Resin composition, copper-clad board, circuit board and manufacturing method

A technology of resin composition and copper clad laminate, applied in the direction of printed circuit, chemical instrument and method, synthetic resin layered products, etc., can solve the problems of low peel strength and poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

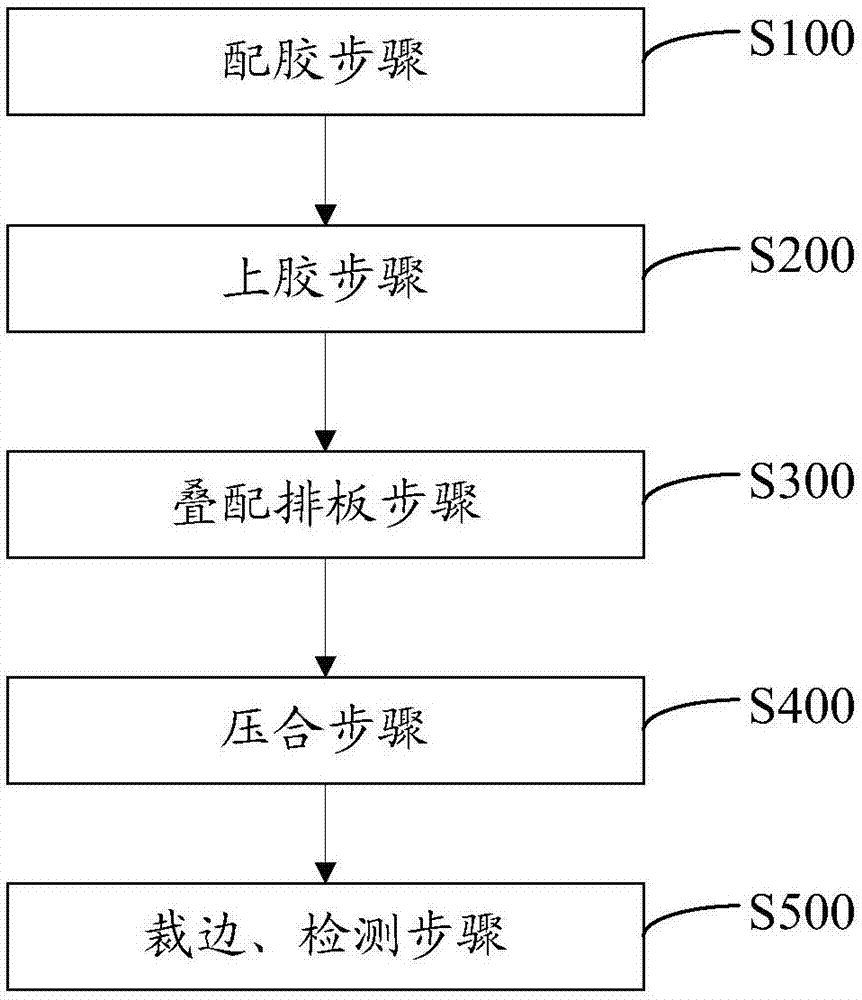

[0046] see figure 1 Shown, the present invention also provides a kind of preparation method of above-mentioned copper-clad laminate, and this preparation method comprises the following steps:

[0047] S100, a glue compounding step, uniformly mixing each component in the resin composition according to the formula amount to prepare a glue solution.

[0048] Optionally, in S100, the glue compounding step includes the following steps:

[0049] Dissolving the curing agent in a part of the formula amount of solvent to completely dissolve the curing agent to obtain a curing agent solution;

[0050] The accelerator is dissolved in the solvent of the remaining formulation amount to obtain an accelerator solution;

[0051] Stirring and mixing the curing agent solution with low-bromine epoxy resin and bromine-free epoxy resin to obtain a resin solution;

[0052] Aluminum oxyhydroxide is added to the resin solution and mixed with stirring to prepare a resin-aluminum oxyhydroxide mixtur...

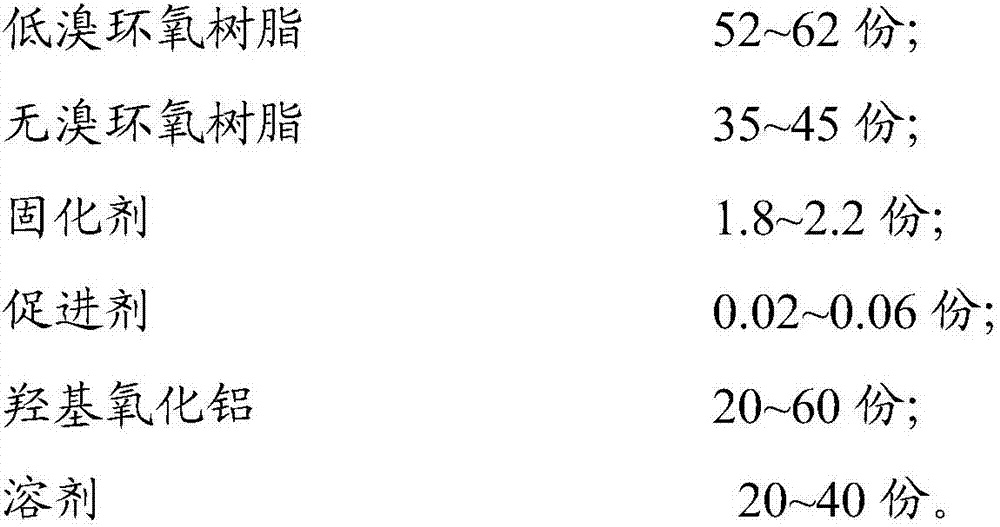

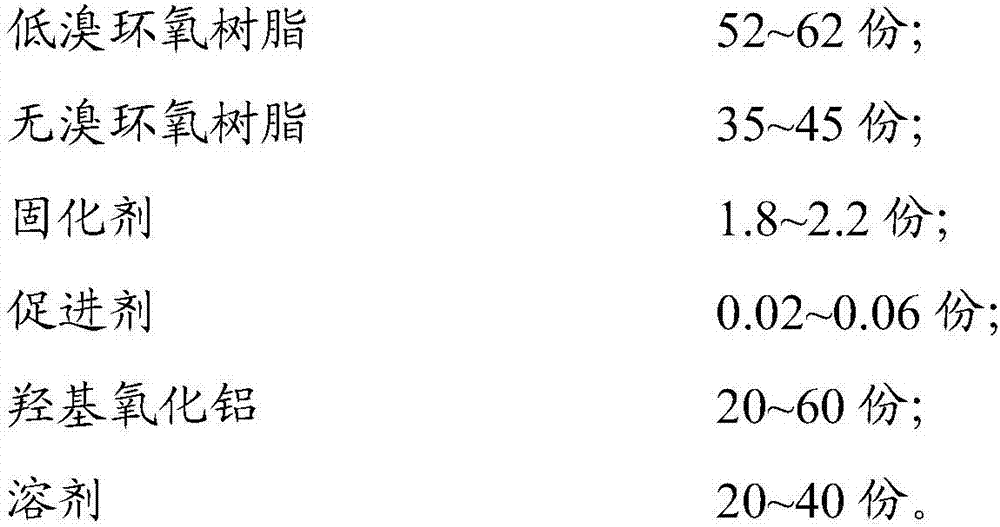

Embodiment 1

[0074] Dissolve 2.0kg of dicyandiamide in 22kg of dimethylformamide to completely dissolve the dicyandiamide to prepare a curing agent solution. 0.04 kg of 2-methylimidazole was dissolved in 10 kg of dimethylformamide to prepare an accelerator solution. Add the curing agent solution, 39kg of bromine-free epoxy resin, and 55kg of reactive xanthan resin into the high-shear cylinder, and stir and mix at a speed of 1400r / min to prepare a resin solution. Add 45kg of aluminum oxyhydroxide to the resin solution and stir and mix at a speed of 1400r / min. During stirring, control the temperature not higher than 45°C and keep stirring for 1h to obtain a resin-aluminum oxyhydroxide mixture. Add the accelerator solution to the resin-aluminum oxyhydroxide mixture, stir and mix at a speed of 1400r / min, and keep stirring for 1h to obtain a glue solution.

[0075] Measure the viscosity of the glue, when the viscosity is 25+ / -10s / 4 # When the cup is used, transfer it to a common cylinder and ...

Embodiment 2

[0091] Dissolve 2.0kg of dicyandiamide in 22kg of dimethylformamide to completely dissolve the dicyandiamide to prepare a curing agent solution. 0.04 kg of 2-methylimidazole was dissolved in 10 kg of dimethylformamide to prepare an accelerator solution. Add the curing agent solution, 39kg of bromine-free epoxy resin, and 55kg of reactive xanthan resin into the high-shear cylinder, and stir and mix at a speed of 1400r / min to prepare a resin solution. Add 45kg of aluminum oxyhydroxide to the resin solution in portions and stir and mix at a speed of 1400r / min. During stirring, control the temperature not higher than 45°C and keep stirring for 1h to obtain a resin-aluminum oxyhydroxide mixture. Add the accelerator solution to the resin-aluminum oxyhydroxide mixture, stir and mix at a speed of 1400r / min, and keep stirring for 1h to obtain a glue solution.

[0092] Measure the viscosity of the glue, when the viscosity is 25+ / -10s / 4 # When the cup is used, transfer it to a common c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com