Preparation method of anti-coking composite ceramic coating for power station boiler

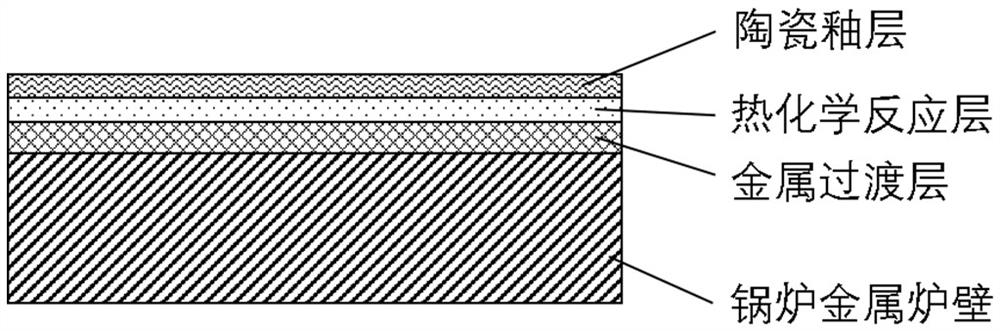

A technology of composite ceramics and ceramic coatings, applied in coatings, metal material coating processes, fusion spraying, etc. Quality and other issues, to achieve the effect of prolonging safety and service life, improving emissivity and thermal conductivity, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation operation steps of an anti-coking composite ceramic coating for utility boilers are as follows:

[0033] (1) Preparation of thermochemical reaction ceramic coating materials

[0034] (1.1) Mix 5kg of chrome green, 7kg of boron nitride and 28kg of alumina to obtain aggregate.

[0035] (1.2), mix 29.8kg of phosphoric acid with a mass concentration of 85%, 1.5kg of magnesium oxide, 3kg of aluminum hydroxide, 3kg of zinc oxide and 14.7kg of deionized water to obtain a binder;

[0036] (1.3) Mix the aggregate, the binder and 2 kg of polyacrylic acid, stir evenly, add deionized water to adjust the acidity pH to 2, and obtain a thermochemical reaction ceramic coating material.

[0037] (2) Preparation of surface glaze material

[0038] Mix 37kg of spodumene powder, 27kg of alumina micropowder, 17kg of calcium carbonate micropowder, 4kg of modified glass fiber, 4kg of potassium feldspar, and 4kg of zirconia to obtain a surface glaze layer material.

[0039] (...

Embodiment 2

[0046] The preparation operation steps of an anti-coking composite ceramic coating for utility boilers are as follows:

[0047] (1) Preparation of thermochemical reaction ceramic coating materials

[0048] (1.1) Mix 5kg of chrome green, 15kg of boron nitride and 15kg of alumina to obtain aggregate.

[0049] (1.2) Mix 28.6kg of phosphoric acid with a mass concentration of 85%, 1.4kg of magnesium oxide, 2.9kg of aluminum hydroxide, 2.9kg of zinc oxide and 14.2kg of deionized water to obtain a binder.

[0050] (1.3) Mix the aggregate, the binder and 2kg of polyacrylic acid, stir evenly, add deionized water to adjust the appropriate viscosity and acidity pH to 1, and obtain a thermochemical reaction ceramic coating material.

[0051] (2) Preparation of surface glaze material

[0052] Mix 35kg of spodumene powder, 25kg of alumina micropowder, 15kg of calcium carbonate micropowder, 3kg of modified glass fiber, 3kg of potassium feldspar, and 3kg of zirconia to obtain a surface glaz...

Embodiment 3

[0060] The preparation operation steps of an anti-coking composite ceramic coating for utility boilers are as follows:

[0061] (1) Preparation of thermochemical reaction ceramic coating materials

[0062] (1.1) Mix 5kg of chrome green, 32kg of boron nitride and 8kg of alumina to obtain aggregate.

[0063] (1.2) Mix 31.4 kg of phosphoric acid with a mass concentration of 85%, 1.6 kg of magnesium oxide, 3.2 kg of aluminum hydroxide, 3.2 kg of zinc oxide and 15.6 kg of deionized water to obtain a binder.

[0064] (1.3) Mix the aggregate, the binder and 5kg of polyacrylic acid, stir evenly, add deionized water to adjust the appropriate viscosity and acidity pH to 3, and obtain a thermochemical reaction ceramic coating material.

[0065] (2) Preparation of surface glaze material

[0066] Mix 35kg of spodumene powder, 25kg of alumina micropowder, 15kg of calcium carbonate micropowder, 3kg of modified glass fiber, 3kg of potassium feldspar, and 3kg of zirconia to obtain a surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com