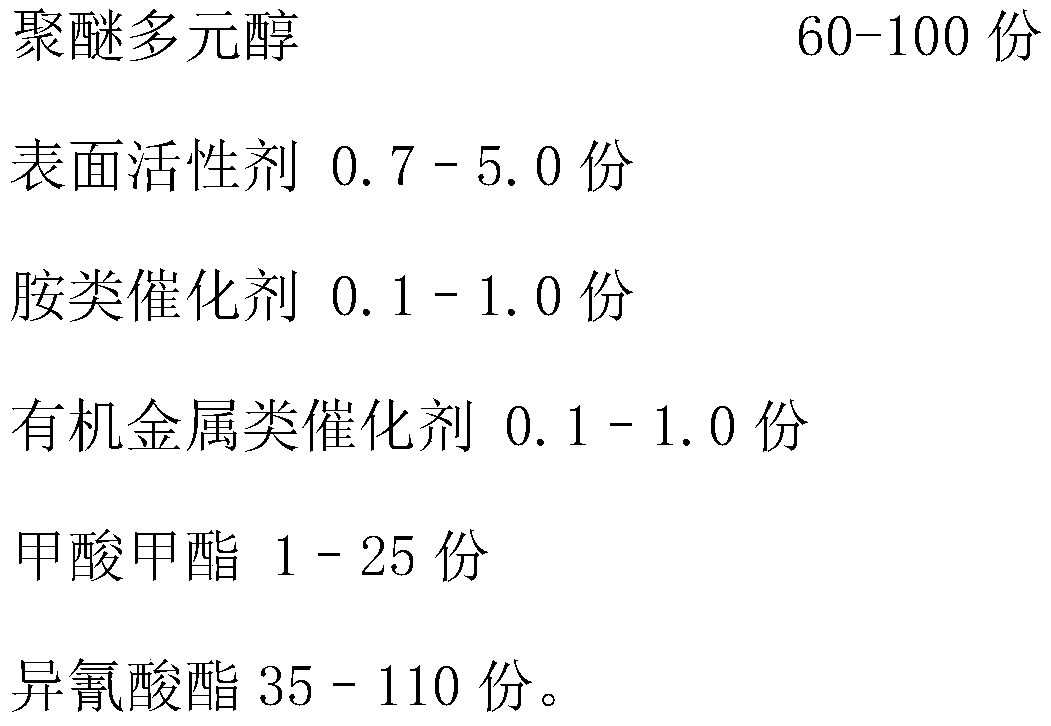

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a soft polyurethane foam sponge, the preparation method of which is as follows:

[0034] 1) Mix the raw materials by the weight described in Table 1, and add them to the low-pressure foaming machine;

[0035] 2) Add 110g of toluene diisocyanate T80 into the low-pressure foaming machine, mix at a stirring speed of 4000 rpm under the conditions of a pressure of 1.6 bar and a temperature of 21°C for foaming reaction, and place it at a temperature of 22°C for 48 hours Afterwards obtain described polyurethane soft foam sponge.

[0036] Table 1

[0037] raw material Weight / g Polyether polyol: Jiahua Puranol F 3031K 100 water 8.0 Surfactant: Evonik Tegoamin SMP 1.0 Amine catalyst: EvonikKosmos K29 1.0 Organometallic catalyst: EvonikTegostab B8123 8.0 Methyl formate 25 index 120

Embodiment 2

[0039] The present embodiment provides a soft polyurethane foam sponge, the preparation method of which is as follows:

[0040] 1) Mix the raw materials by the weight stated in Table 2, and add them to the low-pressure foaming machine;

[0041] 2) Add 72.6g of toluene diisocyanate T80 into the low-pressure foaming machine, mix at a stirring speed of 4500 rpm under the conditions of a pressure of 1.7 bar and a temperature of 22°C, and perform a foaming reaction, and place it at a temperature of 23°C for 48 Obtain described polyurethane soft foam sponge after hour.

[0042] Table 2

[0043] raw material Weight / g Polyether polyol: Jiahua Puranol F 3031K 80 Polymer polyol: Jiahua Puranol PP 2045B 20 water 5.5 Surfactant: Evonik Tegoamin A33 0.15 Amine catalyst: EvonikKosmos K29 0.36 Organometallic catalyst: EvonikTegostab B8123 1.8 Methyl formate 7.1 index 120

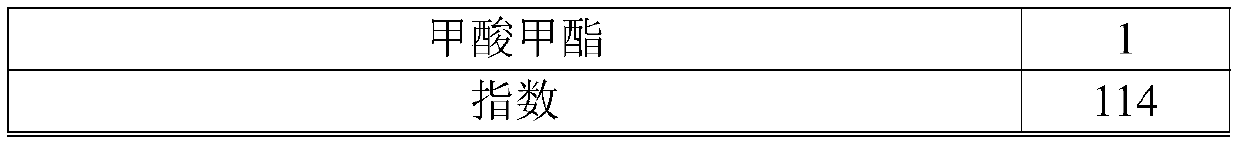

Embodiment 3

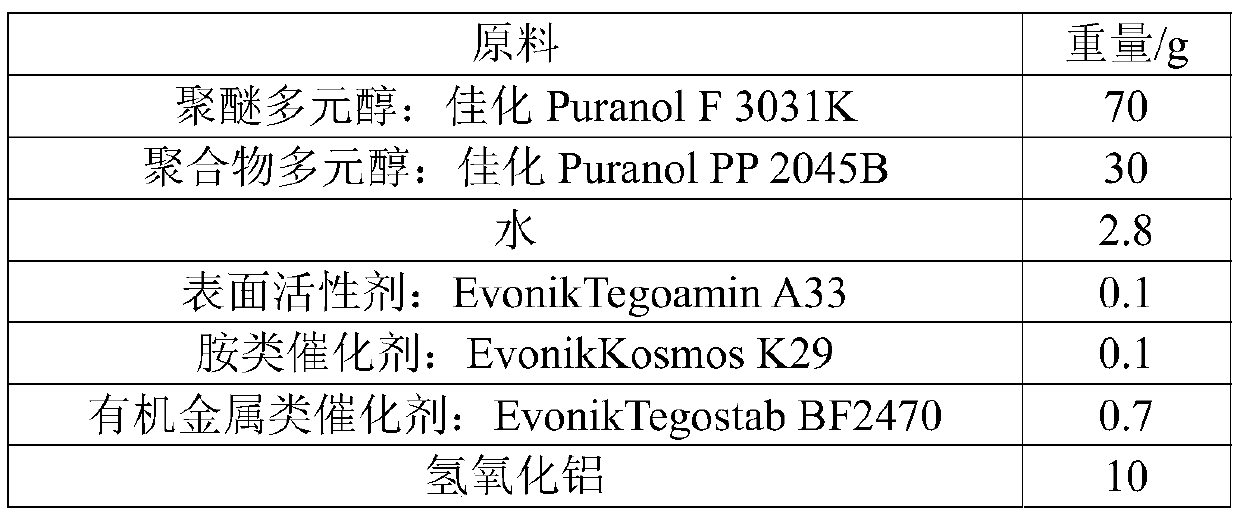

[0045] The present embodiment provides a soft polyurethane foam sponge, the preparation method of which is as follows:

[0046] 1) Mix the raw materials by the weight described in Table 3, and add them to the low-pressure foaming machine;

[0047] 2) Add 68g of toluene diisocyanate T80 into the low-pressure foaming machine, mix at a stirring speed of 5000 rpm under the conditions of a pressure of 2.0 bar and a temperature of 23°C for foaming reaction, and place it at a temperature of 22°C for 48 hours Afterwards obtain described polyurethane soft foam sponge.

[0048] table 3

[0049] raw material Weight / g Polyether polyol: Jiahua Puranol F 3031K 100 water 4.8 Surfactant: Evonik Tegoamin A33 0.3 Amine catalyst: EvonikKosmos K29 0.2 Organometallic catalyst: EvonikTegostab B8110 2.0 calcium carbonate 100 Methyl formate 5.0 index 125

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com