Radiator, engine cooling system comprising radiator and engine

A radiator and net cover technology, applied in the cooling of the engine, machine/engine, engine components, etc., can solve the problems of non-rotating fans, poor reliability, and easy jamming of electric push rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

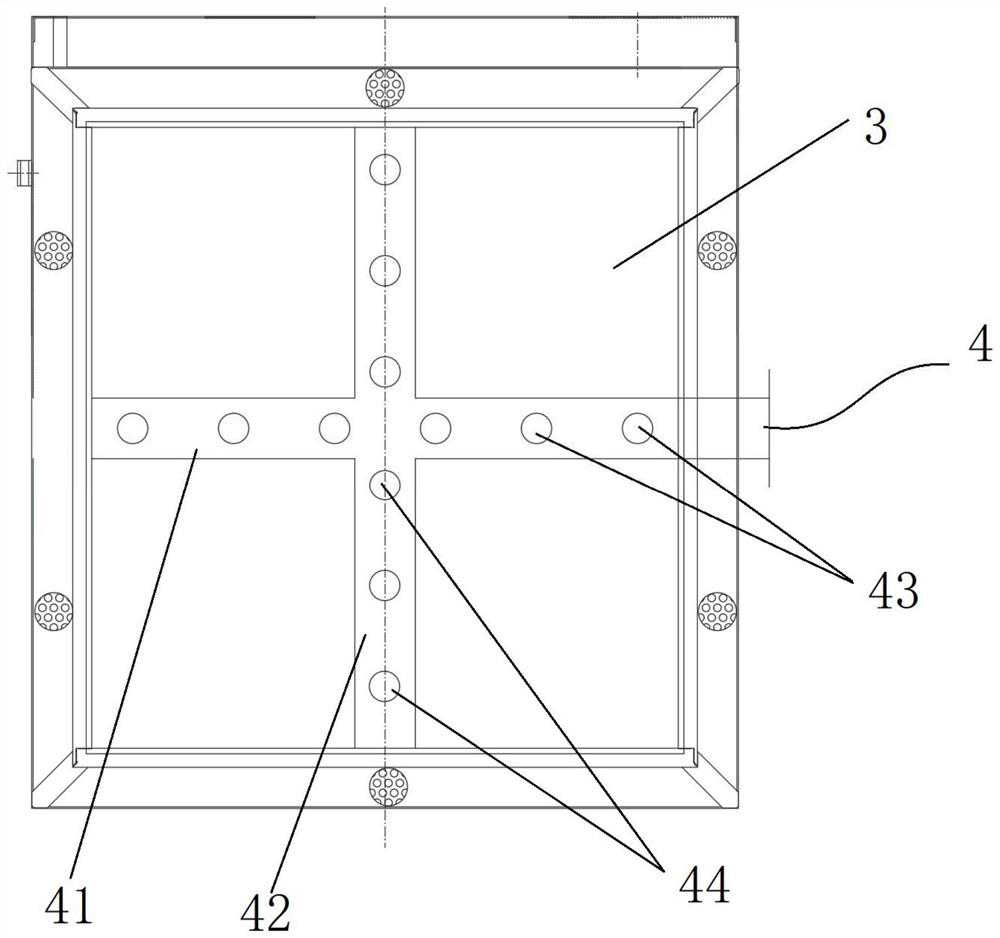

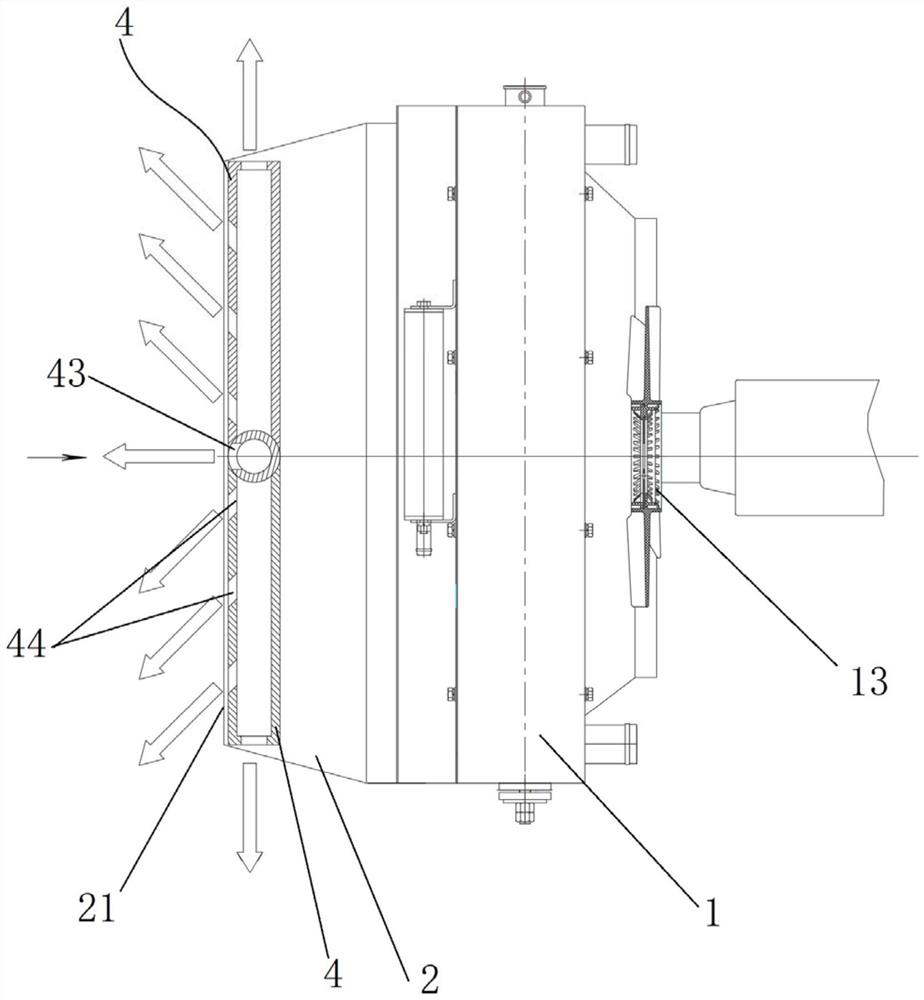

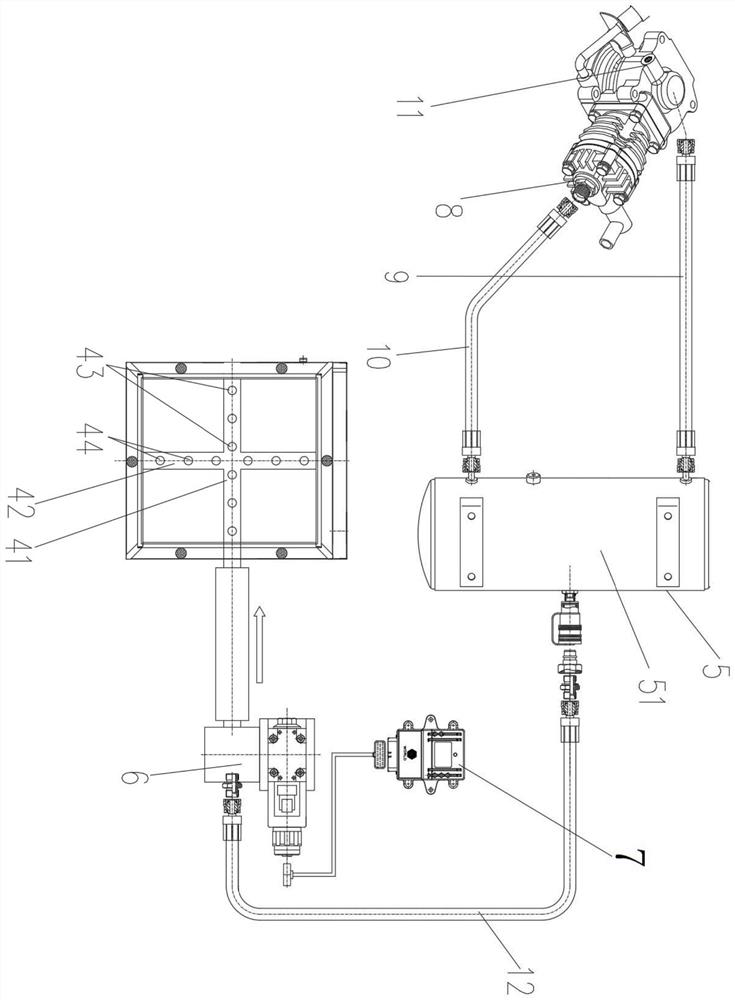

[0036] This embodiment describes a radiator, see Figure 1-Figure 3 , the radiator includes a box body 1, a net cover 2 and a cleaning device, wherein the box body 1 is a water tank, and the net cover 2 is detachably installed on the box body 1, wherein a water circuit is set inside the water tank cover, and the water tank cover A fan 13 is set on one side of the water tank, and the engine cooling water is cooled by using the fan 13. A net cover 2 is set outside the water tank, specifically on the other side away from the fan on the water tank. When cooling the engine cooling water, the impurities on the impurity intercepting surface 21 on the net cover 2 are adsorbed by the wind. After the impurities are covered with the impurity intercepting surface 21, they have a certain thickness, such as straw, bean grass and other debris. An installation cavity 3 is formed between the body 1 and the net cover 2. The cleaning device is arranged on the side of the installation cavity 3 cl...

Embodiment 2

[0049] This embodiment describes an engine cooling system, including a cooling circuit and the radiator described in Embodiment 1, wherein the cooling circuit circulates cooling water for the engine body, and the cooling circuit is arranged in the radiator casing 1, The engine cooling system has good cooling effect, can be used under different working conditions, and has high reliability.

Embodiment 3

[0051] This embodiment describes an engine, which includes the engine cooling system described in Embodiment 2, and the engine can be continuously and well cooled by using the cooling system to ensure engine performance. Apparently, the above-mentioned embodiments are only examples for clear description, rather than limiting the implementation. For those of ordinary skill in the art, on the basis of the above description, other changes or changes in different forms can also be made. It is not necessary and impossible to exhaustively list all the implementation manners here. And the obvious changes or changes derived therefrom are still within the scope of protection of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com