Preparation method of CMAS high temperature and corrosion resistant composite thermal barrier coating

A thermal barrier coating, high temperature corrosion technology, applied in the direction of coating, metal material coating process, fusion spray plating, etc., can solve the problems of low bonding strength, poor thermal shock resistance, etc., to achieve low porosity, thermal shock resistance Good performance, improve the effect of CMAS corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

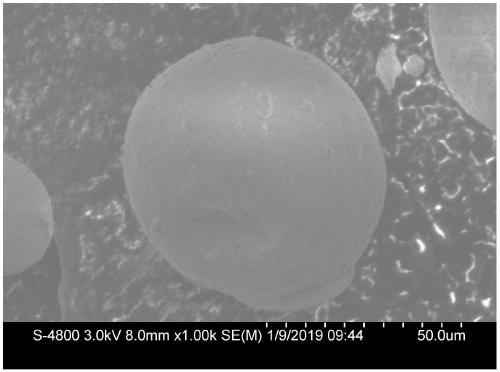

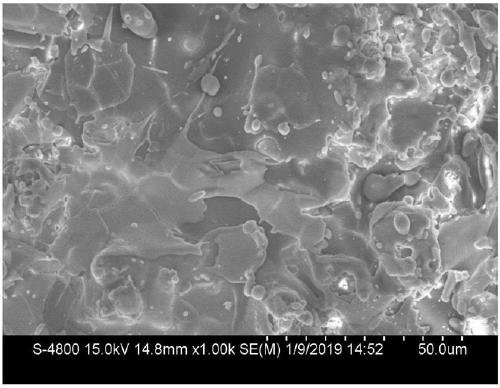

[0036] Step 1: Formulating LZ / Al for Plasma Spraying 2 o 3 compound powder;

[0037] LZ powder with a particle size range of 15 microns to 40 microns, Al with a particle size range of 0.07 microns to 1 micron 2 o 3 Mix the powder evenly into a powder mixture. Among them, Al 2 o 3 The weight percentage of LZ powder accounting for the total mass of raw material powder is 5%, the weight percentage of LZ powder accounting for the total mass of raw material powder is 95%, and the weight percentage of Al 2 o 3 The weight ratio between LZ and LZ is 5:95, and then uniformly mix into the binder with a weight ratio of powder: polyvinyl alcohol = 100:1, ultrasonically vibrate for 20 minutes, and then stir for 90 minutes by mechanical mixing. This is formulated as LZ / Al for plasma spraying 2 o 3 compound powder;

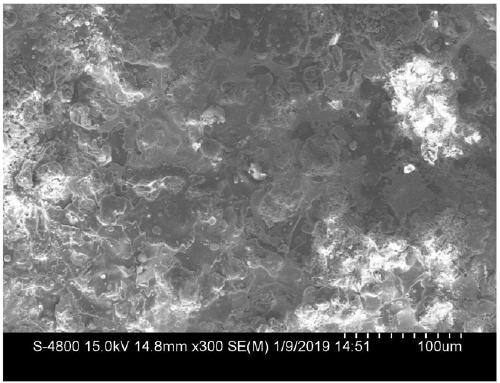

[0038] The second step, metal matrix material pretreatment:

[0039] Sandblasting is performed on the surface of the GH3044 nickel-based superalloy to be coated, and ...

Embodiment 2

[0043] Step 1: Formulating LZ / Al for Plasma Spraying 2 o 3 compound powder;

[0044] LZ powder with a particle size range of 15 microns to 40 microns, Al with a particle size range of 0.07 microns to 1 micron 2 o 3 Mix the powder evenly into a powder mixture. Among them, Al 2 o 3 The weight percentage of LZ powder accounting for the total mass of raw material powder is 10%, the weight percentage of LZ powder accounting for the total mass of raw material powder is 90%, and the weight percentage of Al 2 o 3 The weight ratio between LZ and LZ is 10:90, and then uniformly mix into the binder with a weight ratio of powder: polyvinyl alcohol = 100:1, ultrasonically vibrate for 20 minutes, and then stir for 90 minutes by mechanical mixing. This is formulated as LZ / Al for plasma spraying 2 o 3 compound powder;

[0045] The second step, metal matrix material pretreatment:

[0046] Sandblasting is performed on the surface of the GH3044 nickel-based superalloy to be coated, an...

Embodiment 3

[0050] Step 1: Formulating LZ / Al for Plasma Spraying 2 o 3 compound powder;

[0051] LZ powder with a particle size range of 15 microns to 40 microns, Al with a particle size range of 0.07 microns to 1 micron 2 o 3 Mix the powder evenly into a powder mixture. Among them, Al 2 o 3 Powder accounts for 15% by weight of the total mass of raw material powder, LZ powder accounts for 85% by weight of the total mass of raw material powder, Al 2 o 3 The weight ratio between LZ and LZ is 15:85, and then evenly mix into the binder with a weight ratio of powder: polyvinyl alcohol = 100:1, ultrasonically vibrate for 20 minutes, and then stir for 90 minutes by mechanical mixing. This is formulated as LZ / Al for plasma spraying 2 o 3 compound powder;

[0052] The second step, metal matrix material pretreatment:

[0053] Sandblasting is performed on the surface of the GH3044 nickel-based superalloy to be coated, and then a NiCoCrAlY bottom layer is sprayed on the surface of the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com