Elastic cured foam material for underground goaf and application thereof

A technology for curing foam and goaf, which is applied in the field of elastic curing foam material in underground goaf, can solve the problems of poor compression resistance of closed walls, rupture of closed walls, and poor compression resistance of underground goafs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] An elastic solidified foam material for downhole goaf, prepared from raw materials including the following parts by weight: 30 parts of polyphenyl polymethylene polyisocyanate, 2 parts of polyester polyol, 1 part of hydrofluoroalkane, ethylene glycol 2 parts, 1 part of diethylene glycol, 10 parts of tris(2-chloropropyl) phosphate, 1 part of polydimethylsiloxane-alkylene oxide copolymer, 4,4,-bis(α,α -Dimethylbenzyl)diphenylamine 3 parts, CaCO 3 6 parts, 0.1 part of dibutyltin dilaurate, 5 parts of sulfonated polybutadiene. The above-mentioned raw materials are mixed to obtain an elastic solidified foam material in the downhole goaf. After testing, the foaming time of the elastic solidified foam material in the underground goaf area prepared in Example 1 is 1 min, the curing time is 10 min, and the aging time is increased by 50 years.

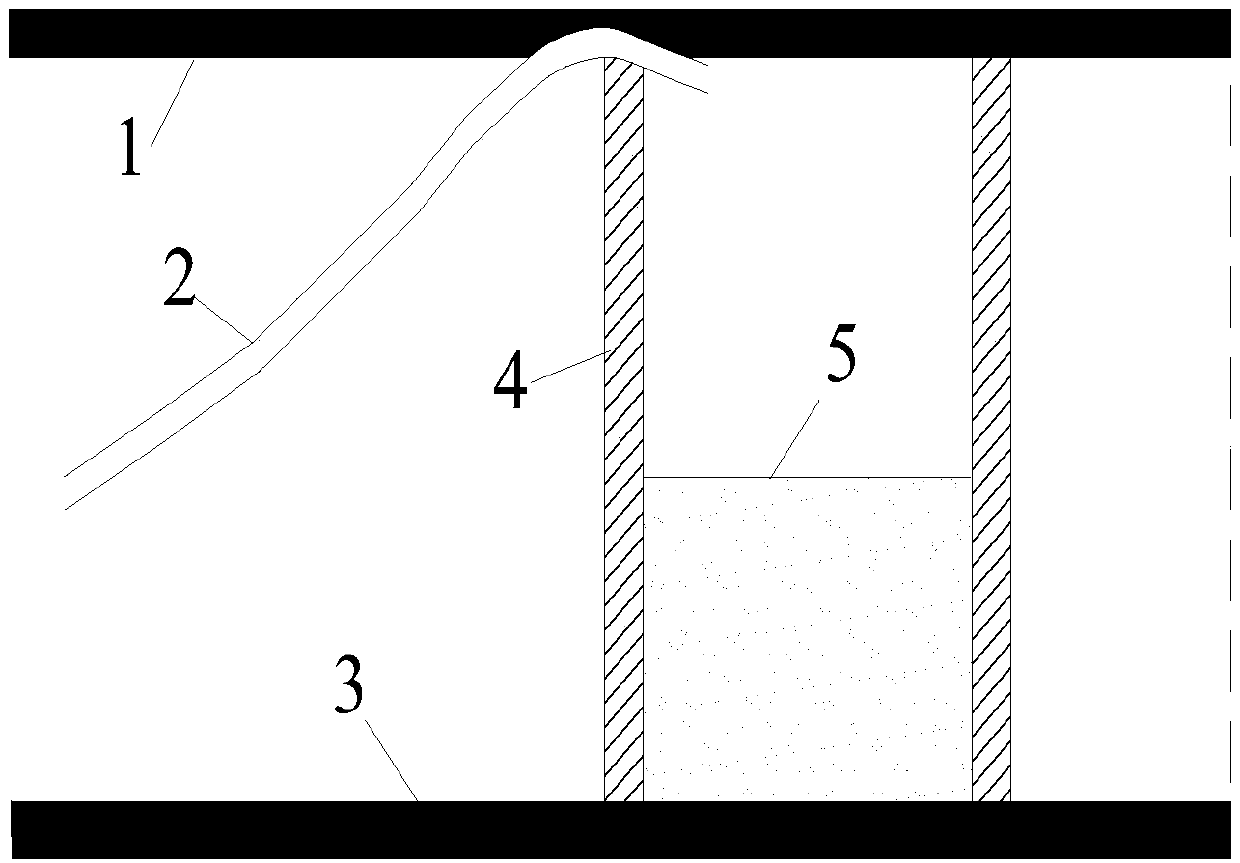

[0044] The filling template construction method is used to prepare the sealing wall of the underground goaf. Two filling templates are set...

Embodiment 2

[0046] An elastic solidified foam material for underground mined-out areas, prepared from raw materials including the following parts by weight: 50 parts by weight of toluene diisocyanate, 10 parts by polyester polyol, 5 parts by n-pentane, and 6 parts by 1,4-butanediol , 6 parts of diethylene glycol, 4 parts of polydimethylsiloxane-alkylene oxide copolymer, 2 parts of stannous octoate. The above-mentioned raw materials are mixed to obtain an elastic solidified foam material in the downhole goaf. After testing, the foaming time of the elastic solidified foam material in the underground goaf area prepared in Example 1 is 1 min, and the curing time is 10 min.

[0047] The filling template construction method is used to prepare the sealing wall of the underground goaf. Two filling templates are set at the predetermined closed wall position in the underground goaf. The distance between the two filling templates is 1m, and the height of the template and the tunnel in the underground g...

Embodiment 3

[0049] An elastic solidified foam material for underground mined-out areas, prepared from raw materials including the following parts by weight: 35 parts of xylylmethane diisocyanate, 5 parts of polyether polyol, and liquid CO 2 2 parts, 3,5-dimethylthiotoluenediamine 3 parts, trimethylolpropane 3 parts, trichloroethyl phosphate (TCEP) 3 parts, polydimethylsiloxane-alkylene oxide copolymer 2 Parts, 1 part of 4,4,-bis(α,α-dimethylbenzyl)diphenylamine, nano SiO 2 5 parts, 0.5 parts of triethylenediamine, 1 part of glutaraldehyde. The above-mentioned raw materials are mixed to obtain an elastic solidified foam material in the downhole goaf. After testing, the foaming time of the elastic solidified foam material in the underground goaf area prepared in Example 1 is 2 min, and the curing time is 10 min.

[0050] The filling template construction method is used to prepare the sealing wall of the underground goaf. Two filling templates are set at the predetermined closed wall position i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com