Cleaning machine

A cleaning machine and cleaning mechanism technology, applied in the direction of dryers, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of elongating the size of the whole machine, increasing the floor area of the whole machine, and poor drying effect, etc. Achieve the effect of reducing the floor area, simple and compact structure, and improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

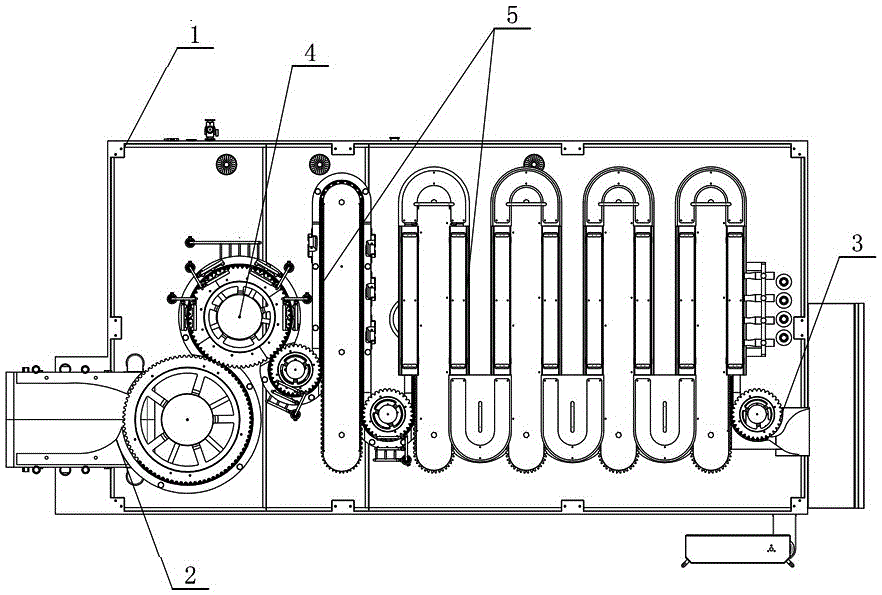

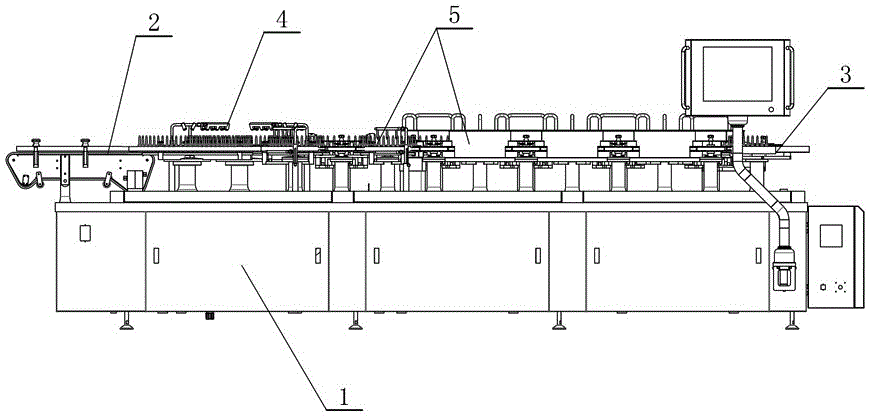

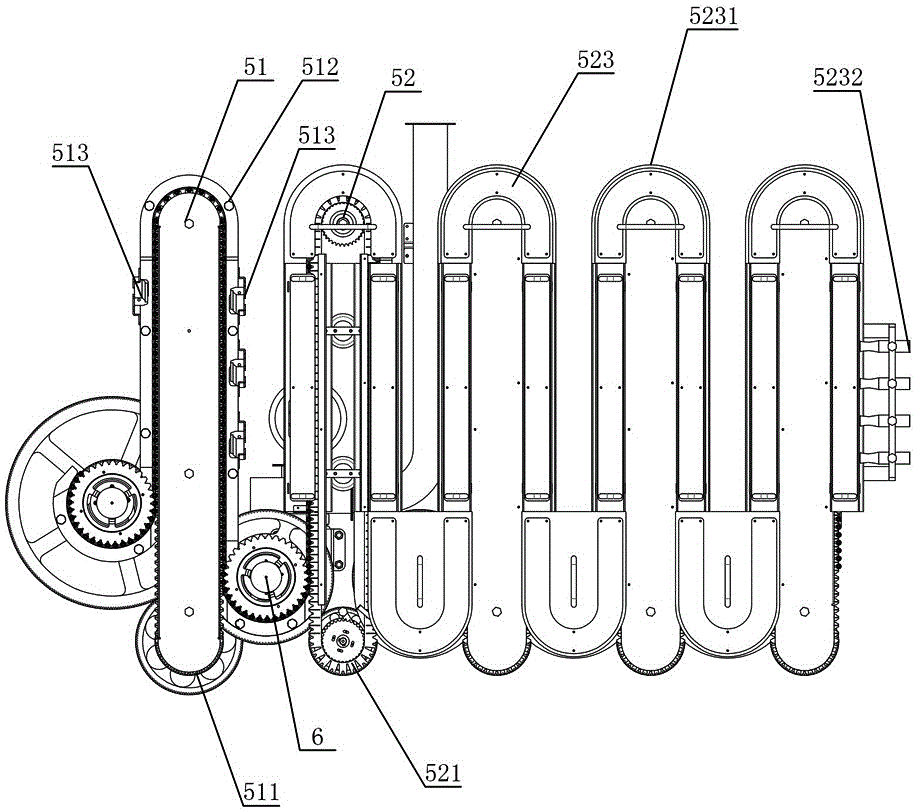

[0031] Figure 1 to Figure 10 A kind of embodiment of cleaning machine of the present invention is shown, and this cleaning machine comprises frame 1, and frame 1 is respectively equipped with bottle-feeding mechanism 2 and bottle-out mechanism 3 in the head and tail section, and frame 1 is on bottle-feeding mechanism 2 A cleaning mechanism 4 docked with the bottle inlet mechanism 2 is installed between the bottle outlet mechanism 3, and a bottle blowing conveying mechanism 5 with an S-shaped bottle delivery path is docked between the cleaning mechanism 4 and the bottle outlet mechanism 3 on the frame 1 . In this structure, the bottle body enters the cleaning mechanism 4 through the bottle feeding mechanism 2 for cleaning, and then enters the bottle blowing conveying mechanism 5 in an S-shaped bottle conveying path for blowing and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com