Method for controlling blowing bottle of automatic bottle blowing machine with dual-station

A control method and technology of a blowing machine, applied in the field of blowing control, can solve the problems of inconsistent actions, inability to overcome the mold base, and different lengths of the material tubes, and achieve the effect of ensuring the process requirements and improving the product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

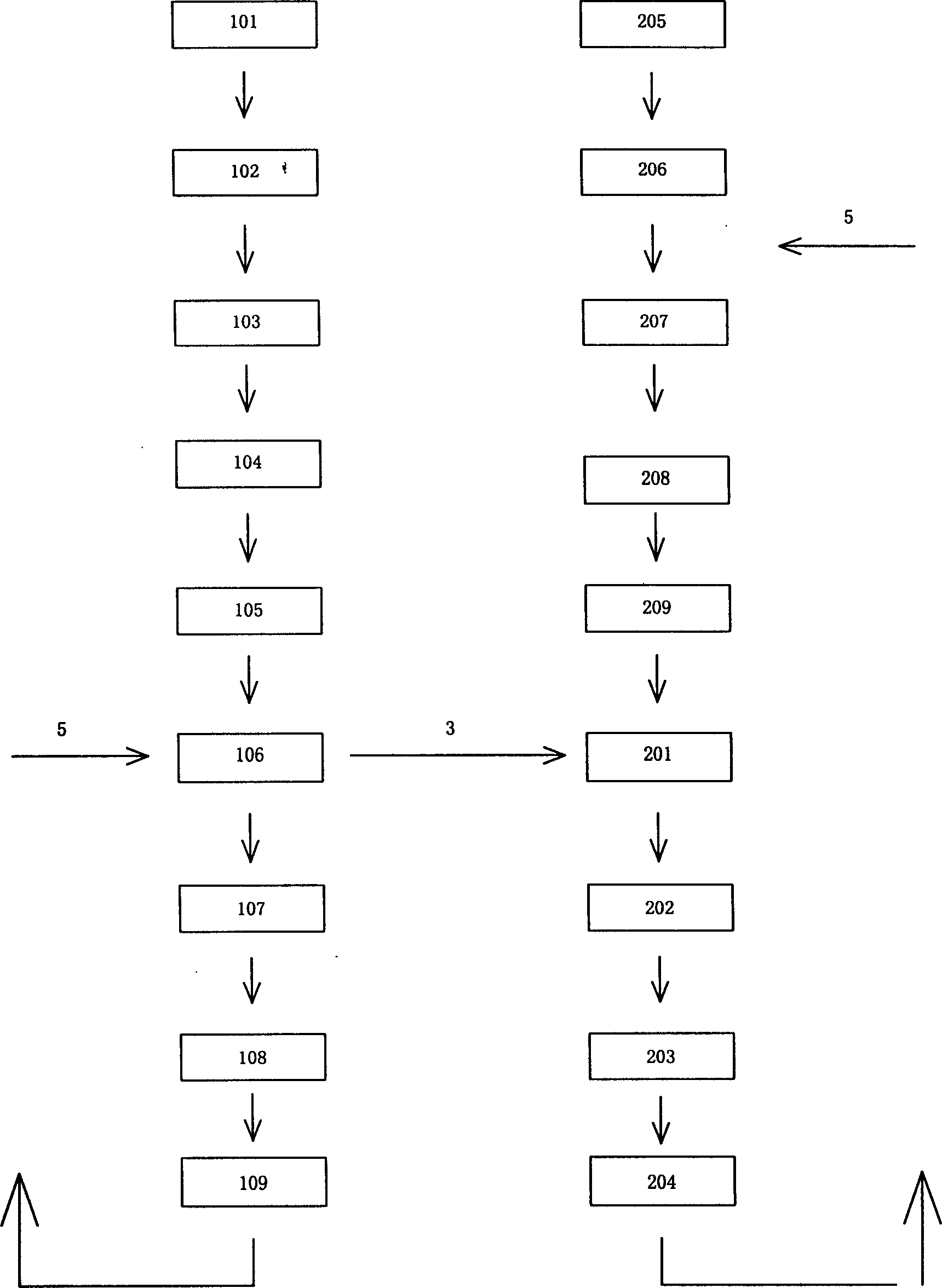

[0011] Such as figure 1 As shown, a bottle blowing control method of a double-station automatic bottle blowing machine, the bottle blowing machine is mainly composed of an extruder and two independent mold frames, the mold frame is provided with a mold, and the mold frame of the bottle blowing machine is 1 The working procedure is from 101 on the mold base → clamping mold 102 → cutting material 103 → under the mold base 104 → inserting the pen down 105 → blowing air 106 → deflated 107 → opening the mold 108 → inserting the pen 109, and the mold base 1 continuously circulates the above The working procedure of the mold base 2 of the bottle blowing machine is from 201 on the mold base → clamping mold 202 → material cutting 203 → under the mold base 204 → under the pen insertion 205 → air blowing 206 → deflation 207 → mold opening 208 → on the pen insertion 209. The mold base 2 continuously circulates the above-mentioned program. After each of the above-mentioned mold bases compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com