Apparatus for equalizing the tensions among elevator wire ropes

A technology of tension uniformity and steel wire rope, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problems of unbalanced steel wire rope, uneven tension of steel wire rope, and difference in length of steel wire rope, etc., to achieve uniform tension, improve stability, improve durability and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

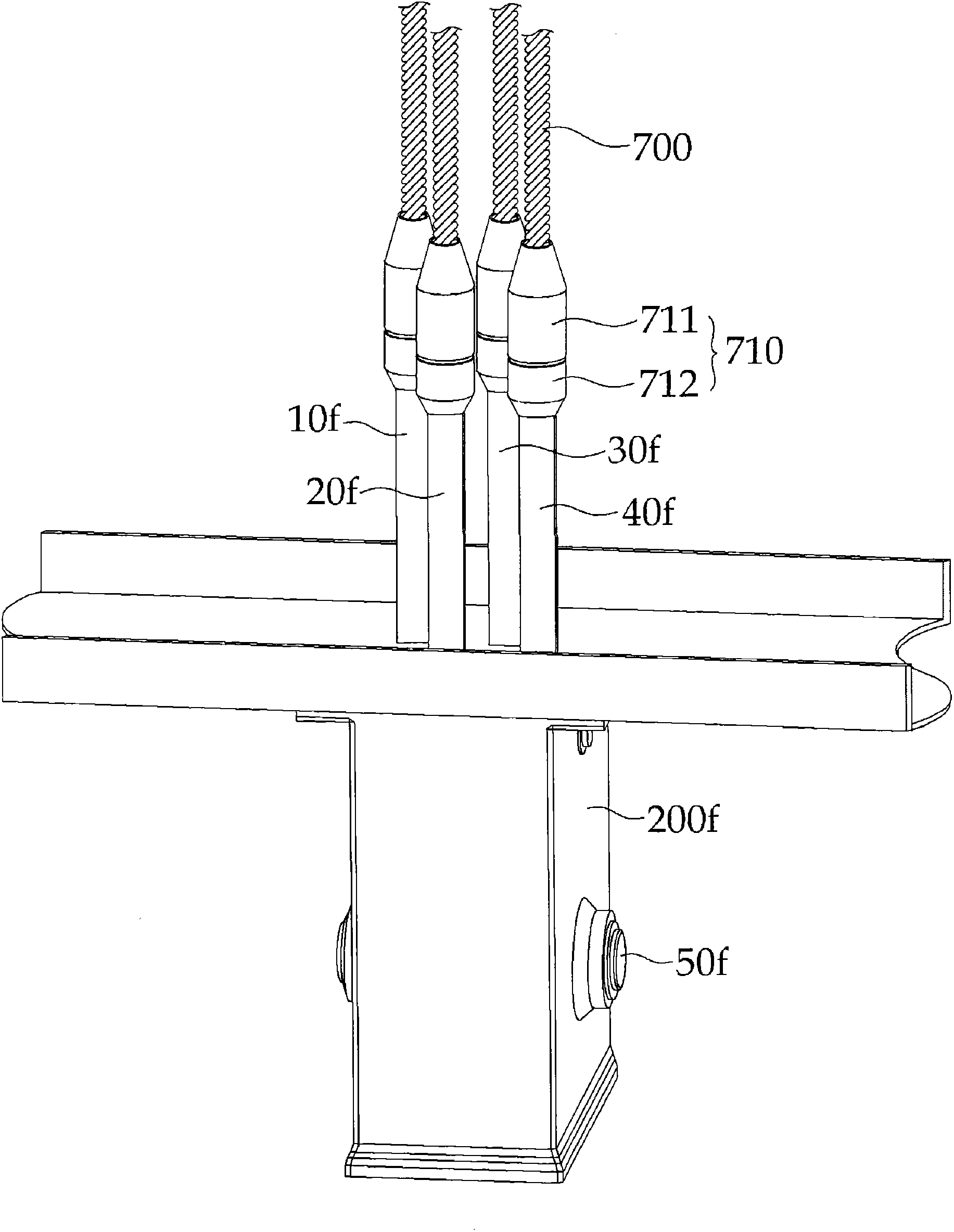

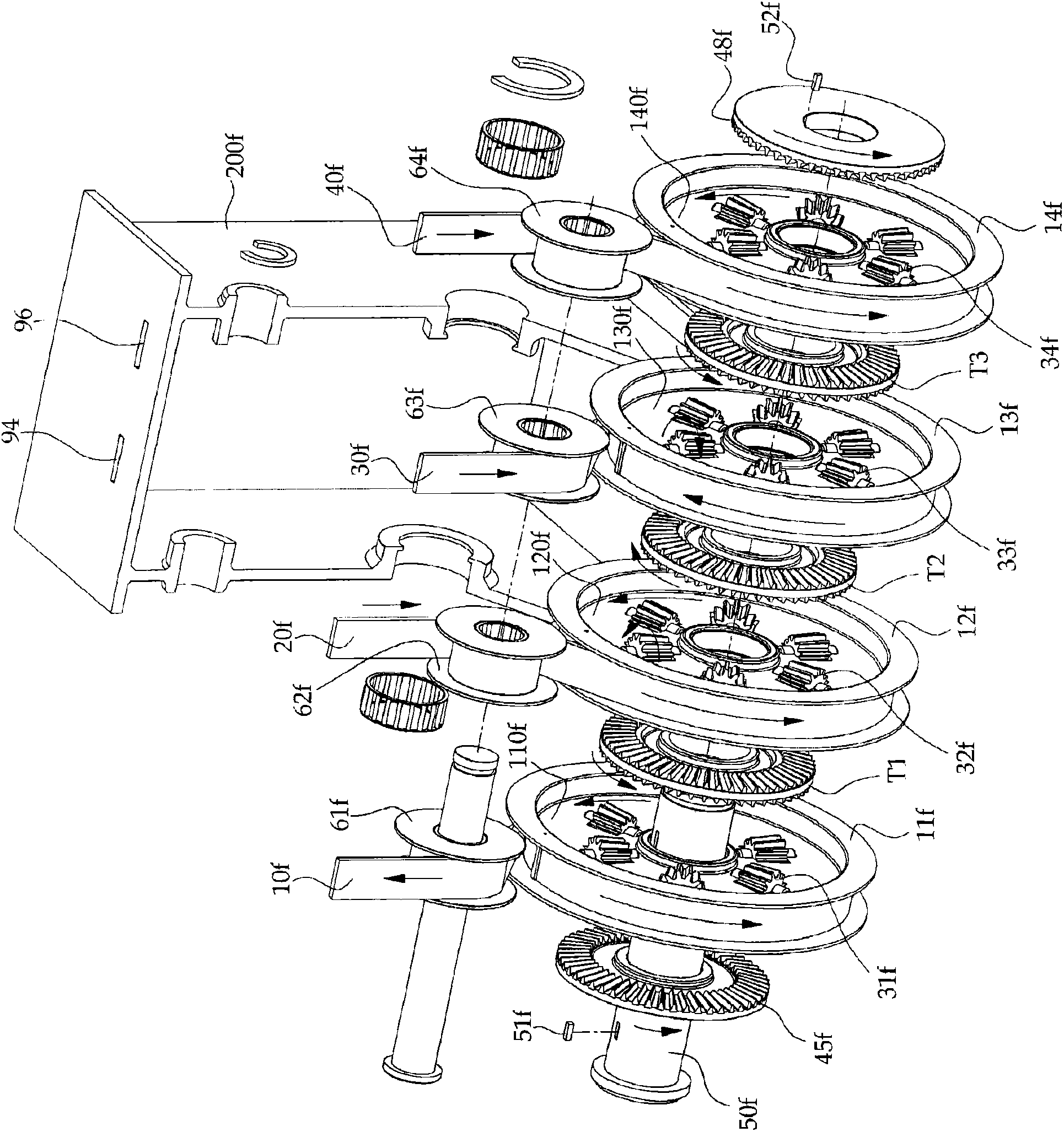

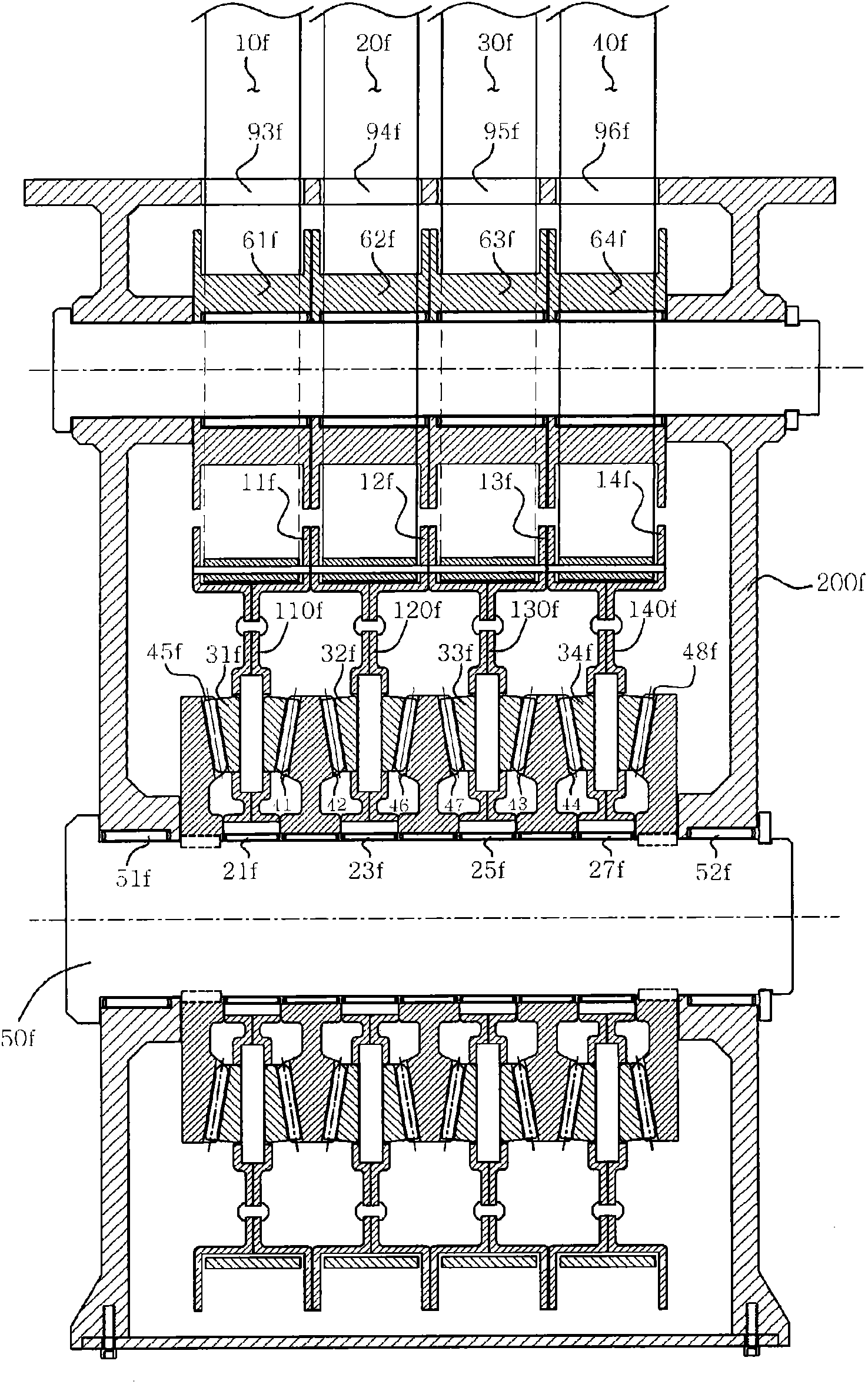

[0027] figure 1 It is a perspective view showing an installation example of the elevator wire rope tension equalization device of the present invention, figure 2 It is an exploded perspective view showing the elevator wire rope tension equalization device according to the first embodiment of the present invention, image 3 is a front sectional view showing an elevator wire rope tension equalization device according to a first embodiment of the present invention, Figure 4 It is a side sectional view showing the elevator rope tension equalization device according to the first embodiment of the present invention.

[0028] Such as Figure 1 to Figure 4 As shown, the elevator wire rope tension equalization device according to the first embodiment of the present invention includes: a main body 200f formed with an accommodation space inside; combined with a plurality of belts 10f, 20f, 30f, 40f connected to the elevator wire rope 700, and set The tension adjustment mechanism in ...

no. 2 example

[0080] Figure 5 It is an exploded perspective view showing an elevator wire rope tension equalization device according to a second embodiment of the present invention, Figure 6 It is a combined perspective view showing an elevator wire rope tension equalization device according to a second embodiment of the present invention, Figure 7 It is a front sectional view showing an elevator wire rope tension equalization device according to a second embodiment of the present invention, Figure 8 It is a diagram showing an operation example of the elevator rope tension equalization device according to the second embodiment of the present invention.

[0081] Such as Figure 5 to Figure 8 As shown, the elevator wire rope tension equalization device according to the second embodiment of the present invention includes: a main body 200 with an accommodation space formed on the inside; a tension force that is combined with a plurality of belts connected to the elevator wire rope 700 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com