Thermal-insulation decorative plate and preparation method thereof

A technology for thermal insulation decorative boards and foam materials, which is applied in the field of building materials, can solve the problems of easy delamination, insufficient bonding fastness of the thermal insulation layer and the decorative layer, etc., and achieve firm bonding, avoid delamination, and tightly bond Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

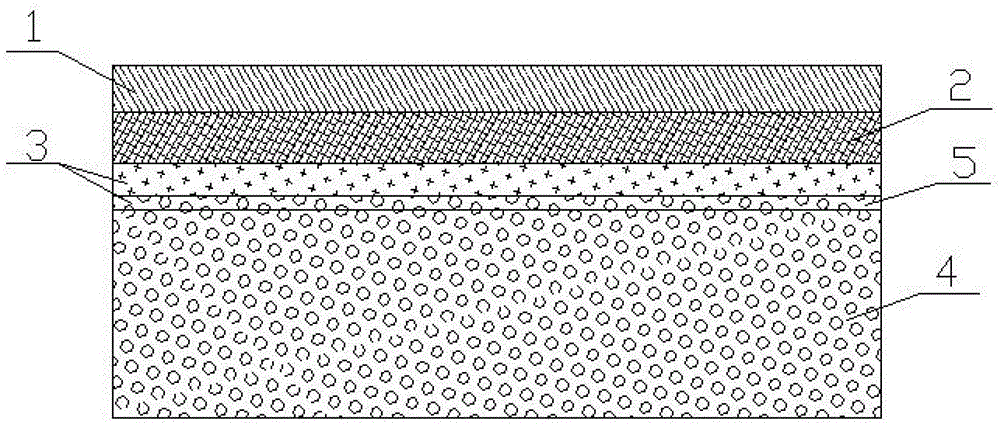

[0039] Insulation decorative board of the present invention, as figure 1 As shown, its structure includes a foam material layer 4 and a cloth surface material layer 3 that is arranged on the foam material layer 4 and allows the foam material layer 4 to penetrate into it, and is coated on the cloth surface material layer 3 A sand-fixing material layer 2 is covered, and decorative sand 1 for forming decorative patterns is solidified in the sand-fixing material layer 2 .

[0040] The foaming material is phenolic resin, the cloth surface material is glass fiber cloth, and besides PVC, the sand-fixing material layer 2 also contains 1% of the mass percentage of the sand-fixing material layer 2. A curing agent, the curing agent is hexamethylenetetramine.

[0041] The making of above-mentioned thermal insulation decorative board comprises the following steps:

[0042] The first step: coating liquid PVC with a mass fraction of 1% hexamethylenetetramine on the upper surface of the gla...

Embodiment 2

[0045] Insulation decorative board of the present invention, as figure 1 As shown, its structure includes a foam material layer 4 and a cloth surface material layer 3 that is arranged on the foam material layer 4 and allows the foam material layer 4 to penetrate into it, and is coated on the cloth surface material layer 3 A sand-fixing material layer 2 is covered, and decorative sand 1 for forming decorative patterns is solidified in the sand-fixing material layer 2 .

[0046] In addition to the phenolic resin, the foaming material layer 4 also contains a foaming agent accounting for 1% by mass of the foaming material layer 4 and glass that accounts for 4% by mass of the foaming material layer 4. fiber, the blowing agent is liquid CO 2 The cloth surface material is a glass fiber cloth; except that PVC is contained in the described sand-fixing material layer 2, it also contains a curing agent accounting for 30% of the mass percentage of the sand-fixing material layer 2, and th...

Embodiment 3

[0052] Insulation decorative board of the present invention, as figure 1 As shown, its structure includes a foam material layer 4 and a cloth surface material layer 3 that is arranged on the foam material layer 4 and allows the foam material layer 4 to penetrate into it, and is coated on the cloth surface material layer 3 A sand-fixing material layer 2 is covered, and decorative sand 1 for forming decorative patterns is solidified in the sand-fixing material layer 2 .

[0053] In addition to the phenolic resin, the foam material layer 4 also contains 2% of the mass percent of the foam material layer 4, a surfactant and 4% of the glass mass percent of the foam material layer 4. fiber, the surfactant is fatty alcohol polysiloxane ether; the cloth surface material is glass fiber cloth; in addition to PVC, the sand-fixing material layer 2 also contains The mass percentage is 10% curing agent, and described curing agent is p-toluenesulfonic acid.

[0054] The making of above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com