Preparation method of foam titanium under hydrogen-assisted action

A technology of foamed titanium, applied in the field of titanium and titanium alloys, can solve the problems that industrial production is difficult to control, not suitable for mass production, and high manufacturing cost, and achieves the effects of improving plasticity, realizing batch industrial production, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

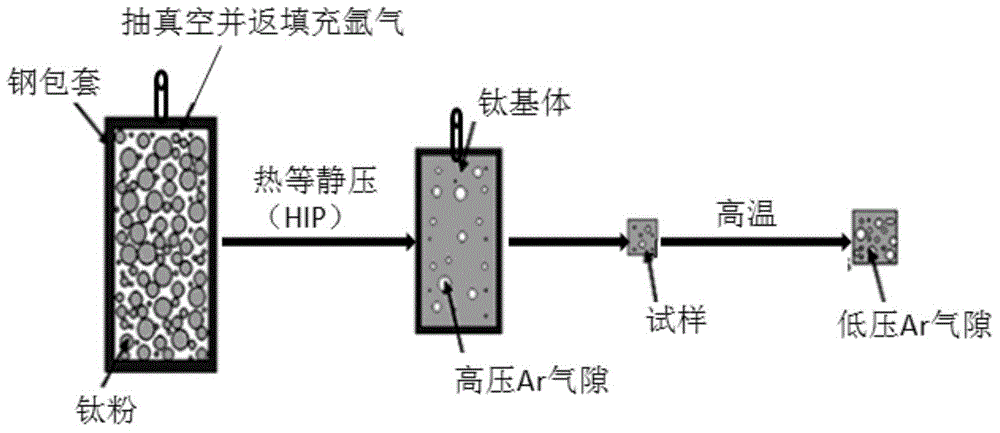

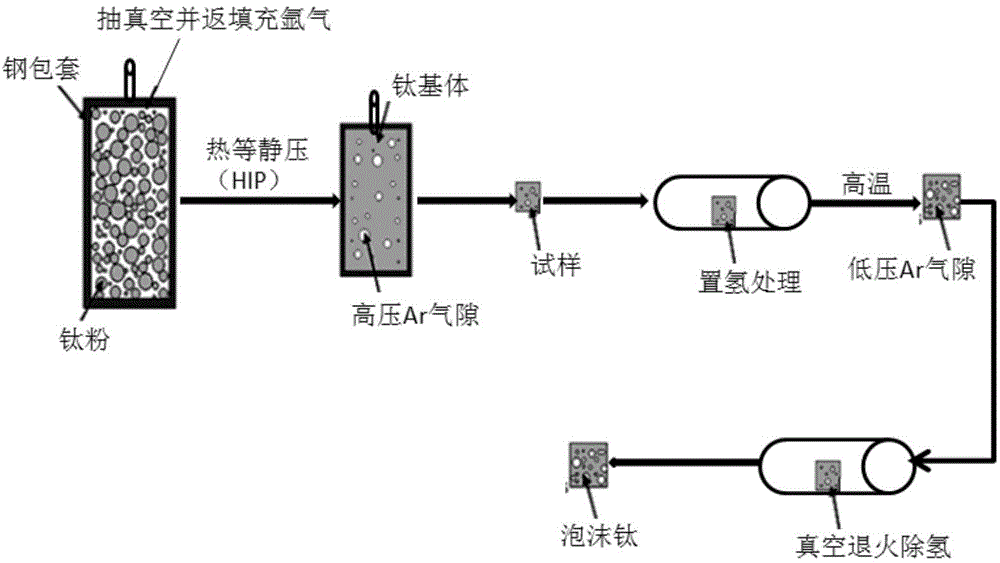

[0027] This embodiment provides a method for preparing foamed titanium under the assistance of hydrogen, such as figure 2 As shown in the technological process, it comprises the following steps:

[0028] (1) Preparation of preform samples:

[0029] Put the TC4 powder into the Q235 steel ladle, vacuumize the sheath and then fill it with 0.4MPa argon, then seal the sheath, and put the sealed sheath into the hot isostatic pressure furnace, at 980℃ , 100MPa under the condition of compaction for 4 hours, and then use high-pressure water cutting to cut the preform formed by hot isostatic pressing into small pieces of samples, and process them into regular rectangular parallelepiped samples by milling;

[0030] (2) hydrogenation:

[0031] Put the prepared preform sample into the tubular hydrogen treatment furnace. Before hydrogen charging, the vacuum degree of the hydrogen treatment furnace is kept at 10 -3 Pa order of magnitude, the hydrogenation temperature is 600°C, and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com