Easy-to-spray high-rigidity alloy material and preparation method thereof

A technology of alloy materials and acrylonitrile, which is applied in the field of easy-to-spray high-rigid alloy materials and their preparation, can solve problems such as metal assembly gap fluctuations, stress cracking, and structural design restrictions, so as to reduce thermal linear expansion coefficient and improve chemical resistance. Product performance, ease of use and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

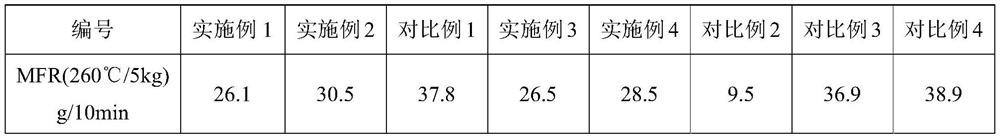

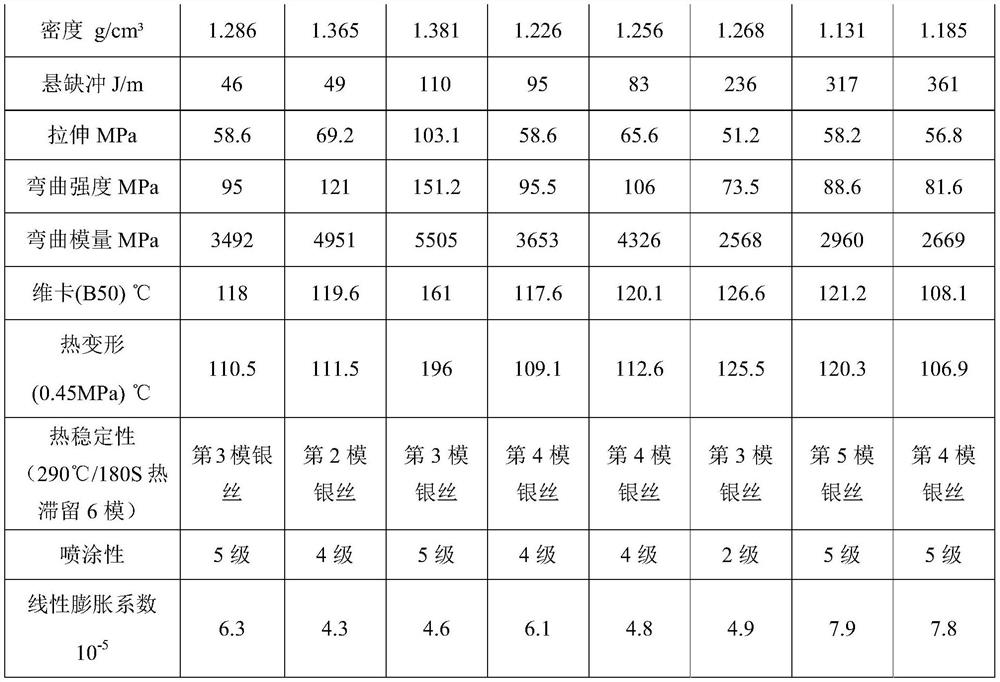

Examples

Embodiment 1

[0030] An easy-to-spray high-rigid reinforced alloy material is made of the following raw materials in parts by weight: 34 parts of PC resin pellets, 10 parts of PC resin powder, 10 parts of AS resin, 30 parts of PET resin, 5 parts of toughening agent, glass fiber 10 parts, 0.5 parts of styrene-acrylonitrile-GMA-MMA tetrapolymer, 0.4 parts of antioxidant, 0.3 parts of lubricant, 0.2 parts of transesterification inhibitor, 1 part of black masterbatch. Among them, the PC resin is mixed with pellets and powder at the same time, so as to facilitate the full mixing of fillers and tougheners.

[0031] Among them, the PC resin material is PC 2220R from SABIC; the PC resin powder is PC 2220 from Wanhua; the AS resin is 80HF from LG Yongxing; the PET resin is PET CB602 from Yuanfang Shanghai; the glass fiber is chopped glass fiber from Chongqing International. ECS303H-3; MBS EM500 from LG Chemical is used as the toughening agent; RAS-302 from Huawen Chemical Co., Ltd. is used for the s...

Embodiment 2

[0035] An easy-to-spray high-rigid reinforced alloy material is made of the following raw materials in parts by weight: 36 parts of PC resin pellets, 20 parts of PC resin powder, 5 parts of AS resin, 10 parts of PBT resin, 4 parts of EM500 toughening agent, 14 parts of toughening agent HR-18, 20 parts of talcum powder, 1.5 parts of styrene-acrylonitrile-GMA-MMA tetrapolymer, 0.4 parts of antioxidant, 0.3 parts of lubricant, 0.2 parts of transesterification inhibitor, 1 part of black masterbatch .

[0036] Among them, the PC resin material is PC 2220R from SABIC; the PC resin powder is PC 2220 from Wanhua; the AS resin is D-168 from Zhenjiang Chimei; the PBT resin is 211M from Changchun Chemical; the talcum powder is Mengdu M05SLC; LG Chem’s MBS EM500 and Kumho’s HR-181; the styrene-acrylonitrile-GMA-MMA tetrapolymer uses Huawen Chemical’s RAS-302; the antioxidants are Lianlong’s 1076 and 168; its weight The ratio is 1:1; the lubricant is Italian hair-based pentaerythritol ste...

Embodiment 3

[0045] An easy-to-spray high-rigid reinforced alloy material is made of the following raw materials in parts by weight: 46 parts of PC resin pellets, 10 parts of PC resin powder, 22 parts of AS resin, 5 parts of PBT tree, 3 parts of EM500 toughening agent, HR 3 parts of -181 toughening agent, 10 parts of talcum powder, 1 part of styrene-acrylonitrile-GMA-MMA tetrapolymer, 0.4 parts of antioxidant, 0.2 parts of lubricant, 0.2 parts of transesterification inhibitor, 1 part of black masterbatch share.

[0046] Among them, PC resin pellets are PC 2220R from SABIC; PC resin powder is PC 2220 from Wanhua; AS resin is 80HF from LG Yongxing and PN-108 from Zhenjiang Chimei in a ratio of 1:1; PBT resin is 211M from Changchun Chemical Industry ;Talc powder is selected from Mengdu M05SLC; the toughening agent is selected from MBS EM500 of LG Chemical and HR-181 of Korea Kumho; the styrene-acrylonitrile-GMA-MMA tetrapolymer is selected from Huawen Chemical RAS-302; The lubricant is Lianl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com