Method for producing high-strength cr-ni alloy seamless pipe

A manufacturing method and high-strength technology are applied in the manufacturing field of high-strength Cr-Ni alloy seamless pipes, which can solve problems such as insufficient research and achieve the effects of excellent hot workability and stress corrosion cracking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

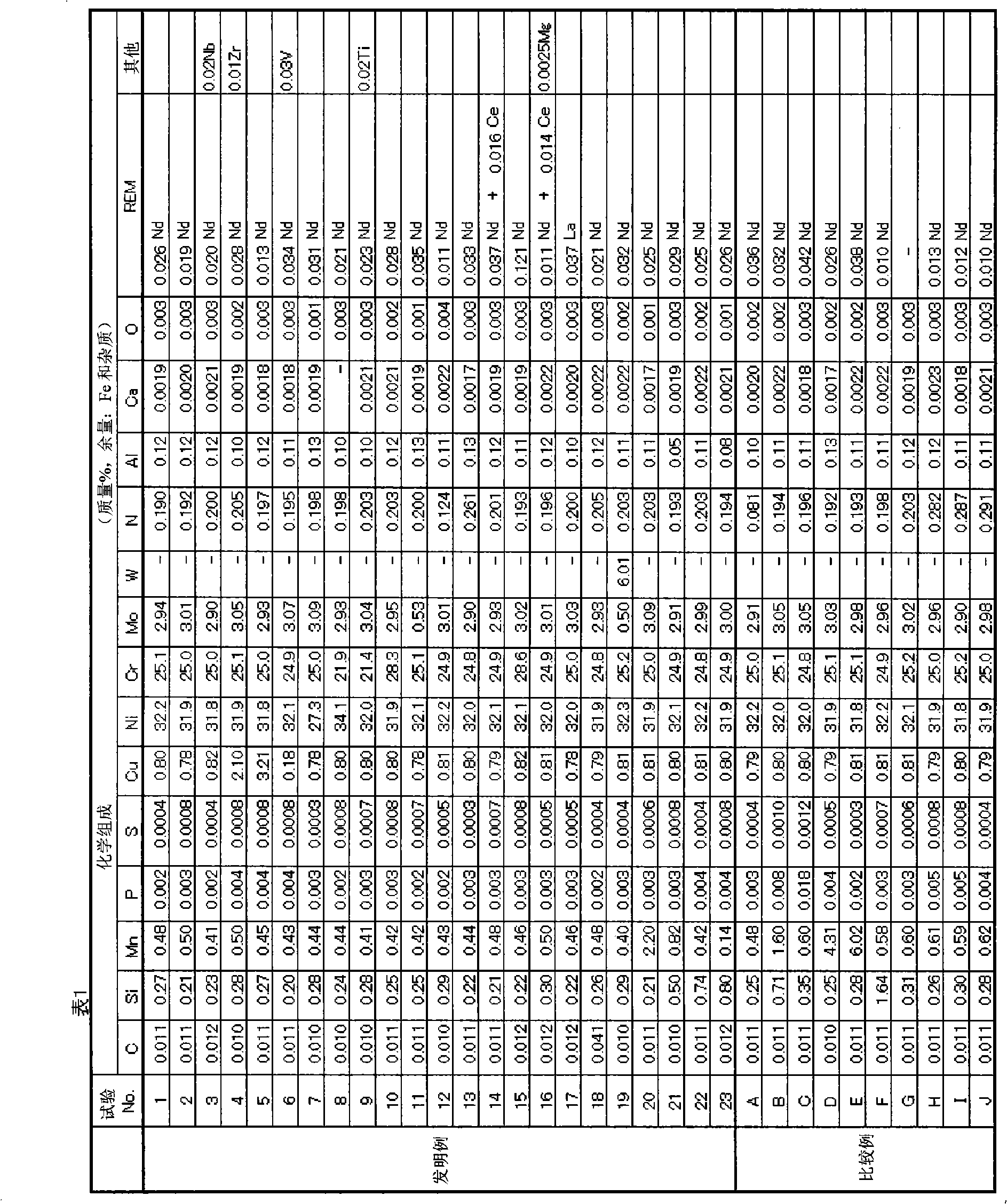

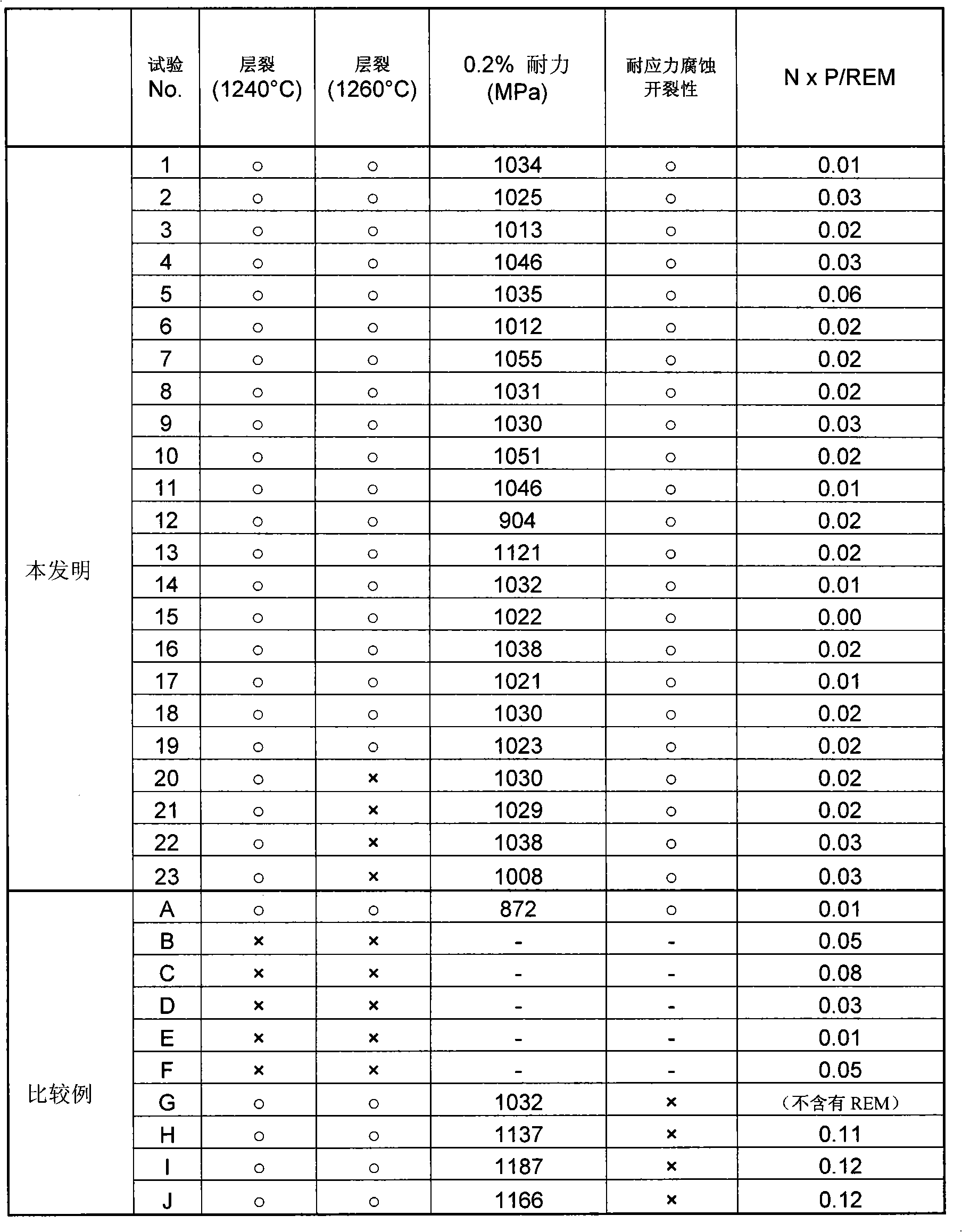

[0096] In Table 1, the chemical composition (mass %) of the example (test No. 1-23) of this invention and a comparative example (test No.A-J) is shown. The alloy of the example of the present invention was melted and ingot-cast using a vacuum induction electric melting furnace, and cast into a 30 kg ingot. This ingot was hot forged to form a billet with an outer diameter of 100 mm. The billet heated at 1240°C and 1260°C was pierced and rolled by a small inclined piercing and rolling device, and the pipe was made into a pipe with an outer diameter of 116mm and a thickness of 20mm.

[0097]

[0098] The rear end of the pierced and rolled seamless billet was cut into circular pieces at a position of 50 mm in the longitudinal direction, and the presence or absence of lamination of the billet was checked. It was judged as (◯) if spalling did not occur, and as (×) if it occurred.

[0099] In addition, the seamless steel pipe obtained by heating at 1240° C., piercing and rolling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com