Rapier loom edge fabric yarn guide device

A technology of rapier looms and yarn guide devices, which is applied in the fields of looms, textiles, textiles, and papermaking. It can solve the problems of reduced warp tension of waste edges, reduce breakage, improve the quality of waste edges, and prevent tension from breaking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

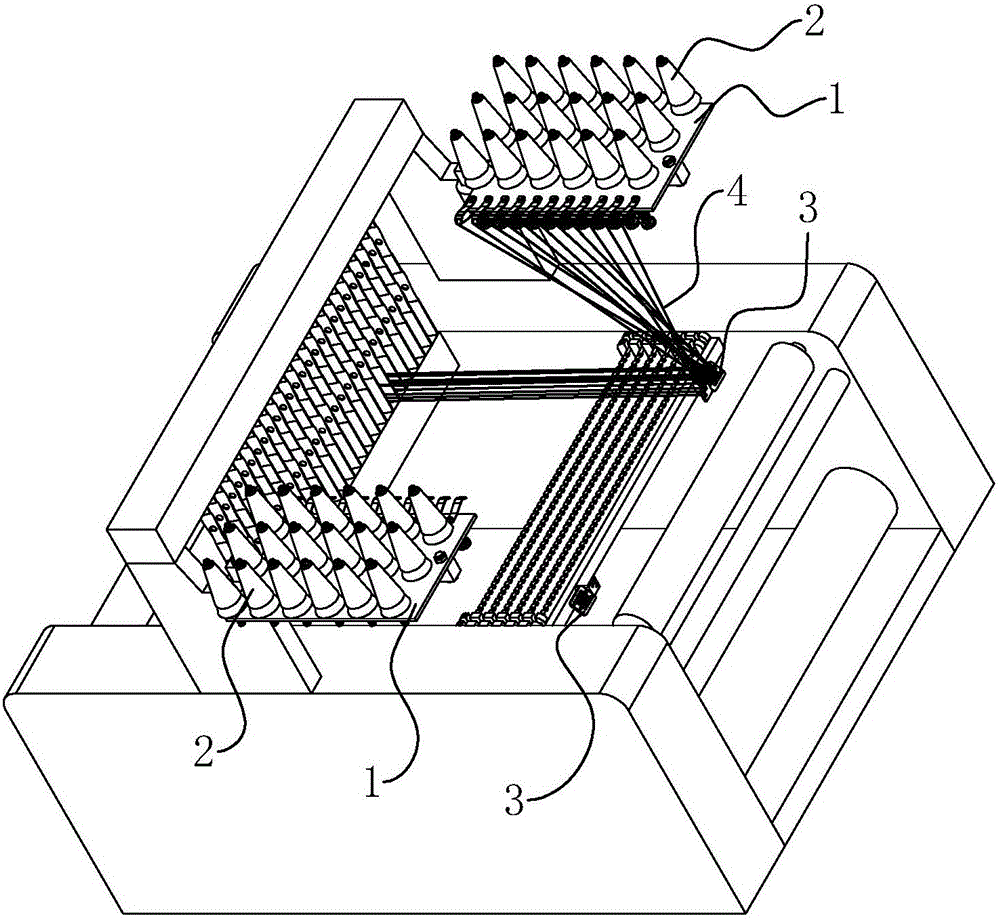

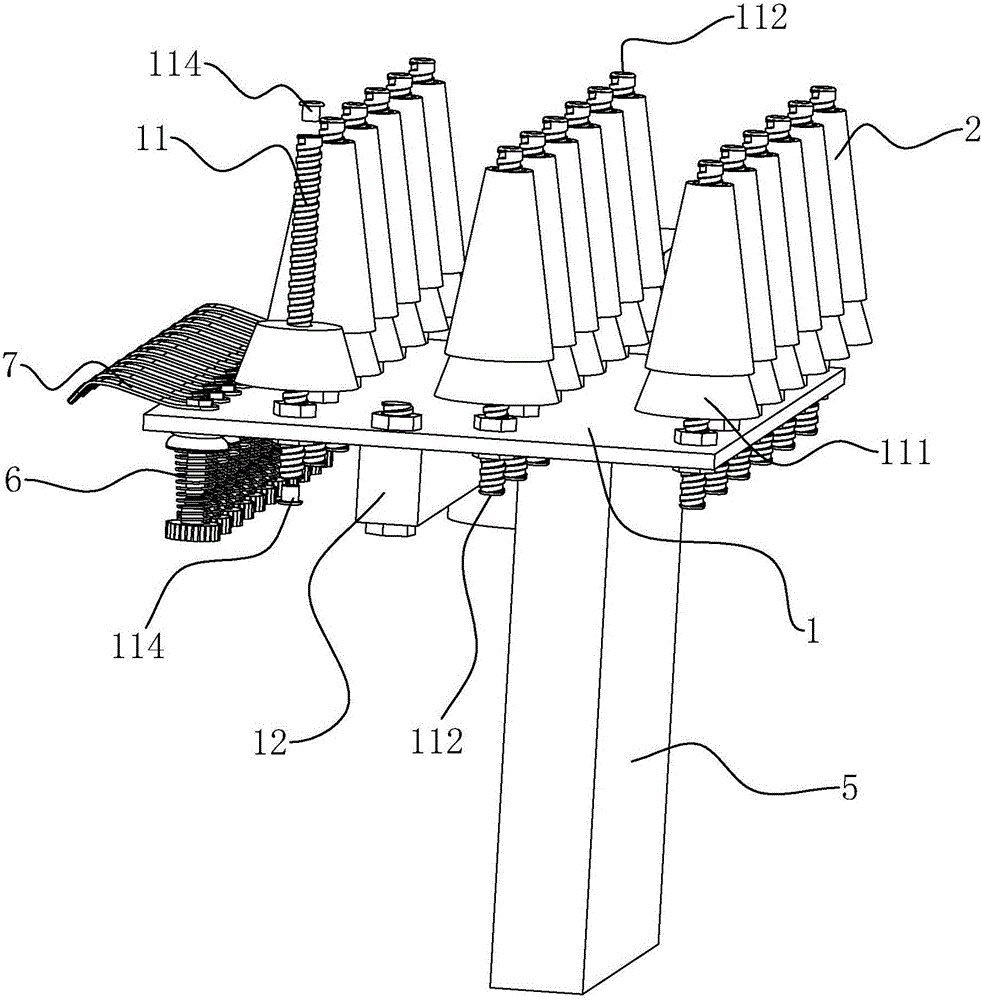

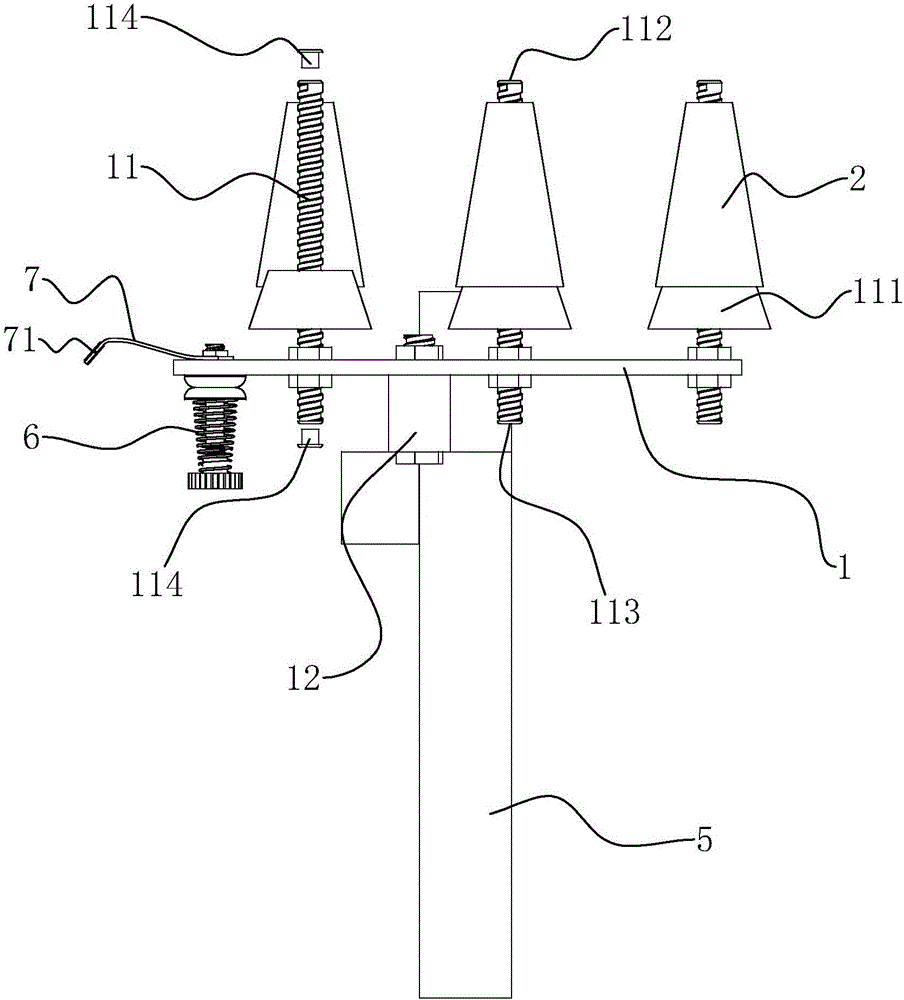

[0052] Embodiment 1: A kind of side cloth guide device of rapier loom, such as figure 1 As shown, it includes a creel platform 1 and a threading plate 3, and the threading plate 3 is provided with several yarn guide holes; the creel platform 1 is arranged horizontally, and a connecting rod 12 is fixedly connected to the bottom of the creel platform 12, and one end of the connecting rod 12 protrudes from the creel platform 1 It is rotatably connected with a support 5, and the support 5 is fixedly connected on the rapier loom by bolts.

[0053] refer to figure 2 , A number of through holes are arranged on the creel platform 1, and the through holes are arranged in an array. In this embodiment, the through holes are arranged in three rows, and the number of each row is six. Wherein, a yarn rod 11 is inserted into each through hole, and the surface of the yarn rod 11 is provided with external threads, which are clamped and fixed on the creel platform 1 by two nuts respectively l...

Embodiment 2

[0062] Embodiment 2: as Figure 5 and Figure 6 As shown, the difference from Embodiment 1 is that an oiling mechanism is also provided at the bottom end of the creel table 1, and the oiling mechanism is located between the two rows of yarn rods 11 near the tension regulator 6, and the oiling mechanism includes The oil pot 84 and the oil core inserted in the oil pot 84 are connected with the wool felt 81 between the oil core and a discharge yarn opening 113 close to the tension regulator 6 .

[0063] Among them, refer to Figure 7 , Figure 8 and Figure 10 One end of the wool felt 81 is connected with a felt belt 82, and the two ends of the felt belt 82 are integrally connected to the wool felt 81 to form a ring structure, and an elastic belt is connected to the felt belt 82, and the elastic belt and the felt belt 82 form a circular collar. The shape collar is set on the yarn outlet 113 of the yarn rod 11 to realize the connection between the wool felt 81 and the yarn out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com