Automatic device used for blowing making of bottle blank of vertical type transfusion bag

A technology of automation devices and infusion bags, applied in applications, household appliances, household components, etc., can solve the problems of quality risk, high risk of foreign matter, and many operators, so as to reduce the risk of foreign matter, optimize the process, and shorten the distance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

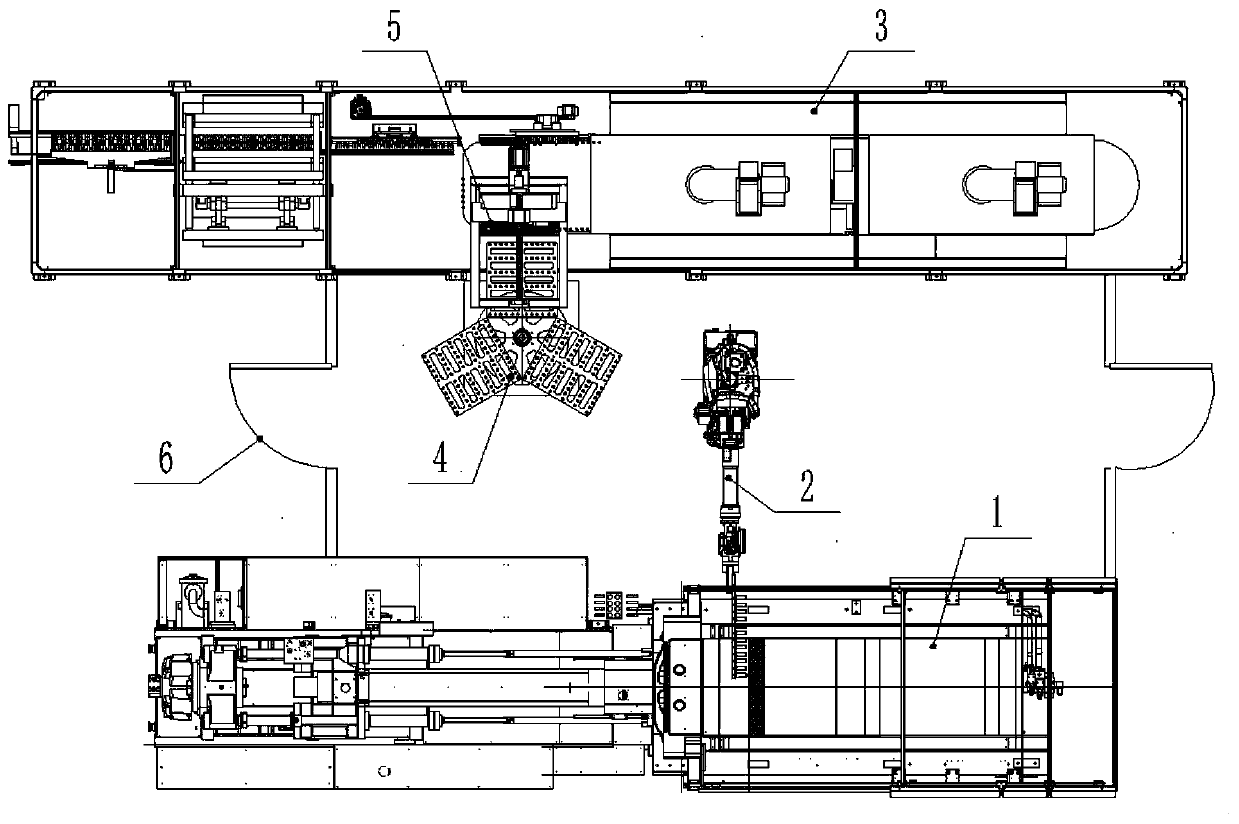

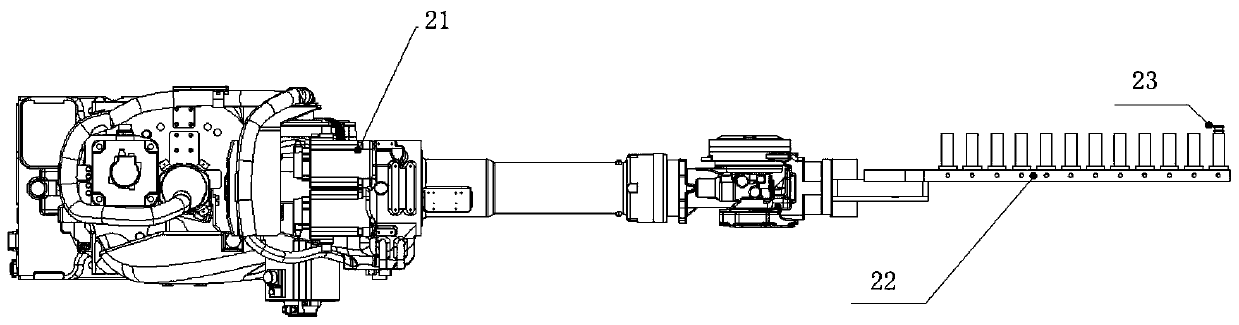

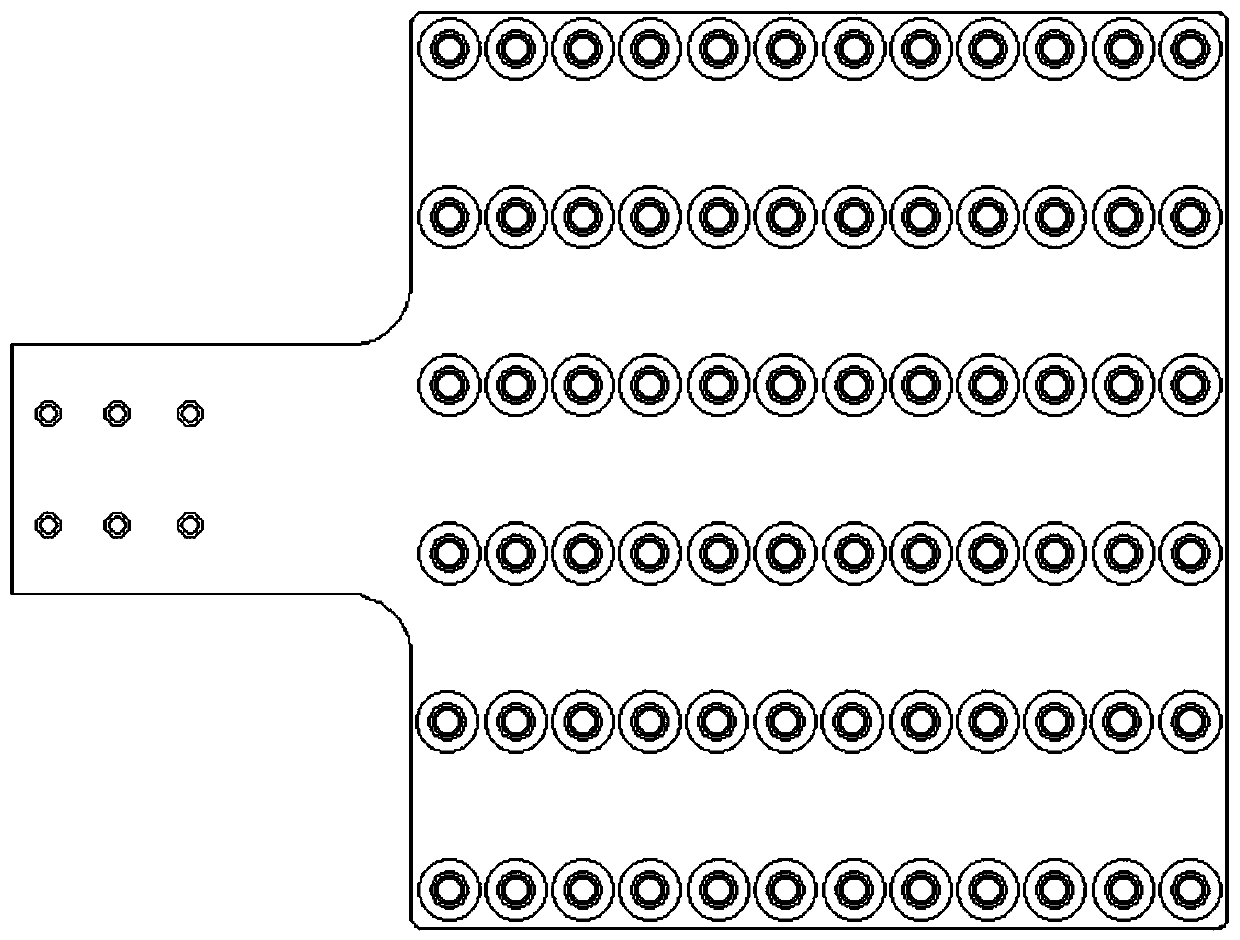

[0034] Such as figure 1 As shown, an automatic device for blowing preforms of upright infusion bags, including bottle blowing equipment 3 and injection molding equipment 1, the bottle blowing equipment 3 and injection molding equipment 1 are arranged in parallel, and the distance between the two equipment is about 3 meters . And between the bottle blowing equipment 3 and the injection molding equipment 1, a preform 23 transfer system is installed, and the preform 23 transfer system includes a blanking mechanical device 2 for taking out the preform 23 injected in the injection molding equipment 1. The preforms 23 are temporarily stored on the transfer table 4 and the feeding mechanism 5 is used to send the preforms 23 on the transfer table 4 to the large chain pallet of the blow molding equipment 3 .

[0035] In this embodiment, the injection molding equipment 1 is a high-speed injection molding equipment 1 with a matching mold. The high-speed injection molding equipment 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com