Coated foaming agent and preparation method thereof and preparation method of foamed aluminum

A foaming agent and coating type technology, which is applied in the field of preparing foamed aluminum by melt foaming, can solve the problems of large foaming pore size, non-uniformity, waste of air source, etc., and achieves delaying foaming time, increasing wettability, Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

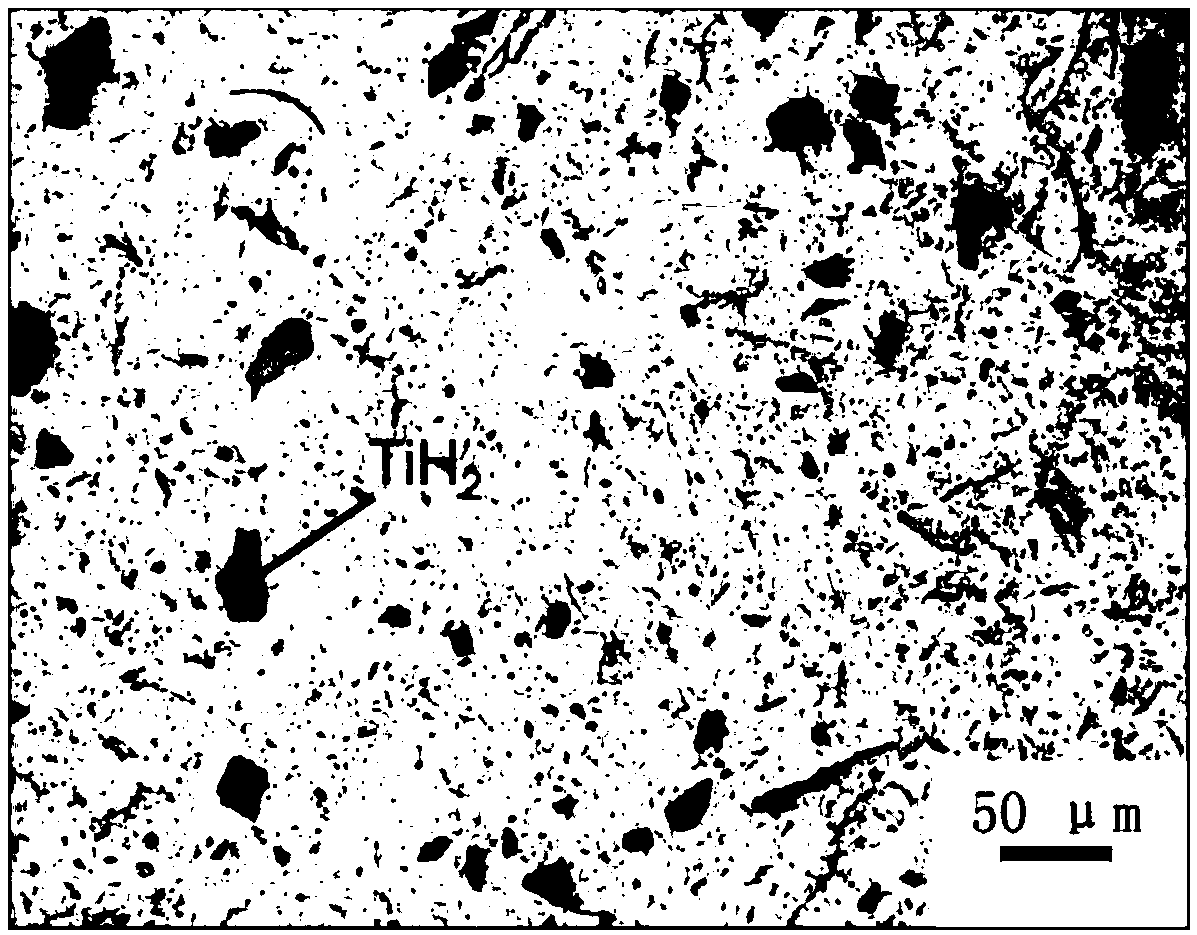

[0039] The above-mentioned preparation method of foamed aluminum adopts a new foaming agent. In the new foaming agent, titanium hydride composite particles coated with an oxide layer on the surface of titanium hydride are used as the foaming component. Since the titanium hydride particles are covered with oxide , so that when the foaming agent is added to the melt, it will not decompose immediately, avoiding the problem that titanium hydride is easily burned when it is added to the melt. Covering further delays the foaming time of the foaming agent, and more importantly, the presence of alloys or metals also increases the wettability of the foaming agent and the aluminum melt, so that the foaming agent can be evenly dispersed in the aluminum melt Middle; when the temperature of the aluminum melt reaches the dehydrogenation temperature of titanium hydride, the particles of titanium hydride can stably form uniform small-pore bubbles in the aluminum melt, thereby preparing aluminu...

Embodiment 1

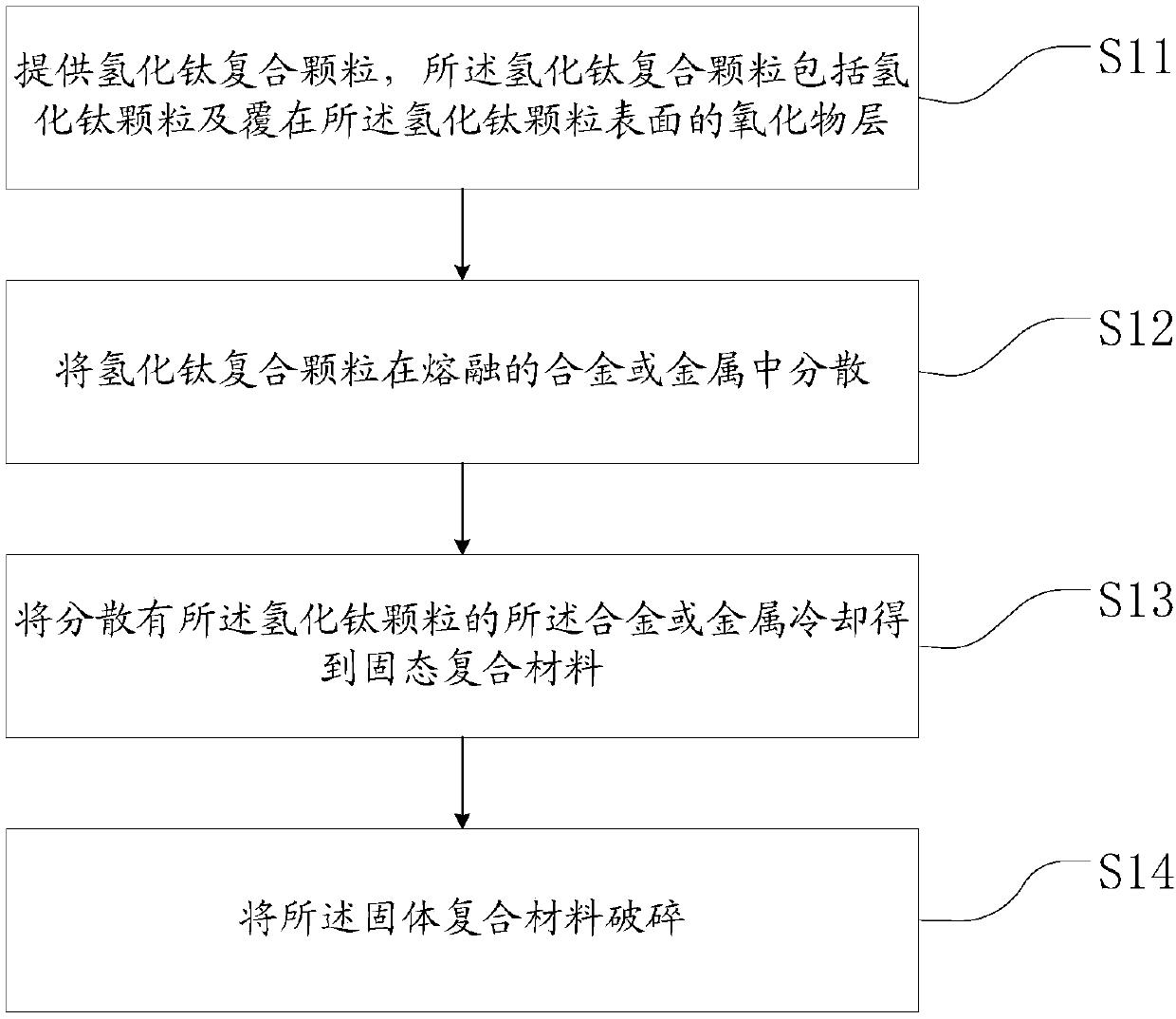

[0071] Preparation of foaming agent: Strictly sieve titanium hydride, select titanium hydride particles of 200-400 mesh, and then obtain titanium hydride composite particles after being kept at 500°C for 2 hours in an air atmosphere, and the titanium hydride composite particles are below 500°C , no decomposition occurs. Then use liquid-solid mixing to mix 5wt% titanium hydride composite particles into the alloy, stir at a speed of 2100r / min at an ambient temperature of less than 500°C for 2 hours, crush and sieve out a foaming agent with a diameter of about 5mm after cooling .

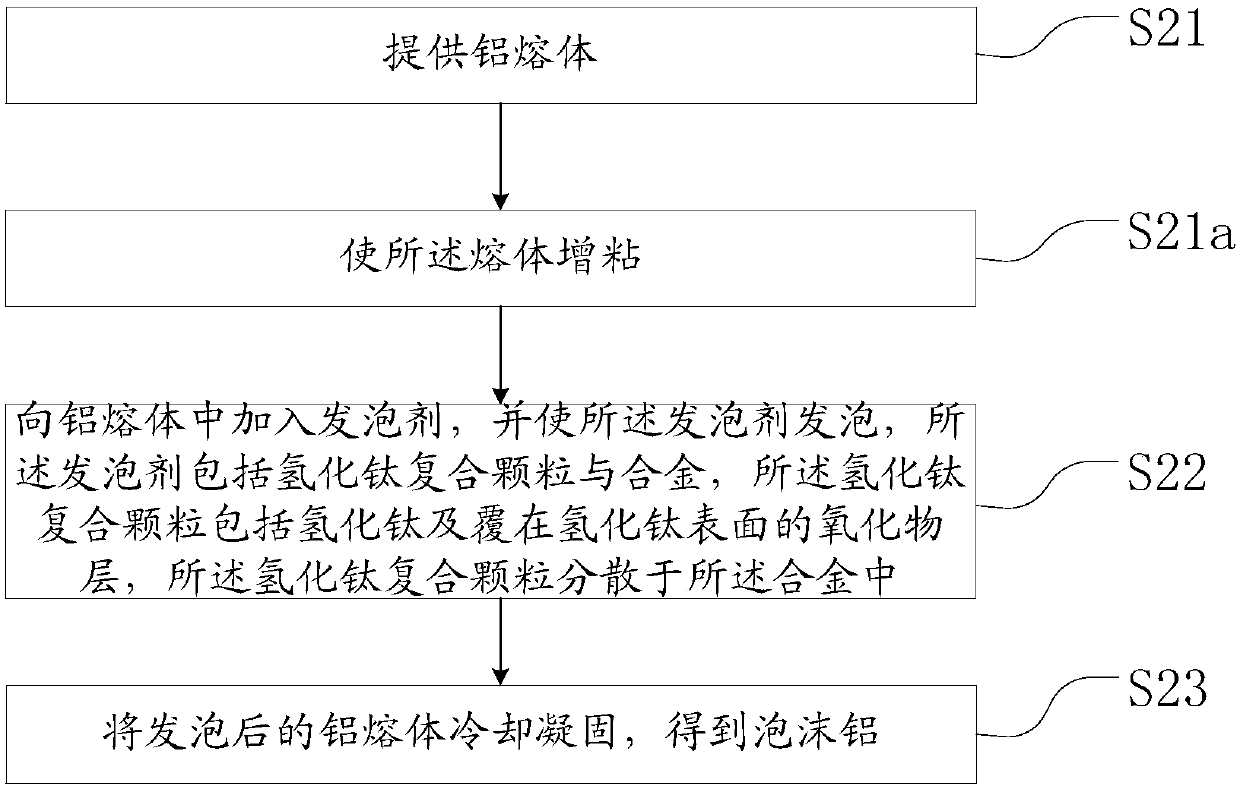

[0072] Preparation of foamed aluminum: heat aluminum to 680°C, melt it, add 3wt% calcium particles, stir for 10 minutes, and then add 5wt% new foaming agent at 660°C, at this time, the addition equivalent of titanium hydride composite particles is aluminum 0.25wt% of the melt, stirred for 5min at 2100r / min, put out the stirring paddle, then kept the temperature for 5min, and cooled with the furnace. ...

Embodiment 2

[0074] Preparation of foaming agent: sieve titanium hydride, select titanium hydride particles with a mesh size of 100-200, and then keep warm at 500° C. for 2 hours in an air atmosphere to obtain titanium hydride composite particles. Then use liquid-solid mixing to mix 5wt% titanium hydride composite particles into the alloy, and use a speed of 2100r / min at a temperature of less than 450-500°C, stir for 2 hours, crush and sieve after cooling to obtain a foaming agent with a diameter of about 5mm .

[0075] Preparation of foamed aluminum: Heat aluminum to 680°C to melt, add 3wt% calcium particles, stir for 10 minutes, then add 10wt% new foaming agent at 660°C, at this time, the addition of titanium hydride is equivalent to that of aluminum melt 0.5wt%, 2100r / min under the condition of stirring for 5min, put out the stirring paddle, then keep warm for 5min, cool with the furnace, the prepared small-pore foam aluminum sample refer to Figure 5 , the pore diameter is about 3mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com