High-CTI and high-strength flame-retardant polyamide material and preparation method thereof

A flame-retardant polyamide and high-strength technology, which is applied in the field of high-CTI and high-strength flame-retardant polyamide materials and their preparation, can solve the problems of a large amount of flame retardants, a large amount of flame retardants, and a decrease in electrical insulation. , to achieve good flame retardant properties, high CTI value, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1, the preparation of high CTI flame-retardant polyamide material

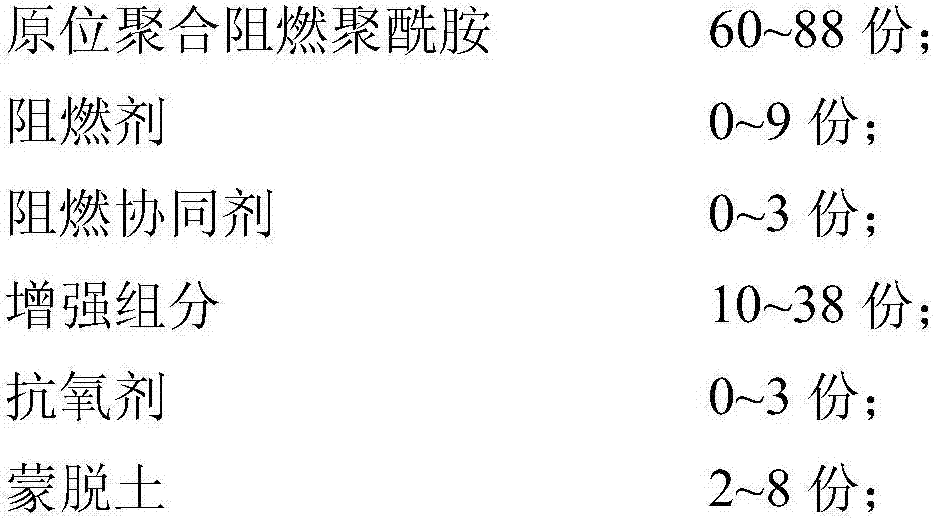

[0061] The mass percentage of each component is shown in Table 1.

[0062] The mass percent of each component of table 1

[0063]

[0064] Wherein, the inorganic glass fiber is subjected to the following chemical surface modification treatment: it is etched in a strong alkali solution of sodium hydroxide with a mass concentration of 10% for 60 minutes, and then polyether (polyethylene glycol ether) with a weight average molecular weight of 2000 is added in the Reaction at 180°C for 2h.

[0065] Mix in-situ polymerized flame retardant polyamide 6, flame retardant, flame retardant synergist, antioxidant, and montmorillonite according to the ratio in Table 1, and then extrude it with the reinforcing component (inorganic glass fiber) through twin-screw Machine melt extrusion granulation to obtain high CTI flame retardant polyamide material.

[0066] The obtained flame-retardant polyamide ma...

Embodiment 2

[0067] Embodiment 2, the preparation of high CTI flame-retardant polyamide material

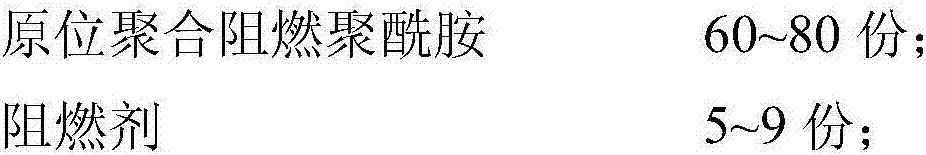

[0068] The mass percentage of each component is shown in Table 2.

[0069] The mass percent of each component of table 2

[0070]

[0071]

[0072] Among them, the aramid fiber is subjected to the following chemical surface modification treatment: it is etched in a strong alkali solution of potassium hydroxide with a mass concentration of 20% for 20 minutes, and then polyether (polyethylene glycol ether) with a weight average molecular weight of 4000 is added in Reaction at 200°C for 1h.

[0073] After mixing in-situ polymerized flame retardant polyamide 66, flame retardant, flame retardant synergist, antioxidant, and montmorillonite according to the ratio in Table 2, it is then extruded with the reinforcing component (aramid fiber) through a twin-screw Machine melt extrusion granulation to obtain high CTI flame retardant polyamide material.

[0074] The obtained flame-retardant polyam...

Embodiment 3

[0075] Embodiment 3, the preparation of high CTI flame-retardant polyamide material

[0076] The mass percentage of each component is shown in Table 3.

[0077] The mass percent of each component of table 3

[0078]

[0079] Among them, the carbon fiber is subjected to the following chemical surface modification treatment: it is etched in a strong alkali solution of potassium hydroxide with a mass concentration of 15% for 40 minutes, and then polyether (polyethylene glycol ether) with a weight average molecular weight of 3000 is added at 200 ° C. Reaction 1.5h.

[0080] After mixing the flame retardant polyamide 6 and the flame retardant polyamide 66 copolymer flame retardant, flame retardant synergist, antioxidant, and montmorillonite in the ratio in Table 2, then with the reinforcing component (carbon fiber) through double The screw extruder melts and extrudes and granulates to obtain a high CTI flame-retardant polyamide material.

[0081] The obtained flame-retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com