High-magnification thermoplastic polyurethane microporous foamed plate and production method thereof

A thermoplastic polyurethane and microcellular foaming technology, which is applied in the field of high-rate thermoplastic polyurethane microcellular foamed sheets, can solve the problems of low foaming ratio and achieve the effects of large foaming ratio, shortened foaming time, and shortened diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

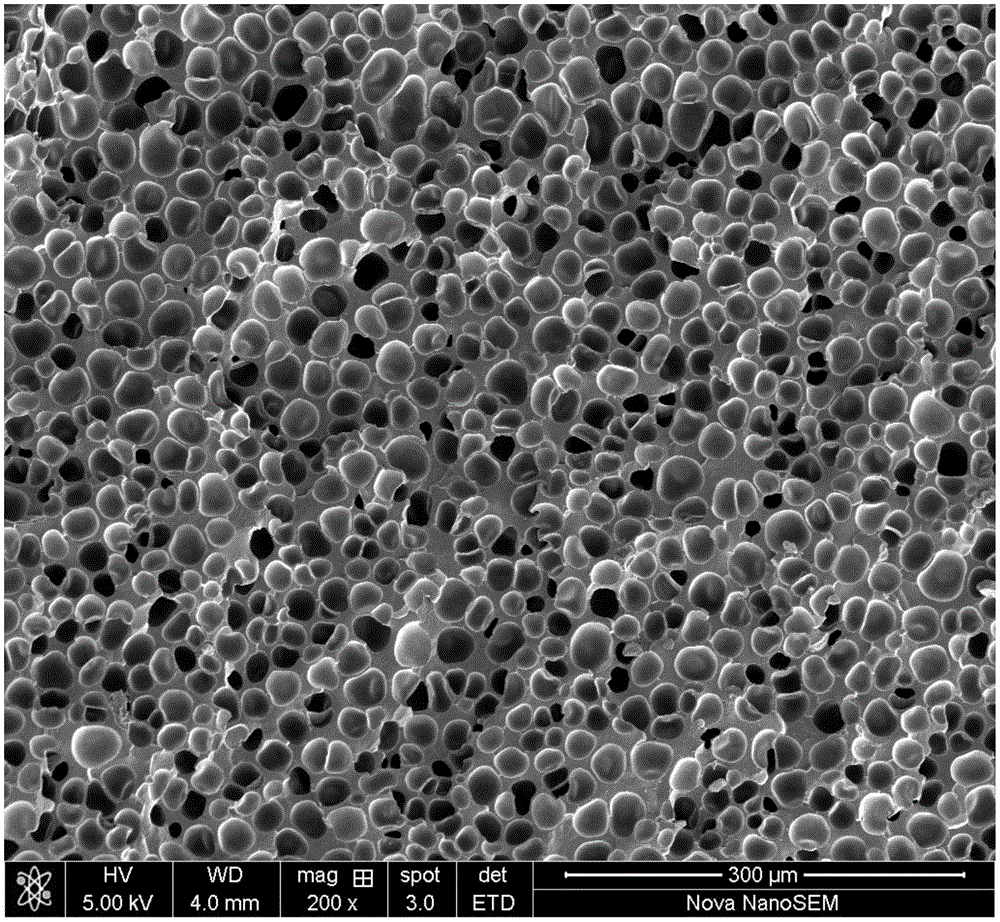

[0029] Such as figure 1 As shown, a high-magnification thermoplastic polyurethane microcellular foamed sheet includes the following components: 100 parts by weight of TPU, the molecular weight of the TPU is 60,000, the hardness is shore A 75, and the TPU is polyester TPU particles.

[0030] A method for producing a high-magnification thermoplastic polyurethane microcellular foamed sheet, comprising the following steps:

[0031] a) After dehumidifying and drying the TPU, add it to the extruder, then shape it through a hanger-type die, cool it, cut it to length, and cut it into a TPU solid plate with a width of 150mm, a length of 400mm, and a thickness of 10mm;

[0032] b) Put the TPU solid plate obtained in step a) into a high-pressure foaming mold, and the volume ratio of the mold cavity in the mold to the TPU solid plate is 3:1, the mold is clamped by hydraulic pressure, and the mold is protected by a sealing ring. Force sealing, the mold is heated to 140°C through heat tran...

Embodiment 2

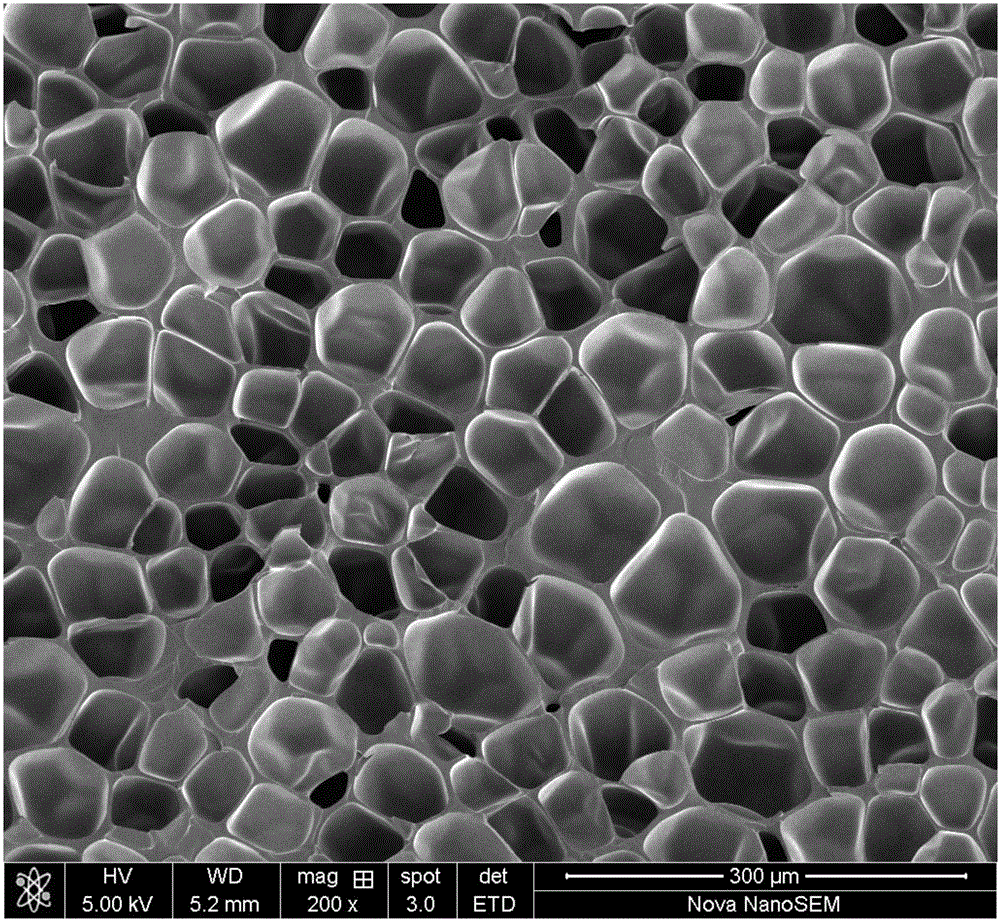

[0035] Such as figure 2 As described, a high-magnification thermoplastic polyurethane microcellular foamed sheet includes the following components: 95 parts by weight of TPU, 5 parts by weight of polydimethylsiloxane, the molecular weight of TPU is 65,000, and the hardness is shore A 80 , TPU is polyether TPU particles, and polydimethylsiloxane is double-terminated amino polydimethylsiloxane.

[0036] A method for producing a high-magnification thermoplastic polyurethane microcellular foamed sheet, comprising the following steps:

[0037] a) Mix TPU and polydimethylsiloxane, dehumidify and dry it, add it to the extruder, then shape it through a hanger-type die, cool it, cut it to length, and cut it into a solid TPU with a width of 150mm, a length of 400mm, and a thickness of 10mm plate;

[0038] b) Put the TPU solid plate obtained in step a) into a high-pressure foaming mold, and the volume ratio of the mold cavity in the mold to the TPU solid plate is 2:1, the mold is clampe...

Embodiment 3

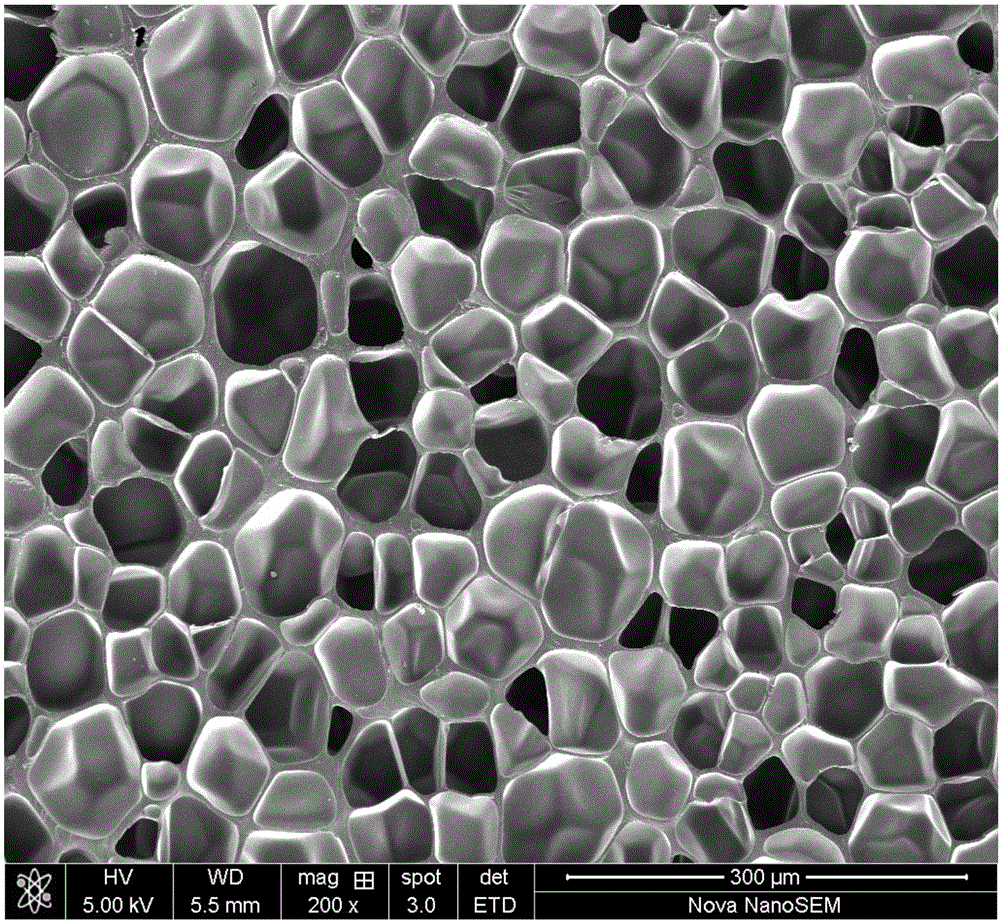

[0041] Such as image 3 As shown, a high-magnification thermoplastic polyurethane microcellular foamed board includes the following components: 100 parts by weight of TPU, the molecular weight of the TPU is 80,000, the hardness is shore A 85, and the TPU is polyether TPU particles.

[0042] A method for producing a high-magnification thermoplastic polyurethane microcellular foamed sheet, comprising the following steps:

[0043] a) After dehumidifying and drying the TPU, add it to the extruder, and then shape it through a hanger-type die, cool it, cut it to length, and cut it into a TPU solid plate with a width of 500mm, a length of 1500mm, and a thickness of 20mm;

[0044] b) Put the TPU solid plate obtained in step a) into a high-pressure foaming mold, and the volume ratio of the mold cavity in the mold to the TPU solid plate is 3:2, the mold is clamped by hydraulic pressure, and the mold is protected by a sealing ring. Force sealing, the mold is heated to 155°C through heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com