Patents

Literature

50results about How to "High temperature corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of production of cold-rolled metal coated steel products, and the products obtained, having a low yield ratio

InactiveUS6641931B2High strengthGood molding effectHot-dipping/immersion processesFurnace typesManganeseYield ratio

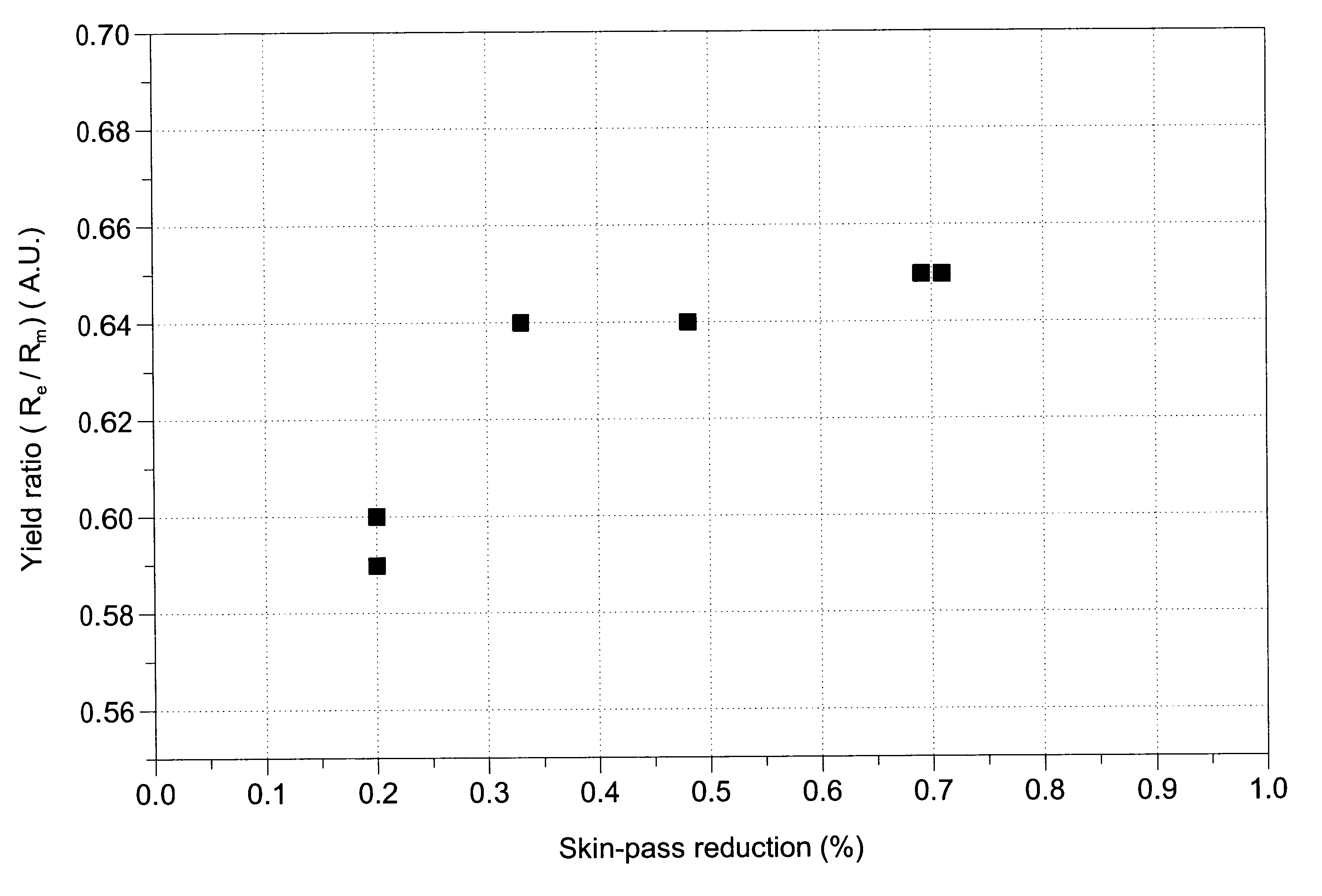

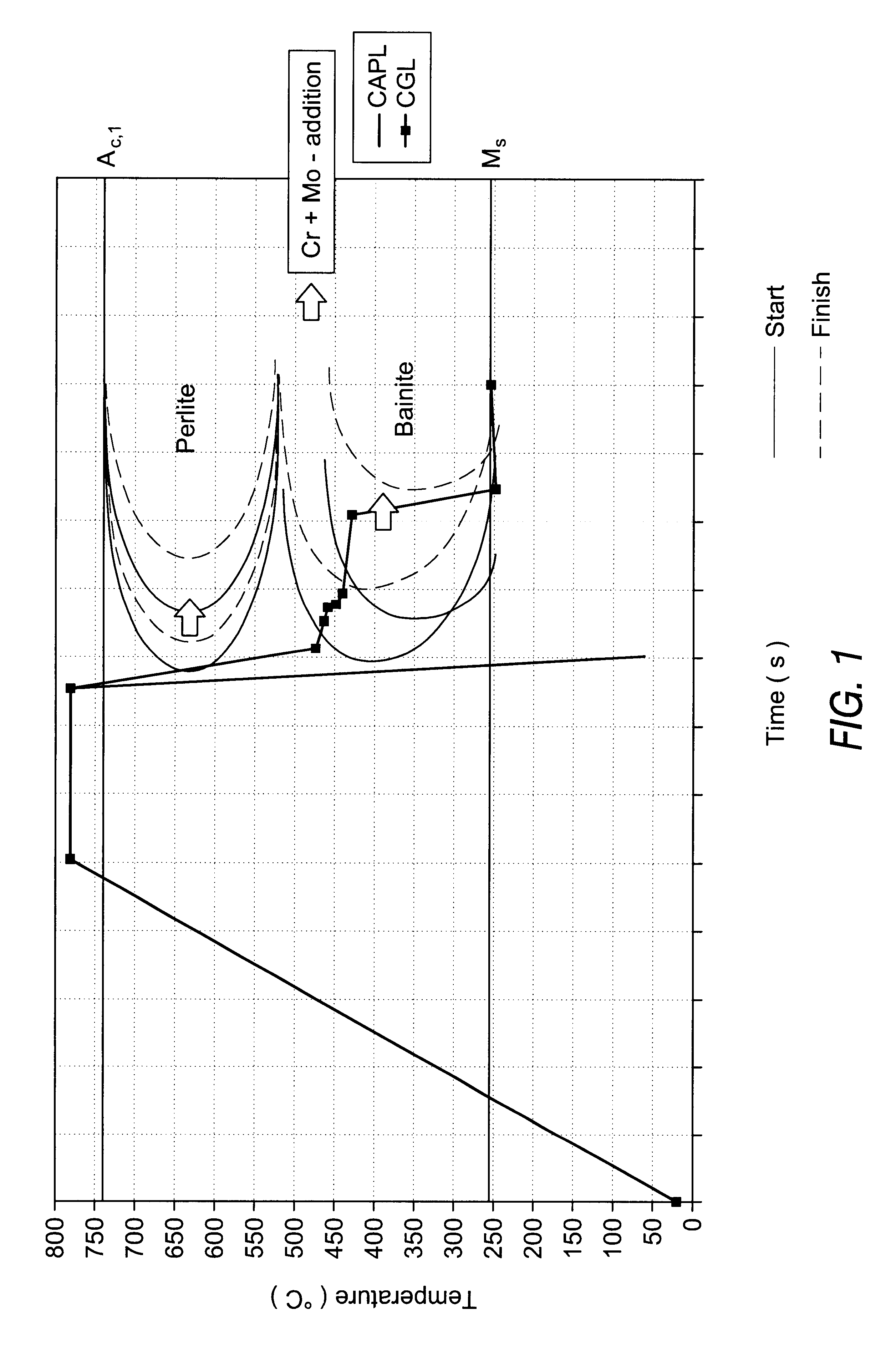

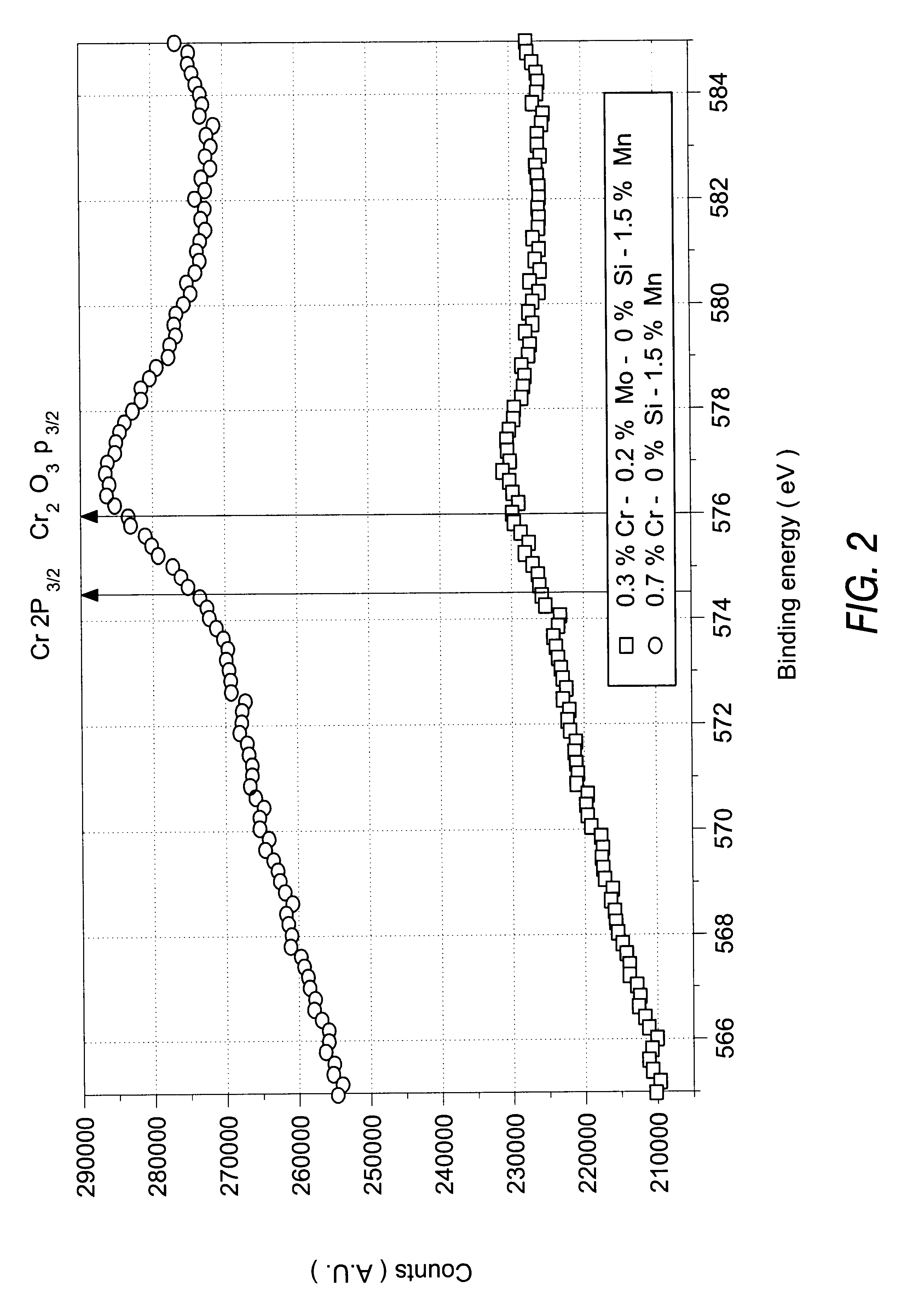

The present invention aims to produce a cold rolled metal coated multi-phase steel, characterized by a tensile strength of at least 500 MPa, a yield ratio (Re / Rm) lower than 0.65 in skinned conditions, lower than 0.60 in unskinned conditions, and with good metal coating adhesion behavior. In the case of the aluminized steel according to the invention, the steel also has superior resistance to temperature corrosion up to 900° C. and excellent mechanical properties at this high temperature. The hot metal coated steel product having a steel composition with a manganese content lower than 1.5%, chrome content between 0.2 and 0.5%, molybdenum content between 0.1 and 0.25%, and a relation between the chrome and molybdenum content as follows Cr+2 Mo higher than or equal to 0.7%, undergoes a thermal treatment in the hot dip metal coating line defined by a soaking temperature between Ac1 and Ac3, a primary cooling speed higher than 25° C. / sec and a secondary cooling speed higher than 4° C. / sec.

Owner:SIDMAR

High-temperature nano ceramic coating with high emissivity

The invention relates to the technical field of a coating, and particularly relates to a high-temperature nano ceramic coating with high emissivity. The high-temperature nano ceramic coating with high emissivity is prepared from 20-27wt% of binder, 40-51% of wt% of filler, 21-39% of water and 0.5-1.5wt% of assistant, wherein the binder is one or two of a styrene-acrylic emulsion and ludox; the filler comprises calcined kaolin, a niobium oxide, a rare-earth oxide and an inorganic black pigment; the assistant comprises a dispersant and a defoamer. The high-temperature nano ceramic coating with high emissivity has high temperature resistance, fouling and slagging resistance, high-temperature corrosion resistance and wear resistance, and the emissivity is not smaller than 0.94.

Owner:GUANGDONG ZHONGQING HUAXIN ENERGY SCI & TECH IND

High-temperature anticorrosive coating for locomotive engine and preparation method of high-temperature anticorrosive coating

InactiveCN104962196AThe source of raw materials is convenient and cheapConvenient and cheap sourceAnti-corrosive paintsFilling materialsCeramic glaze

The invention discloses a high-temperature anticorrosive coating for a locomotive engine and a preparation method of the high-temperature anticorrosive coating, and in particular relates to a high-temperature anticorrosive coating on the surface of the locomotive engine by adopting an organic silicon system, belonging to the technical field of chemical engineering paints. An inorganic high-temperature-resistant anticorrosive wearable coating is developed by taking organic silicon resin and high-purity aluminium oxide as main film forming matters, iron oxide as a conditioning agent and high-purity kaolin, nano calcium carbonate and nanometer magnesia as functional filling materials; the coating can automatically react on a metallic surface at high temperature in the use process so as to generate a compact ceramic glaze protective layer; furthermore, a metal complexing layer having high adhesion property is formed on the metallic surface within a short time; the coating can be used at more than or equal to 1350 DEG C for a long time; and the coating has excellent high-temperature-resistant corrosion property, wear-resisting property, high and low temperature impact property and the like.

Owner:广东华材实业股份有限公司 +2

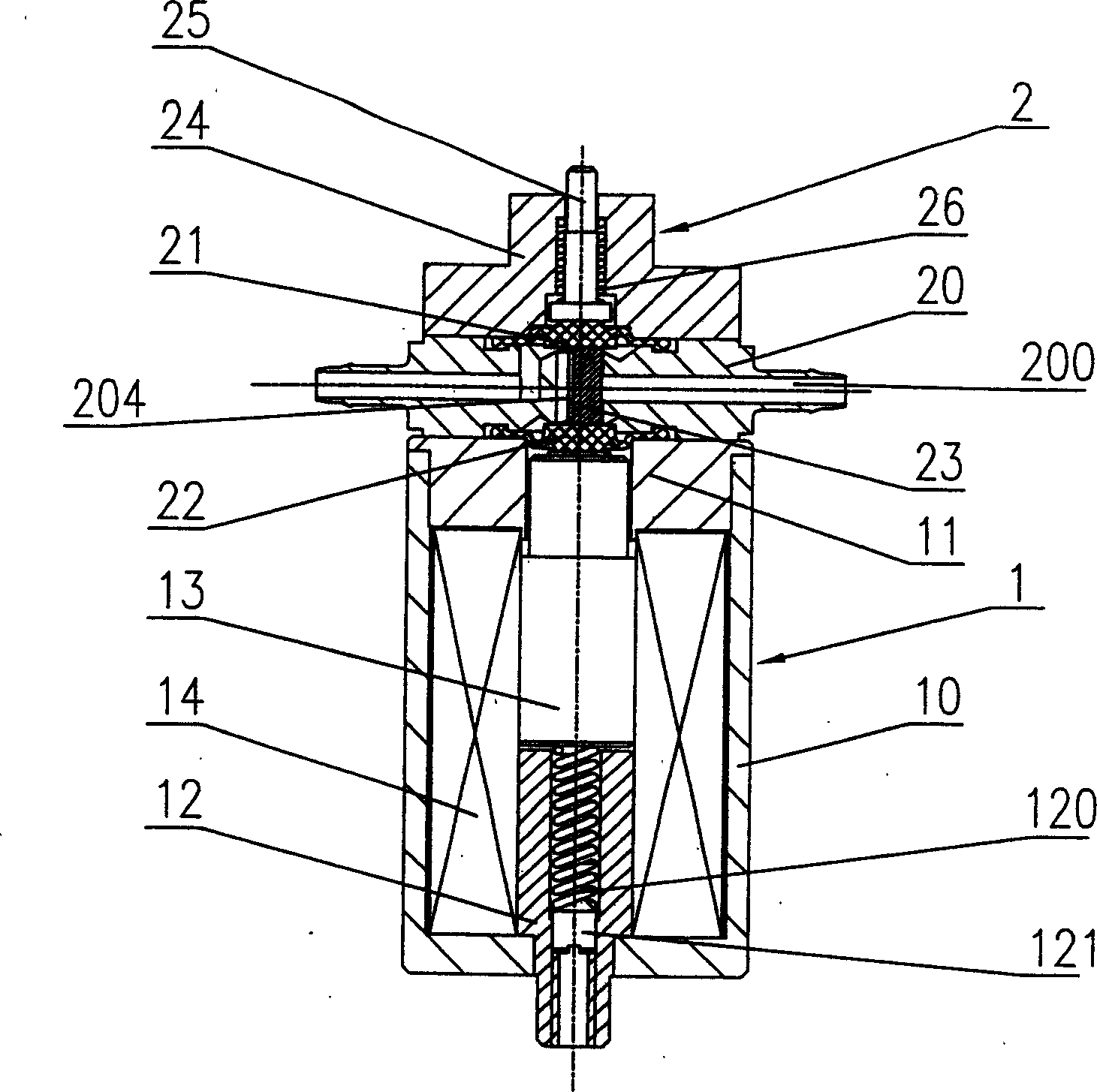

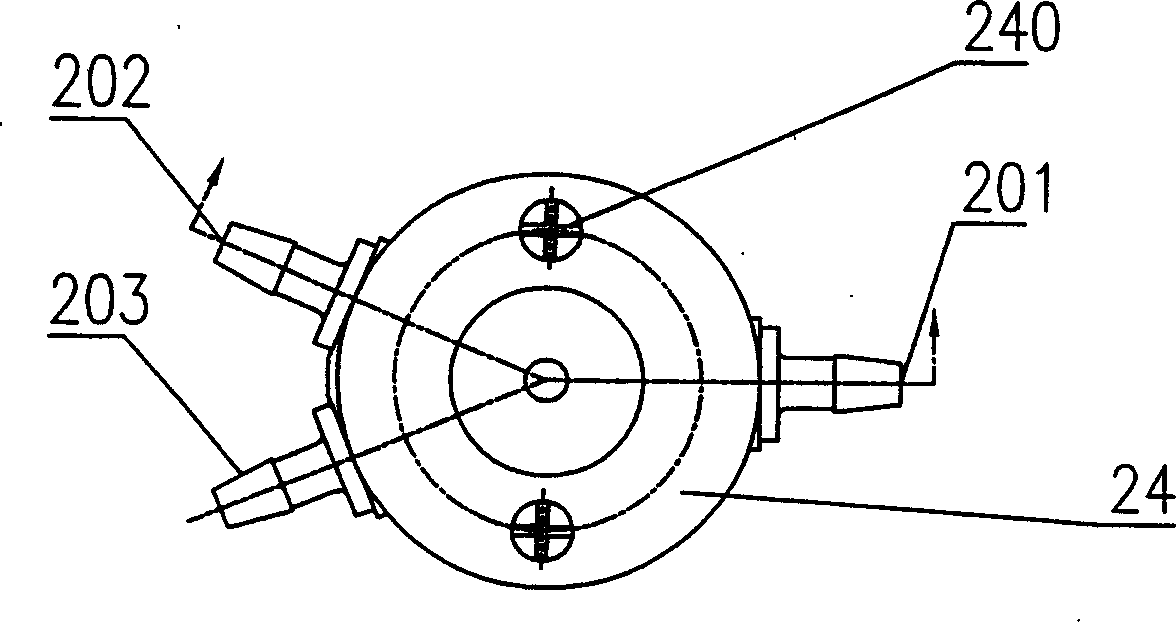

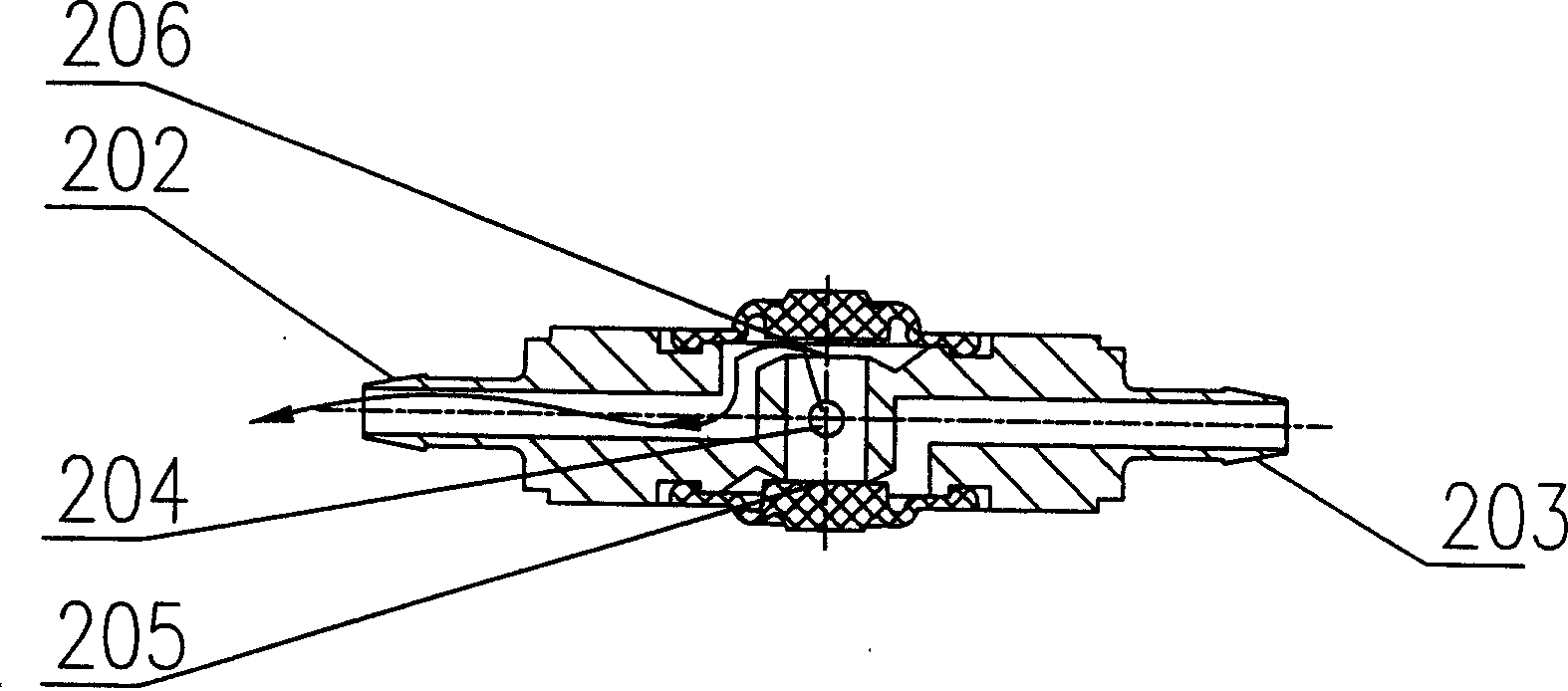

Minitype double-diaphragm electromagnetic valve

InactiveCN1479030ASimple processCompensation for deviations in fitOperating means/releasing devices for valvesMultiple way valvesAxial forceEngineering

A miniature dual-diaphragm electromagnetic valve with autocontroller of fluid medium is composed of an electromagnetic assembly and a valve body assembly. Said electromagnetic assembly consists of valve sleeve, hollow iron barrier, lower spring and its regulator, valve core, electromagnetic coil and electromagnetic end cover. Said valve body assembly consists of main valve body with 2 or more channels, upper and lower diaphragms, axial force-transferring rod, cover, elestic head for manual switch, and spring.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

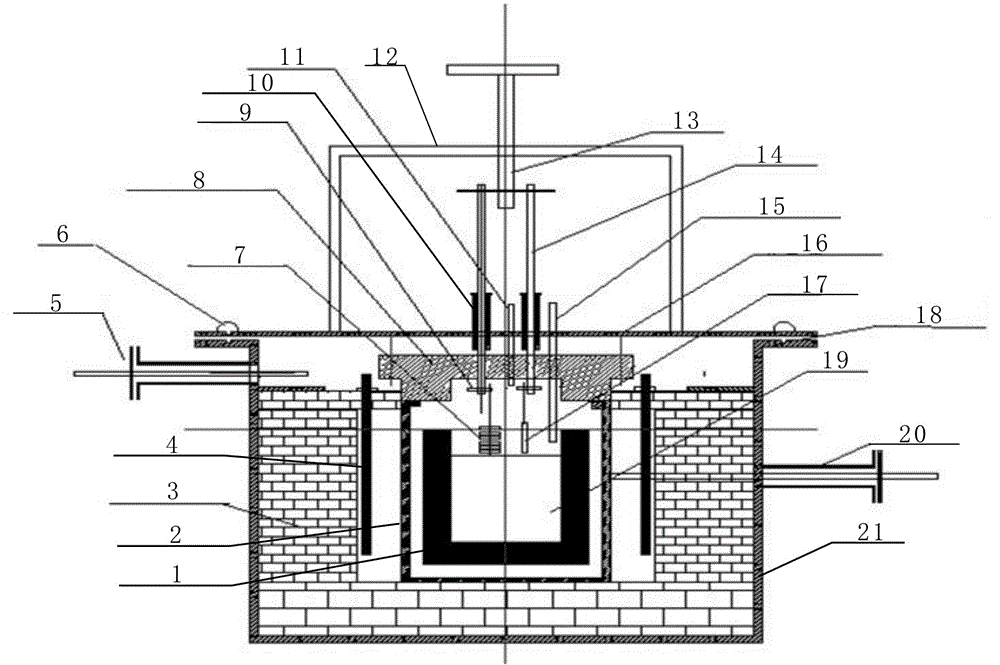

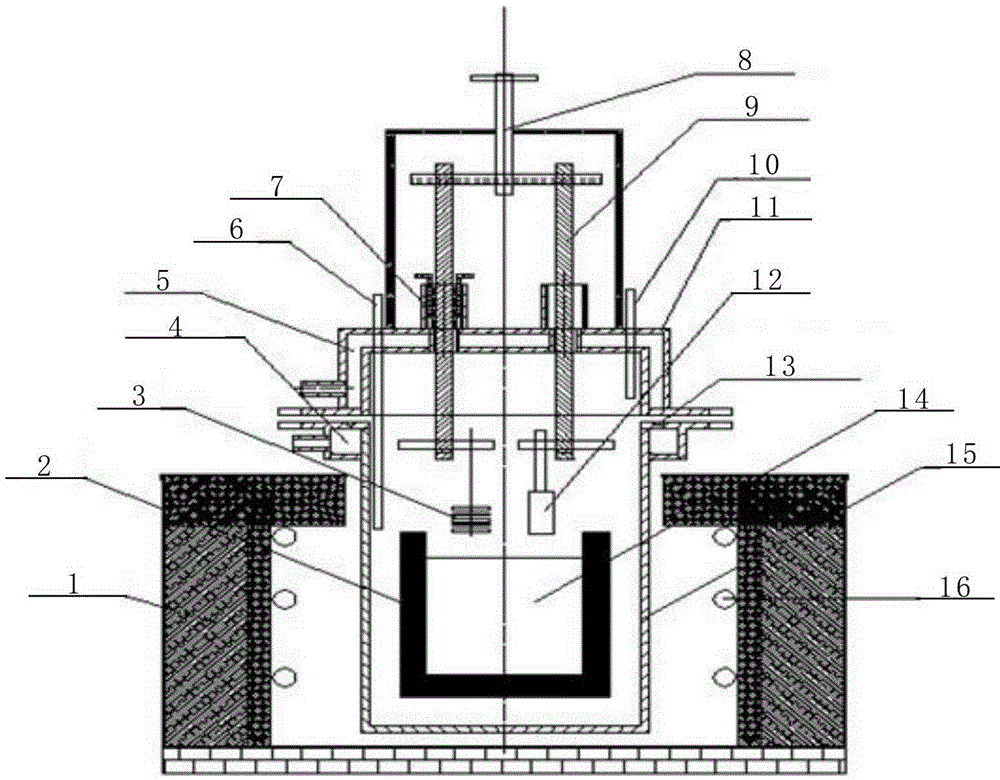

Method for preparing sponge titanium on special resistance furnace by molten salt electrolysis method

The invention discloses a method for preparing sponge titanium on a special resistance furnace by a molten salt electrolysis method. The method comprises the following steps of: placing a crucible (1) filled with a calcium chloride molten salt (19) into a vacuum reactor (2); performing low-constant-temperature water-pumping treatment on the calcium chloride molten salt in the crucible at first; after water is removed, charging argon via an argon inlet tube (11), and cooling a furnace upper cover (16) via a water jacket (6); heating the special resistance furnace (3) to 1000 DEG C at a constant speed; automatically lowering two electrode rods (14) via a lifting rod (13) to cause titanium dioxide (7) and a graphite plate (17) to enter in the crucible, and controlling currents to be 50 A; exhausting the carbon monoxide and carbon dioxide generated by electrolysis, and the remainder argon into a waste gas recovery tank via a gas outlet tube (15); and when the vacuum reactor is automatically cooled to a room temperature along with a furnace body, lifting the furnace upper cover and a fire-resistant cover (8) out of the furnace body via the lifting rod under the action of a limit baffle (9), and taking out the electrolysed titanium dioxide.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Ferrite heat-resistant steel

The invention discloses a ferrite heat-resistant steel. The ferrite heat-resistant steel is a heat-resistant alloy steel which has high temperature resistance and corrosion resistance and is used for an ultra supercritical fire-coal thermal power station boiler. The ferrite heat-resistant steel comprises, by mass, less than or equal to 0.10% of C, 8 to 15% of Cr, less than or equal to 3.0% of W, less than or equal to 3.0% of Co, 0.1 to 0.5% of Si, 0.2 to 0.8% of Mn, 0.3 to 0.6% of Mo, 0.2 to 0.3% of V, 0.05 to 0.10% of Nb, less than or equal to 0.05% of N, less than or equal to 0.08% of Ta, and the balance Fe and unavoidable impurities. The ferrite heat-resistant steel can be used at a high temperature of 650 DEG C and has excellent heat resistance and good corrosion resistance.

Owner:JIANGSU XIHU SPECIAL STEEL

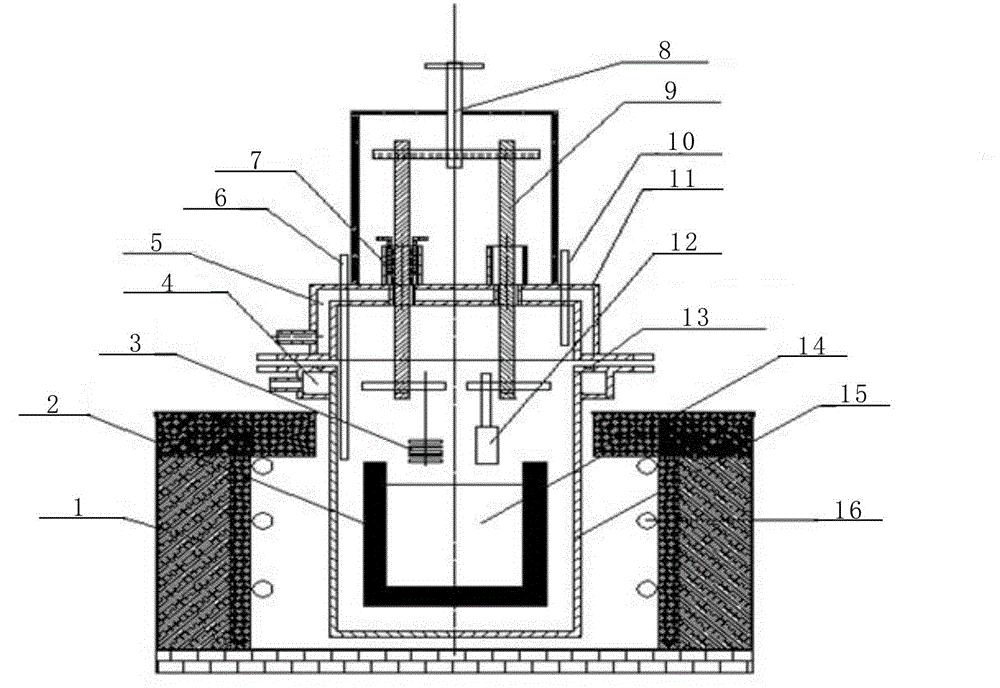

Method for preparing titanium sponge through resistance furnace by adopting molten salt electrolysis method

The invention provides a method for preparing a titanium sponge through a resistance furnace by using a molten salt electrolysis method. The method comprises the following steps of: processing a calcium chloride fused salt (14) in a graphite crucible (2) in a low and constant temperature water extracting manner; charging argon into a sealed vacuum reactor through an air inlet pipe (6) after the water is removed; heating the resistance furnace (1) at a constant speed until reaching 1,000 DEG C; automatically lowering two electrode stems (9) through a lifting rod (8) in order to drive titanium dioxide (3) and a graphite plate (12) to enter the graphite crucible, wherein all current is 50A; exhausting carbon monoxide and carbon dioxide generated in electrolysis and the rest argon into a waste gas recycling tank through an air outlet pipe (10); lifting out the sealed vacuum reactor after electrolyzing to prepare the titanium sponge; pouring cooling water into an annular circulating water jacket (4) and an inner water jacket (5) until reaching room temperature; opening a reversed U shaped upper cover (11); taking out electrolyzed titanium dioxide; and then cleaning to obtain the titanium sponge with the purity up to 99.0%. The method has the characteristics of mature performance, safety and energy conservation performance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

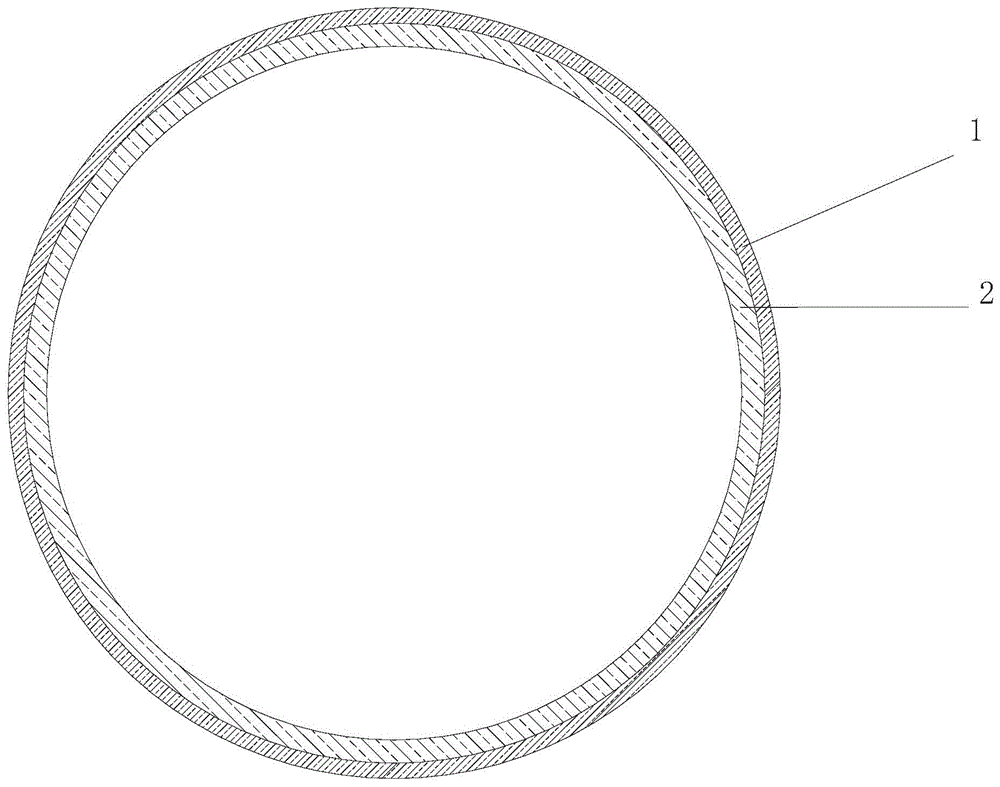

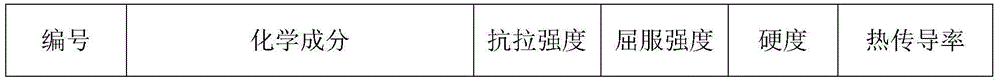

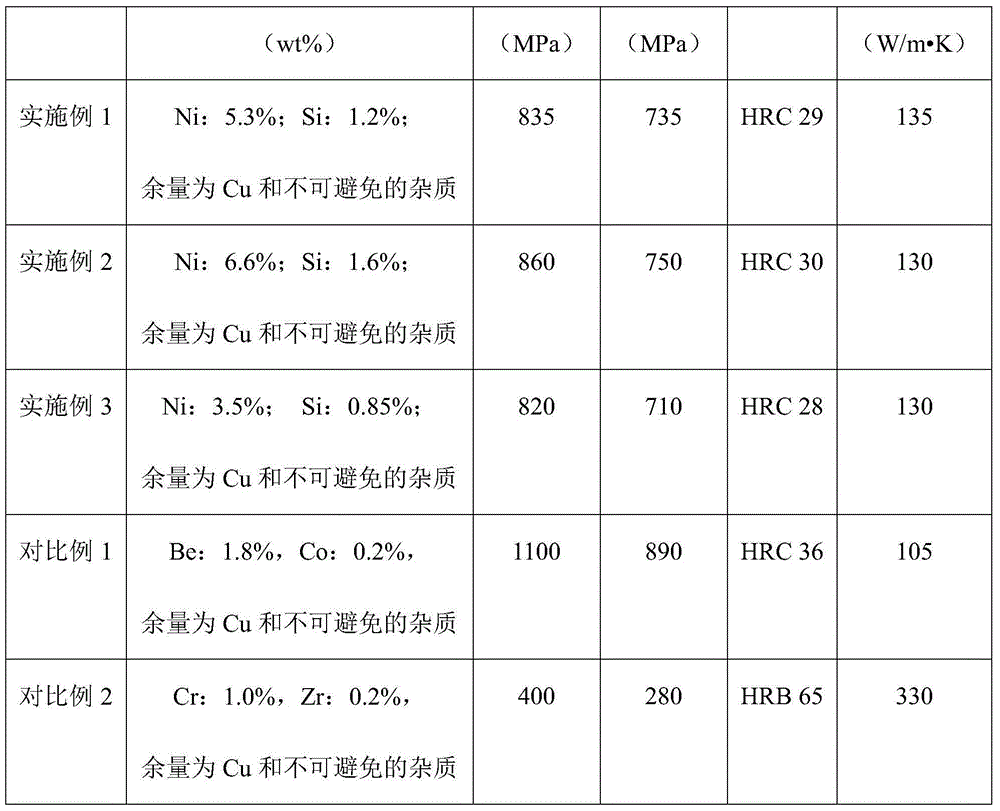

Cu-Ni-Si alloy material and cooling roller sleeve containing alloy

The invention discloses a Cu-Ni-Si alloy material and a cooling roller sleeve containing the alloy. The Cu-Ni-Si alloy is composed of the following components by weight percentage: 3-7% of Ni, 0.8-2.2% of Si, and the balance of Cu and unavoidable impurities. The Cu-Ni-Si alloy comprising the components is applied to the cooling roller sleeve for the amorphous / nano-crystal strip production and a novel cooling roller composite structure roller sleeve is provided. The composite roller sleeve is composed of an inner layer and an outer layer, wherein the outer layer is a Cu-Ni-Si alloy and the inner layer is brass with low cost. The Cu-Ni-Si alloy sleeve is free of an expensive metal Be, cheaper than the beryllium copper, safe and environmentally friendly, so that the amorphous strip lamination coefficient and the finished product ratio can be effectively improved and the service life of the copper roller is prolonged. The composite roller sleeve disclosed by the invention is simple in structure and additionally the material cost is reduced.

Owner:北京电力自动化设备有限公司

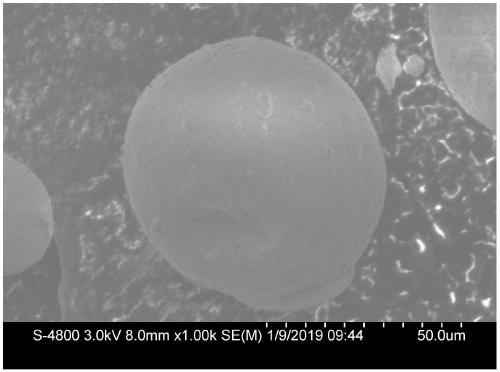

Preparation method of high temperature CMAS and rain corrosion-resistant composite thermal barrier coating

InactiveCN110643930AImprove performanceImprove CMAS corrosion resistanceMolten spray coatingSand blastingPlasma coating

The present invention relates to a preparation method of a high temperature CMAS and rain corrosion-resistant composite thermal barrier coating. The method includes the following steps: step 1: mechanically mixing Gd2Zr2O7 powder and Al2O3 powder to form mixed powder, then adding a binder, stirring and performing ultrasonic shaking to obtain Gd2Zr2O7 / Al2O3 composite powder; step 2: performing sandblasting to the surface of the metallic matrix material of the desired coating, then coating a bonding layer on the surface of the metallic matrix material after sand blasting, and completing pre-treatment to the metallic matrix material; and step 3: using a method of plasma coating to spray the Gd2Zr2O7 / Al2O3 composite powder to the surface of the metallic matrix material so as to form a Gd2Zr2O7 / Al2O3 composite coating. The preparation method of the present invention improves the high-temperature resistance and corrosion resistance of the thermal barrier coating, and overcomes the performance defect of the coating under high temperature CMAS and rain corrosion.

Owner:HEBEI UNIV OF TECH

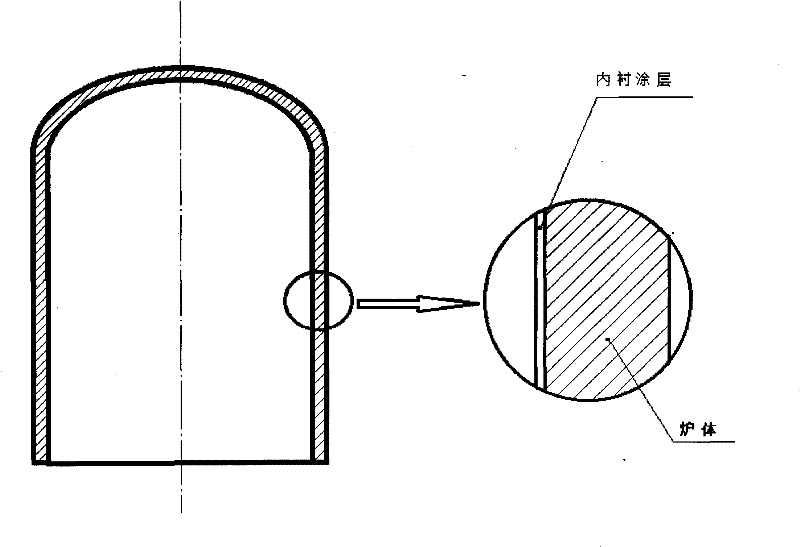

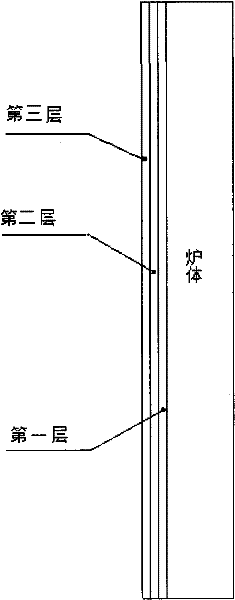

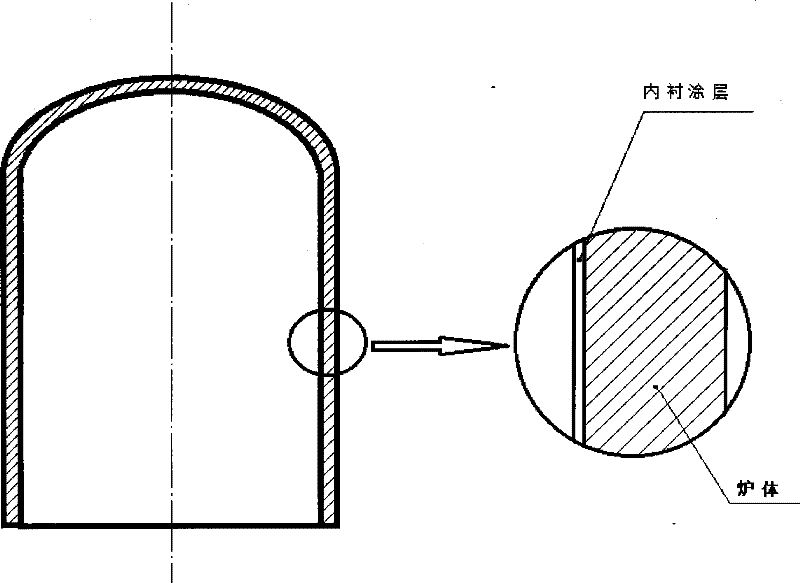

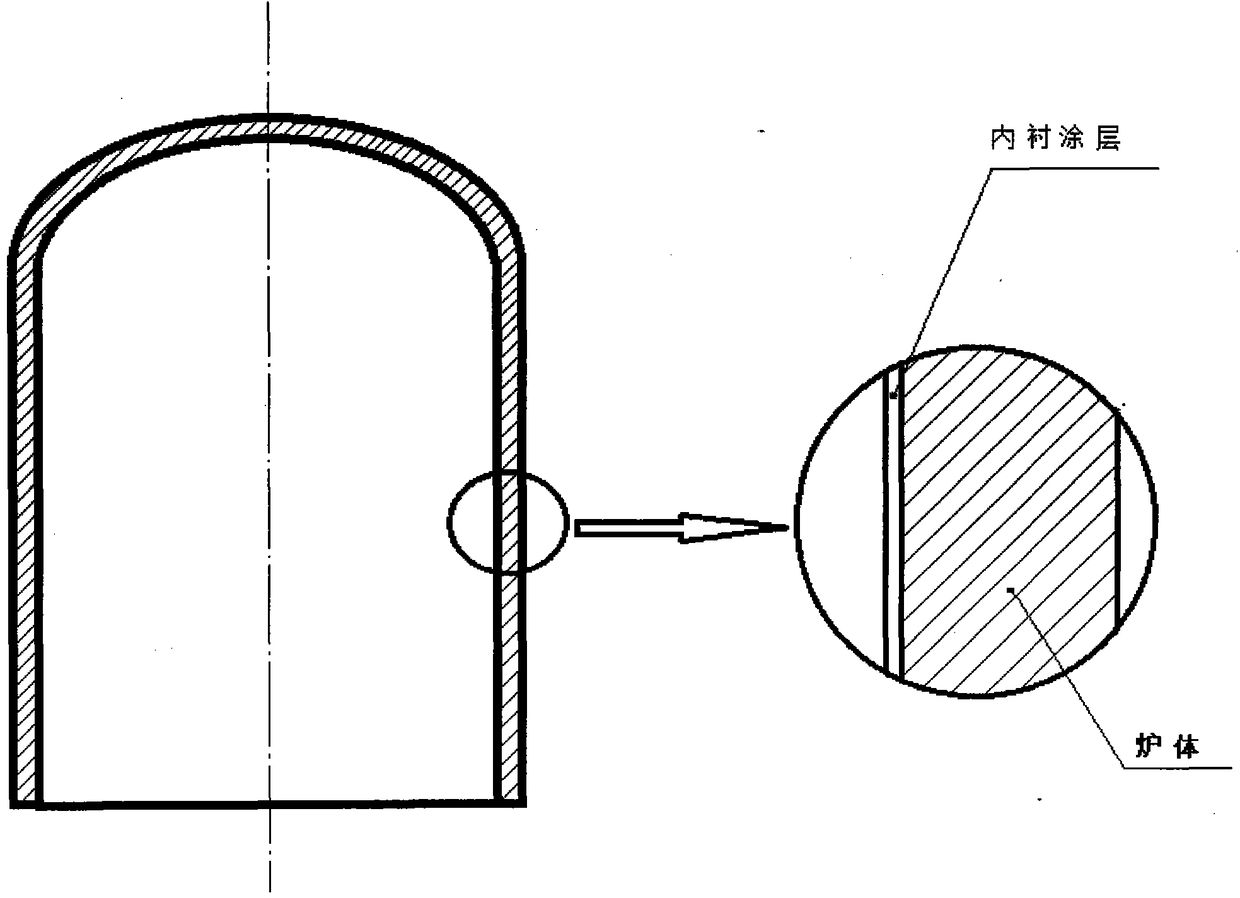

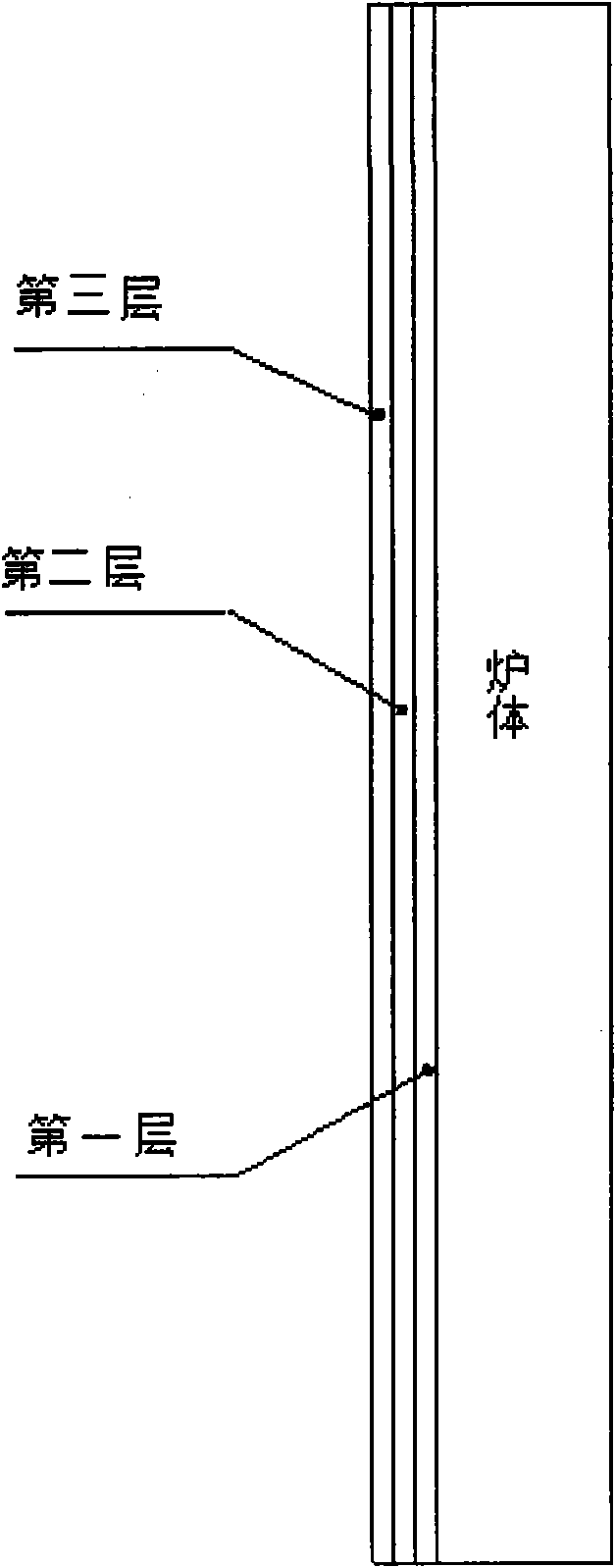

Polycrystalline silicon reduction furnace lining coating and production method thereof

The invention relates to a coating for a furnace wall on the internal side of the furnace body of a polycrystalline silicon reduction furnace (a lining coating for short) and a production method of the coating, in particular to a lining anticorrosive infrared reflection coating of an improved-Siemens-process polycrystalline silicon reduction furnace. The coating is made of a metal-ceramic material. The coating is directly coated on the furnace wall on the internal side of the furnace body of the improved-Siemens-process polycrystalline silicon reduction furnace. The adopted coating method is a physical vapor deposition method or a chemical vapor deposition method. The thickness of the lining coating of the polycrystalline silicon reduction furnace is 1-10 micrometers, the production cost is low and the adhesive force of the coating on the furnace wall is strong. The coating can resist high temperature, strong acid and alkali corrosion and mechanical impact and scraping, the infrared reflection efficiency is high, the service life is long and the loss of heat in the improved-Siemens-process polycrystalline silicon reduction furnace because of heat transfer towards the outside of the furnace can be effectively reduced. Since the coating replaces a pure-gold infrared reflection coating, the expense of the coating material is greatly decreased and the cost of producing polycrystalline silicon products by adopting an improved Siemens process can be greatly decreased.

Owner:胡倾宇

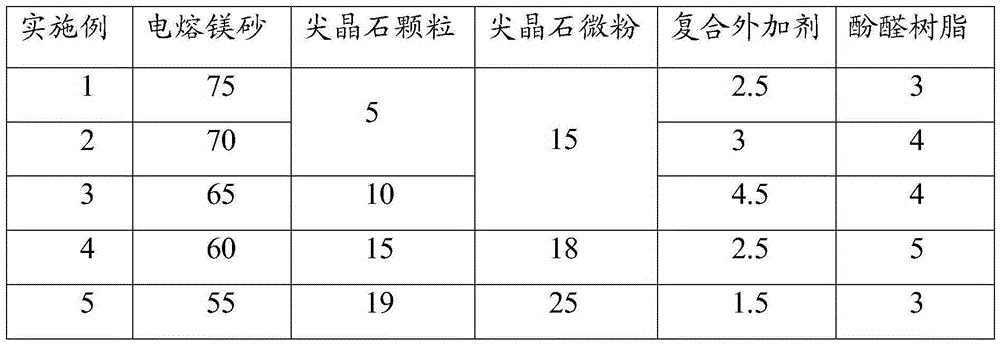

Refractory brick and preparation method thereof

ActiveCN105272306AImprove performanceImprove medium temperature strength and room temperature strengthEnvironmentally friendlyVolume expansion

The invention discloses a refractory brick and a preparation method thereof. The refractory brick is prepared from, by weight, 50-60% of fused magnesia particles, 0-15% of fused magnesia powder, 0-20% of fused spinel particles, 0-20% of fused spinel powder, 0-9% of fused spinel micro powder and 1-6% of compound admixtures; secondary spinel is generated through the amphigama of the fused spinel micro powder and sintering activity in the high-temperature use process, volume expansion caused by an electric smelting method or a sintering method is avoided, and the medium-temperature strength and normal-temperature strength are improved; the critical grain size of the components is increased, a firm framework structure is provided for the refractory brick, and high-temperature strength is improved; the refractory brick and the preparation method thereof are used for solving the technical problem that in the prior art, an refractory brick cannot integrate environmental protection and strength; the refractory brick is environmentally friendly and high in strength.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

Ceramic identification coating suitable for metal substrate and preparation method thereof

The invention provides a ceramic identification coating suitable for a metal substrate and a preparation method of the ceramic identification coating. The ceramic identification coating is particularly suitable for a metal substrate in a power plant boiler. The ceramic identification coating is composed of a base layer and a surface layer. The base layer is also called as an identification layer and is white, and the thickness of the base layer is 0.10-0.15 mm; the surface layer is green, and the thickness of the surface layer is 0.10-0.15 mm; and the color difference between the surface layerand the base layer is obvious, and an identification degree is high. In the using process of the ceramic identification coating, sand blasting is not needed when the base layer part is exposed and the surface layer is re-sprayed; and after floating ash on a heating surface is blown and cleaned through high-pressure air or high-pressure water, surface layer paint can be directly sprayed to the part, where the white base layer is exposed, of the ceramic identification coating. The ceramic identification coating has the functions of resisting high-temperature corrosion, resisting dirt adhesion and coking and improving heat exchange efficiency, the service life of the substrate can be effectively prolonged, the manpower and economic cost of subsequent maintenance is remarkably reduced, and long-life-cycle protection of the heating surface is achieved.

Owner:旭贞新能源科技(上海)有限公司

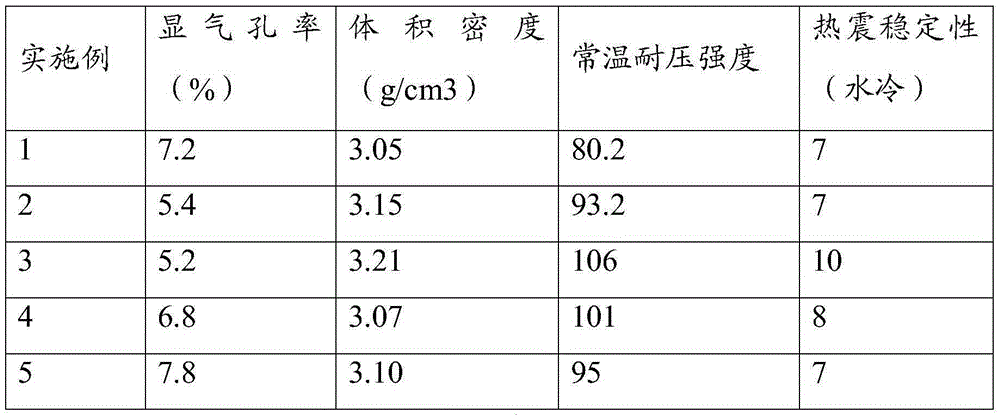

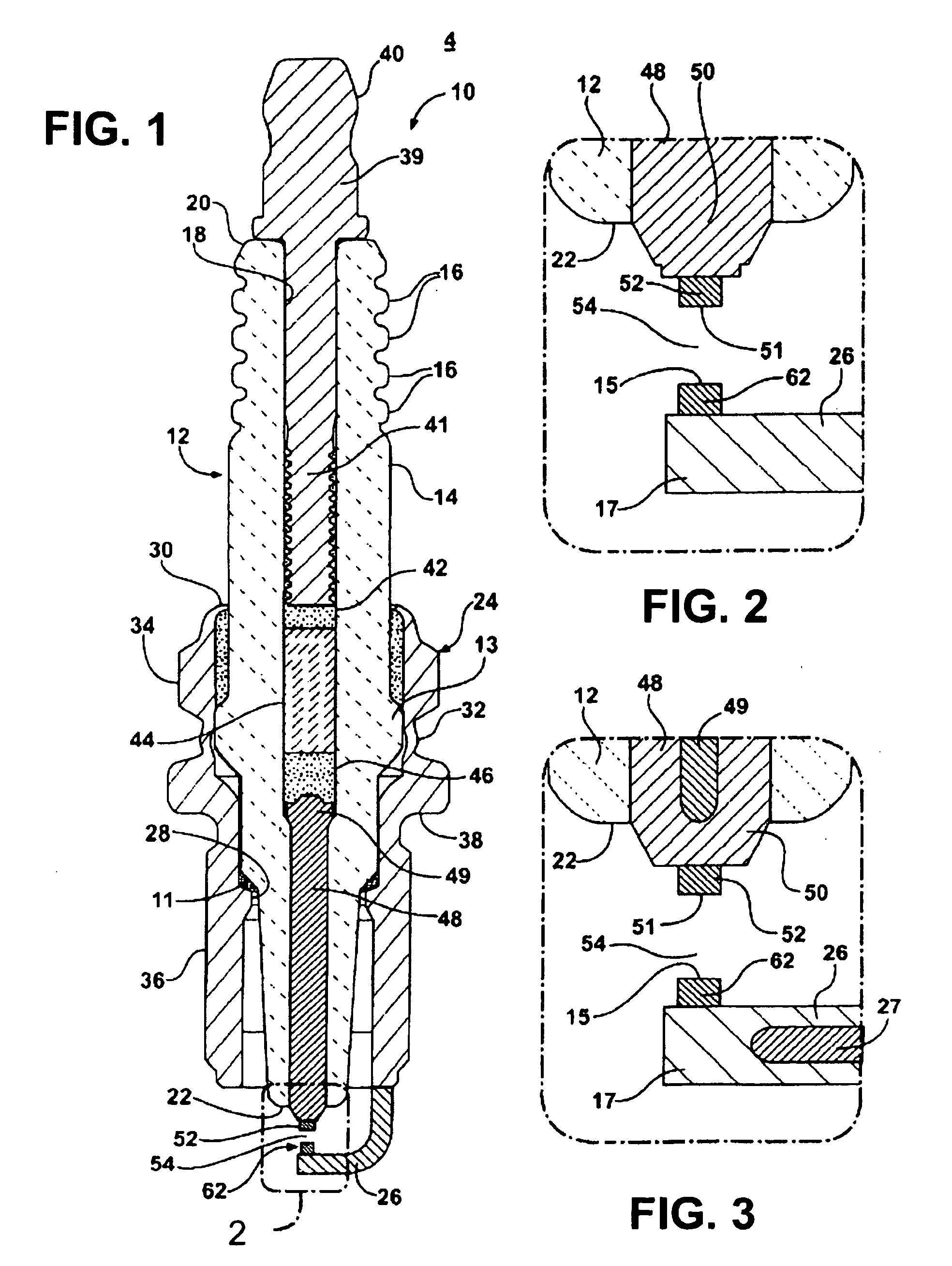

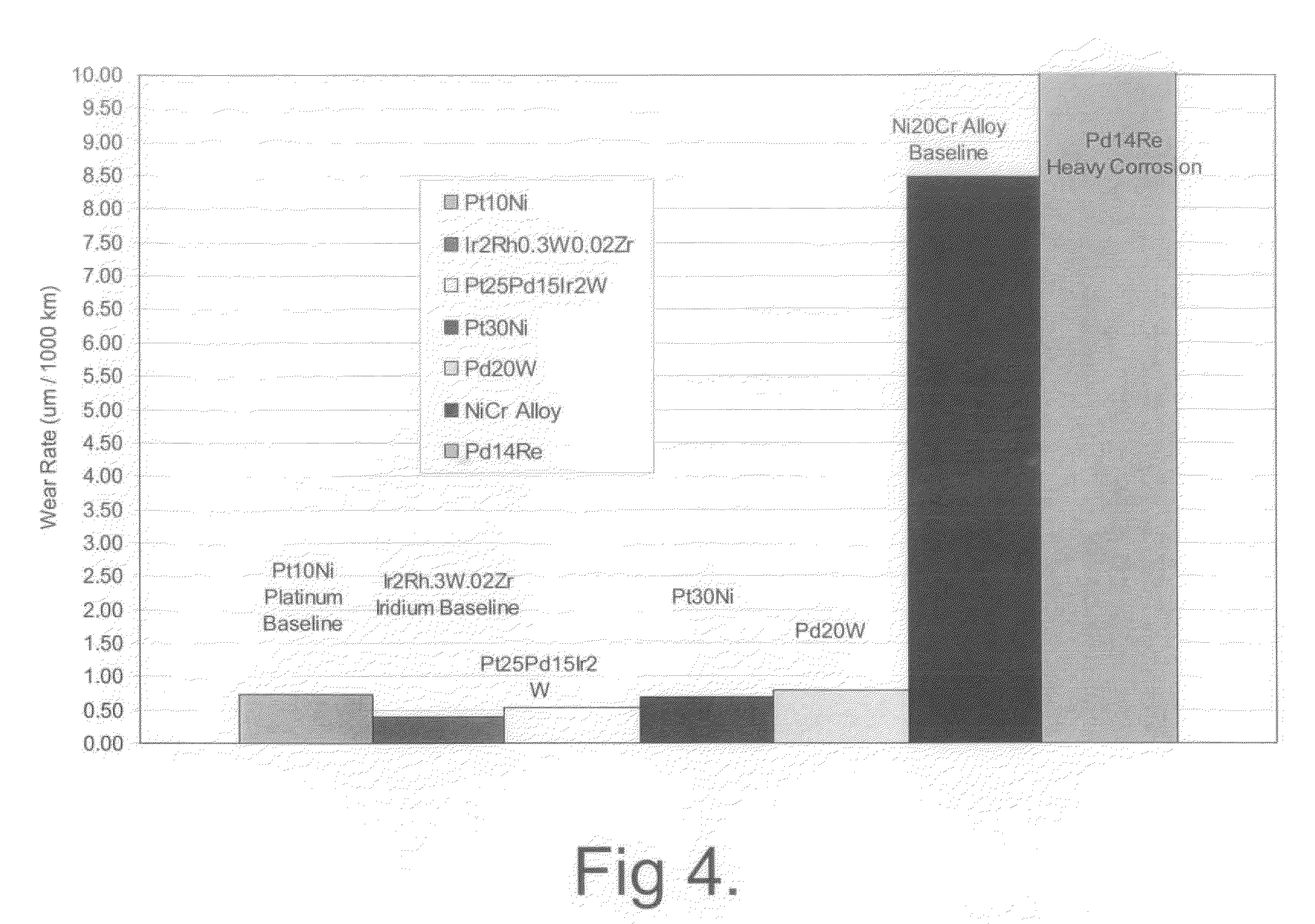

Alloys for spark ignition device electrode spark surfaces

An electrode for a spark ignition device, including a spark plug, which includes an alloy consisting essentially of, in weight percent, at least 15% Ni and the balance substantially Pt, and more particularly 15-45% Ni and the balance substantially Pt; 5-35% W, and the balance substantially Pd; and 5-15% Ni, 5-15% Pt, less than 10% Ir, and the balance substantially Pd.

Owner:LYKOWSKI JAMES D

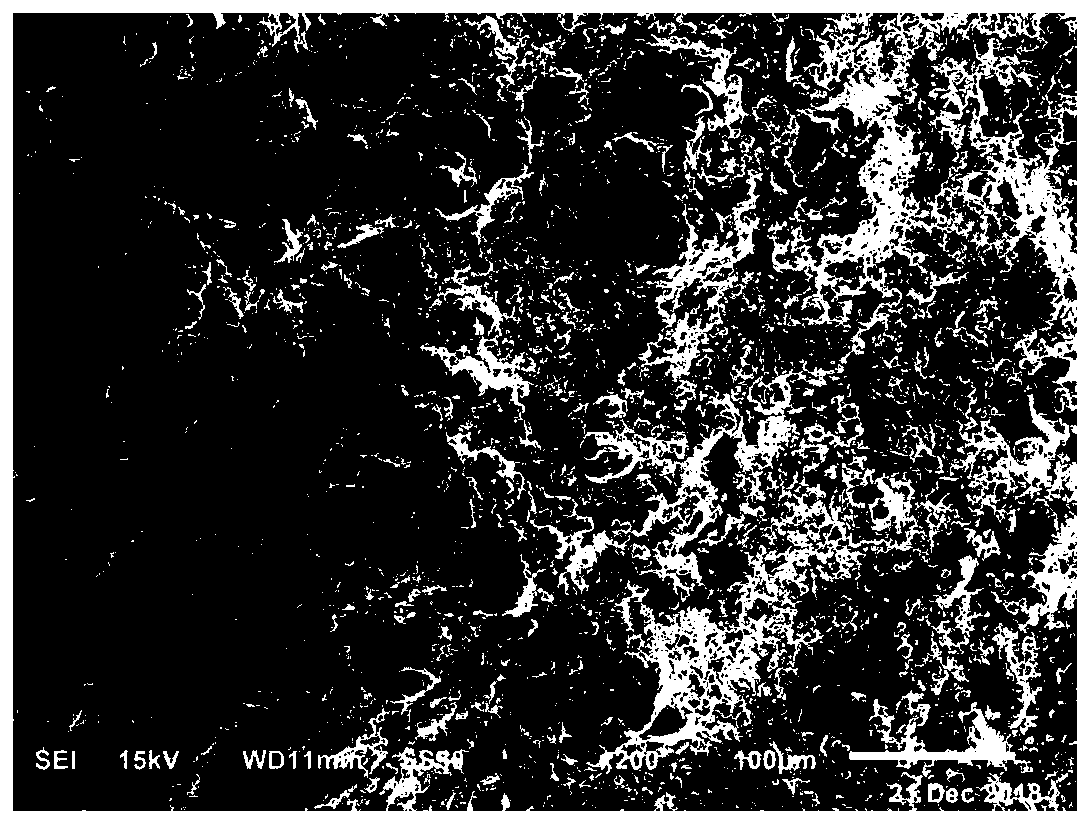

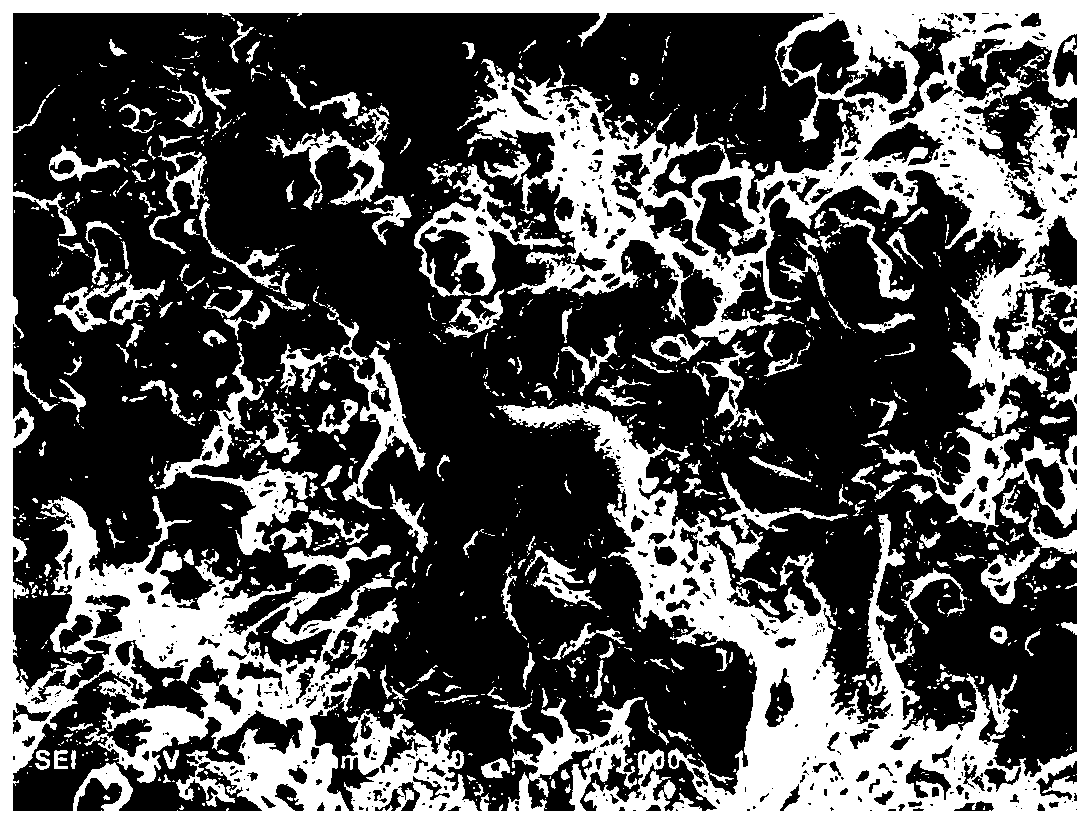

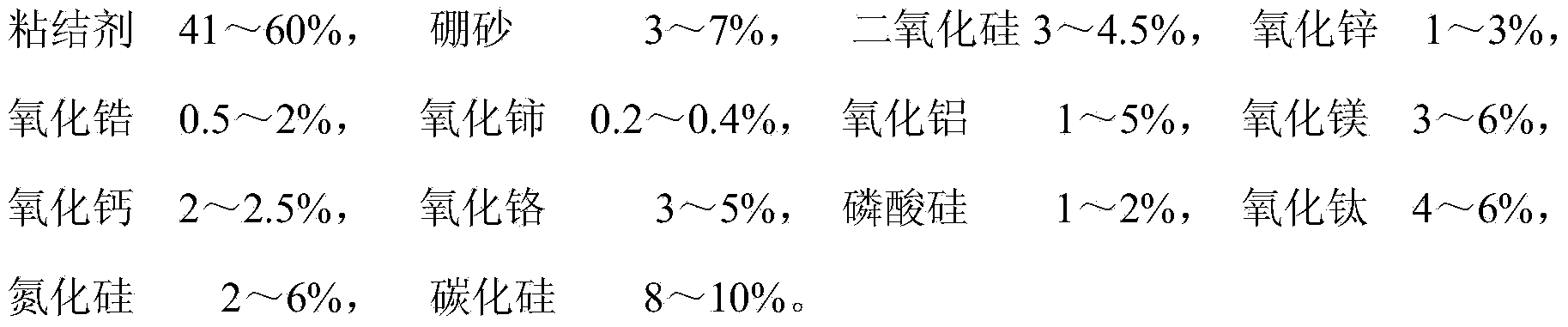

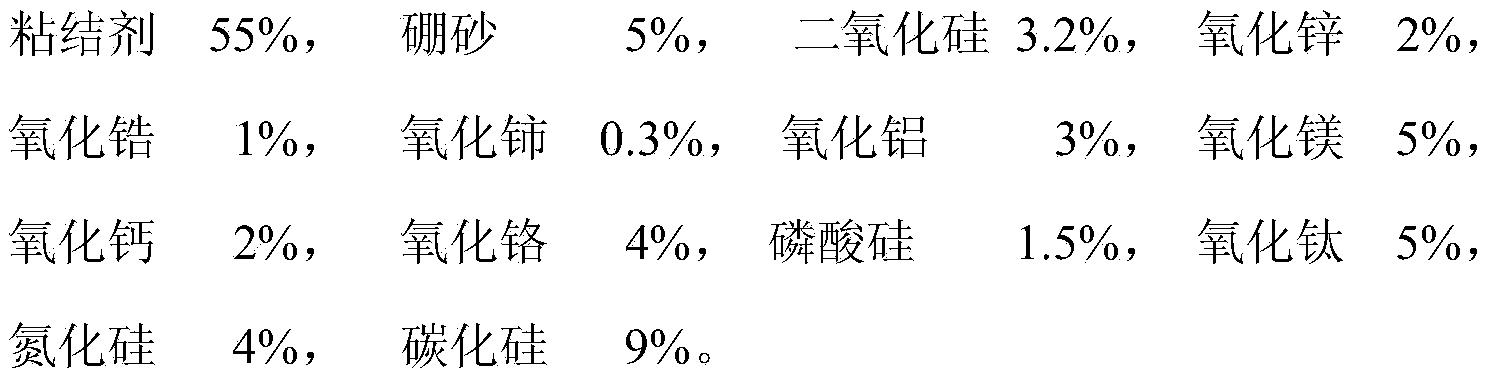

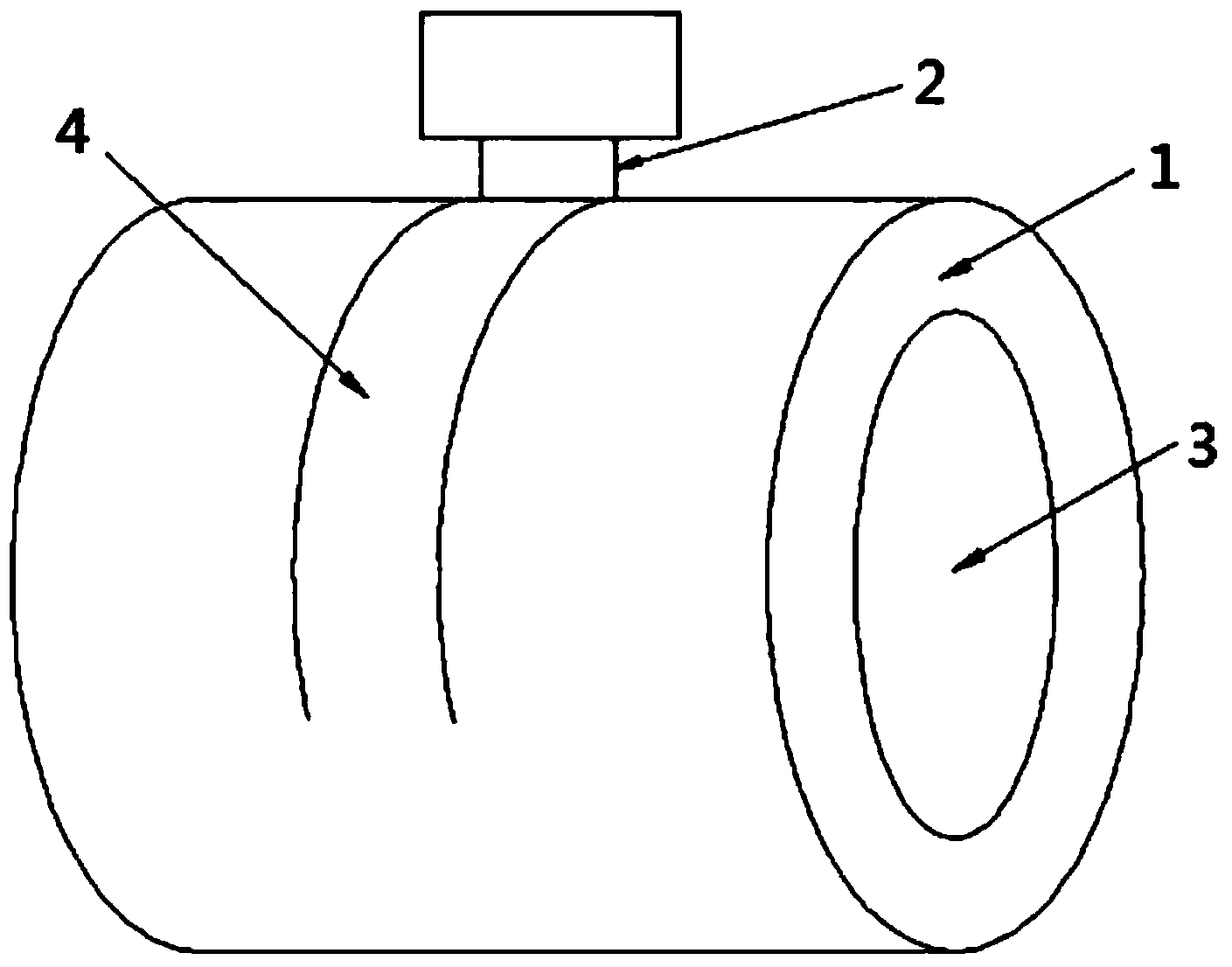

Nanocomposite and nanocomposite furnace tube

ActiveCN103965666AHigh emissivityHigh temperature corrosion resistanceAntifouling/underwater paintsAlkali metal silicate coatingsPhosphateSlag

The invention relates to a nanocomposite and a nanocomposite furnace tube. The nanocomposite is used for solving the problems of high-temperature corrosion, wear resistance, sticking pollution and slag formation resistance and low heat transfer efficiency of the furnace tube. According to the technical scheme, the designed nanocomposite prepared from different proportions of a binder, borax, silicon dioxide, zinc oxide, zirconium oxide, cerium oxide, aluminum oxide, magnesium oxide, calcium oxide, silicon phosphate, titanium oxide, silicon nitride and silicon carbide is sprayed on the common furnace tube, and the common furnace tube is fired by heating to 500 DEG C so as to form the composite furnace tube. The nanocomposite and the nanocomposite furnace tube have the advantages that a construction process is simple and easy to operate, the combination degree of the nanocomposite and the furnace tube is high, the nanocomposite furnace tube has strong thermal shock resistance and high temperature corrosion resistance and is free of pollution and slag formation and high in emissivity, and energy sources are saved. The nanocomposite can be widely applied to the furnace tubes of bath boilers heated by fire coal, fuel oil, gas and biomass, small and medium-sized industrial boilers, petroleum and petrochemical boilers, power station boilers and heating furnaces.

Owner:CHAOYANG ATT ELECTRIC POWER ENERGY SAVING TECH

Composite copper bush and preparation method thereof

ActiveCN103909240AExtended service lifeImprove cooling efficiencyMetal layered productsThermal conductivityCooling efficiency

The invention discloses a composite copper bush for cooling. The composite copper bush comprises an outer copper bush, a horizontal high-heat-conductivity material layer and an inner copper bush which are laminated together closely and sequentially from outside to inside, the outer copper bush is prepared from chromium zirconium copper, and the outer copper bush is prepared from oxygen-free copper. The composite copper bush has high cooling efficiency, can improve performance of amorphous and nanocrystalline products, and can increase product percent of pass of amorphous and nanocrystalline belting equipment. The invention further discloses a preparation method of the composite copper bush.

Owner:GUANGZHOU QIDA MATERIAL & TECH

A martensite alloy steel material used for an air valve of an internal combustion engine and a preparation method of the alloy steel material

The invention discloses a martensite alloy steel material used for an air valve of an internal combustion engine. The alloy steel material comprises following elements by weight: 0.6-0.8% of carbon, 0.2-0.3% of silicon, 3.3-3.5% of manganese, 0.4-0.5% of chromium, 0.03-0.05% of molybdenum, 0.004-0.005% of vanadium, 0.06-0.08% of Ti, 2.3-2.5% of Ni, 0.01-0.03% of Sb, S not more than 0.030% and P not more than 0.030%, with the balance being iron. According to the alloy steel material and the method, by using composition of the antimony and other raw materials, and by reasonably arranging the ratio and the production technology and reasonably arranging the adding sequence, the alloy material formed has characteristics of high strength, high hardness, good wear resistance, good toughness, resistance to high-temperature corrosion, oxidation resistance, and the like. The alloy steel material is suitable for the air valve of the internal combustion engine so that the air valve has high air tightness. A portion of waste iron is used as a raw material to make the alloy quality stable and uniform. By addition of a refining agent, the porosity degree is reduced by 1-2 degrees.

Owner:WUHU HONGKUN AUTO PARTS

High-temperature-corrosion-resistant wear-resistant paint for power plant boiler pipelines and preparation method thereof

InactiveCN104962177AConvenient and cheap sourceHigh temperature corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses a high-temperature-corrosion-resistant wear-resistant paint for power plant boiler pipelines and a preparation method thereof, and particularly relates to a high-temperature-corrosion-resistant wear-resistant coating prepared from an inorganic mineral material on a power plant boiler pipeline surface and a preparation method thereof, belonging to the technical field of chemical paints. The paint is composed of an epoxy resin E-20, an organosilicon low polymer, kaolin, wollastonite, talcum powder, potash feldspar, albite and nano calcium carbonate. The paint is a high-temperature corrosion-resistant developed by using the inorganic mineral as the raw material, solves the problems of high-temperature high-pressure corrosion, scour abrasion resistance and the like in the boiler pipeline, prolongs the pipeline replacement period, and enhances the benefit of the power generation industry.

Owner:广东华材实业股份有限公司 +1

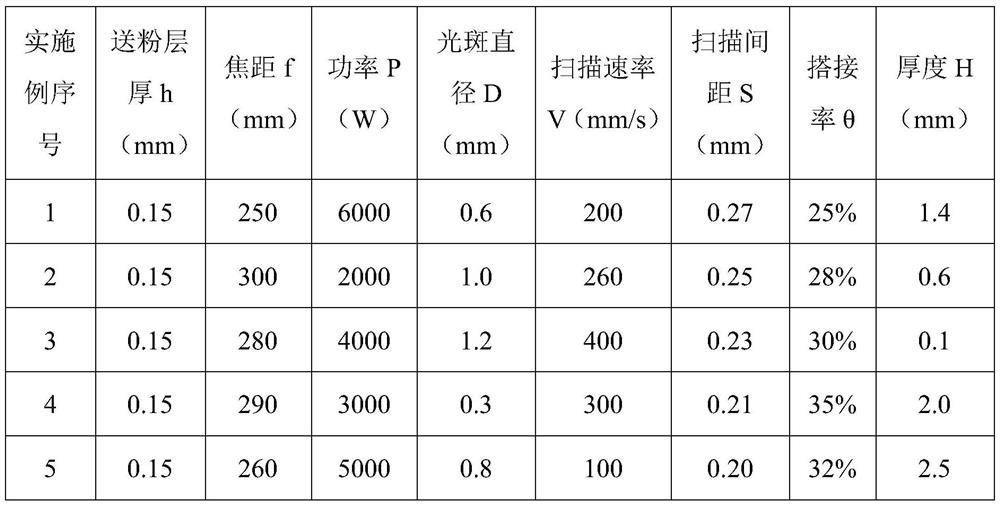

Ball valve surface laser cladding nickel-based material and additive manufacturing process thereof

InactiveCN110923696AHigh bonding strengthPrevent falling offAdditive manufacturing apparatusMetallic material coating processesBall valveNickel

The invention discloses a ball valve surface laser cladding nickel-based material and an additive manufacturing process thereof. The nickel-based material is prepared from the following chemical components in percentage by mass: 2.0-4.0% of B, 0.3-1% of C, 10.0-20.0% of Cr, 2.5-4.5% of Fe, 3.0-5.0% of Si, 10.0-20.0% of W and the balance of Ni. The method is mainly used for valve trim additive manufacturing of a ball valve, meets the working condition requirements of the surfaces of the valve ball and a ball seat through process transformation and material change, meets the requirements for high hardening, high-temperature corrosion resistance and high-temperature abrasion resistance of the surface of base metal, and achieves a low-cost and high-performance surface treatment process throughcontinuous research, development and innovation.

Owner:江苏特维克科技有限公司

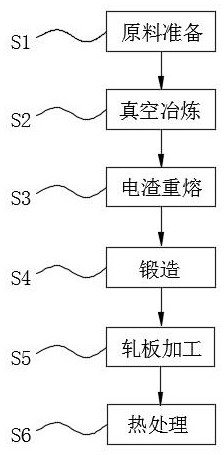

High-temperature fan corrosion-resistant alloy and preparation method thereof

InactiveCN112458339AGood high temperature strengthHigh temperature corrosion resistanceCorrosionTa element

The invention provides a high-temperature fan corrosion-resistant alloy. The alloy comprises the following elements, in percentage by weight, of 0.05% to 0.10% of C, less than or equal to 0.70% of Si,less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.0% to 23.0% of Cr, 0.60% to 1.50% of Al, less than or equal to 2.0% of Fe, 10.0% to 13.0% of Co, 0.20% to 0.60% of Ti and the balance Ni and inevitable impurities. A preparation method of the high-temperature fan corrosion-resistant alloy comprises the steps of raw material preparation, vacuum smelting, electroslag remelting, forging, plate rolling and heat treatment. According to the alloy and the method, components and a process of the alloy are optimally designed, the alloy has the advantages of being good in high-temperature strength, high in high-temperature corrosion resistance and high in oxidation resistance, and the service life of a high-temperature fan can be prolonged.

Owner:江苏新核合金科技有限公司

Antifriction heat-resistant cobalt-based alloy material used for laser composite manufacturing of large and medium proximate matter rollers

InactiveCN106756256AHeat fatigue resistantHigh temperature corrosion resistanceMetallic material coating processesHigh pressureLaser

The invention discloses antifriction heat-resistant cobalt-based alloy powder used for laser composite manufacturing of large and medium proximate matter rollers. The antifriction heat-resistant cobalt-based alloy powder is characterized in that the components of the cobalt-based alloy powder material comprise, by weight, 0.55-1.25% of C, 20.00-27.00% of Cr, 1.00-1.30% of Si, 10.00-15.00% of Ni, 0.20-0.50% of Mn, 5.50-11.50% of W, 1.00-1.50% of Fe, 3.00-5.00% of B, 2.50-5.20% of N and the balance Co. By optimizing the matching of the laser cladding powder material, the antifriction heat-resistant material suitable for the large and medium proximate matter rollers is designed, and cladding layers are manufactured on the surfaces of the large and medium proximate matter rollers through the laser cladding technology, so that the abrasion resistance requirement of the rollers under the high temperature and high pressure conditions is met.

Owner:沈阳大陆激光工程技术有限公司

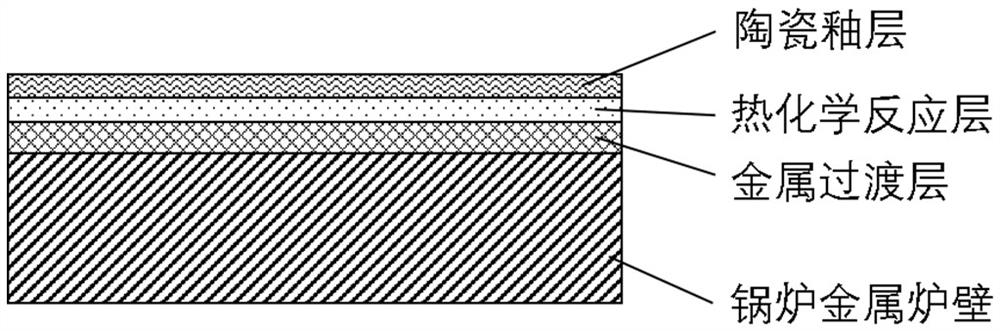

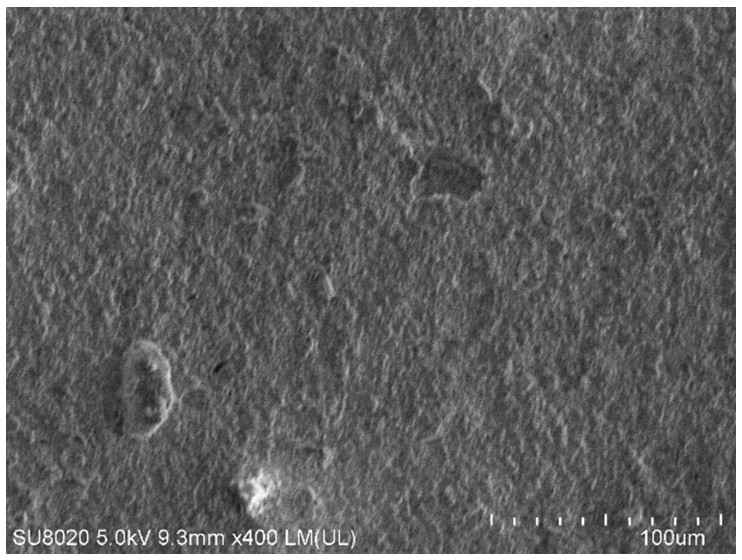

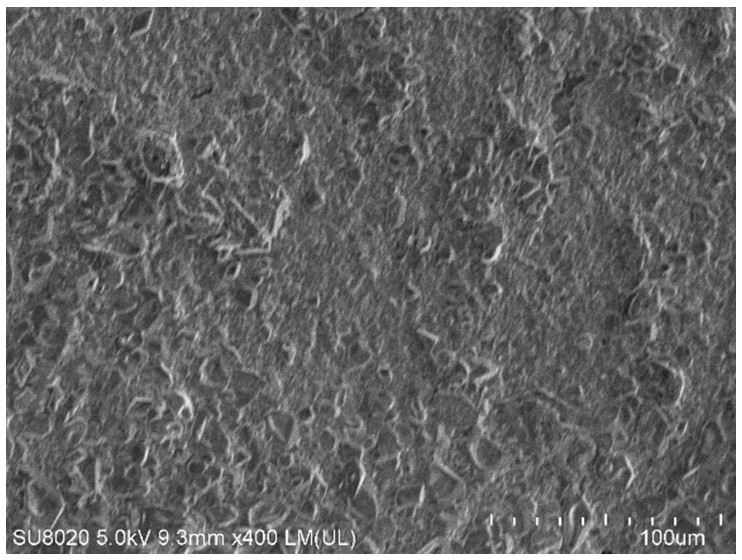

Preparation method of anti-coking composite ceramic coating for power station boiler

ActiveCN114525466AImprove thermal conductivityImprove heat transfer efficiencyMolten spray coatingComposite ceramicAluminium hydroxide

The invention relates to a preparation method of an anti-coking composite ceramic coating for a power station boiler, and belongs to the technical field of high-temperature protective coatings. The invention particularly relates to an anti-coking composite ceramic coating material and a preparation method thereof. The composite ceramic coating material is composed of a thermal chemical reaction ceramic bottom layer and a surface glaze layer. The thermal chemical reaction ceramic bottom layer comprises the following raw materials: aggregate, a binder, a dispersing agent and water; the aggregate is prepared by uniformly mixing chrome green, boron nitride and aluminum oxide; the binder is prepared by uniformly mixing phosphoric acid with the mass concentration of 85%, magnesium oxide, aluminum hydroxide, zinc oxide and deionized water; the dispersing agent is polyacrylic acid. The bonding strength of the anti-coking composite ceramic coating is 26.6-30.2 Mpa, the high temperature corrosion resistance index is 0.116-0.158 mg / mm < 2 >, and the thermal shock resistance index is 7-15. The boiler surface is effectively prevented from coking, and the heat efficiency of the boiler is improved to a small extent. And the actual service life of the coating can exceed 10000 hours, so that the use safety and the service life of the boiler are prolonged.

Owner:ZHONGDIAN HUACHUANG ELECTRIC POWER TECH RES +2

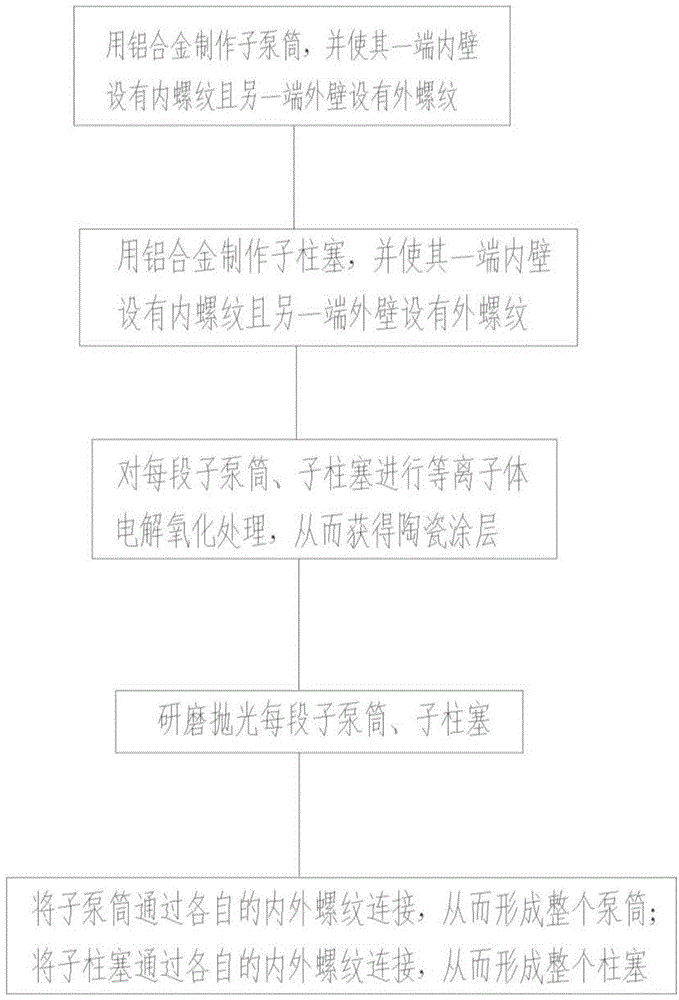

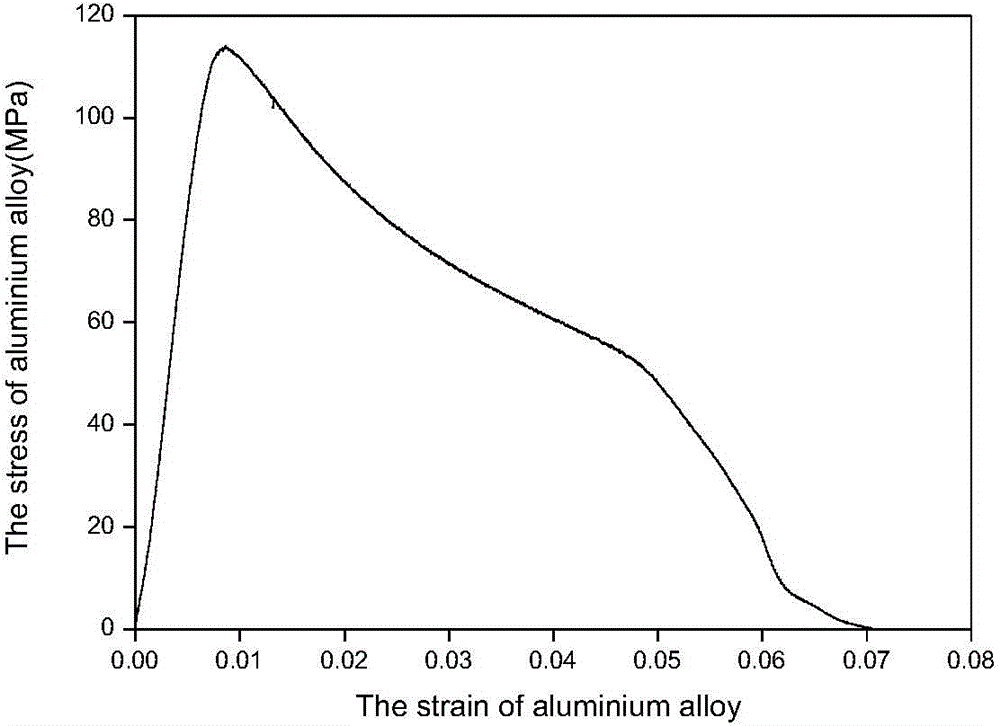

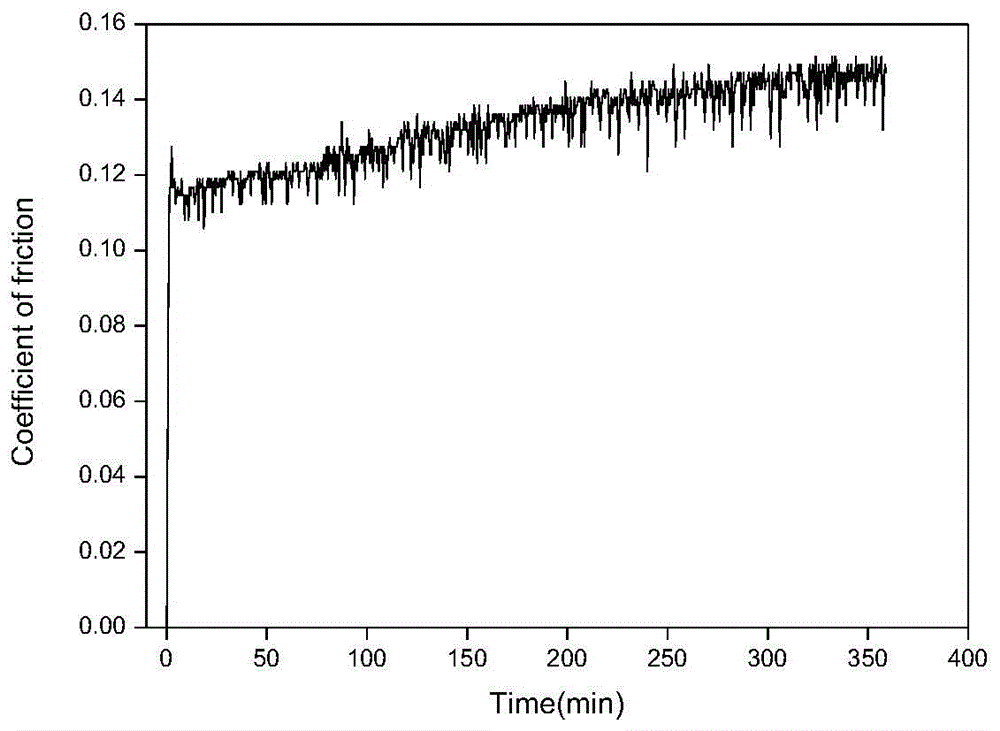

Oil well pump and manufacturing method thereof

ActiveCN104929928AHigh temperature corrosion resistanceExcellent friction and wear resistanceAnodisationPositive displacement pump componentsCeramic coatingWear resistance

The invention discloses an oil well pump which comprises a pump cylinder and a plunger piston, wherein ceramic coatings are arranged on the inner wall and the outer wall of the pump cylinder respectively; and ceramic coatings are arranged on the inner wall and the outer wall of the plunger piston respectively. The ceramic coatings are arranged on the inner wall and the outer wall of the pump cylinder respectively, the ceramic coatings are arranged on the inner wall and the outer wall of the plunger piston respectively, and the ceramic coatings are in a very compact structure, so that high temperature resistance ability and high corrosion resistance ability of the oil well pump are guaranteed, the anti-friction ability and the wear resistance ability are high, and the service life is greatly prolonged. A manufacturing method of the oil well pump is also provided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

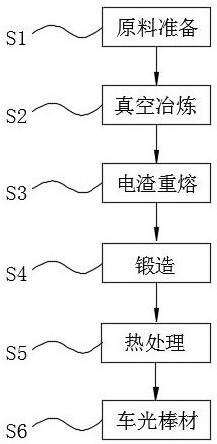

Nickel-based alloy for high-temperature fan shaft and preparation method thereof

InactiveCN112458340AExtended service lifeImprove high temperature strengthChemical compositionUltimate tensile strength

The invention provides a nickel-based alloy for a high-temperature fan shaft. The nickel-based alloy comprises the following elements of, in percentage by weight, 0.05-0.10% of C, less than or equal to 0.70% of Si, less than or equal to 0.70% of Mn, less than or equal to 0.012% of P, less than or equal to 0.008% of S, 20.0-23.0% of Cr, 0.60-1.50% of Al, less than or equal to 2.0% of Fe, 10.0-13.0%of Co, 0.20-0.60% of Ti and the balance Ni and inevitable impurities. A preparation method of the nickel-based alloy for the high-temperature fan shaft comprises the steps of raw material preparation, vacuum smelting, electroslag remelting, forging, heat treatment and bar turning. The nickel-based alloy prepared through the method has the advantages of being good in high-temperature strength, high in high-temperature corrosion resistance and high in oxidation resistance, the alloy purity is high, impurities are few, metallographic structures and chemical components are uniform, the nickel-based alloy is applied to manufacturing of the high-temperature fan shaft, and the service life of a high-temperature fan can be prolonged.

Owner:江苏新核合金科技有限公司

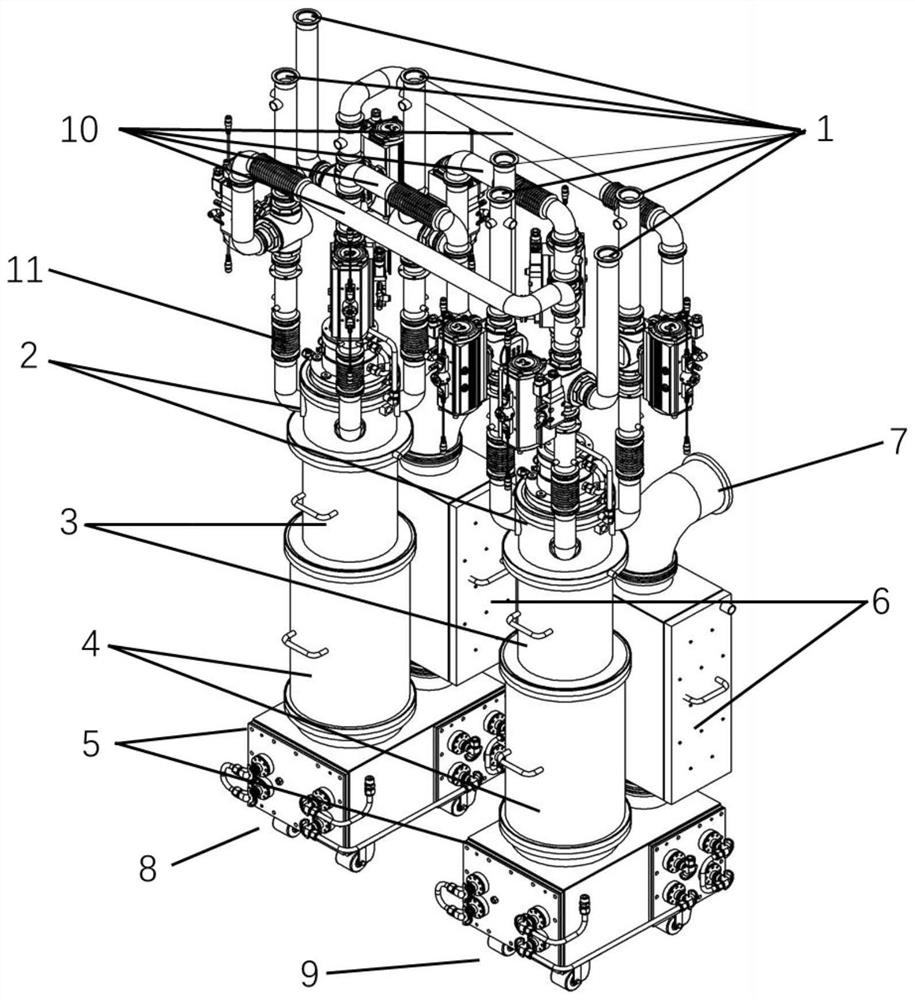

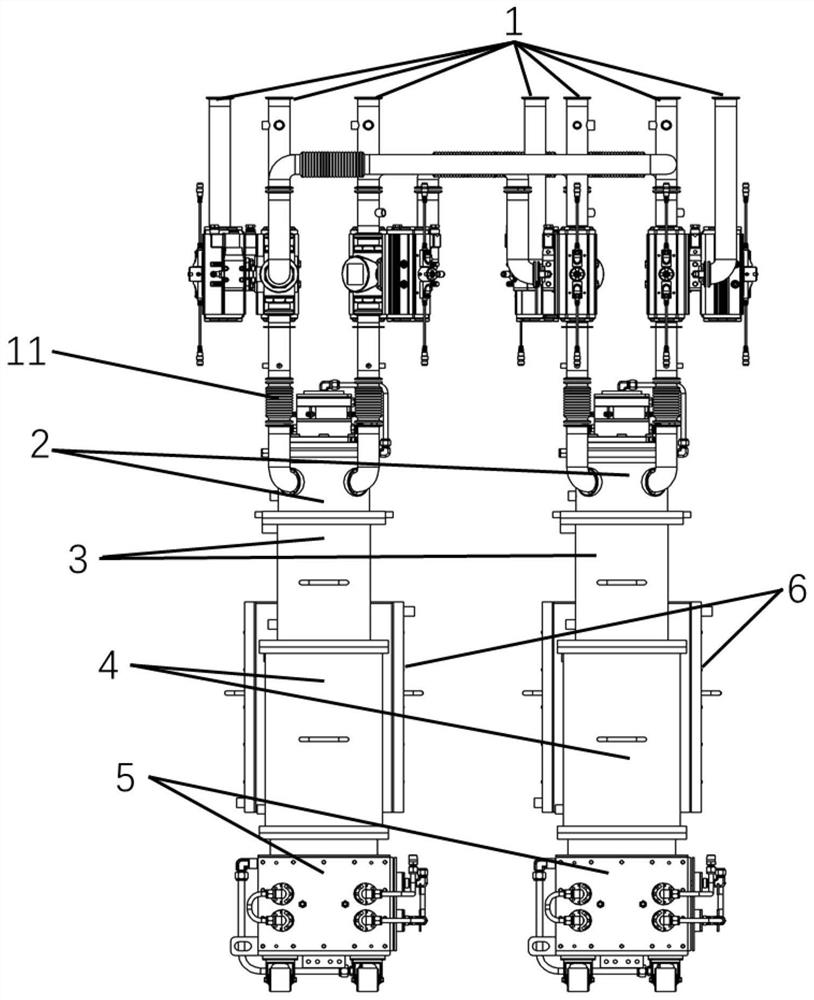

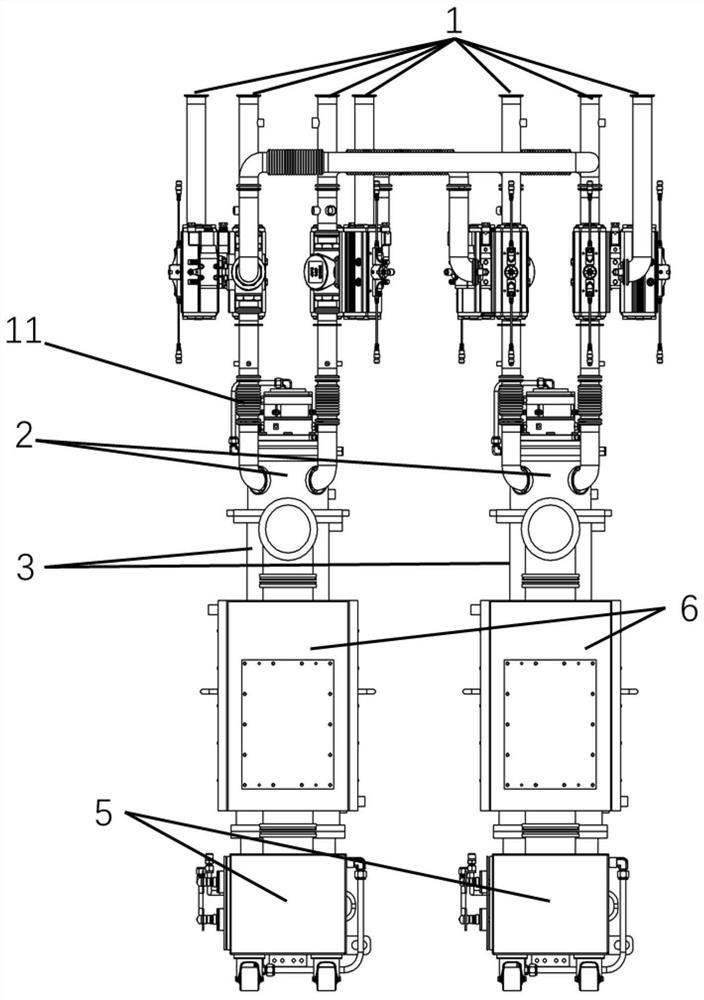

Waste gas treatment device

PendingCN114688547ALong working hoursShort maintenance timeIncinerator apparatusWastewaterProcess engineering

The invention discloses a waste gas treatment device which comprises two treatment modules, and the two treatment modules both have complete waste gas treatment capacity, namely, the two treatment modules can work independently and can also be connected with other treatment modules in parallel or in series. Each processing module comprises one or more air inlets, a plasma torch, a reaction cavity, a cooling cavity, a collector, a heat exchanger and an exhaust port. The waste gas treatment device has the advantages that the ion ignition device is long in continuous working time, short in maintenance time, free of hydration and harm removal, high in corrosion resistance and free of wastewater discharge, secondary pollution is reduced, the shutdown probability of the device is reduced, and non-shutdown maintenance is achieved.

Owner:上海协微环境科技有限公司

Preparation method of CMAS high temperature and corrosion resistant composite thermal barrier coating

InactiveCN109504932AReduce porosityImprove thermal shock resistanceMolten spray coatingThermal barrier coatingThermal shock

The invention relates to a preparation method of a CMAS high temperature and corrosion resistant composite thermal barrier coating. The preparation method comprises the steps that LZ ceramic powders and Al2O3 powders are mechanically mixed, and LZ / Al2O3 composite powders are obtained by ultrasonic concussion, and then the LZ / Al2O3 composite coating with Al2O3 content being 5%-30% is synthesized byplasma spray. According to the preparation method of the CMAS high temperature and corrosion resistant composite thermal barrier coating, the thermal shock resistance of TBCs is improved, and the defect of the loss of corrosion resistance of a coating in CMAS environment is overcome.

Owner:HEBEI UNIV OF TECH

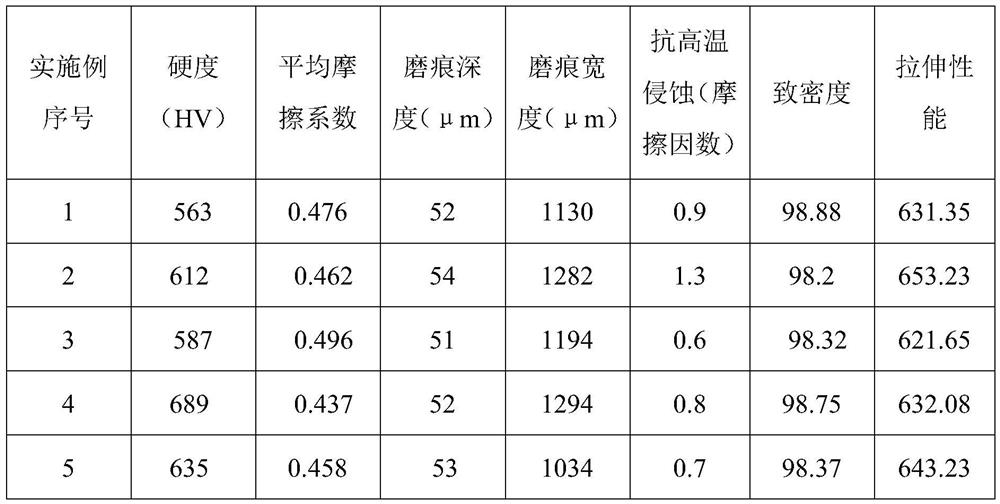

Alloy material with wear resistance and high-temperature erosion resistance, surface treatment method for mold copper plate and mold copper plate

The invention discloses an alloy material with wear resistance and high-temperature erosion resistance. The alloy material comprises nickel, carbon, cobalt, boron, silicon, phosphorus, tungsten, beryllium, copper and other substances. Meanwhile, the invention further discloses a surface treatment method for a mold copper plate and the mold copper plate. The surface treatment method for the mold copper plate includes the following steps: 1) polishing, 2) cleaning, and 3) laser 3D printing, and further includes a cooling step. The surface of the mold copper plate is provided with an alloy material layer with wear resistance and high-temperature erosion resistance, and the thickness of the alloy material layer is 0.1-2.5 mm. The mold copper plate prepared by the surface treatment method for the mold copper plate by using the alloy material with wear resistance and high-temperature erosion resistance has higher hardness, a smaller average friction coefficient, better wear resistance, higher high-temperature erosion performance and higher density and tensile performance.

Owner:唐山中科量子激光科技有限公司

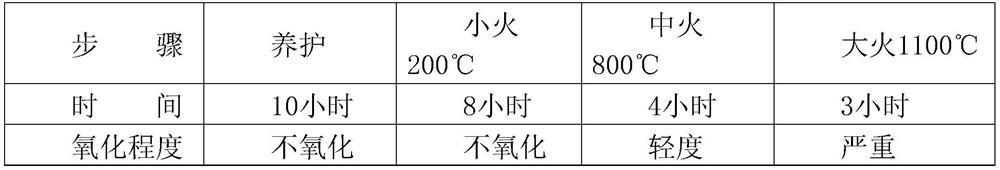

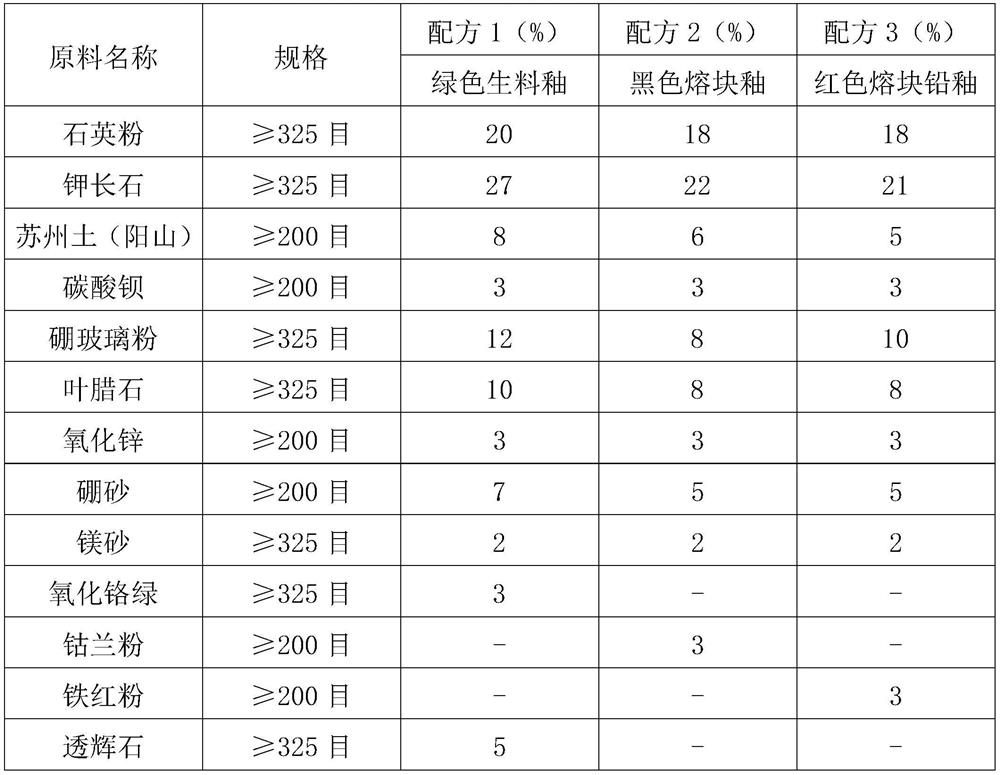

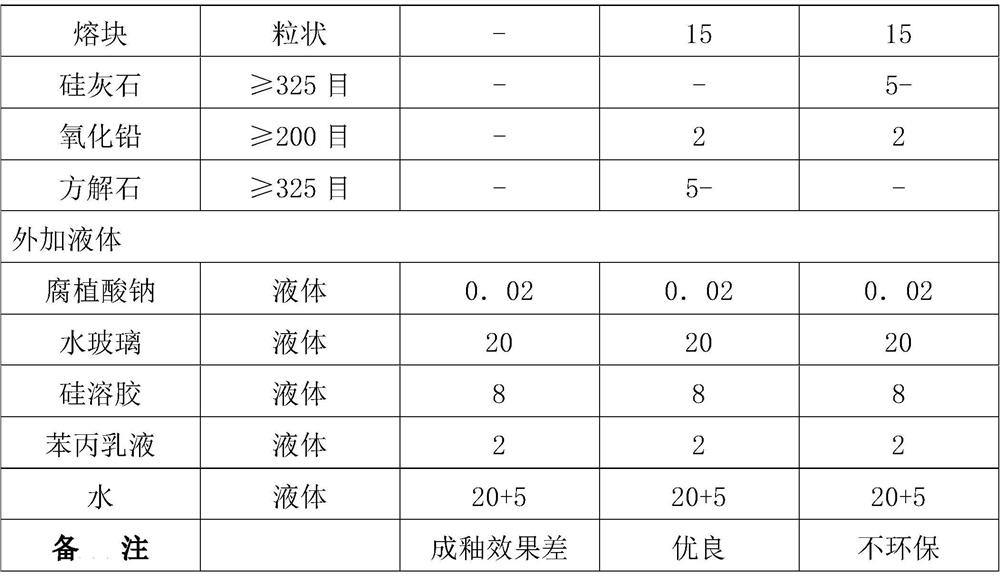

Continuous casting three-piece composite oxidation-resistant erosion-resistant ceramic glaze and preparation method thereof

The invention discloses a continuous casting three-piece composite oxidation-resistant erosion-resistant ceramic glaze which comprises the following components in percentage by weight: 18%-20% of quartz powder, 21%-27% of potassium feldspar, 5%-8% of Suzhou clay, 0%-3% of barium carbonate, 8%-12% of boron glass powder, 8%-10% of pyrophyllite, 0%-3% of zinc oxide, 5%-7% of borax, 0%-2% of magnesia,0%-3% of chromium oxide green, 0%-3% of cobalt blue powder, 0%-3% of iron oxide red powder, 0%-5% of diopside, 0%-15% of frit, 0%-5% of wollastonite, 0%-2% of lead oxide, 0%-5% of calcite, 0%-0.2% ofsodium humate, 0%-2% of a binder, 0%-8% ofsilica sol, 0%-2% of styrene-acrylic emulsion and 20%-25% of water. The ceramic glaze has the beneficial effects of no pollution to the environment, good oxidation resistance, wear resistance, good adhesion effect and capability of effectively prolonging the service life of the continuous casting three-piece of the sprayed product.

Owner:无锡市南方耐材有限公司

Electrode materials of composite rare-earth iridium alloy and sparking plug of using the electrode materials

ActiveCN101550499BRaise the growth initiation temperatureReduce corrosion rateSparking plugsIridiumRare earth

The present invention discloses an electrode materials of composite rare-earth iridium alloy that is a noble metal alloy containing Ir. The noble metal alloy contains 99.5-99.9 wt% Ir and 0.10-0.50 wt% X; the X is one or a mixture of some of the La, Nd, Pr, Y, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Ce; the noble metal alloy can also contains Th and Al added at the same time. The invention also discloses a sparking plug of composite rare-earth iridium alloy, includes a center electrode and at least a lateral electrode, ignition tip of the center electrode and / or the lateral electrode is the noble metal alloy. The invention provided electrode materials has advantage of high-temperature resistance, strong high-temperature corrosion resistance and excellent performance price ratio; sparking plug of using the electrode materials can provide strong spark on time even the motor is in high-speed, high-temperature high-pressure condition.

Owner:昆明富尔诺林科技发展有限公司

A method for preparing sponge titanium by molten salt electrolysis in a resistance furnace

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A preparation method for lining coating of polysilicon reduction furnace

The invention relates to a coating for a furnace wall on the internal side of the furnace body of a polycrystalline silicon reduction furnace (a lining coating for short) and a production method of the coating, in particular to a lining anticorrosive infrared reflection coating of an improved-Siemens-process polycrystalline silicon reduction furnace. The coating is made of a metal-ceramic material. The coating is directly coated on the furnace wall on the internal side of the furnace body of the improved-Siemens-process polycrystalline silicon reduction furnace. The adopted coating method is a physical vapor deposition method or a chemical vapor deposition method. The thickness of the lining coating of the polycrystalline silicon reduction furnace is 1-10 micrometers, the production cost is low and the adhesive force of the coating on the furnace wall is strong. The coating can resist high temperature, strong acid and alkali corrosion and mechanical impact and scraping, the infrared reflection efficiency is high, the service life is long and the loss of heat in the improved-Siemens-process polycrystalline silicon reduction furnace because of heat transfer towards the outside of the furnace can be effectively reduced. Since the coating replaces a pure-gold infrared reflection coating, the expense of the coating material is greatly decreased and the cost of producing polycrystalline silicon products by adopting an improved Siemens process can be greatly decreased.

Owner:胡倾宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com