Oscillating surface microscopic cold forging device

A swinging, cold forging technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of inapplicability, achieve uniform impact strength and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

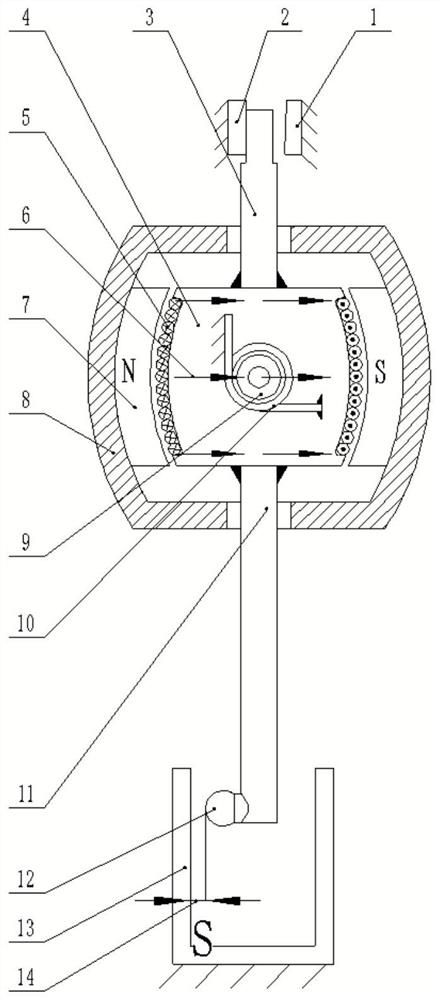

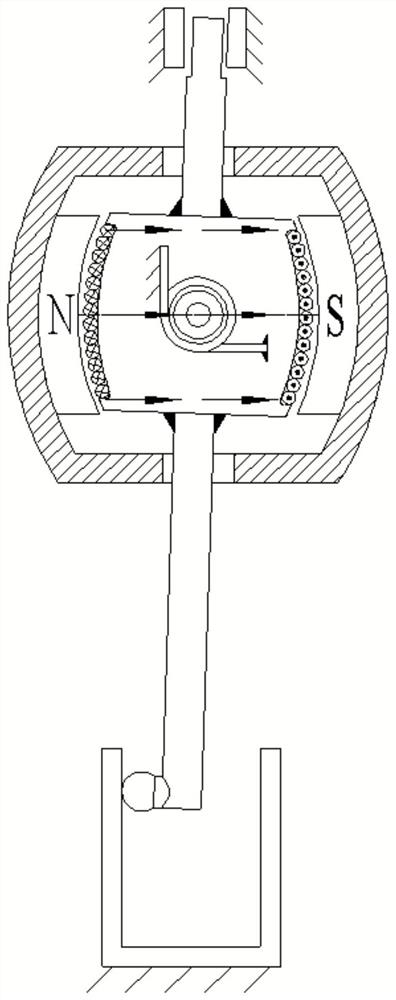

[0020] The vibration mode of the traditional actuator is axial vibration, and the vibration direction is along the axial direction of the extension shaft, which is suitable for the part where the normal line of the surface of the processing part is not shielded. The head cannot be touched and is no longer applicable. This embodiment proposes a micro-cold forging device with swing vibration. The hammering direction of the impact head is along the radial direction of the extension axis, which expands the application range of the micro-cold forging device.

[0021] Such as figure 1 As shown, the oscillating surface micro cold forging device involved in this embodiment includes: a permanent magnet 7 and a yoke 8 as a magnetic field generating device, a limiting device and a rotor, wherein: the magnetic field generating device and the limiting device are both connected to the frame Fixed, a return torsion spring 10 as a reset device is arranged between the rotor with the coil 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com