Filling machine integrated with blanking, bottle blowing, cleaning, filling and sealing

A filling machine and sealing technology, applied in bottling machines, bottle filling, packaging, etc., can solve the problems of particle bottle introduction and pollution, and achieve the effect of clean bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

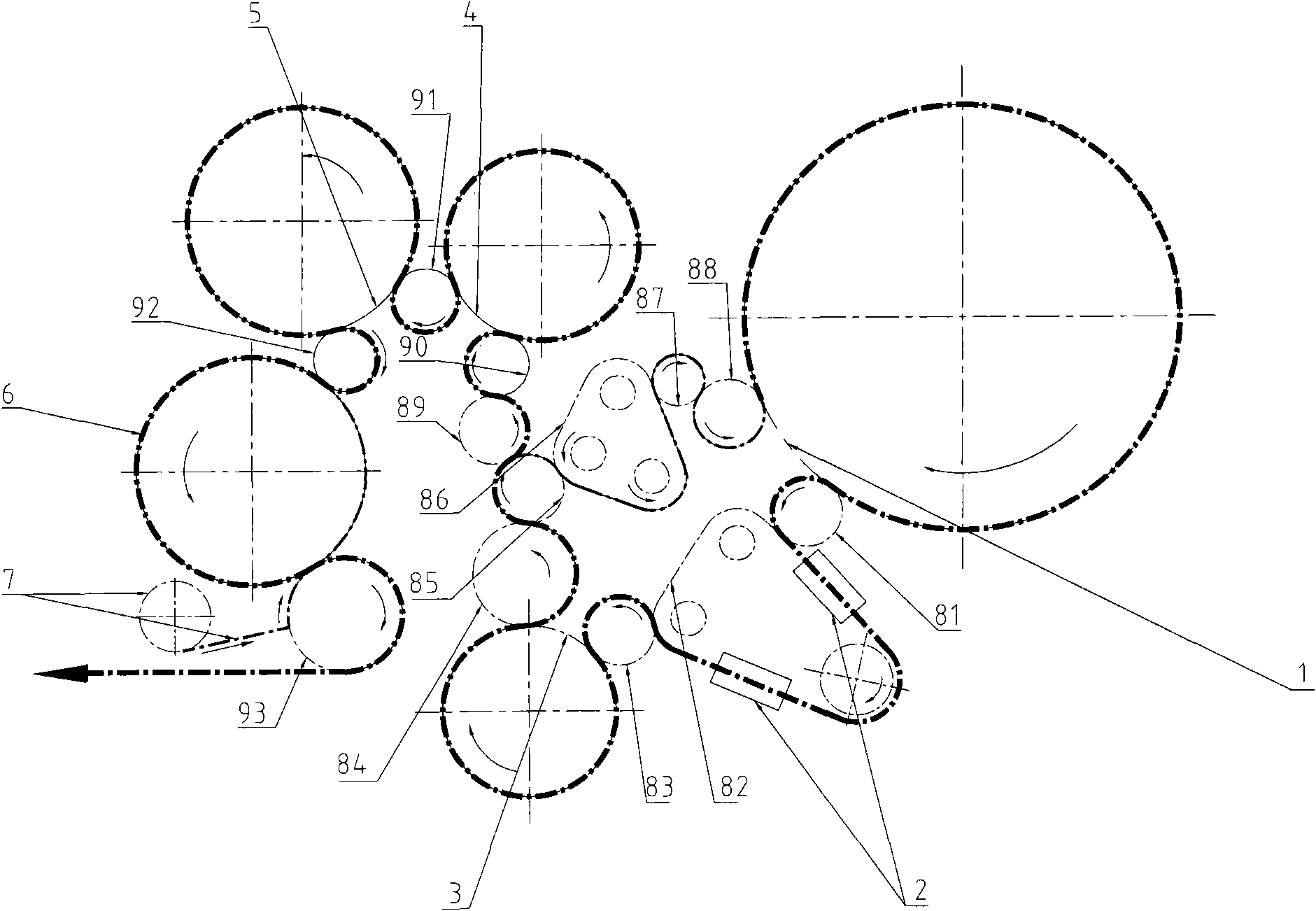

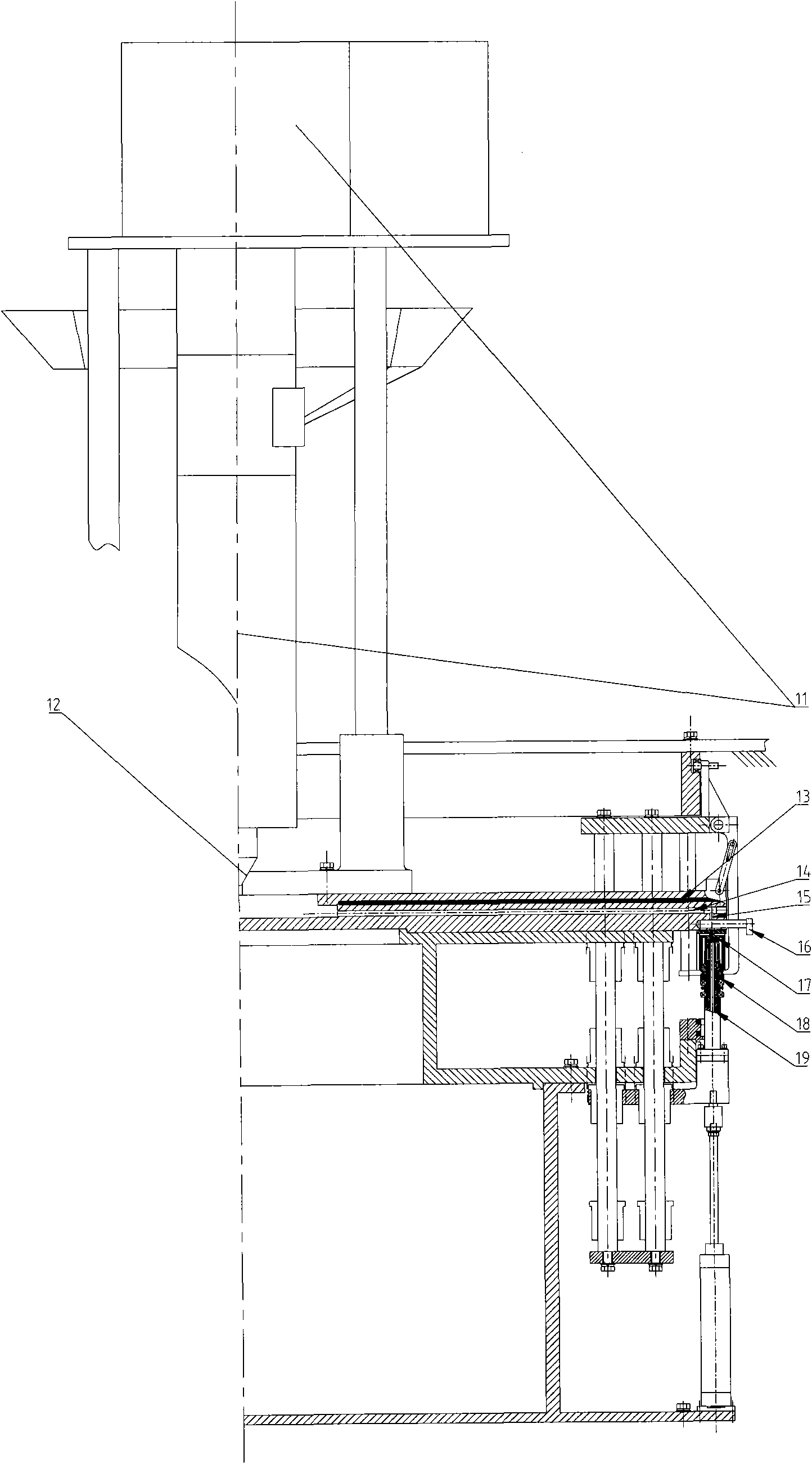

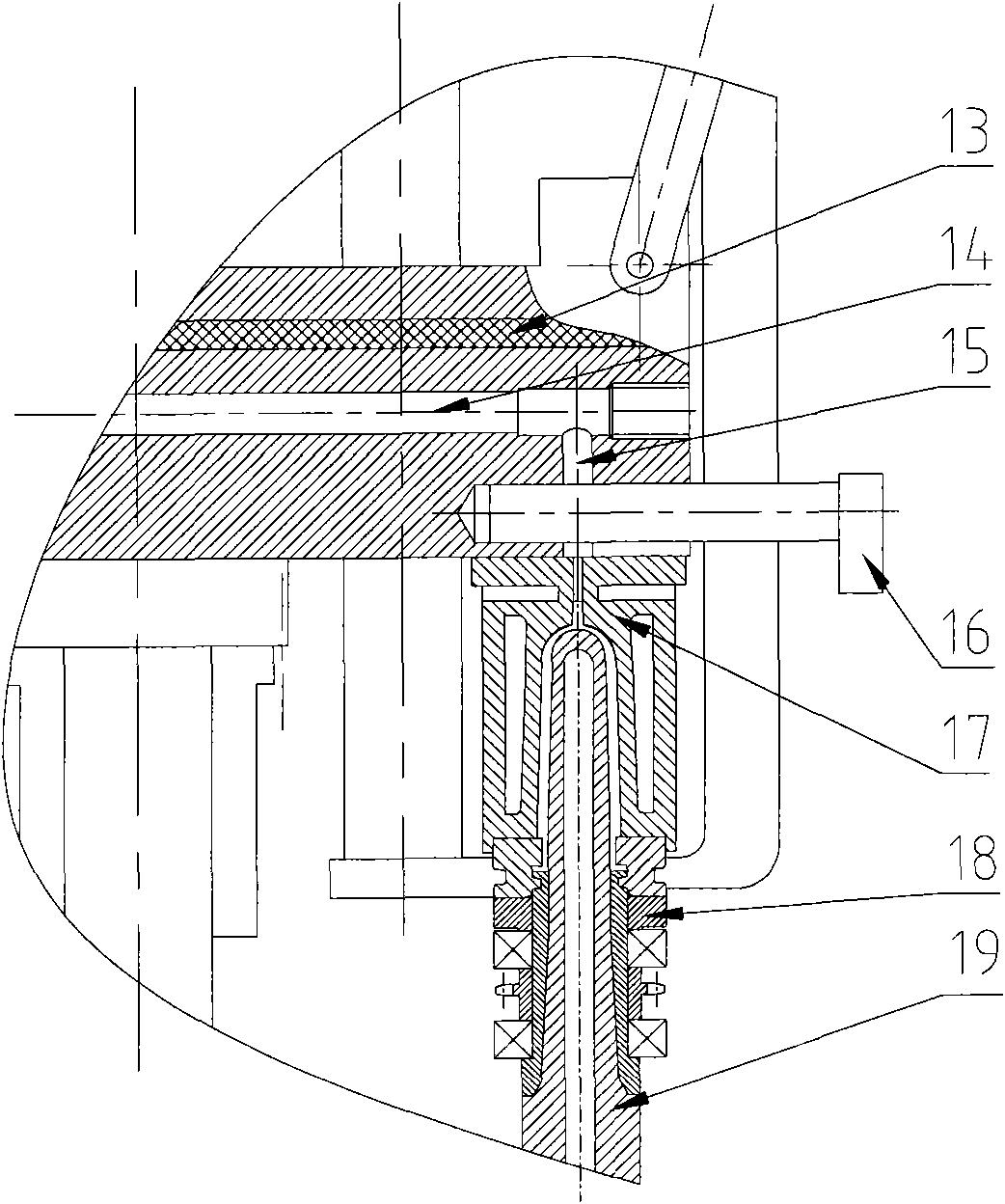

[0026] figure 1 The process flow structure of an embodiment of the present invention is schematically shown. see in conjunction Figure 2-7 , as shown in the figure, in an embodiment of the present invention, a filling machine integrating preform making, bottle blowing, cleaning, filling and sealing is provided, which includes: preform making system 1 for manufacturing bottle Embryo 98; heating system 2, when the preform 98 made passes through the heating system 2, the preform 98 is properly heated to be suitable for blowing the preform 98 into a bottle 99; The preform 98 is blown into a bottle 99; the cleaning system 4 is used to clean the particles adsorbed on the inner wall of the bottle 99, wherein, preferably, the cleaning system 5 is an ion wind cleaning system or a water cleaning system; the filling system 5 is used for clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com