Halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value and preparation method of halogen-free flame-retardant glass fiber-reinforced PA6 composite material with high-ignition-temperature glow wire and high CTI value

A technology of high glow wire and composite material, applied in the field of high glow wire, high CTI value, halogen-free flame retardant glass fiber reinforced PA6 composite material and preparation thereof, and can solve the problem of tracking resistance and tracking resistance of materials that are not involved. problems such as adverse effects on performance, achieve high tracking resistance, ensure good dispersion, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

[0033] Embodiment and comparative example:

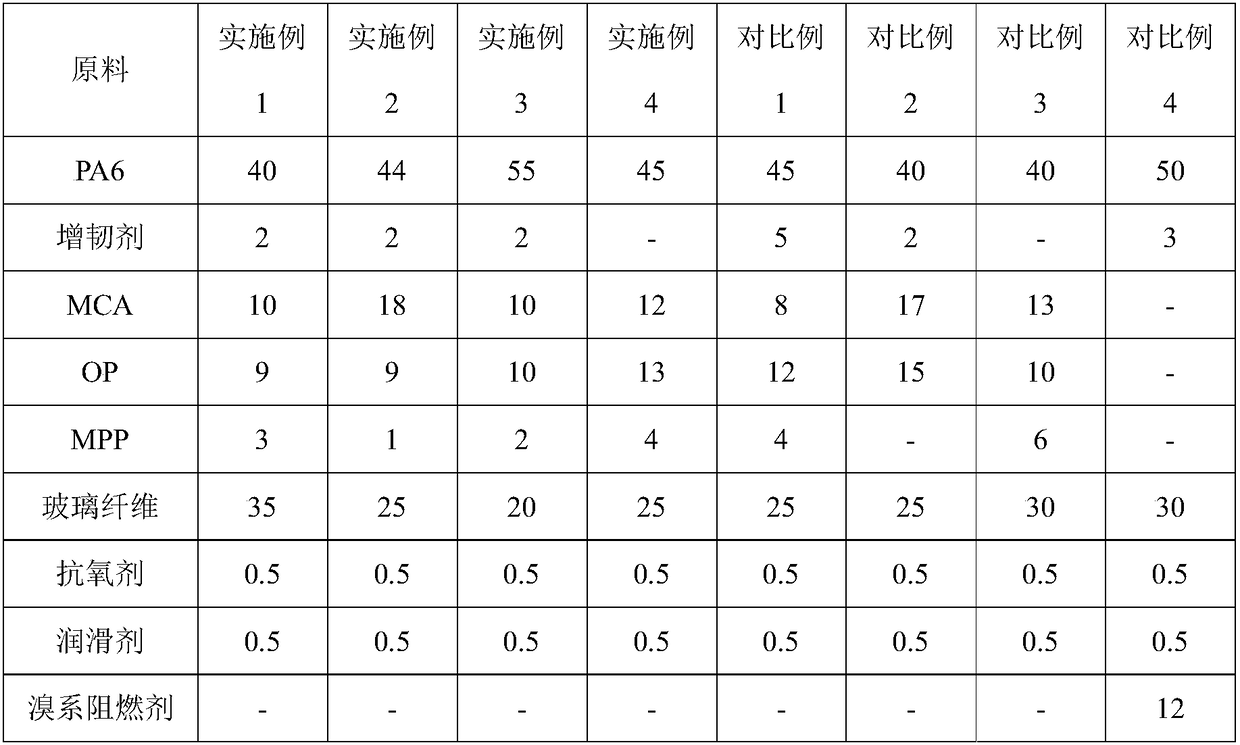

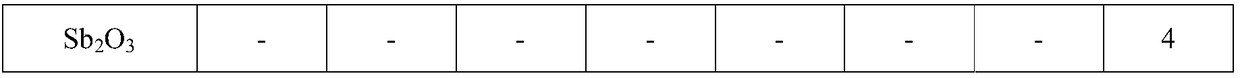

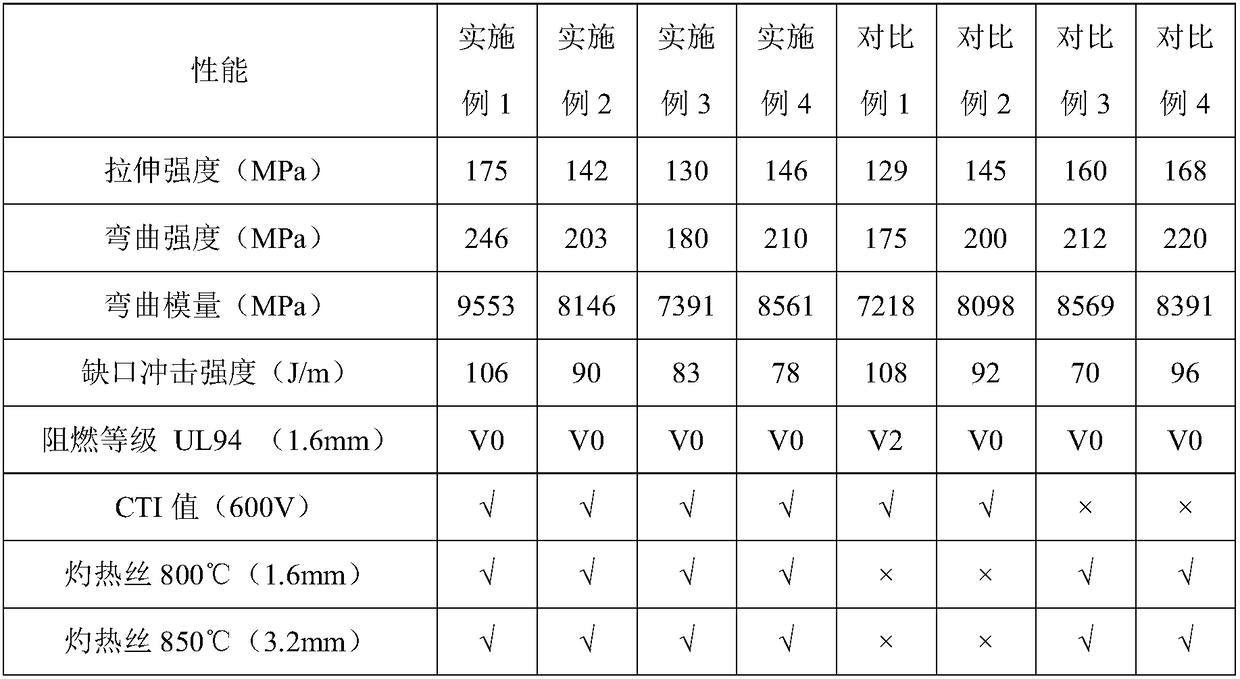

[0034] The raw material compositions of Examples 1-4 and Comparative Examples 1-4 are shown in Table 1.

[0035] The raw material composition of table 1 embodiment and comparative example

[0036]

[0037]

[0038] The raw materials of the above-mentioned components are weighed according to parts by mass, put into a high-speed mixer and stirred for 6-10 minutes, then added to a twin-screw extruder for extrusion, granulation, and drying to obtain a product. The temperature setting of each temperature zone of the twin-screw extruder is: 170°C, 190°C, 235°C, 235°C, 230°C, 220°C, 220°C, 220°C, 235°C.

[0039] The used raw material information of the example of the present invention is as follows:

[0040] PA6 resin: Guangdong Xinhui Meida Nylon Co., Ltd., model: M2400;

[0041] Toughener: Shenyang Ketong Plastic Technology Co., Ltd., model: KT-10A;

[0042] MCA: Hebei Naian Flame Retardant Material Co., Ltd., model: MCA301;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com