Welding device for X-ray tube anode

A welding device and X-ray tube technology, which is applied in the field of X-ray tubes, can solve the problems such as the decrease of the strength against torsional stress, achieve the effects of uniform impact strength, improve the firm strength of welding, and avoid air bubbles and cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

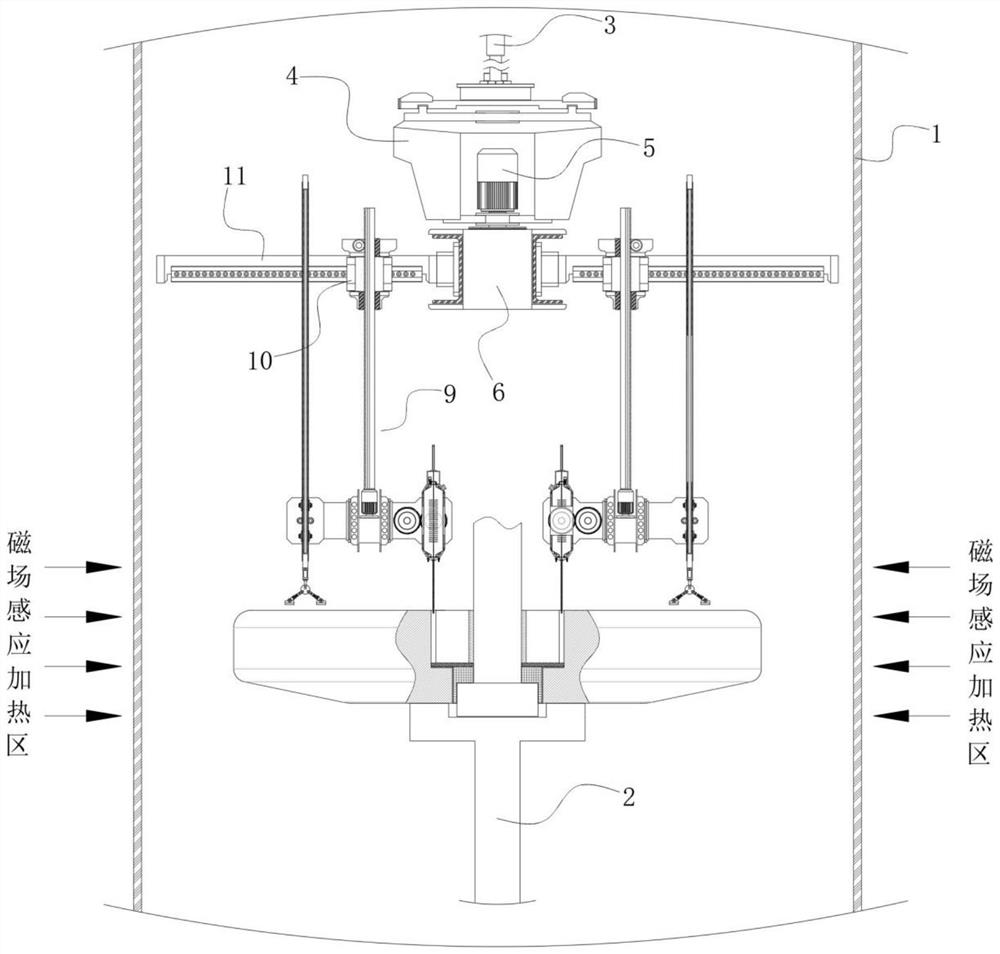

[0041] refer to Figure 1-7 , the present invention provides a technical solution: an anode welding device for X-ray tubes, which includes:

[0042] Vacuum housing 1, the inner upper and lower chambers are respectively equipped with coaxial multi-stage lifting rods 3 and fixed bracket 2, and the upper end of the fixed bracket 2 is coaxially fixed with an anode target, and the center of the anode target is embedded There is a rotor shaft that has been welded and connected to the bearing sleeve, and the anode target is provided with a transverse magnetic field induction heating area on the outside of the partial vacuum housing 1;

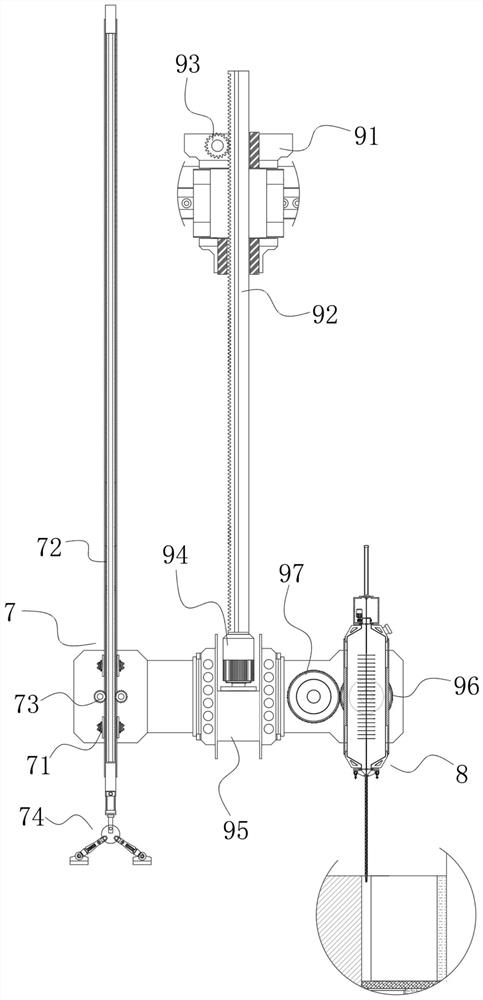

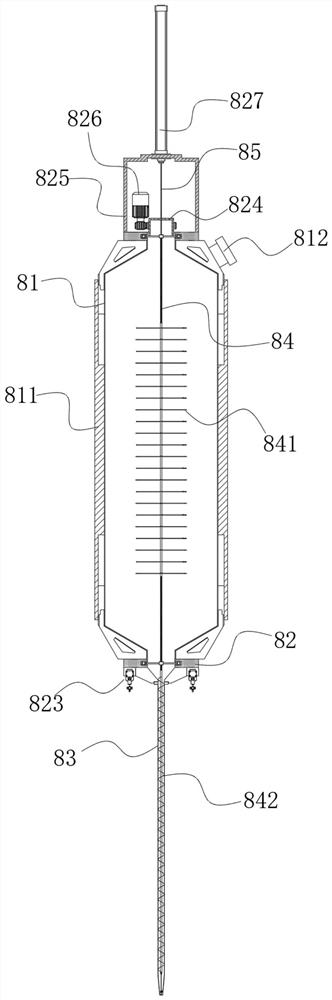

[0043] The lifting seat 4 is fixed on the lower output end of the multi-stage lifting rod 3, and a motor one 5 is installed inside it, and the lower output end of the motor one 5 is fixed with a coarse rotating column 5, and the outer wall of the coarse rotating column 5 is fixed There are guide rails 11 arranged in a circular arrangement, and each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com