Blowing corrosion machine and method for corrosion and cleaning

A technology of etching machine and blowing bottle, which is applied in the field of chemical etching process, manufacturing, and device design of this process. It can solve the problems of poor corrosion marks on wafers, ineffective dispersion and dissociation of wafers, and limited production capacity, and achieve installation and disassembly operations. Convenience, simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

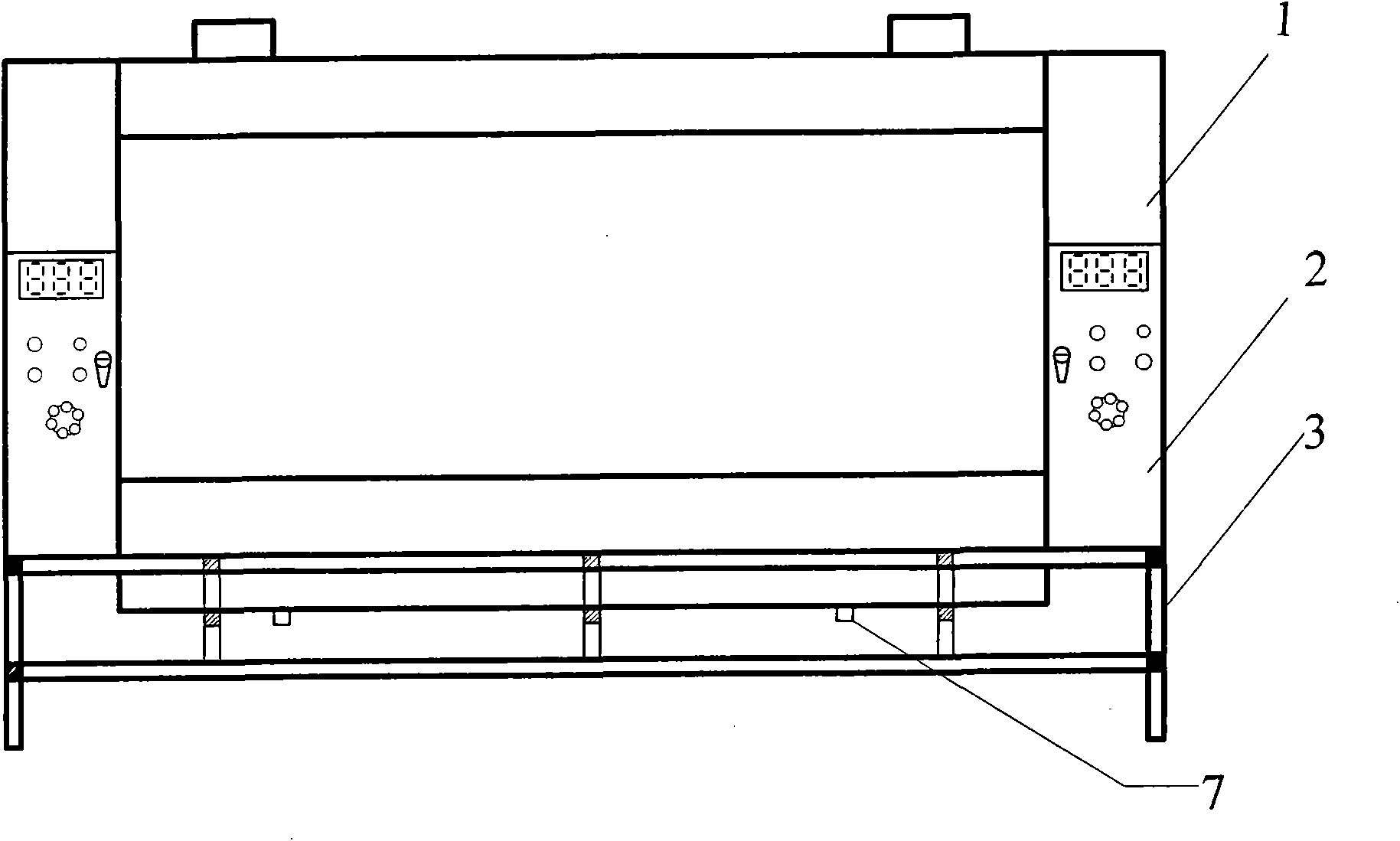

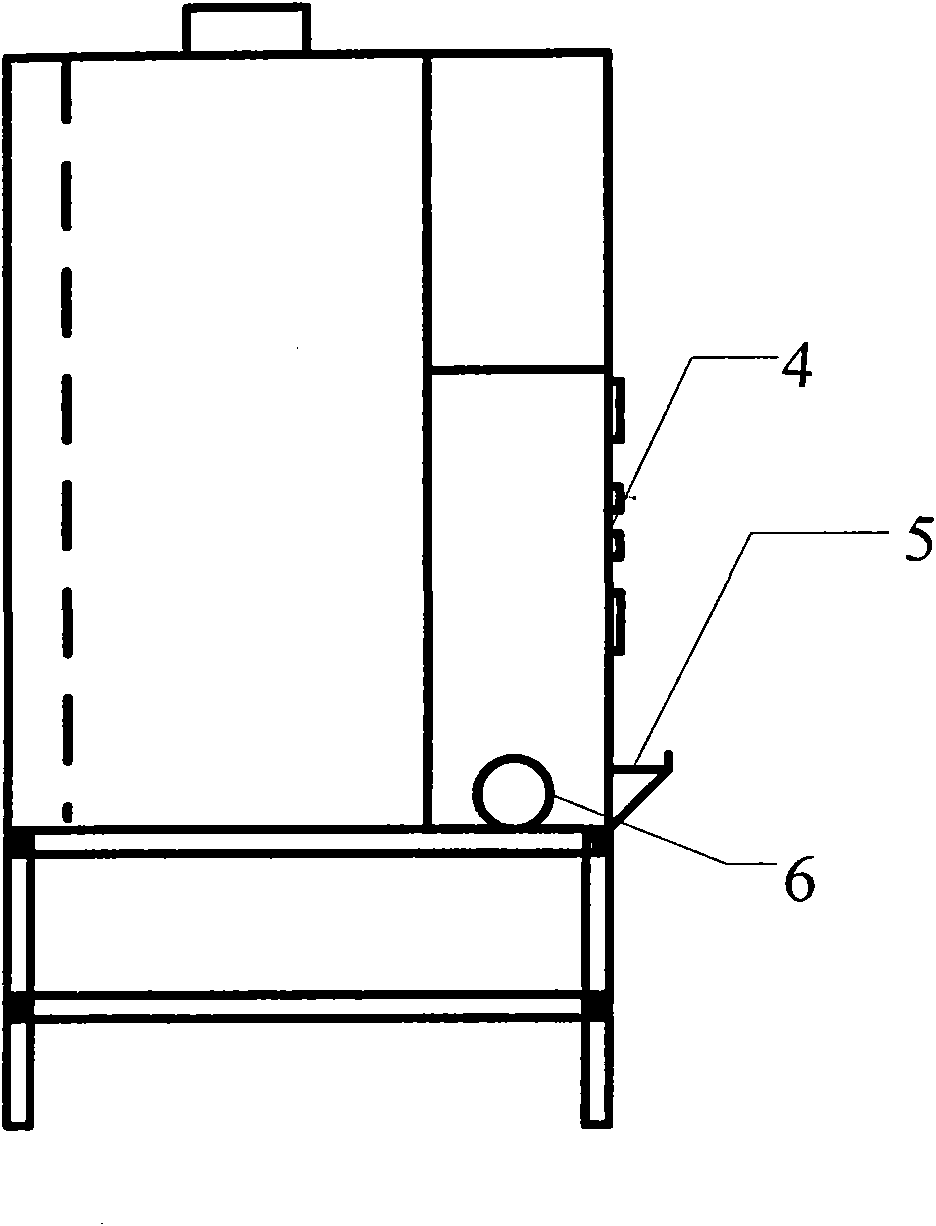

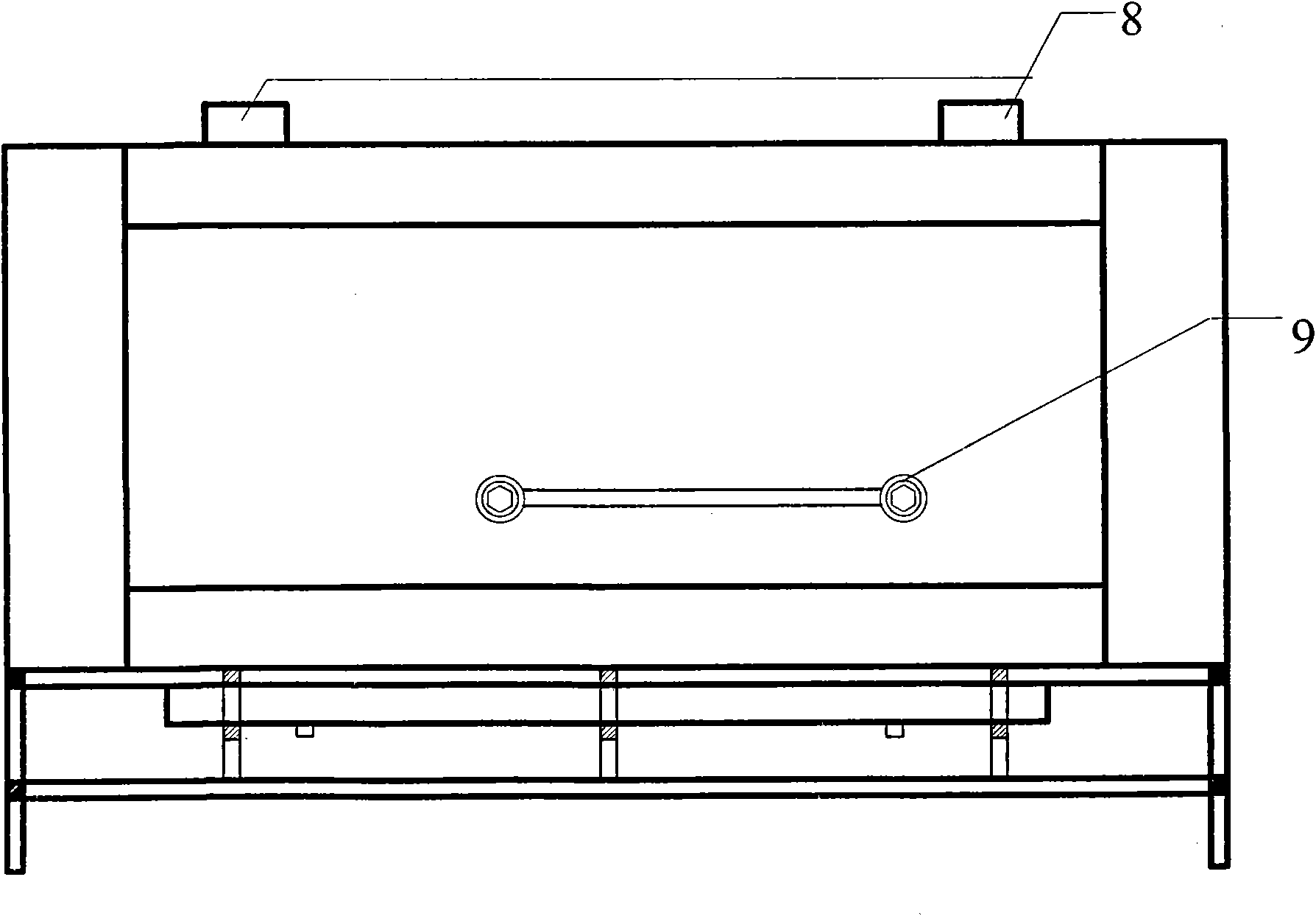

[0017] Control attached Figure 1-3 , its structure includes PVC board box 1, electrical control cabinet 2, stainless steel square pipe bracket 3, controller 4, waste liquid overflow tank 5, sewage outlet 7, exhaust fan hole 8, PPR water supply pipe 9, among which the electrical control cabinet 2 is set on both sides of the PVC board box 1, the stainless steel square pipe support 3 is under the PVC board box 1 to support the PVC board box 1, the control device 4 is set in the electrical control cabinet 2, and the waste liquid overflow tank 5 is integrated with the PVC board box body 1, and the sewage outlet 7 is established at the bottom of the PVC board box body 1, and the exhaust fan hole 8 is opened above the PVC board box body 1, and the PPR water pipe 9 is established at the back side of the PVC board box body 1. Corrosion solution tank, pure water tank, hot water tank are installed in the PVC board box body 1.

[0018] Control attached Figure 4 , its internal structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com