MPPO (modified polyphenylene oxide) composite material and preparation method thereof

A composite material and raw material technology, applied in the field of composite materials, can solve the problems of material product fluidity and CTI value not involved, and achieve the effect of delaying polymer oxidation or auto-oxidation process, high CTI value, and improving impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

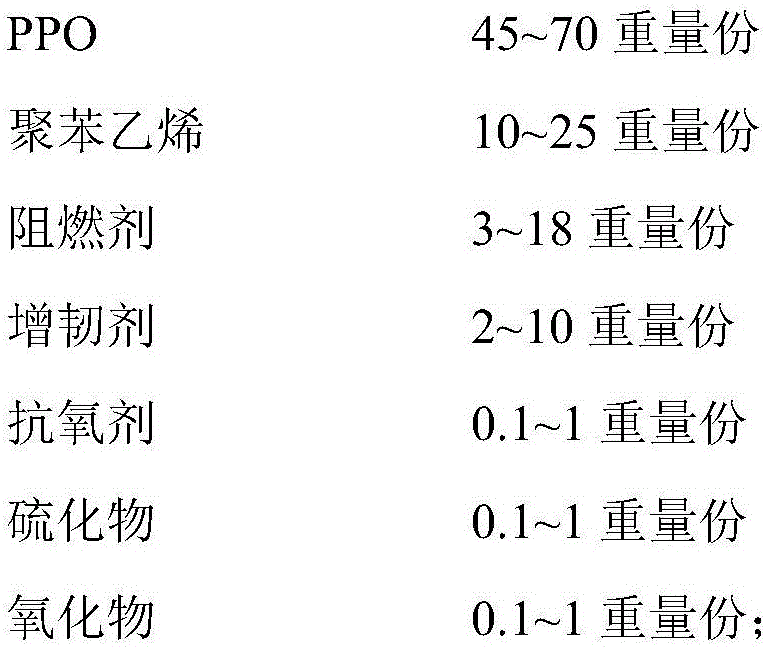

Method used

Image

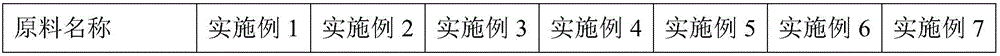

Examples

Embodiment 1

[0028] The preparation of embodiment 1 MPPO composite material

[0029] PPO is compounded by the following two kinds of PPO by weight percentage: PPO, its intrinsic viscosity is 40dl / g, 80%; PPO, its intrinsic viscosity is 45dl / g, 20%. Styrene HIPS has an impact strength of 90J / m and a melt index of 14g / 10min (200°C, 5kg). The flame retardant is resorcinol bis(diphenyl phosphate), the toughening agent is styrene-ethylene-butylene-styrene block copolymer, the antioxidant is antioxidant 1010 and 168, and the sulfide is Zinc sulfide, the oxide is zinc oxide.

[0030] Each raw material component was weighed according to the following weight percentage content: PPO 45kg, polystyrene 25kg, flame retardant 18kg, toughening agent 8kg, antioxidant 1kg, zinc sulfide 1kg, zinc oxide 1kg. Put the weighed raw materials into a mixer, mix at 200r / min for 2min, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 220-...

Embodiment 2

[0031] The preparation of embodiment 2 MPPO composite material

[0032] PPO is compounded by the following two kinds of PPO by weight percentage: PPO, whose intrinsic viscosity is 40dl / g, 70%; PPO, whose intrinsic viscosity is 45dl / g, 30%. Styrene HIPS has an impact strength of 110J / m and a melt index of 11g / 10min (200°C, 5kg). The flame retardant is polyaryl phosphate, the toughening agent is styrene-ethylene-butylene-styrene block copolymer, and the antioxidants are antioxidants 1076 and 168.

[0033] Each raw material component was weighed according to the following weight percentage content: PPO 53kg, polystyrene 20kg, flame retardant 15kg, toughening agent 10kg, antioxidant 1kg. Put the weighed raw materials into a mixer, mix at 300r / min for 2min, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 220-250°C, The extruder includes seven temperature zones, one of which is 230°C, the second section...

Embodiment 3

[0034] The preparation of embodiment 3 MPPO composite material

[0035] The intrinsic viscosity of PPO is 40 dl / g. Polystyrene is a high-flow high-impact polystyrene HIPS, with an impact strength of 100J / m and a melt index of 12g / 10min (200°C, 5kg). The flame retardant is triphenyl phosphate, the toughening agent is styrene-butadiene-styrene block copolymer, and the antioxidants are antioxidants 1076 and 168.

[0036] Each raw material component was weighed according to the following weight percentage content: PPO 65kg, polystyrene 22kg, flame retardant 10kg, toughening agent 3kg, antioxidant 0.2kg. Put the weighed raw materials into a mixer, mix at 200r / min for 5min, discharge, and then extrude and granulate with a twin-screw extruder; the processing temperature of the twin-screw extruder is 220-250°C, The extruder includes seven temperature zones, one of which is 225°C, the second stage is 245°C, the third stage is 255°C, the fourth stage is 255°C, the fifth stage is 255°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com