Multi-angle mold-closing foaming fixture for automotive carpet and use method of multi-angle mold-closing foaming fixture

An automobile carpet and multi-angle technology, which is applied in the field of multi-angle closed-mould foaming fixtures for automobile carpets, can solve the problems of low automation degree of foaming fixtures, high technical dependence of workers, low production efficiency, etc., and achieves simple maintenance and overall strength. Good and easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

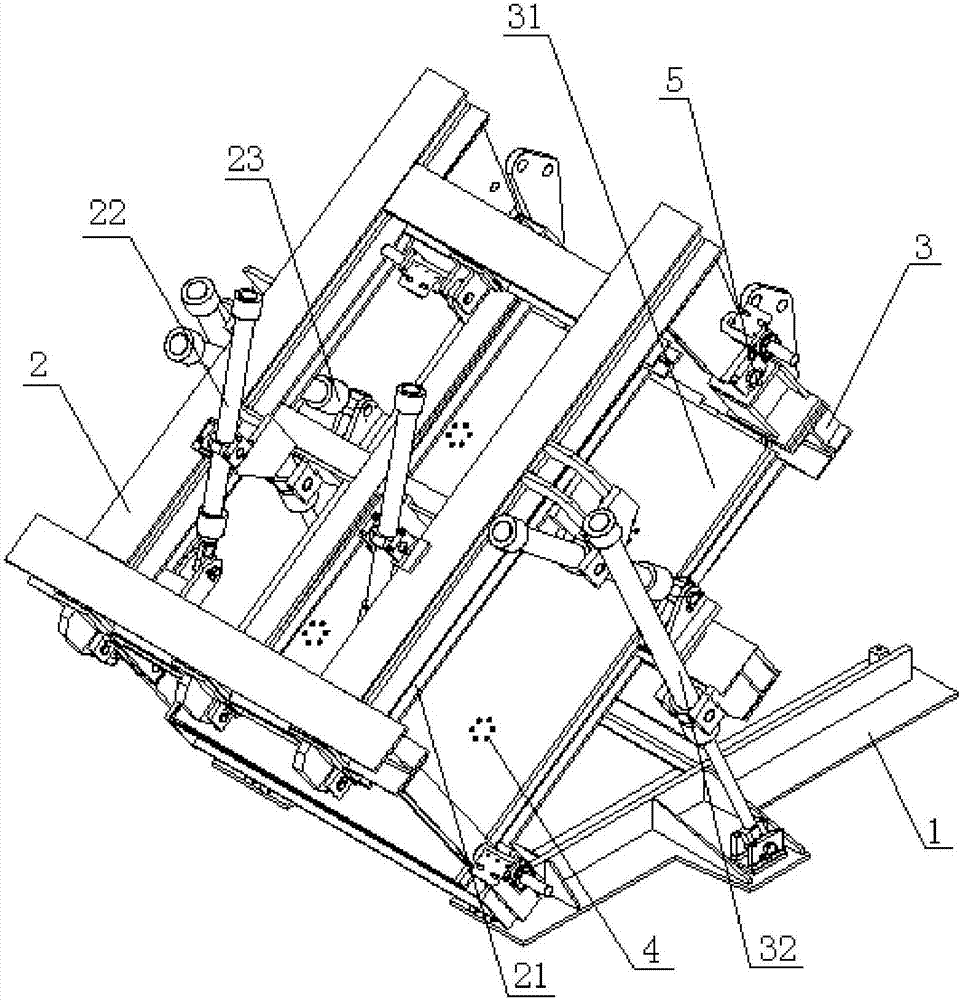

[0021] Such as figure 1 As shown, the present invention provides a multi-angle closed-mold automotive carpet foaming fixture, comprising a base 1 made of section steel, an upper mold frame 2 and a lower mold frame 3 are arranged on the base 1, and the upper mold frame 2 is provided with Upper formwork 21, lower formwork 3 is provided with lower formwork 31, the bottom of lower formwork 3 is provided with air bag 4, and base 1 is provided with upper turning mechanism 22 for upper formwork 2 turning over and for lower formwork 3 turning over. The lower turning mechanism 32, the two sides of the upper mold frame 2 are provided with the side turning mechanism 23 for the side turning of the upper template 21, and the ends of the upper mold frame 2 and the lower mold frame 3 are provided with a locking pin 5 and a The locking hole, the locking pin 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com