Photoresist developing solution

A developer and photoresist technology, applied in optics, photography, optomechanical equipment, etc., can solve the problems of poor process margin of developer, limited types of photoresist, unstable developing performance, etc., and achieve good developing effect, Excellent process margin and long developing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

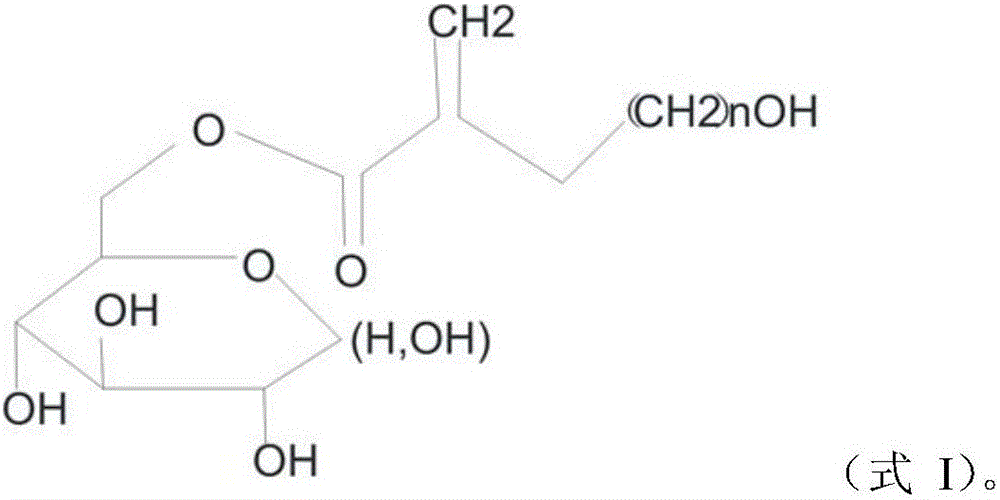

Method used

Image

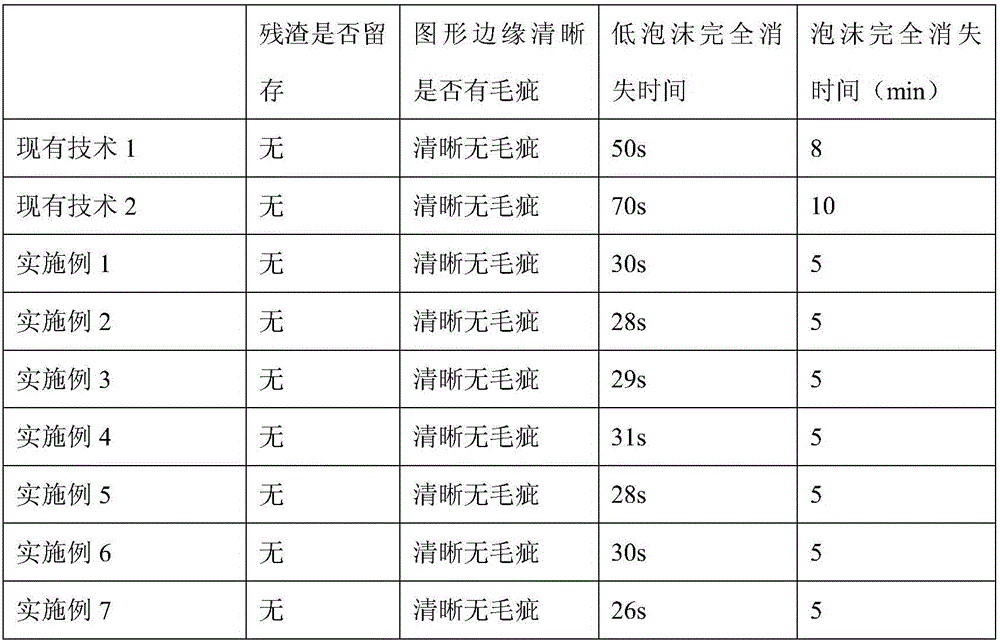

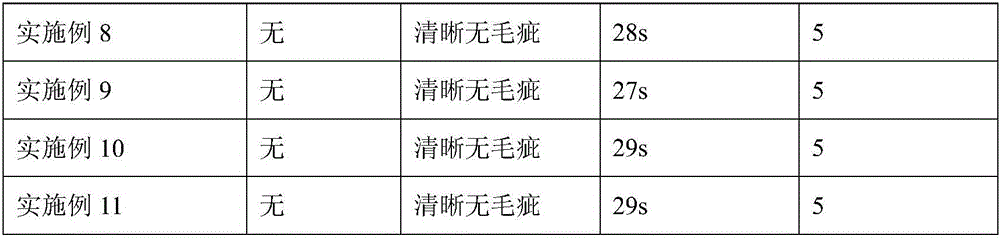

Examples

Embodiment 1

[0027] The developing solution takes 5 parts by weight of nonionic surfactant, 3 parts by weight of inorganic base, and 92 parts by weight of water. Inorganic bases are common alkali metal hydroxides, weak basic compounds and the like. For the convenience of comparative examples, potassium hydroxide is all selected as the alkaline compound of the developer.

Embodiment 2

[0029] The developer was 8 parts by weight of nonionic surfactant, 5 parts by weight of potassium hydroxide, and 87 parts by weight of water.

Embodiment 3

[0031] The developer was 6 parts by weight of nonionic surfactant, 3.5 parts by weight of potassium hydroxide, and 90.5 parts by weight of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com