Method and device for preparing polymeric foam material

A foaming material and polymer technology, which is applied in the field of preparing polymer foaming materials, can solve the problems of uneven cell size of foamed beads, complicated procedures, low production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

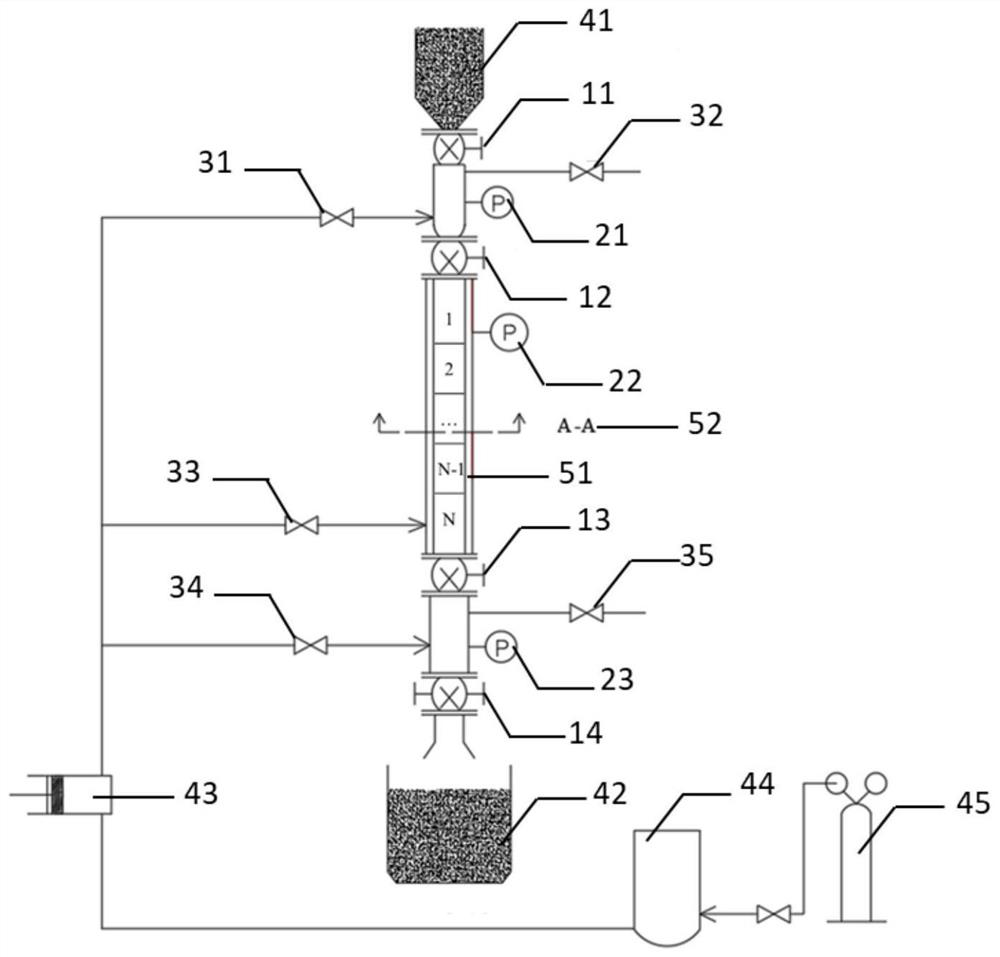

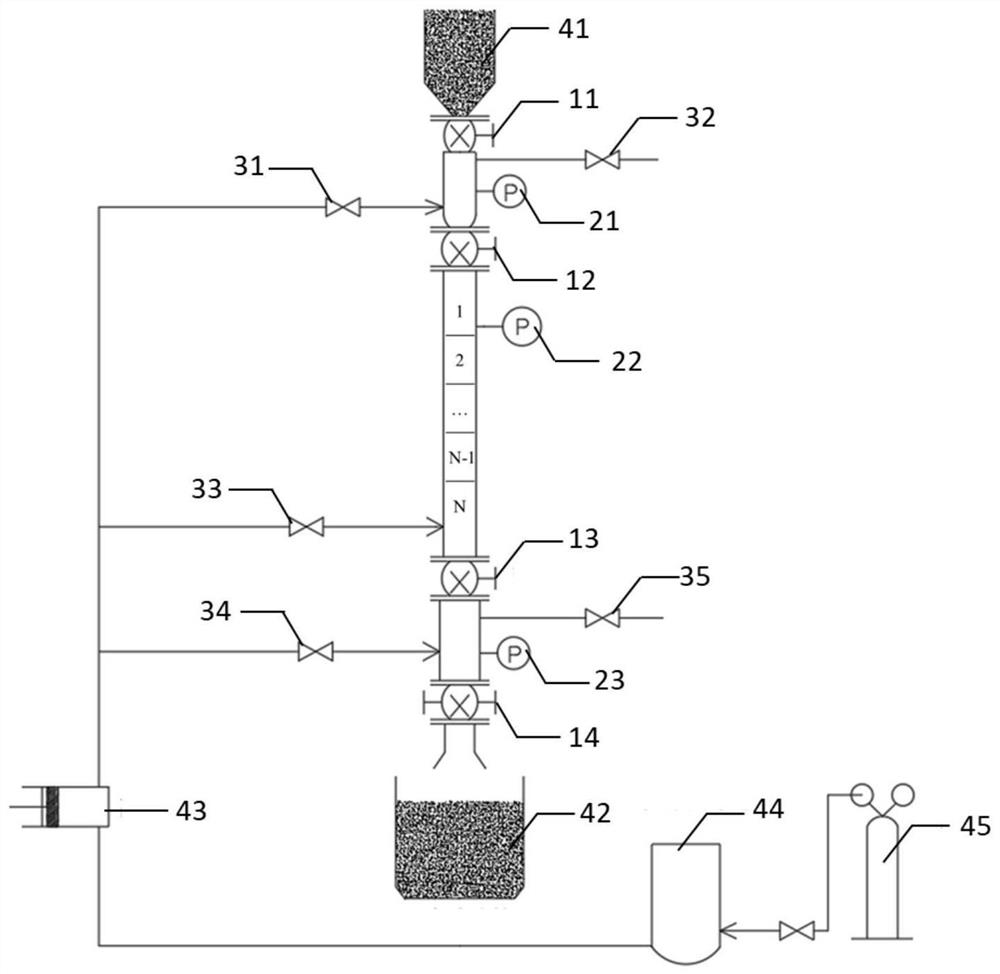

[0132] Such as Figure 10 , Figure 11 and Figure 12 As shown, the present embodiment provides a kind of device for preparing polymer foam material, it comprises:

[0133] The feeding section 21 is provided with a ball valve 111 and a ball valve 212 at both ends respectively, and the lower end of the side wall is connected with the gas outlet end of the high-pressure injection pump 43, controlled by the valve F131, and the upper end of the side wall is also provided with a pipeline connected to the atmosphere, Controlled by valve F2 32; wherein, thermoplastic polypropylene beads are added in the feeding section 21 by opening ball valve 1 11;

[0134] One end of the saturation section 22 is connected to the feeding section 21 through a ball valve 212, and the other end is provided with a ball valve 313, and the lower end of its side wall is connected to the gas outlet of the high-pressure injection pump 43, and is controlled by the valve F333;

[0135] One end of the foamin...

Embodiment 2

[0149] Such as figure 1As shown, the present embodiment provides a kind of device for preparing polymer foam material, and this device except following parts, all the other parts and connections are the same as embodiment 1:

[0150] One end of the foaming section 23 is connected to the saturation section 22 through a ball valve 313, and the other end is provided with a ball valve 414. There is a pipeline connected to the atmosphere, which is controlled by the valve F5 35; among them, the saturated thermoplastic polyurethane beads are added to the foaming section 23 by opening the ball valve 3 13 .

[0151] Concrete preparation steps are as follows:

[0152] ① if figure 1 , pre-fill inert inorganic particles in the moving bed saturation section 22 provided with a radial porous jacket 51, pre-fill thermoplastic polyurethane beads in the feeding section 21, and use CO 2 Replace the internal air. The setting of the porous jacket is the same as in Example 1.

[0153] ②Close b...

Embodiment 3

[0160] The structure of the apparatus for preparing the polymer foam material in this embodiment is the same as that in Embodiment 2.

[0161] Concrete preparation steps are as follows:

[0162] ① if figure 1 , inert inorganic particles are pre-filled in the moving bed saturation section 22 provided with a radial porous jacket 51, thermoplastic polypropylene beads are pre-filled in the feeding section 22, and N 2 Replace the internal air.

[0163] ②Close ball valves 2 12, 3 13, valves F1 31, valves F4 34, open high-pressure injection pump 43, valve F333, maintain a nitrogen saturation pressure of 15 MPa, and heat the saturation section 22 with program temperature control at a heating rate of 5°C / min, and the device was heated to a foaming temperature of 105°C.

[0164] ③Close ball valve 1 11, ball valve 4 14, valve F2 32, valve F5 35, open valve F1 31, valve F4 34, balance the pressure of feeding section 21, foaming section 23 and saturation section 22, all set to 15MPa, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com