High-CTI, high-heat-resistance, halogen-free and flame-retardant PC/ ABS composition and preparation method thereof

A technology of high heat resistance and composition, applied in the field of high heat resistance halogen-free flame retardant PC/ABS composition and its preparation, high CTI, halogen-free flame retardant modified resin composition field, can solve the problem of phosphorus-based flame retardant The problems of large addition amount, low heat distortion temperature and low CTI value can achieve the effect of improving mechanical properties, high flame retardant efficiency and improving CTI value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

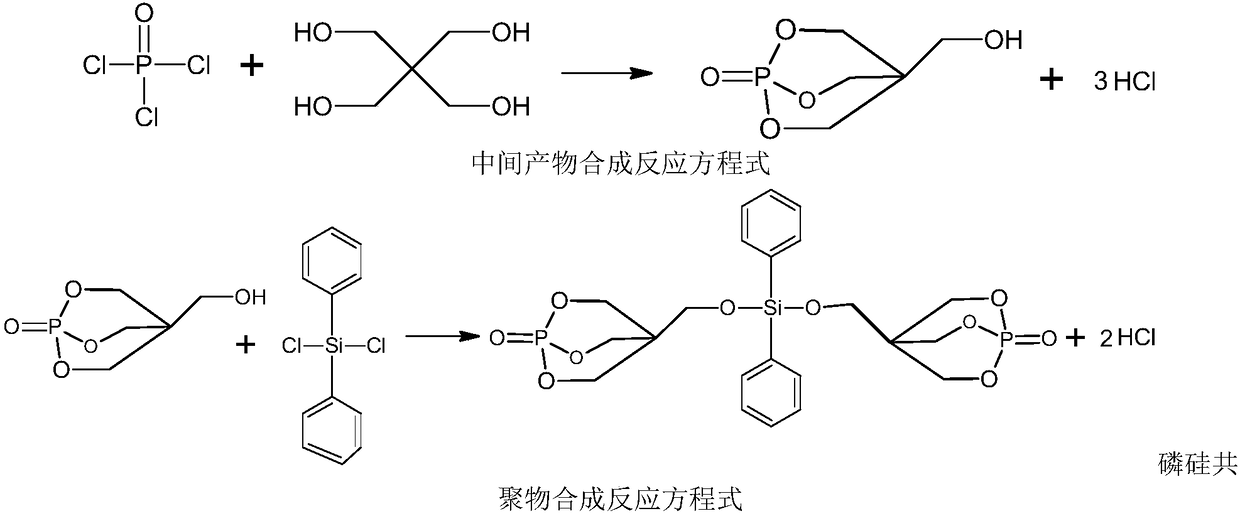

Method used

Image

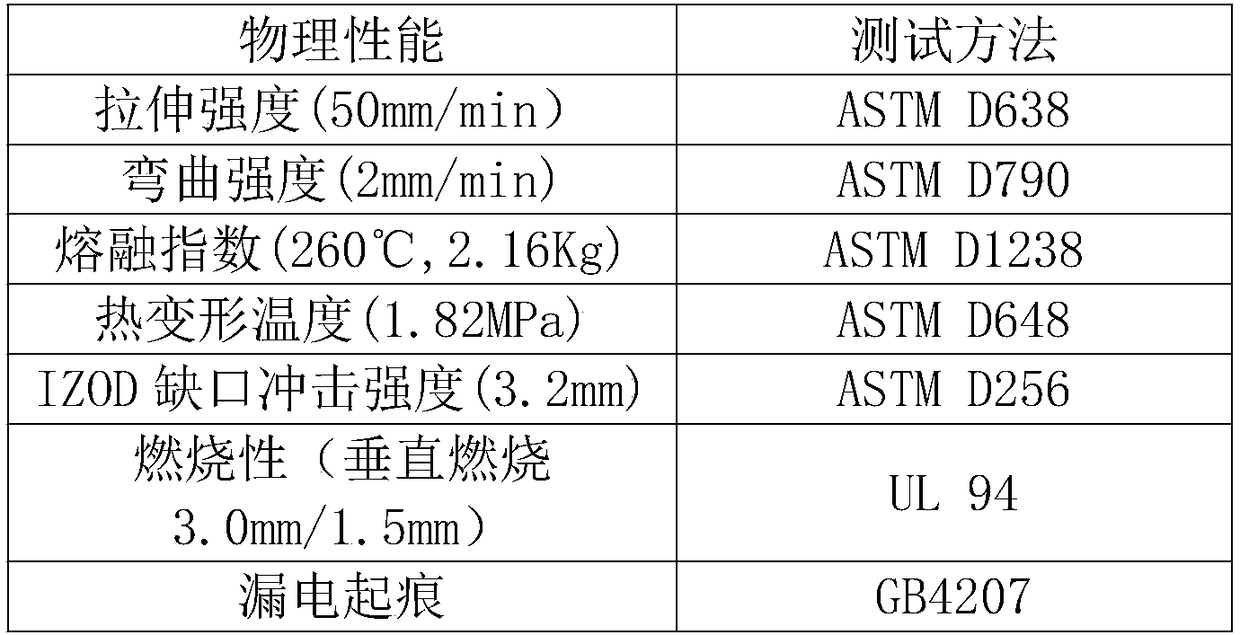

Examples

preparation example Construction

[0034] The preparation method of the high CTI, high heat-resistant halogen-free flame-retardant PC / ABS composition specifically comprises the following steps:

[0035] (1) Preparation of modified porous materials: firstly mix aminohydrocarbyl silane coupling agent and ethanol at a mass ratio of 1:200 to make a solution, then mix the solution and porous material at a mass ratio of 2:1, and heat at 50°C Stir with a mechanical stirrer for 10 minutes, then put it in an oven at 100 degrees Celsius for two hours and set aside;

[0036] (2) Mixing: First, weigh the self-made phosphorus silicon polymer and modified porous material according to the established ratio, stir at high speed with the mixer for 3min-5min, and then mix polycarbonate, ABS resin, toughening agent, antioxidant , anti-dripping agent and lubricant are added according to the ratio, and stirred by a high-speed mixer to make it evenly mixed to obtain a mixture;

[0037] (3) Preparation of PC / ABS composition: Put the ...

Embodiment 1

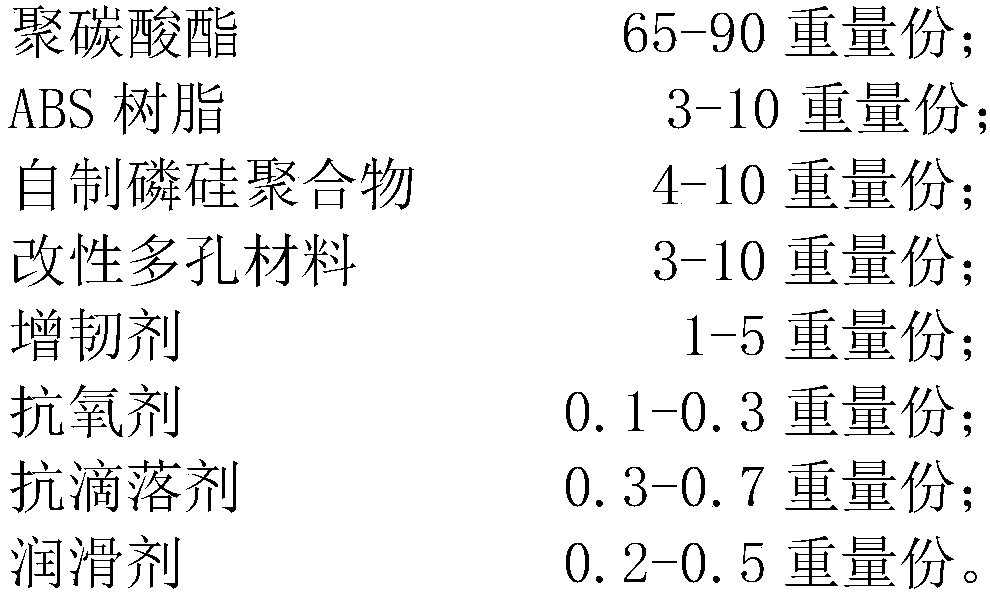

[0045] This embodiment relates to a high CTI, high heat-resistant halogen-free flame-retardant PC / ABS composition, its components and contents are:

[0046]

Embodiment 2

[0048] This embodiment relates to a high CTI, high heat-resistant halogen-free flame-retardant PC / ABS composition, its components and contents are:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com