Preparation system of coal-electricity integrated three-waste-based foamed material and using method thereof

A foaming material and preparation system technology, applied in chemical instruments and methods, mixing methods, mixed material pretreatment, etc., can solve problems such as single method, poor feasibility, low utilization efficiency, etc., to ensure constant current or constant pressure supply , Improve foaming efficiency and facilitate rapid delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with accompanying drawing.

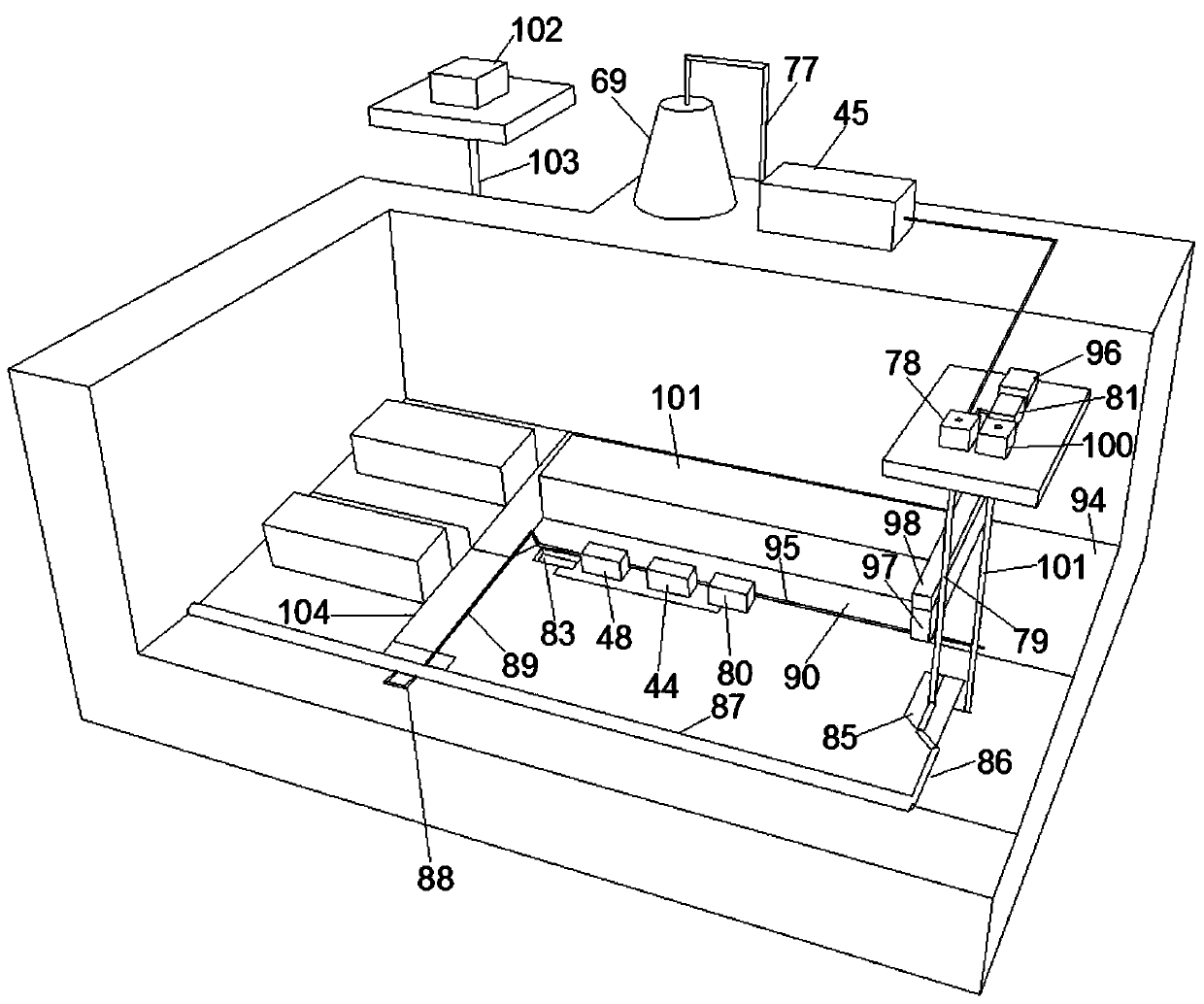

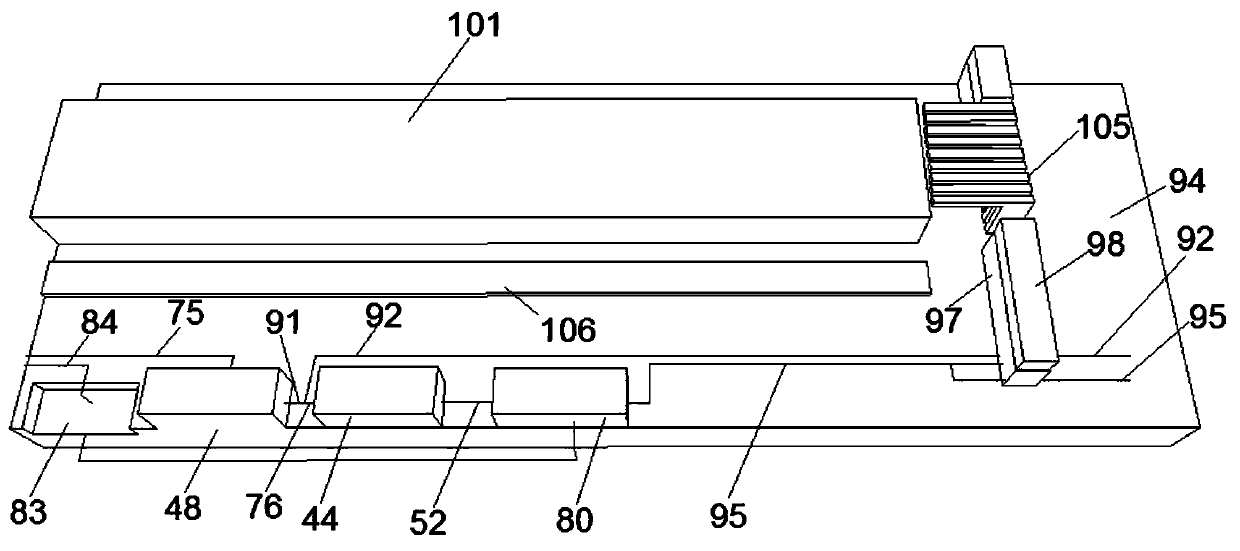

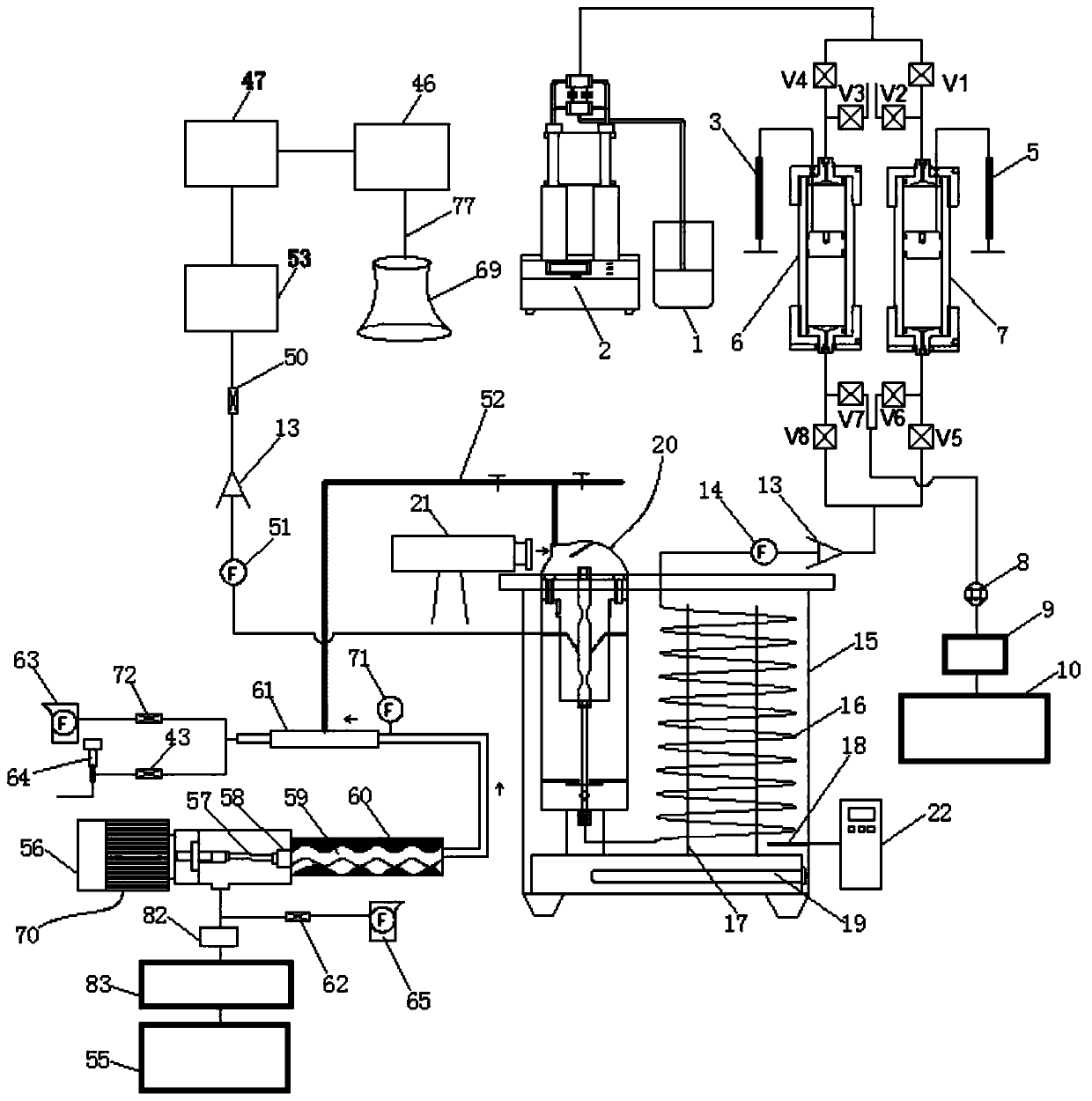

[0052] Such as figure 1 and figure 2 As shown, the power plant 69 in the coal-electricity joint venture is set up close to the coal mine, wherein the coal mine includes a main well room 99, an auxiliary well room 78, an air well room 102, a well bottom parking lot 85 arranged underground, a transportation stone gate 85 arranged underground, The main shaft 100 connecting the main shaft room 99 and the bottom shaft parking lot 85, the auxiliary shaft 79 connecting the auxiliary shaft room 78 and the bottom shaft parking lot 85, the return air shaft 103 connecting the air shaft room 102 and the underground return air channel, and the The working face 101, the transportation chute 90 arranged on one side of the working face 101, the transportation chute tape 106 arranged in the transportation chute 90, the mined-out area 94 located in the underground, and several hydraulic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com