Liquid organic silicon doping hexagonal boron nitride material and automatic preparation and industrial application method thereof

A technology of hexagonal boron nitride and organic silicon, which is applied in the field of optoelectronic components, can solve problems such as adhesion and sealing that are difficult to meet the requirements of use, easy yellowing and aging resistance, and achieve the effect of protecting light decay and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

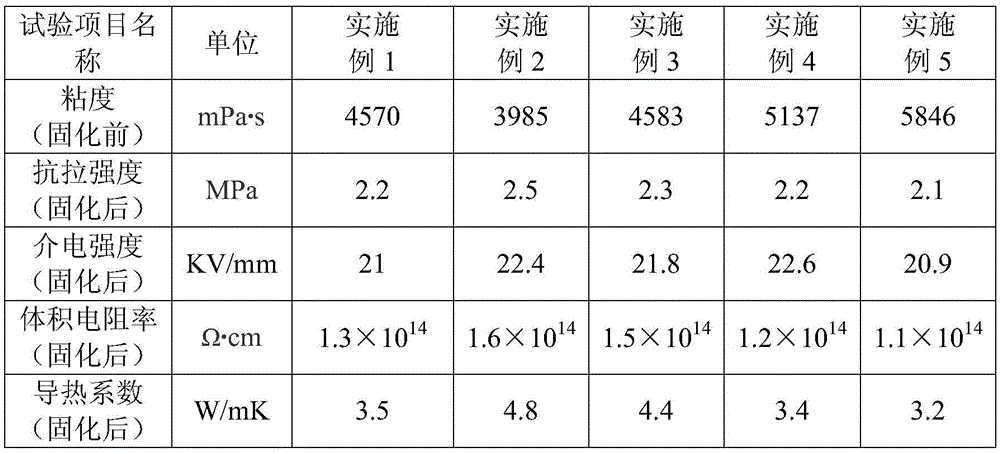

Embodiment 1

[0039] First put hexagonal boron nitride and silane coupling agent KH-570 into the mixing device at a mass ratio of 100:0.8, and after high-speed stirring for 30 minutes, surface-activated hexagonal boron nitride is obtained, and then 58.9 parts of vinyl Silicone oil, 40 parts of surface-activated hexagonal boron nitride, 0.1 part of ethynyl cyclohexanol and 1.0 part of platinum catalyst are delivered to mixer I with a stirrer through a precise metering system; 40 parts of ethylene Base silicone oil, 18 parts of hydrogen-containing silicone oil and 42 parts of surface-activated hexagonal boron nitride are transported to mixer II with a stirrer through an accurate metering and feeding system; after stirring for 10 minutes respectively, component A and component B are obtained. Components; after that, components A and B are transported 1:1 through the precise synchronous feeding system in a vacuum-tight condition, and enter the static mixing pipeline, and then enter the precision...

Embodiment 2

[0041] First put hexagonal boron nitride and silane coupling agent KH-570 into the mixing device at a mass ratio of 100:1.0, and after high-speed stirring for 30 minutes, surface-activated hexagonal boron nitride is obtained, and then 39.57 parts of vinyl Silicone oil, 60 parts of surface-activated hexagonal boron nitride, 0.03 parts of ethynyl cyclohexanol and 0.4 parts of platinum catalyst are delivered to mixer I with a stirrer through a precise metering system; 35 parts of ethylene Base silicone oil, 10 parts of hydrogen-containing silicone oil and 55 parts of surface-activated hexagonal boron nitride are transported to mixer II with a stirrer through an accurate metering and feeding system; after stirring for 10 minutes respectively, component A and component B are obtained. Components; after that, components A and B are transported 1:1 through the precise synchronous feeding system in a vacuum-tight condition, and enter the static mixing pipeline, and then enter the preci...

Embodiment 3

[0043] First put hexagonal boron nitride and silane coupling agent KH-570 into the mixing device at a mass ratio of 100:1.0, and after high-speed stirring for 30 minutes, surface-activated hexagonal boron nitride is obtained, and then 39.1 parts of vinyl Silicone oil, 60 parts of surface-activated hexagonal boron nitride, 0.08 parts of ethynyl cyclohexanol and 0.82 parts of platinum catalyst are delivered to mixer I with a stirrer through a precise metering system; 40.8 parts of ethylene Base silicone oil, 14.2 parts of hydrogen-containing silicone oil and 45 parts of surface-activated hexagonal boron nitride are transported to mixer II with a stirrer through an accurate metering system; after stirring for 10 minutes, component A and component B are obtained. Components; after that, components A and B are transported 1:1 through the precise synchronous feeding system in a vacuum-tight condition, and enter the static mixing pipeline, and then enter the precision injection system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com