Heat-resistant concrete

A technology of heat-resistant concrete and fly ash ceramsite, which is applied in the field of heat-resistant concrete, can solve the problems of increasing the production cost of heat-resistant concrete, and achieve the effect of reducing load and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

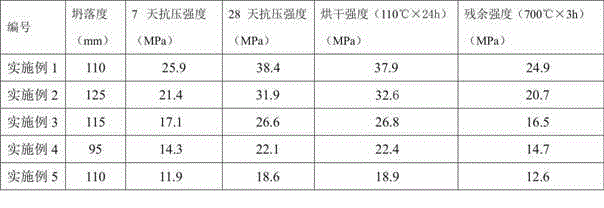

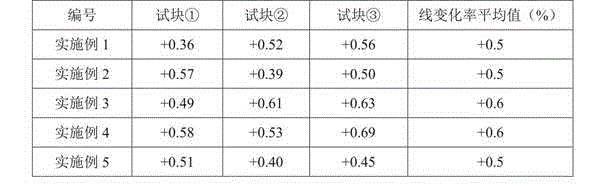

Examples

Embodiment 1

[0026] A heat-resistant concrete composed of 7.56 kg of water, 16.08 kg of cement, 30.56 kg of blast furnace water-quenched slag, 12.52 kg of fly ash ceramsite, 3.20 kg of fly ash, 2.40 kg of mineral powder, and 0.326 kg of water reducing agent; At the same time, first mix the above-mentioned other raw materials (ie weighed cement, blast furnace water quenched slag, fly ash ceramsite, fly ash, slag powder and water reducing agent), and then add the weighed water and stir evenly. It can be the heat-resistant concrete of the present invention.

Embodiment 2

[0028] A heat-resistant concrete composed of 7.60 kg of water, 15.40 kg of cement, 31.28 kg of blast furnace water-quenched slag, 13.08 kg of fly ash ceramsite, 3.08 kg of fly ash, 2.32 kg of mineral powder, and 0.323 kg of water reducing agent; At this time, the above-mentioned other raw materials are mixed first, and then water is added and mixed evenly to form the heat-resistant concrete of the present invention.

Embodiment 3

[0030] A heat-resistant concrete composed of 7.52kg of water, 13.6kg of cement, 33.16kg of blast furnace water-quenched slag, 13.84kg of fly ash ceramsite, 2.72kg of fly ash, 2.04kg of mineral powder, and 0.272kg of water reducer; At this time, the above-mentioned other raw materials are mixed first, and then water is added and mixed evenly to form the heat-resistant concrete of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com