Dispensing insulation paper suitable for wind power and solar transformers, and application thereof

A technology of insulating paper and transformers, applied in the direction of insulators, laminations, lamination devices, etc., can solve the problems of insufficient mechanical strength, low heat resistance level, breakdown voltage resistance of insulating materials, poor oil resistance, etc., to reduce the main insulation distance, Effect of saving metal material and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

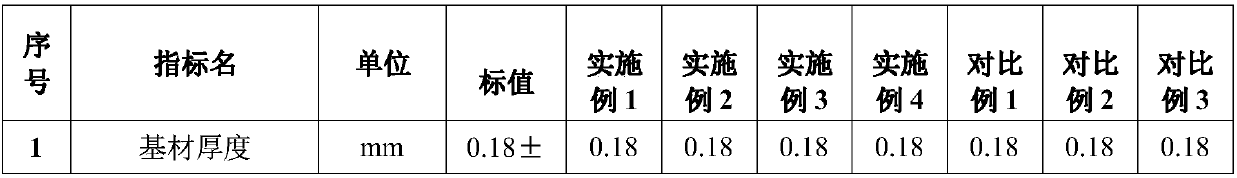

Embodiment 1

[0028] This embodiment provides a dispensing insulating paper suitable for wind power and solar transformers, which includes a first heat-resistant insulating paper, an intermediate layer made of polyimide film, and a second heat-resistant insulating paper stacked in sequence. The first heat-resistant insulating paper and the middle layer, the second heat-resistant insulating paper and the middle layer are all bonded by composite glue;

[0029] Wherein, the composite glue includes PU glue and epoxy glue, and the mass ratio of the PU glue to the epoxy glue is 8:1; the PU glue is selected from Henkel LioHol UR 2716 and curing agent UK 5500 in a mass ratio of 5 : 1 mixture.

[0030] Described epoxy glue comprises modified epoxy resin and epoxy resin solidifying agent, and its mass ratio is 4:1; Described modified epoxy resin is then made of existing liquid epoxy resin CYD128 and solid epoxy resin E12 according to The mass ratio is 0.5:1, and the epoxy resin curing agent is diami...

Embodiment 2

[0034] This embodiment provides a dispensing insulating paper suitable for wind power and solar transformers, which includes a first heat-resistant insulating paper, an intermediate layer made of polyimide film, and a second heat-resistant insulating paper stacked in sequence. The first heat-resistant insulating paper and the middle layer, the second heat-resistant insulating paper and the middle layer are all bonded by composite glue;

[0035] Wherein, the composite glue includes PU glue and epoxy glue, and the mass ratio of the PU glue to the epoxy glue is 9:1; the PU glue is a mixture of AP1387 and Hardener Z with a mass ratio of 6:1.

[0036] Described epoxy glue comprises modified epoxy resin and epoxy resin curing agent, and its mass ratio is 5: 1; Described modified epoxy resin is then made of existing liquid epoxy resin CYD128 and solid epoxy resin E1 according to The mass ratio is 1:1 composition. The epoxy curing agent is diaminodiphenylmethane (DDM).

[0037] The ...

Embodiment 3

[0040] This embodiment provides a dispensing insulating paper suitable for wind power and solar transformers, which includes a first heat-resistant insulating paper, an intermediate layer made of polyimide film, and a second heat-resistant insulating paper stacked in sequence. The first heat-resistant insulating paper and the middle layer, the second heat-resistant insulating paper and the middle layer are all bonded by composite glue;

[0041] Wherein, the composite glue includes PU glue and epoxy glue, and the mass ratio of the PU glue to the epoxy glue is 10:1; the PU glue is selected from Henkel LioHol UR 2716 and curing agent UK 5500 in a mass ratio of 6 : 1 mixture.

[0042] Described epoxy glue comprises modified epoxy resin and epoxy resin curing agent, and its mass ratio is 6: 1; Described modified epoxy resin is then made of existing liquid epoxy resin CYD128 and solid epoxy resin E12 according to The mass ratio is 1.5:1 composition. The epoxy resin curing agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com