Heat accumulator for aluminum oxide ceramic hollow brick heat accumulation heater and preparation method of heat accumulator

A technology of alumina ceramics and heat storage body, applied in heat storage equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve problems affecting economic benefits, affecting production efficiency, and large economic losses, so as to improve quality, Avoid the effect of uneven material and uniform impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

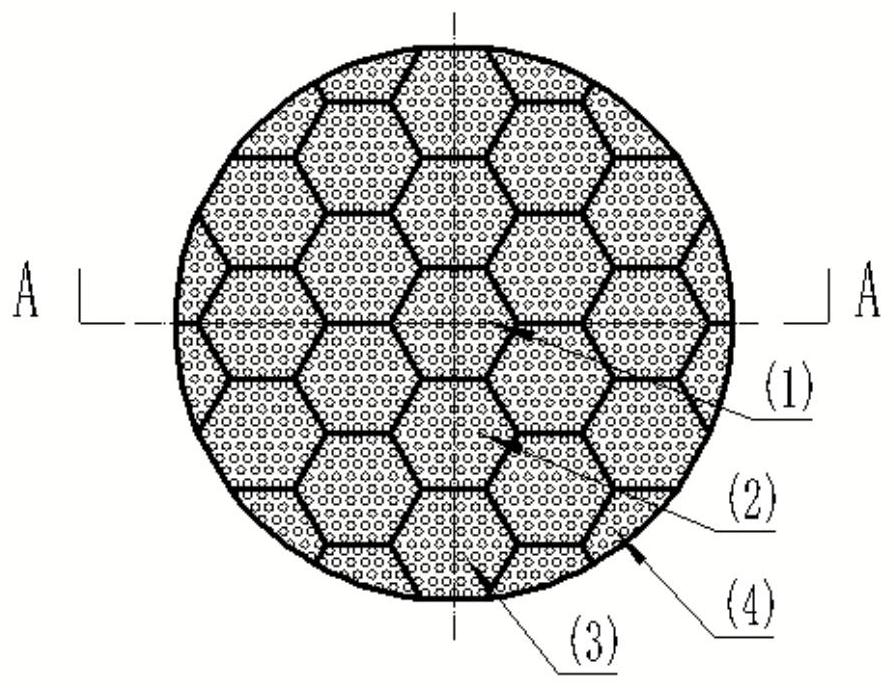

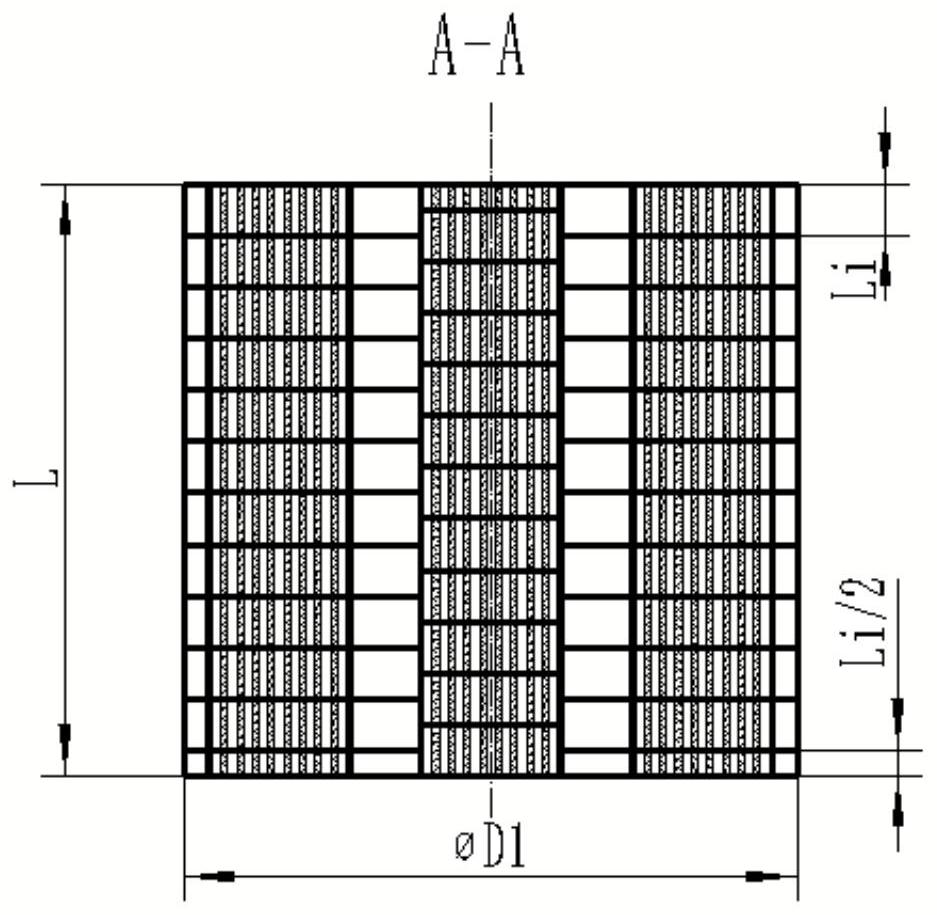

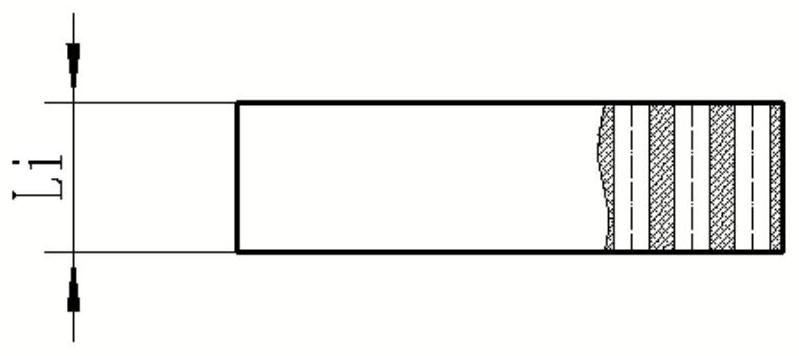

[0040] see figure 1 with figure 2 , A heat storage body for an alumina ceramic hollow brick heat storage heater provided in an embodiment of the present invention is a cylindrical structure assembled from several regular hexagonal prism heat storage blocks and side blocks cut from the heat storage blocks.

[0041] Wherein, the heat storage blocks in each layer of the heat storage body are arranged in sequence along the circumference around the central heat storage block, and the gaps between the outermost heat storage blocks are filled by side blocks. Specifically, the heat storage body is composed of m circles of heat storage blocks and one circle of edge blocks in the radial direction. Usually, the first circle, that is, the central position of the heat storage body, is composed of 1 heat storage block, and the second circle is composed of 6×1 heat storage blocks. face outside. The third circle is composed of 6 × 2 heat storage blocks, and these 12 heat storage blocks ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com